Thermal printer

A thermal printer and heat-sensitive technology, applied in printing devices, printing, etc., can solve the problems of inconvenient adjustment of printing paper and inconvenient paper loading, and achieve the effects of convenient adjustment, convenient paper loading, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

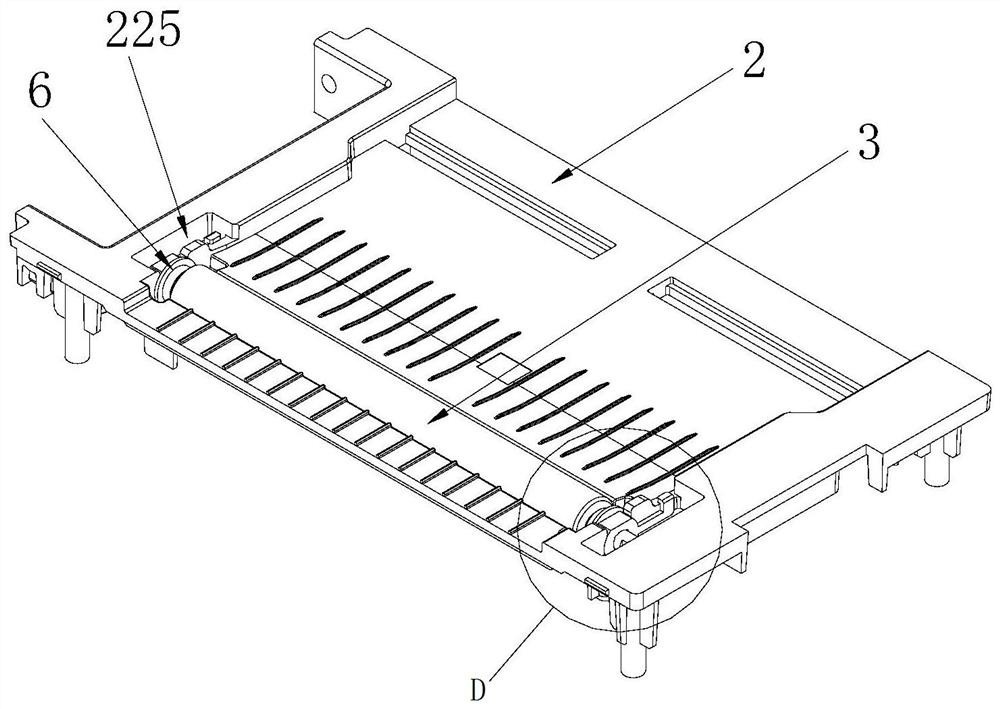

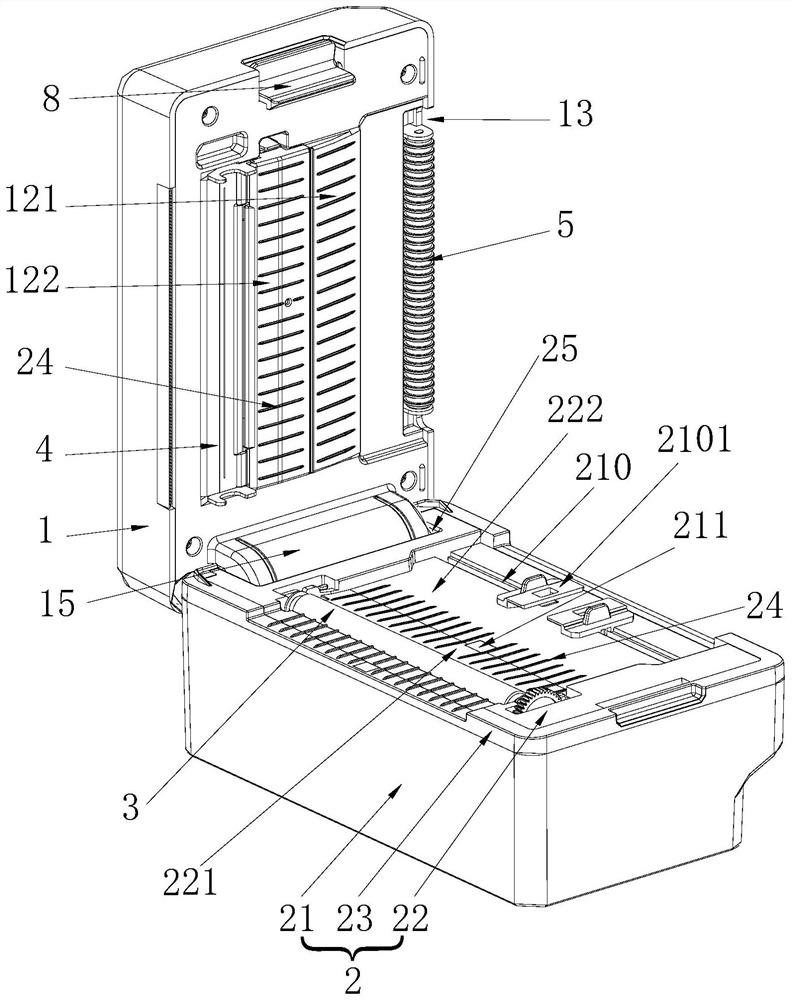

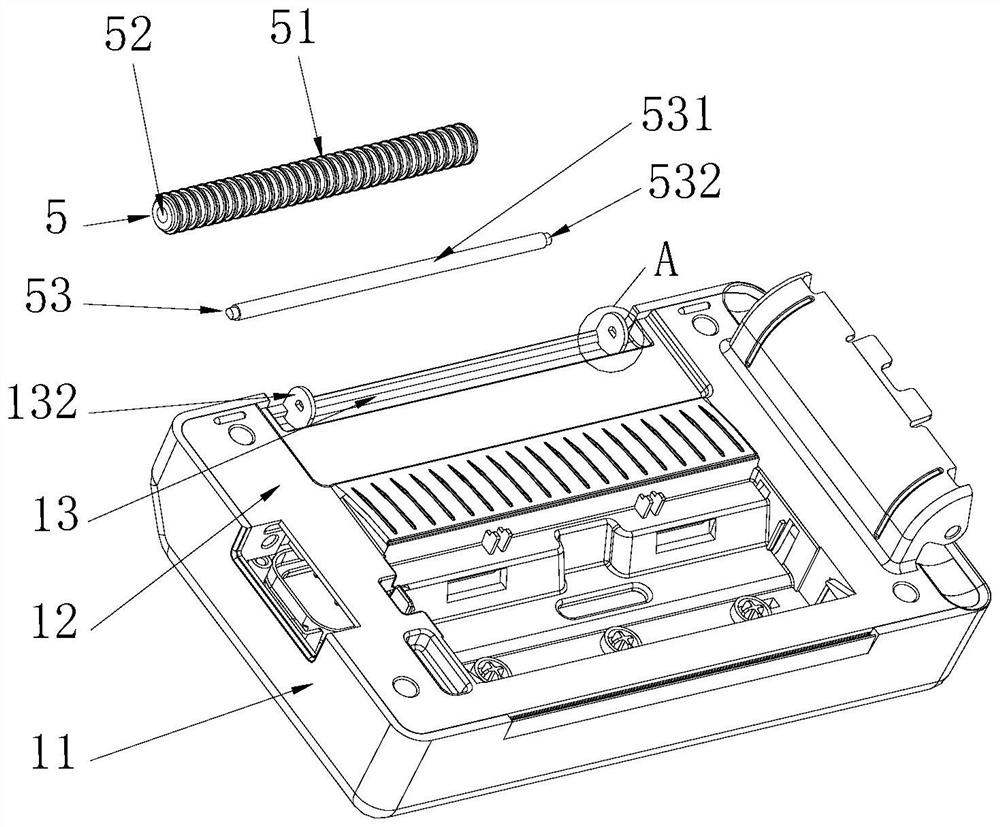

[0039] see Figure 1-Figure 3 , the invention discloses a thermal printer, comprising an upper cover 1 and a lower cover 2, the left end of the upper cover 1 and the left end of the lower cover 2 are hinged to each other, the upper end of the lower cover 2 is provided with a rubber roller 3, the The rubber roller 3 axially extends along the left and right directions, and the position corresponding to the rubber roller 3 of the upper cover 1 is provided with a thermal sheet 4, and the upper end of the lower cover 2 is also provided with a paper width adjustment mechanism 210, and the paper width adjustment The mechanism 210 includes two sliders 2101 slidingly arranged on the lower cover 2 left and right, a paper inlet and a paper outlet are provided between the upper cover 1 and the lower cover 2, and the paper inlet and the paper outlet are respectively provided on the front and back of the printer. Of course, in a thermal printer, the rubber roller 3 can also be installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com