A heating sheet and a carpet with the above-mentioned heating sheet

A technology for heating sheets and carpets, which is applied in the fields of heating sheets and carpets, can solve the problems of uneven heat dissipation of heating bags, loose heat dissipation pipes, and low use costs, and achieves good heating effect, good heat dissipation effect, and good passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

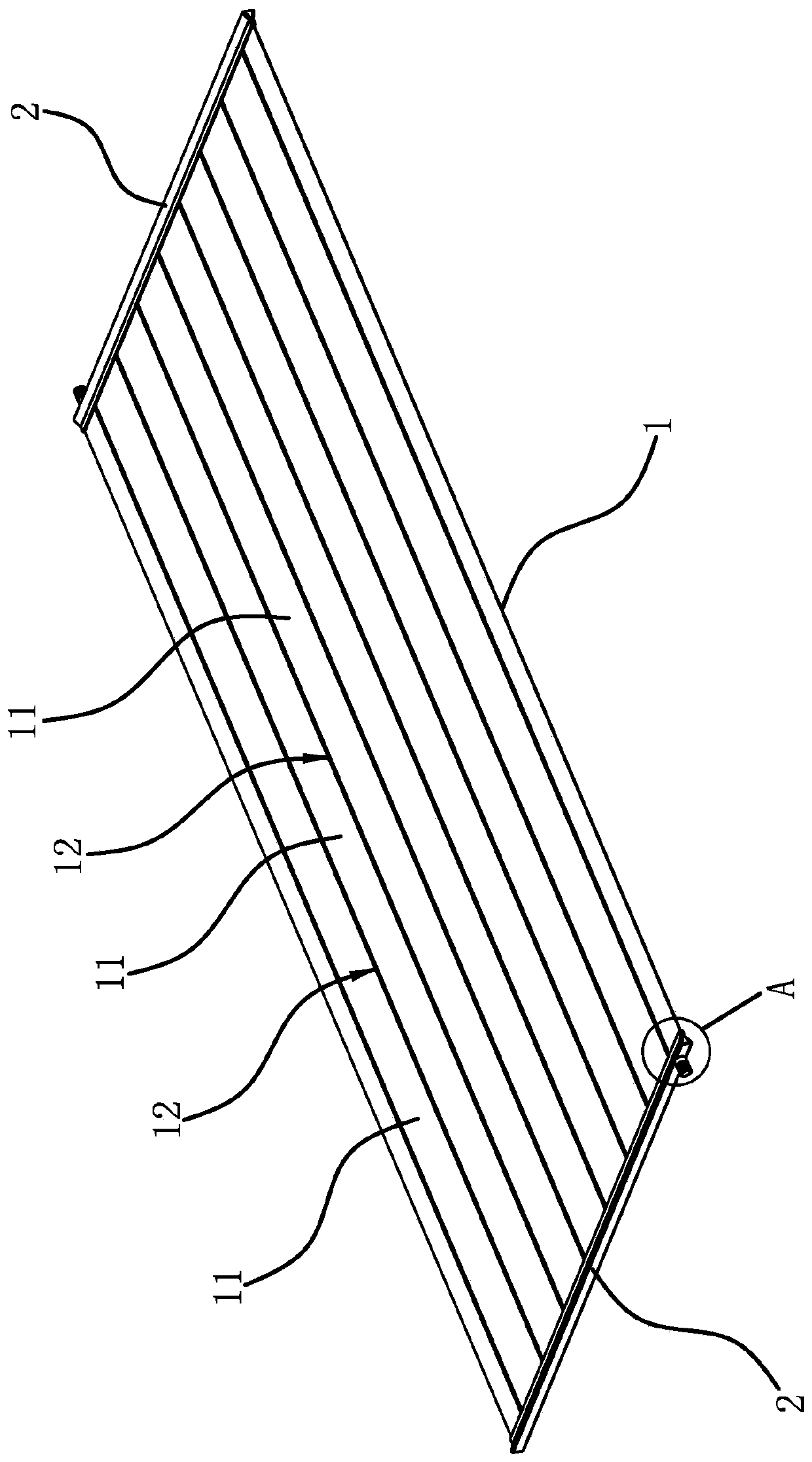

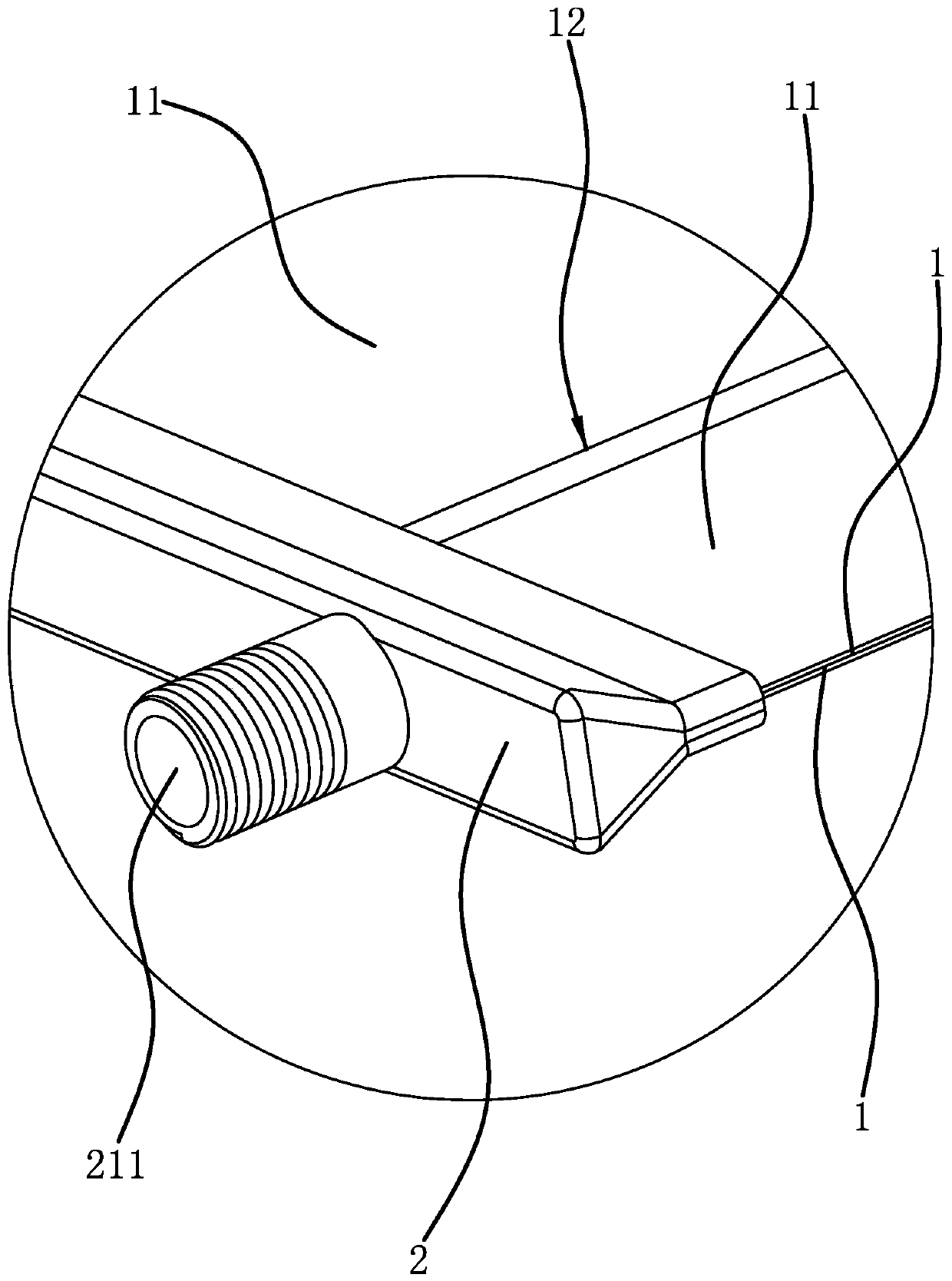

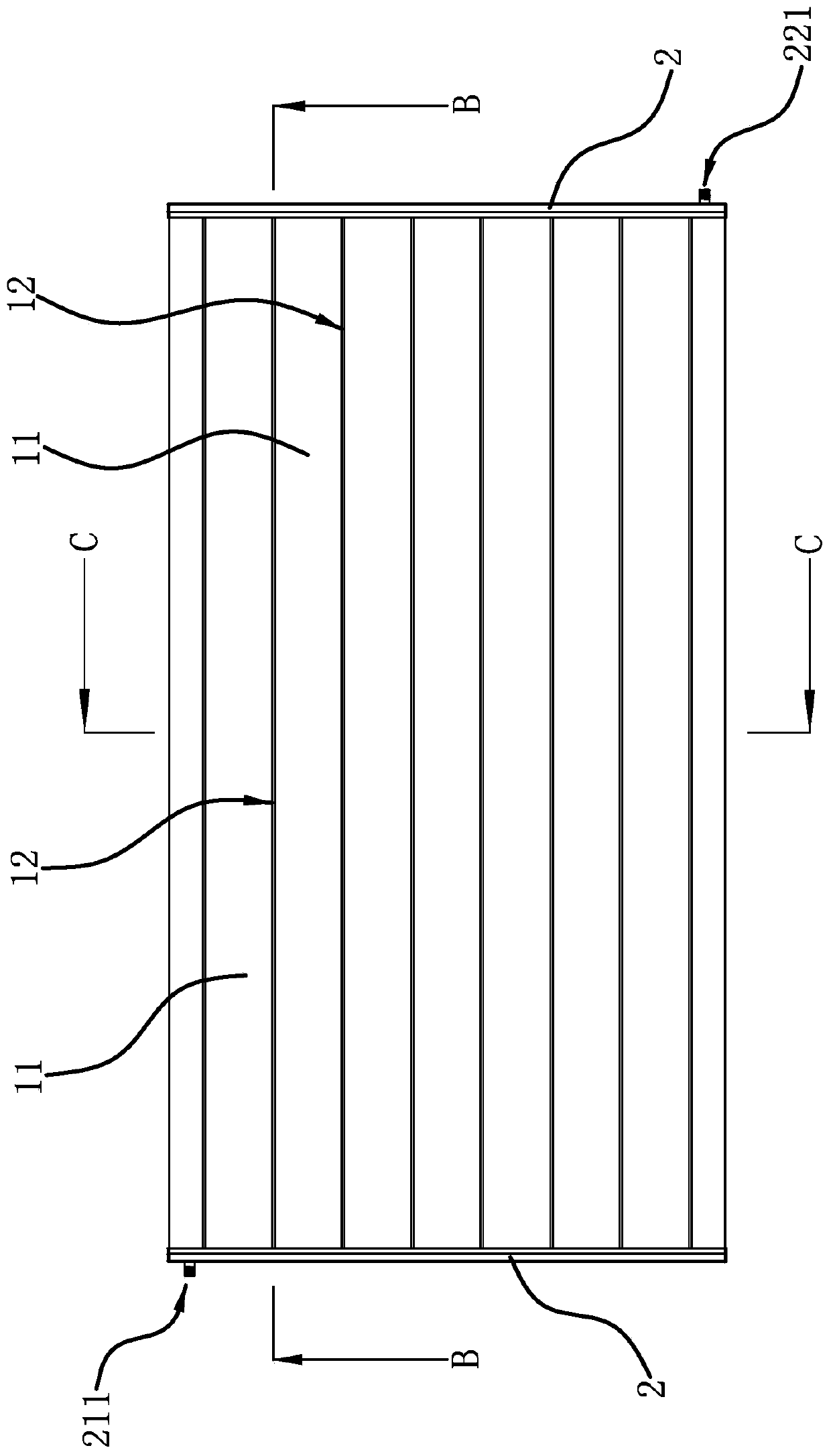

[0046] Such as figure 1 , figure 2 Shown, a kind of heating sheet, the shape of heating sheet is cut according to need, and the shape of heating sheet in the present embodiment is rectangular, comprises upper and lower two layers of plastic film 1, combines image 3 As shown, the two-layer plastic