Vane type cam phaser

A cam phaser, vane technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of small vane width, inability to meet miniaturization, increasing the weight and volume of rotor and vane cam phasers, etc. Achieve the effect of satisfying high torsion-compression ratio and high adjustment angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

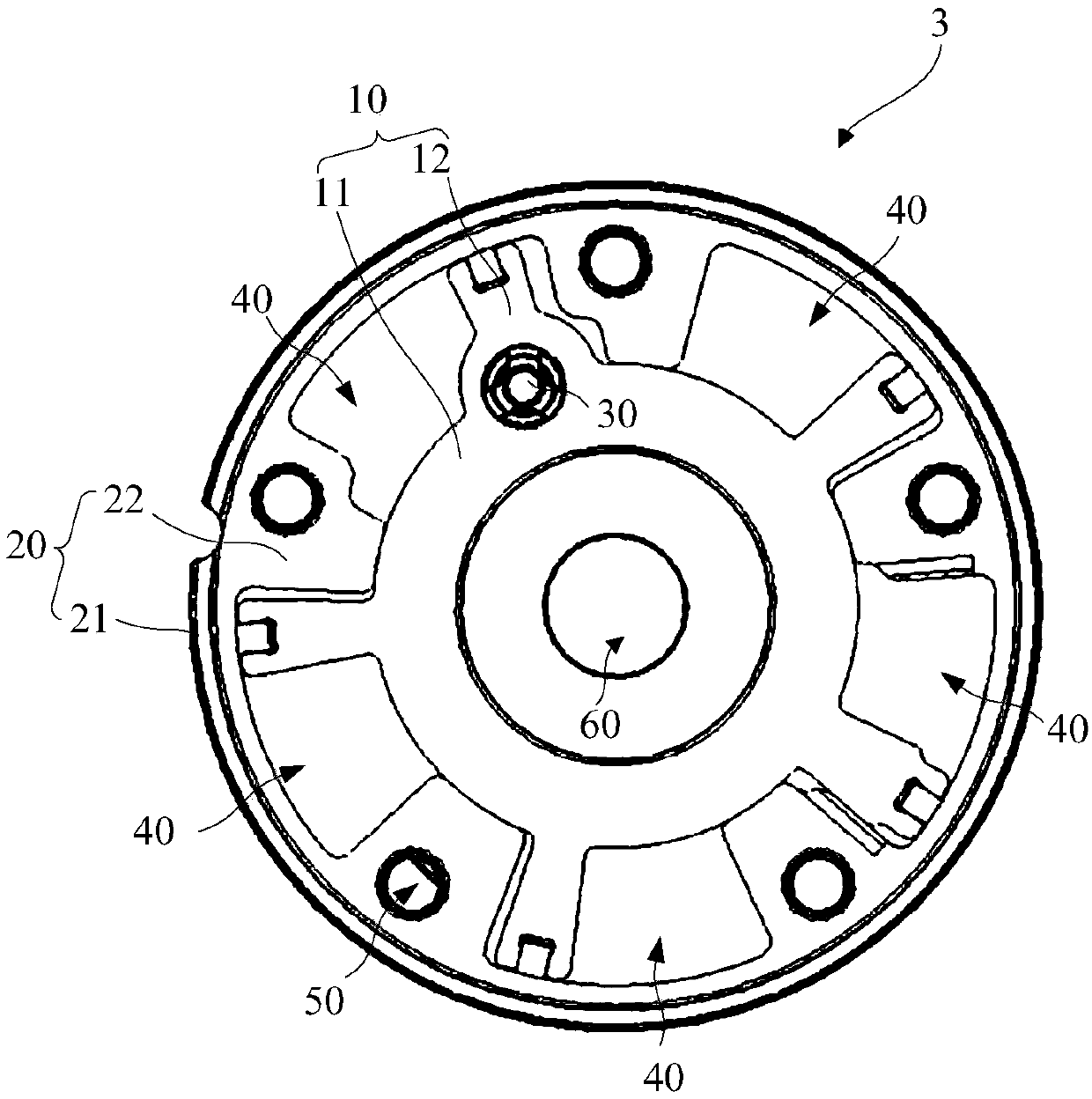

[0019] In view of the technical problems existing in the prior art, the present invention provides a new type of vane cam phaser, so that the size of the rotor base and vanes can be designed according to needs without being limited by the size of the locking unit, so that the vane cam phase can be achieved. The miniaturization of the device meets the requirements of high torsion-pressure ratio and high adjustment angle.

