A kind of white mud lime kiln feeding method and its feeding device

A mud lime kiln and feeding device technology, applied in the field of pulp and paper making, to achieve the effect of ensuring drying effect, improving production capacity and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following examples only illustrate possible implementation forms of the present invention, but they are not intended to limit the scope of the present invention.

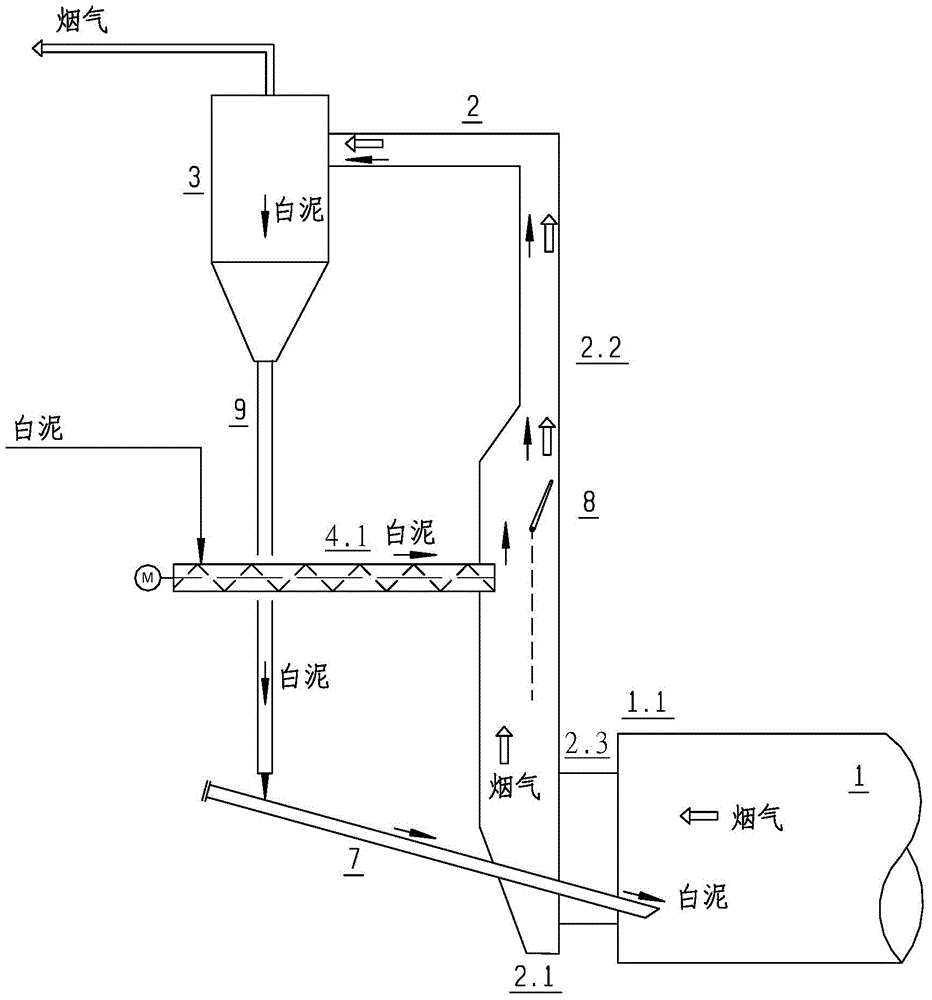

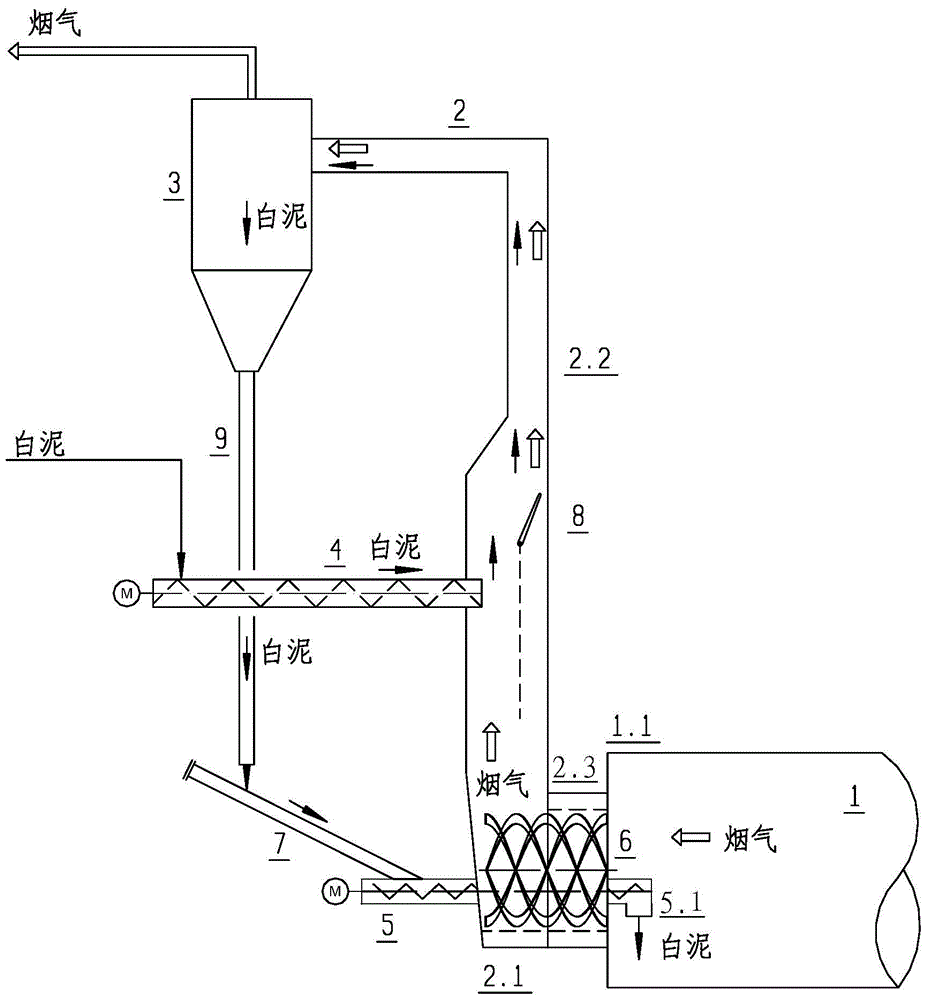

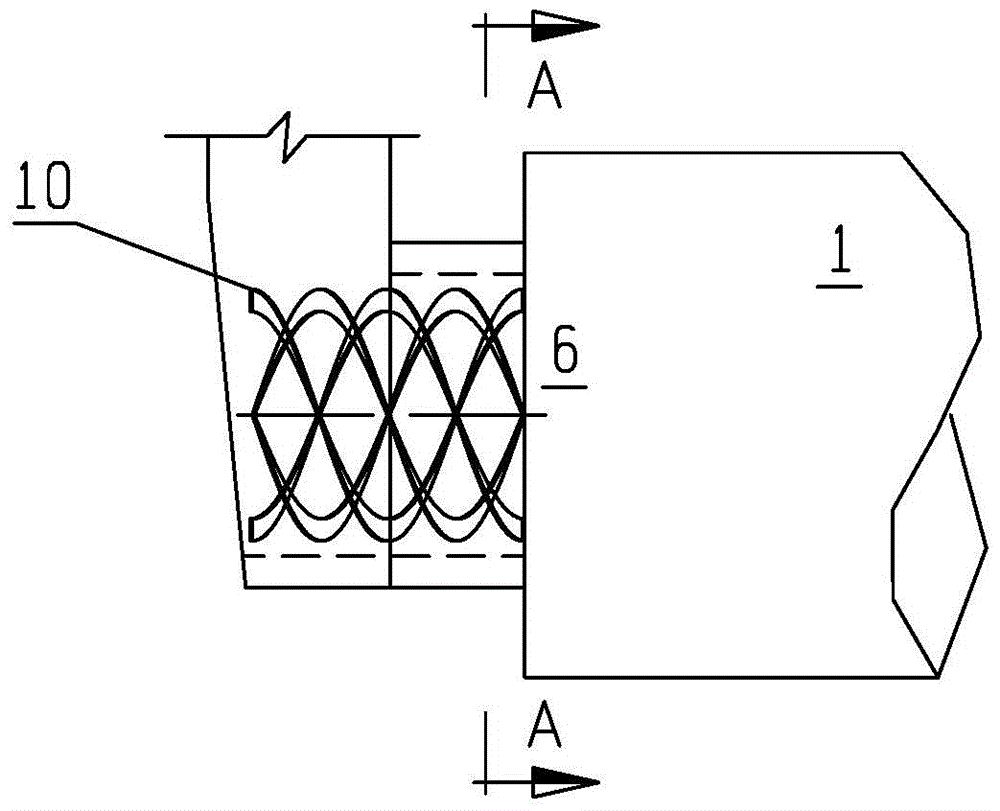

[0058] Such as figure 2 As shown, the main process of the lime kiln feeding method combined with the device description of the present invention is as follows:

[0059] 1) The wet lime mud from the caustic chemical section is first sent to a first feeding propulsion device 4. In this embodiment, the first feeding propulsion device is a screw feeder, and the dryness of the wet lime mud is 65% Above, 70% wet white mud is preferred in this embodiment;

[0060] 2) The wet white mud is driven by the first feeding propulsion device 4 into the riser 2.2 of the flash dryer 2. The wet white mud is mixed with the flue gas from the lime kiln 1, and follows the high temperature from the kiln tail. The flue gas rises, and the ascending process is also a drying process. The ascending flue gas flow enters a cyclone separator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com