film 1 forms sequentially arranged compound regions 11 through continuous hot-melt compounding, and the compound regions 11 are elongated strips, combined Figure 4 , Figure 5 As shown, a seal is formed between the two layers of plastic film 1 in the composite area 11, and the part of the plastic film 1 that is not bonded between two adjacent composite areas 11 forms a heat dissipation flow channel 12, and the heat dissipation flow channels 12 are all in the shape of a straight strip, and Arranged in parallel, heat dissipation channels 12 are evenly arranged and covered with plastic film 1, the width of composite area 11 is larger than the width of heat dissipation flow channel 1...

Embodiment 2

[0049] The structure of the heating plate is basically the same as that of Embodiment 1, the difference is that Figure 9 As shown, the heat dissipation flow channels 12 are arranged obliquely relative to the wrapping 2 to increase the length of the heat dissipation flow channels 12 so that hot water can fully dissipate heat when passing through the heat dissipation flow channels 12 and improve the heating effect.

Embodiment 3

[0051] The structure of the heating plate is basically the same as that of Embodiment 1, the difference is that Figure 10 As shown, the heat dissipation flow channel 12 is curved, and the heat dissipation flow channel 12 is evenly arranged and covered with the plastic film 1, so as to increase the length of the heat dissipation flow channel 12, so that the hot water can fully dissipate heat when passing through the heat dissipation flow channel 12, and improve the manufacturing efficiency. warm effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com