Reinforced concrete shear wall

A reinforced concrete and shear wall technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of high brittleness of concrete shear walls, lack of protection of concrete periphery, insufficient earthquake resistance, etc., to ensure shear resistance and avoid cracking. , the effect of improving the initial stiffness and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

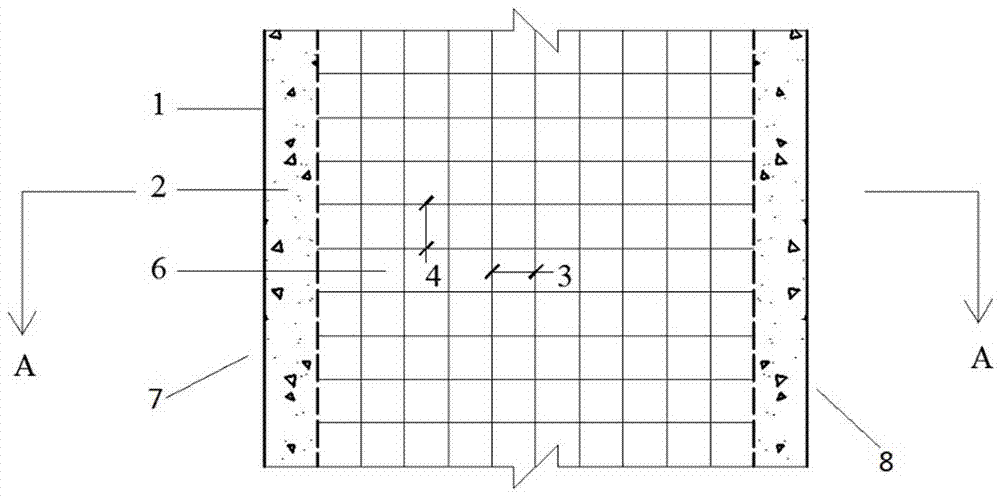

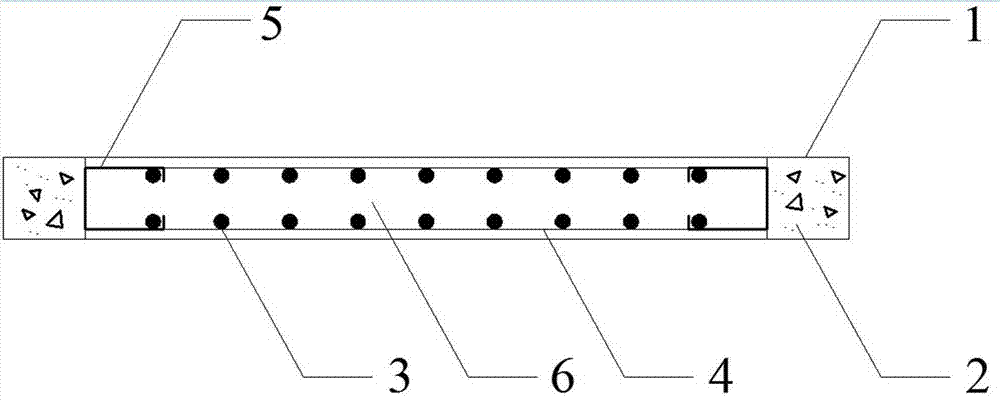

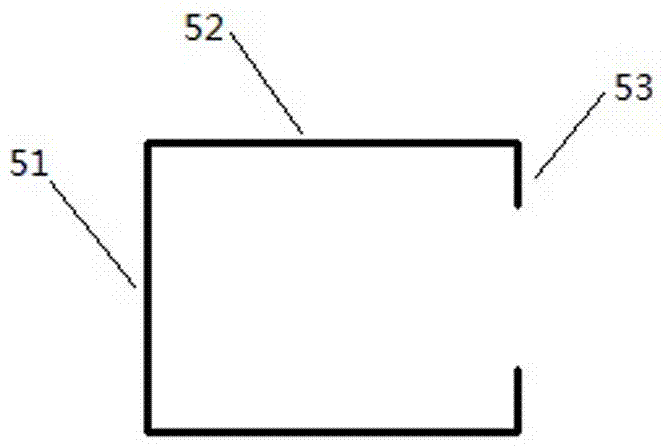

[0021] An example of a reinforced concrete shear wall Figure 1~3 As shown, the reinforced concrete shear wall includes two first columns 7, a second column 8 arranged at intervals from left to right and a wall between the two columns. The first column 7 and the second column 8 include The metal column 1 extending in the direction, the metal column 1 is a square steel pipe structure made of Q390 material, the adjacent sides of the first column 7 and the second column 8 are arranged in parallel, and the metal column concrete 2 is poured in the center hole of the metal column, The metal column concrete is high-strength concrete of C60~C100. The wall includes a metal skeleton, and the metal skeleton includes double rows of horizontal steel bars 4 and double rows of vertical steel bars 3. The horizontal steel bars and vertical steel bars are HRB500 steel bars, and the left end of the metal frame is connected to the first column through a shear connection key 5 On the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com