Interconnect strip cutting and conveying device for crystalline silicon solar cell modules

A solar cell module and transmission device technology, which is applied in the direction of electrical components, semiconductor devices, transportation and packaging, etc., can solve the problems of limited production efficiency of cutting transmission devices, uncontrollable cutting size, and inability to change chains, etc., to achieve increased The scope and flexibility of use, ease of operation, and the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

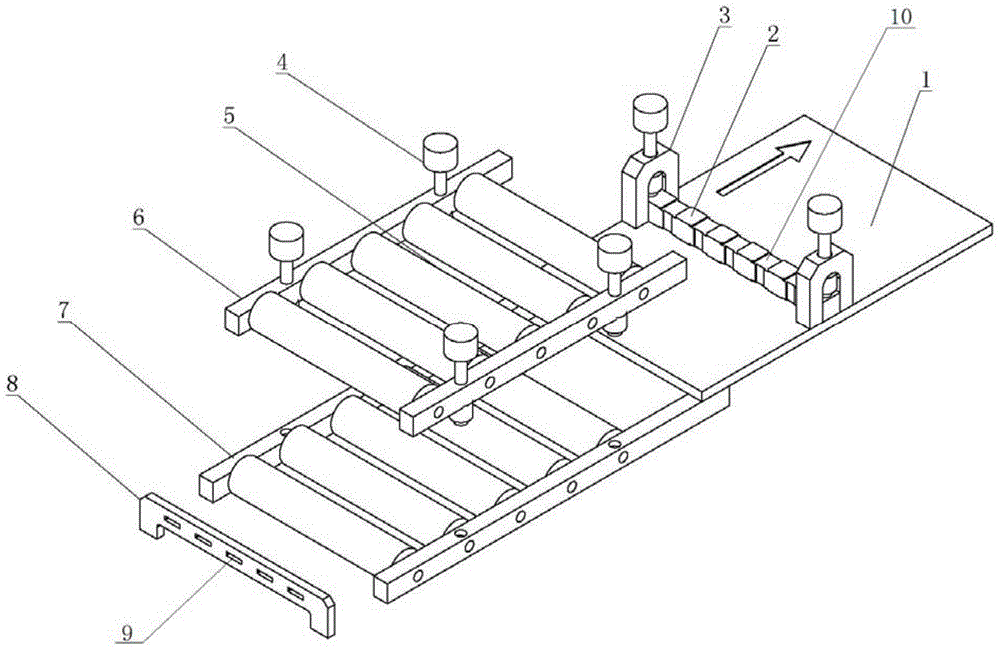

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0023] like figure 1 As shown, a cutting and conveying device for interconnecting strips for crystalline silicon solar cell modules includes a worktable 1, a straightener assembly and a positioning guide assembly. The positioning guide assembly is fixed on the workbench, and the alignment guide assembly The straightener assembly is connected with the workbench. Workbench 1 is connected with an external stepping motor, and the arrow in the figure indicates the direction of transmission.

[0024] The straightener assembly includes an upper rubber roller plate, a lower rubber roller pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com