Rack for binding prefabricated box girder top plate reinforcement cage

A steel skeleton and steel bar technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of slowing down the construction progress, uneven spacing of steel bars, inaccurate positioning, etc., to improve work efficiency, speed up the progress of construction, The effect of evenly spaced rebars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to help better understand the technical solutions of the present application, the specific embodiments of the present application will be described in detail below with reference to the accompanying drawings.

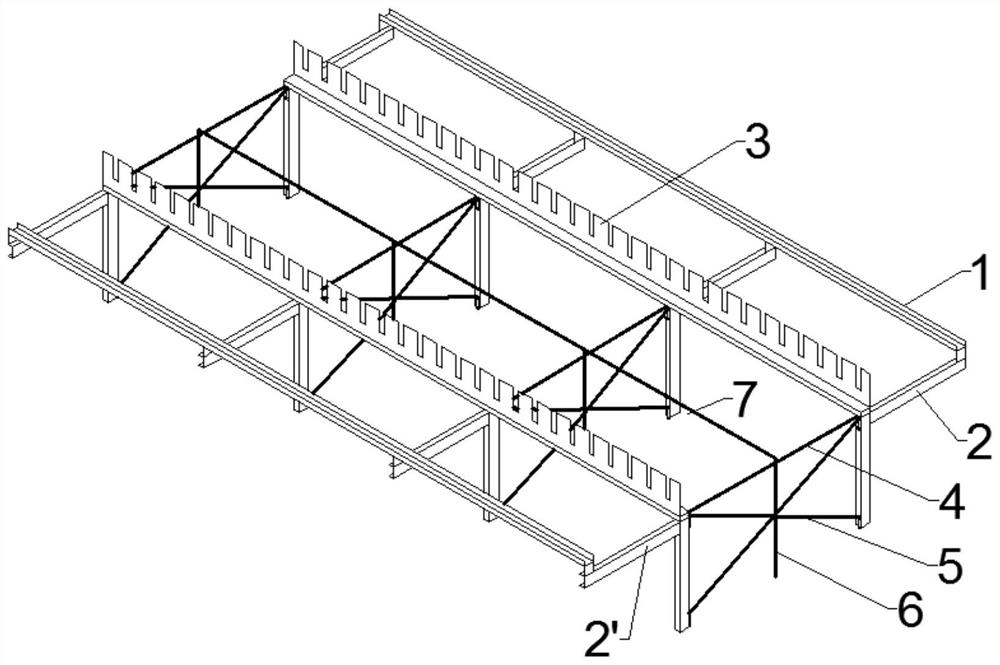

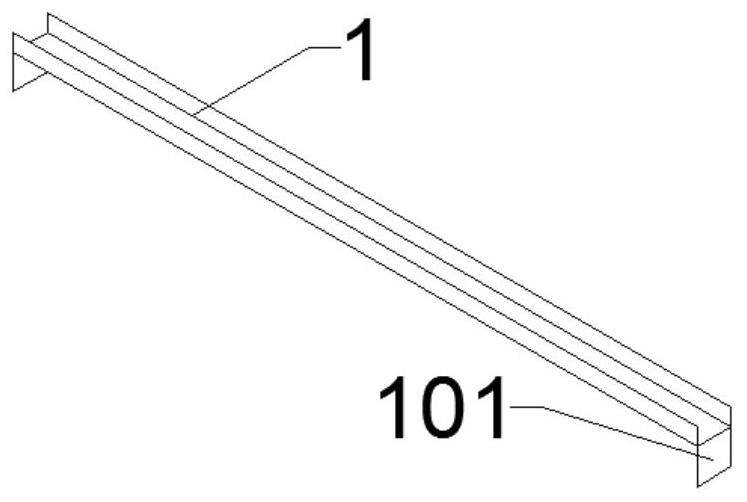

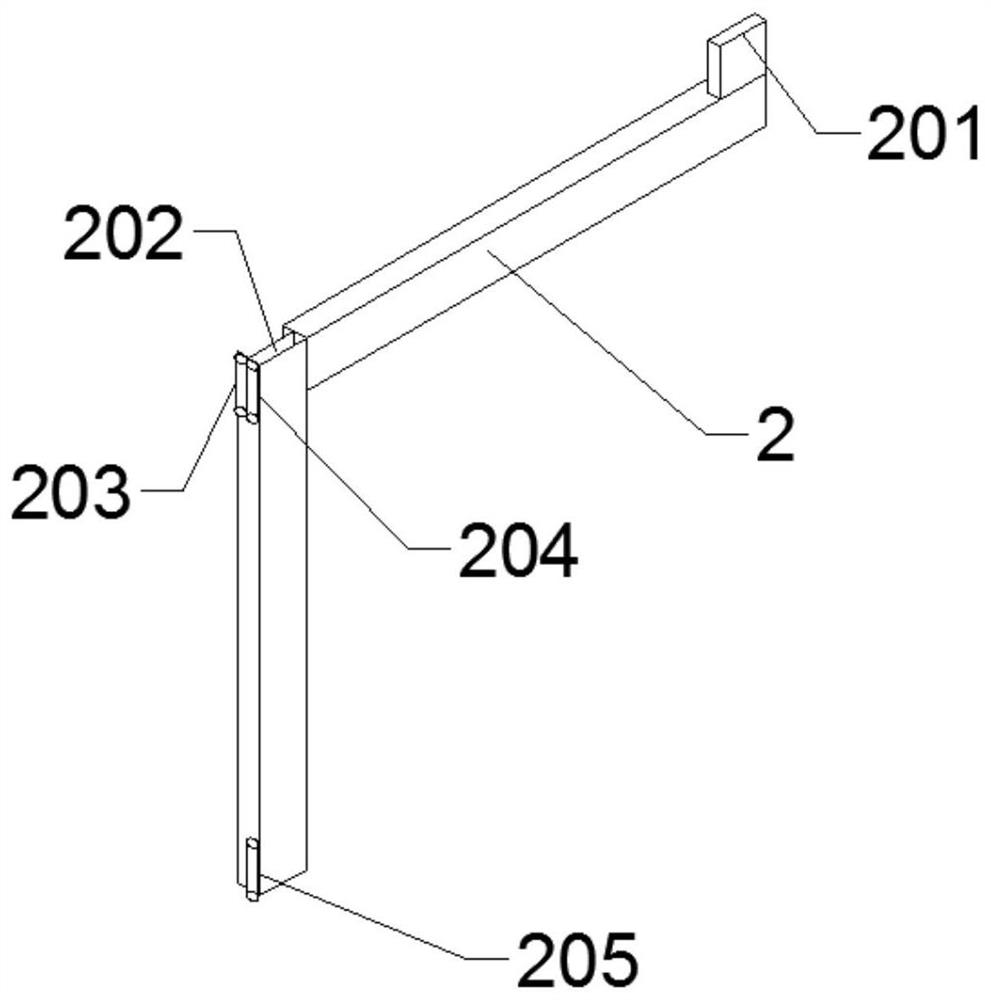

[0031] figure 1 The structure of an exemplary gantry of the present invention is shown, and the gantry is generally composed of four support units, two mutually parallel reinforcing bar limiting members 1, two mutually parallel first reinforcing bar supporting members 3 and a first reinforcing bar supporting member 3. It consists of two steel supporting members 7. Adjacent support units are connected by the steel bar limiting member 1, the first steel support member 3 and the second steel support member 7, and the adjacent support units are preferably separated by 2m. However, those skilled in the art should understand that the structure of the frame for binding the steel frame of the prefabricated box girder roof of the present invention is not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com