[0020] In order to make the above-mentioned objectives, features and beneficial effects of the present invention more obvious and understandable, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

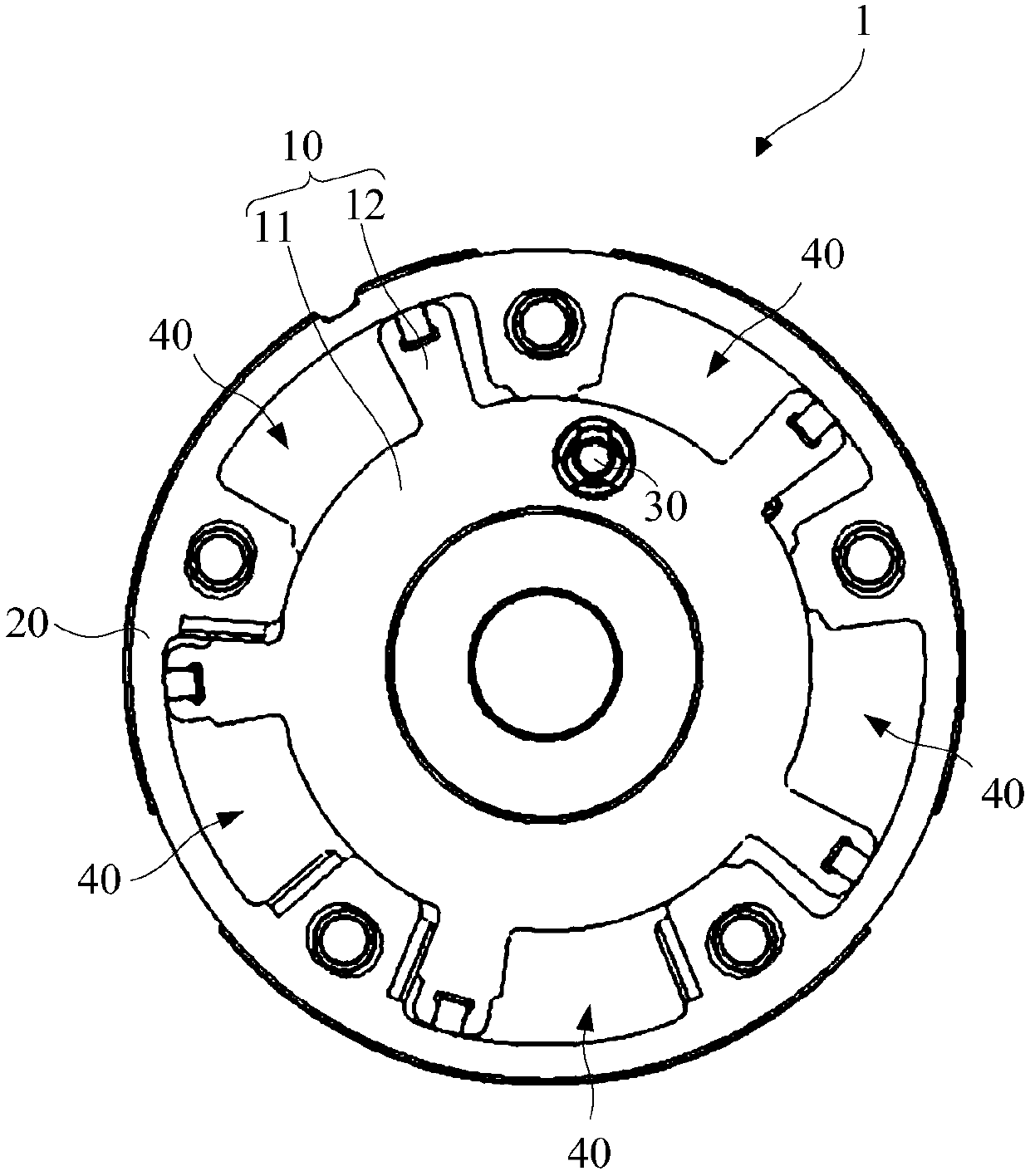

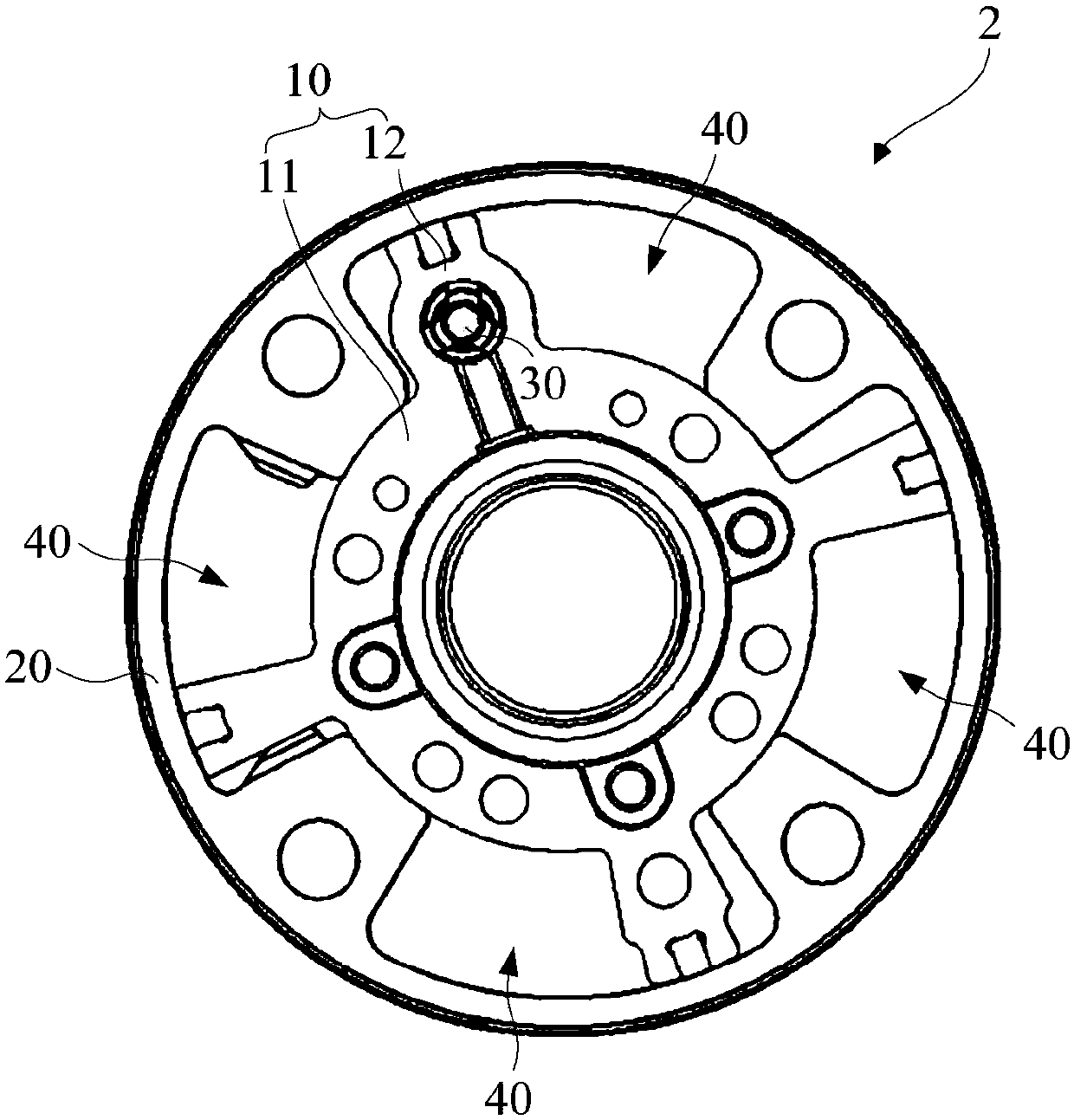

[0021] reference figure 1 , An existing vane type cam phaser 1, which includes a rotor 10 and a stator 20, the rotor 10 is installed in the stator 20 and the rotor 10 and the stator 20 are coaxial. The rotor 10 includes a rotor base 11 and five blades 12 distributed in the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com