Large-span concrete beam retard-bonded prestressed construction method

A technology for bonding prestressing and construction methods, which is applied in construction, building structure, and processing of building materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]Next, the technical solutions in the embodiments of the present invention will be described in connext of the embodiments of the present invention, which is apparent from the embodiments of the present invention, and is apparent from the embodiments of the present invention, not all of the embodiments of the invention.

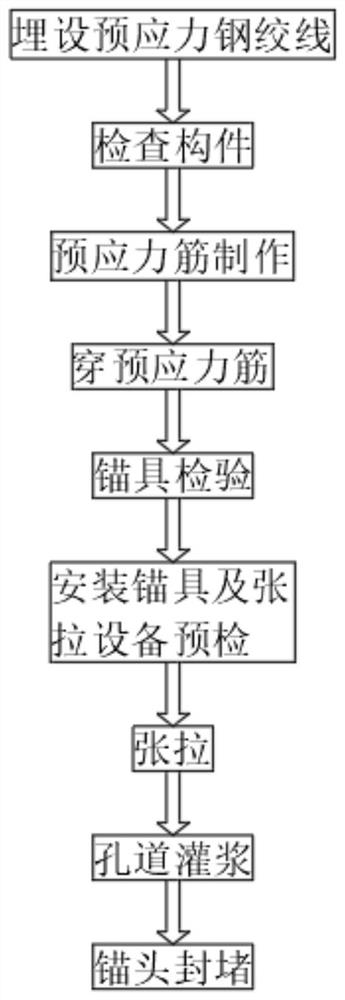

[0049]SeeFigure 1-5One embodiment of the present invention: a large span concrete beam is bonded to a prestressed construction method, including the following steps:

[0050]Step 1: Buried the prestressed steel strand;

[0051]Step 2: Check the component;

[0052]Step 3: Prestressed tendon production;

[0053]Step 4: Wear prestressed tendons;

[0054]Step 5: Anchor inspection;

[0055]Step 6: Install an anchor and tensile equipment preview;

[0056]Step 7: Zhang La;

[0057]Step 8: Confair grout;

[0058]Step 9: Anchor head is blocked.

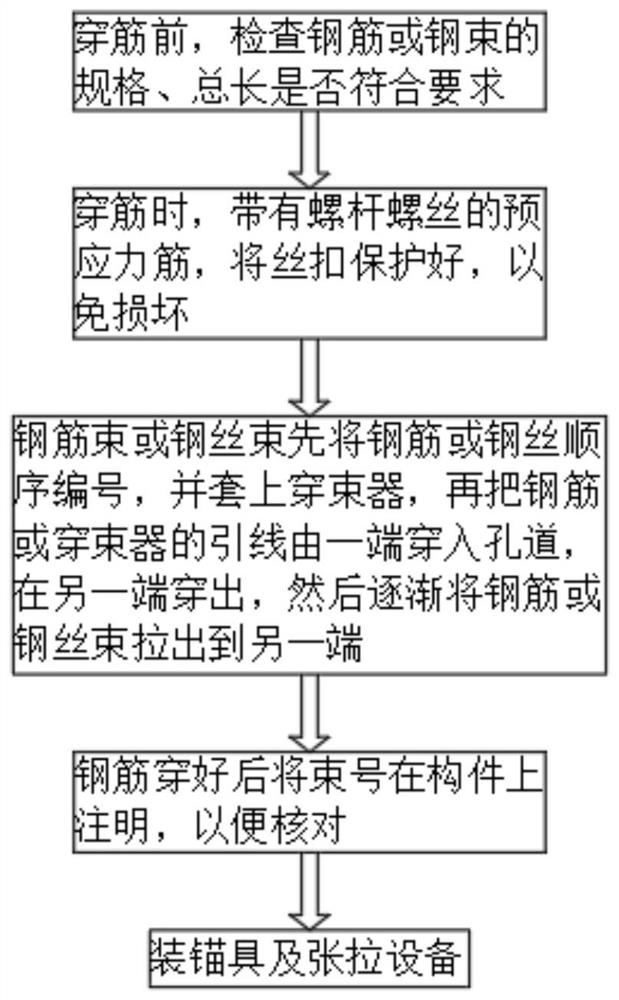

[0059]Further, step 4 is penetrating the prestressed ribs, including:

[0060]Step 4-1: Before wearing tendons, check the specifications of the reinforcement or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com