Swing cloth hopper device of airflow dyeing machine

An airflow dyeing machine and stencil technology, which is applied in textile processing machine accessories, textile material processing, textile material processing equipment configuration, etc., can solve the problems of cloth pressing, affecting air circulation, blocking cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

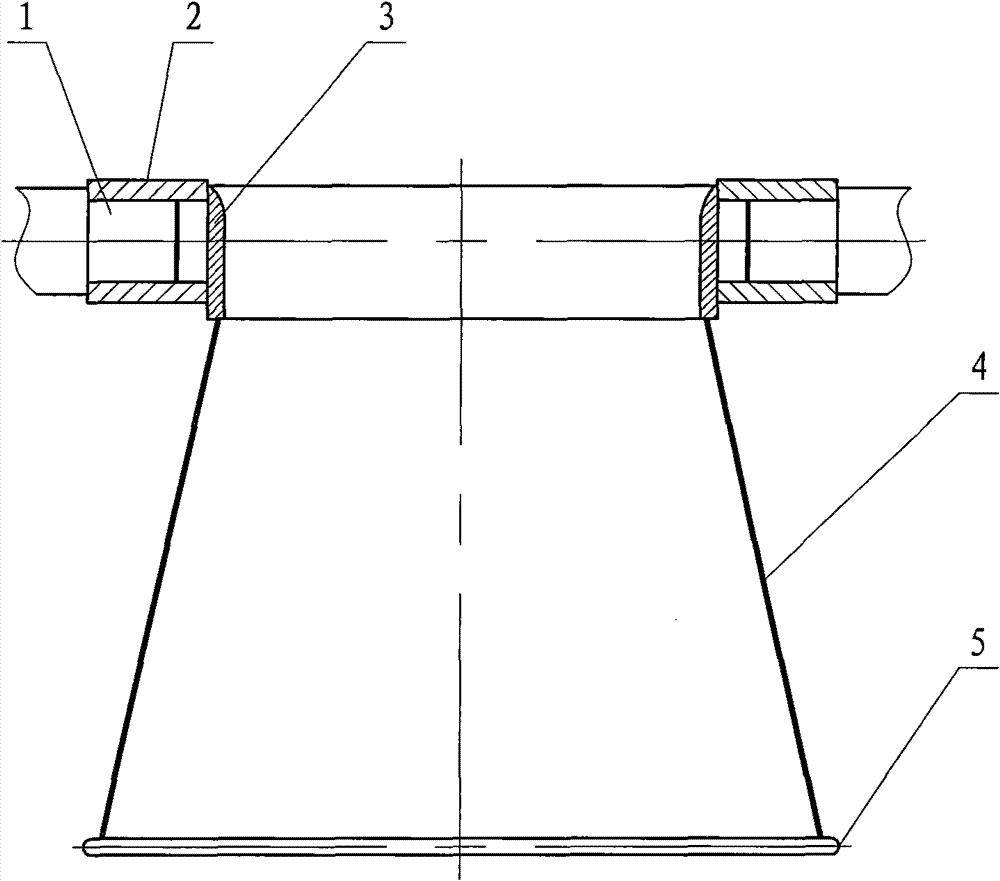

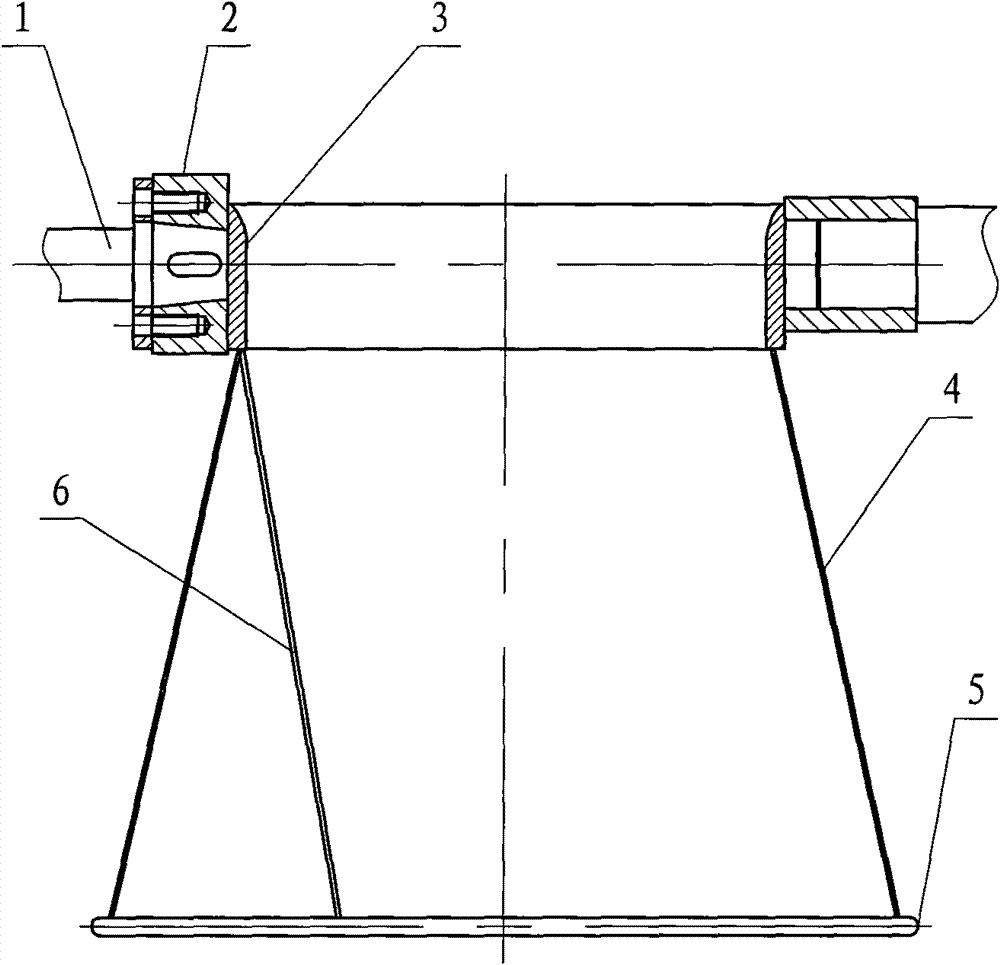

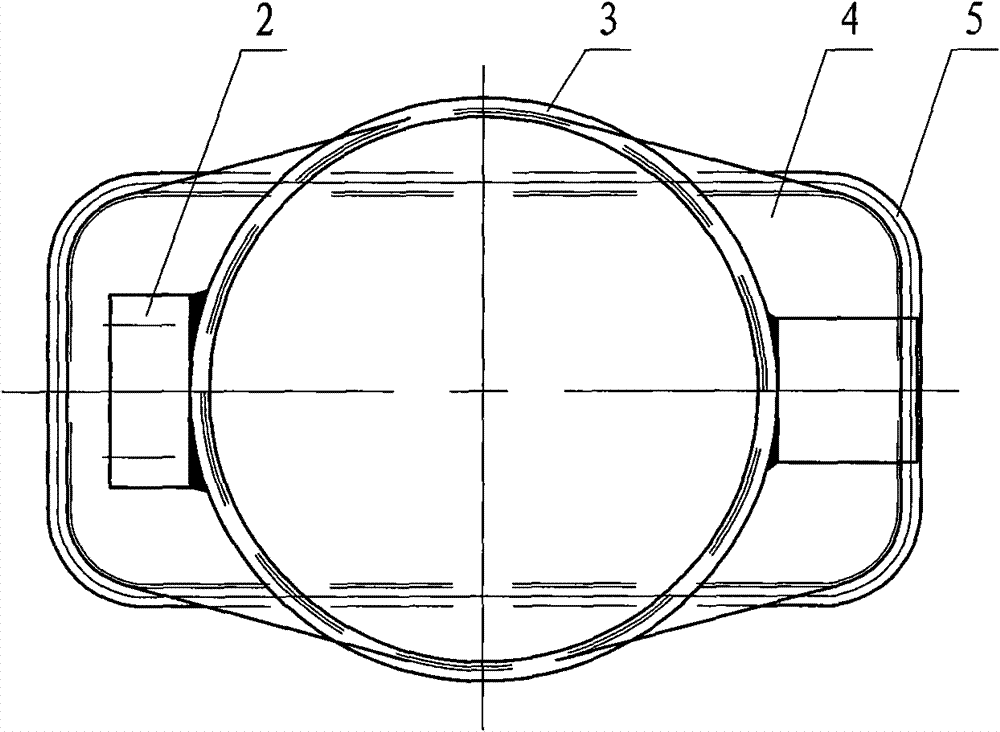

[0012] Such as figure 2 , image 3 As shown, the present invention includes an inner sleeve 3 and a swing bucket 4. The top of the left and right bucket 4 is circular, and the bottom is rectangular. The inner connecting sleeve 3 is in the shape of a circular tube, and an axle sleeve 2 is arranged on its side wall, and a linkage mechanism shaft 1 is installed in the axle sleeve 2, and a linkage mechanism is installed on the linkage mechanism axis 1. The improvement of the present invention lies in that a net plate 6 with ventilation holes 7 is arranged in the swing bucket, the top edge of the net plate 6 is connected with the top of the swing bucket 4, and the side of the net plate 6 is connected with the side of the swing bucket 4. The walls are connected, and the bottom edge of the screen plate 6 is parallel to the short side of the bottom rectangle of the left and right buckets 4.

[0013] Such as Figure 4 As shown, the ventilation holes 7 on the screen 6 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com