Forward flow type smoke purification system and purification flow field thereof

A fume purification and fume technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as high equipment investment and construction costs, variable processing locations, and unorganized fume emissions. Equipment investment and construction costs, avoiding limited workshop width, and avoiding the effect of fugitive emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

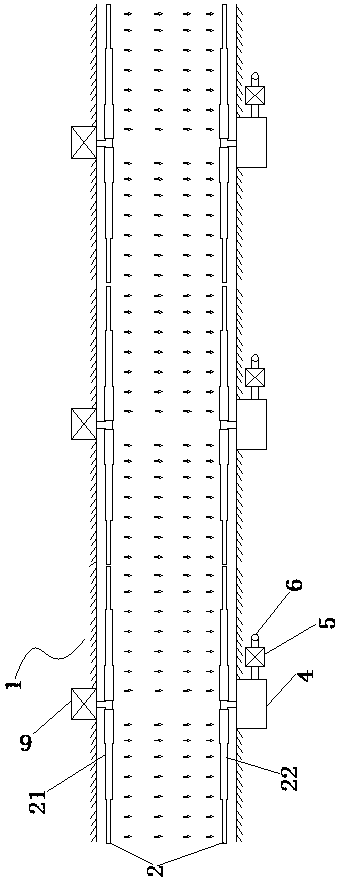

[0023] A downstream smoke purification system, such as figure 1 , including a blower 9 arranged on the outside of the wall of the factory building 1 and three groups of pipes 2 arranged on both sides of the factory building 1, each group of pipes 2 includes an air supply pipe 21 and an air suction pipe 22 arranged on both sides of the factory building, Wherein, the air supply duct 21 and the suction duct 22 are all located at 4-6m away from the ground. 5 is also communicated with dust collector 4.

[0024] A purification flow field of a downstream smoke and dust purification system, which injects clean outdoor air into the factory building 1 through the air supply duct 21 to realize indoor and outdoor air circulation, forming multiple downstream jets in the same direction and parallel, A two-dimensional plane motion is formed in this area of the jet flow, and the gas flow caused by the downstream jet flow brings the welding fume to the suction duct 22, and the airflow in th...

Embodiment 2

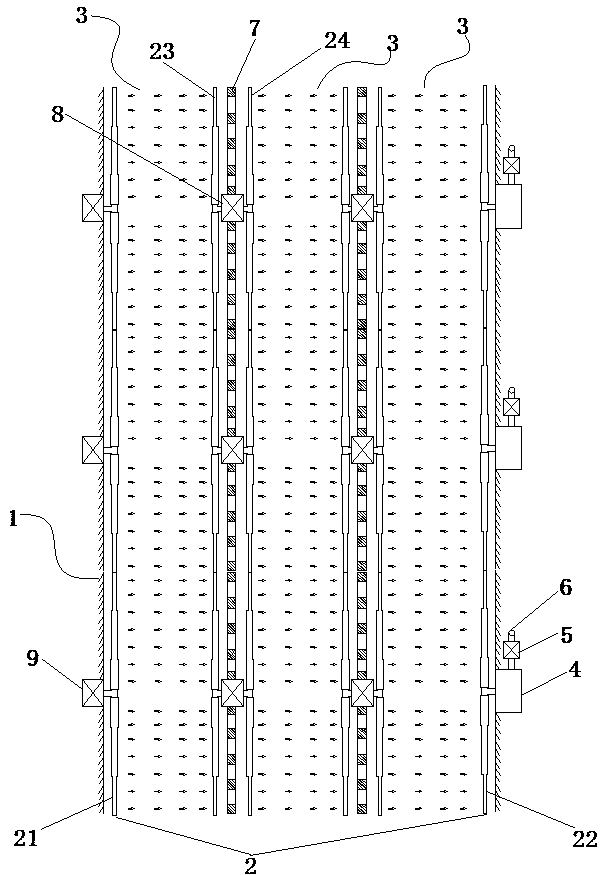

[0026] A downstream smoke purification system, such as figure 2 and 4 , including a blower 9 arranged on the outside of the wall of the factory building 1 and three groups of pipes 2 arranged on both sides of the factory building 1, each group of pipes 2 includes an air supply pipe 21 and an air suction pipe 22 arranged on both sides of the factory building, Wherein, the air supply duct 21 and the suction duct 22 are all located at 4-6m away from the ground. 5 is also connected with a dust collector 4; two rows of columns 7 are arranged in the factory building 1, and workshop units 3 are formed on the left and right sides of each row of columns 7, and one side of the column 7 is fixed with a corresponding air supply duct 21. The air suction duct a23, the other side is fixed with the air supply duct a24 corresponding to the air suction duct a23, and the conveying fan 8 is communicated between the air suction duct a23 and the air supply duct a24.

[0027] A purification flow ...

Embodiment 3

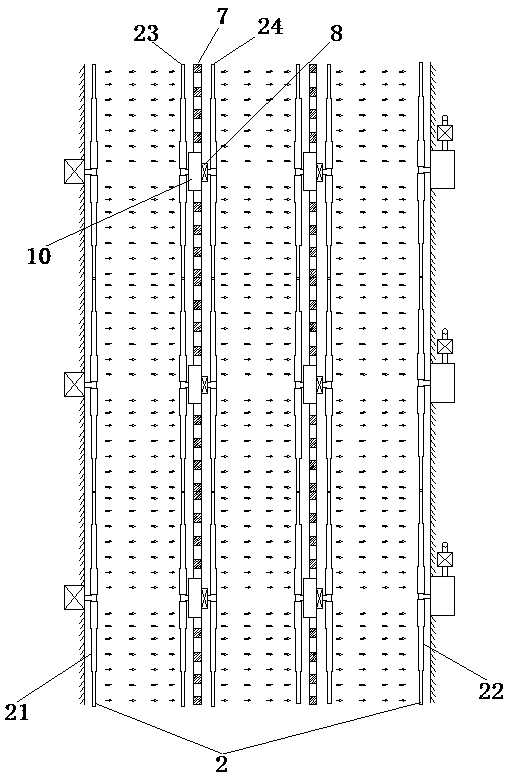

[0029] A downstream smoke purification system, such as figure 2 and 5 , including a blower 9 arranged on the outside of the wall of the factory building 1 and three groups of pipes 2 arranged on both sides of the factory building 1, each group of pipes 2 includes two air supply pipes 21 and air suction pipes 22 arranged on both sides of the factory building, And the air supply ducts 21 in each group of ducts 2 are arranged in parallel up and down, and the air suction ducts 22 correspond to the air supply ducts 21 one by one. Specifically, the air supply ducts 21 and the air suction ducts 22 in the upper layer are arranged at a distance of 6m from the ground. The air supply duct 21 and the air suction duct 22 of the lower floor are arranged at a distance of 4m from the ground.

[0030]Air supply duct 21 is communicated with the air outlet of blower 9, and suction duct 22 is communicated with suction fan 5, is also communicated with dust collector 4 between suction duct 22 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com