Patents

Literature

83results about How to "Orderly flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

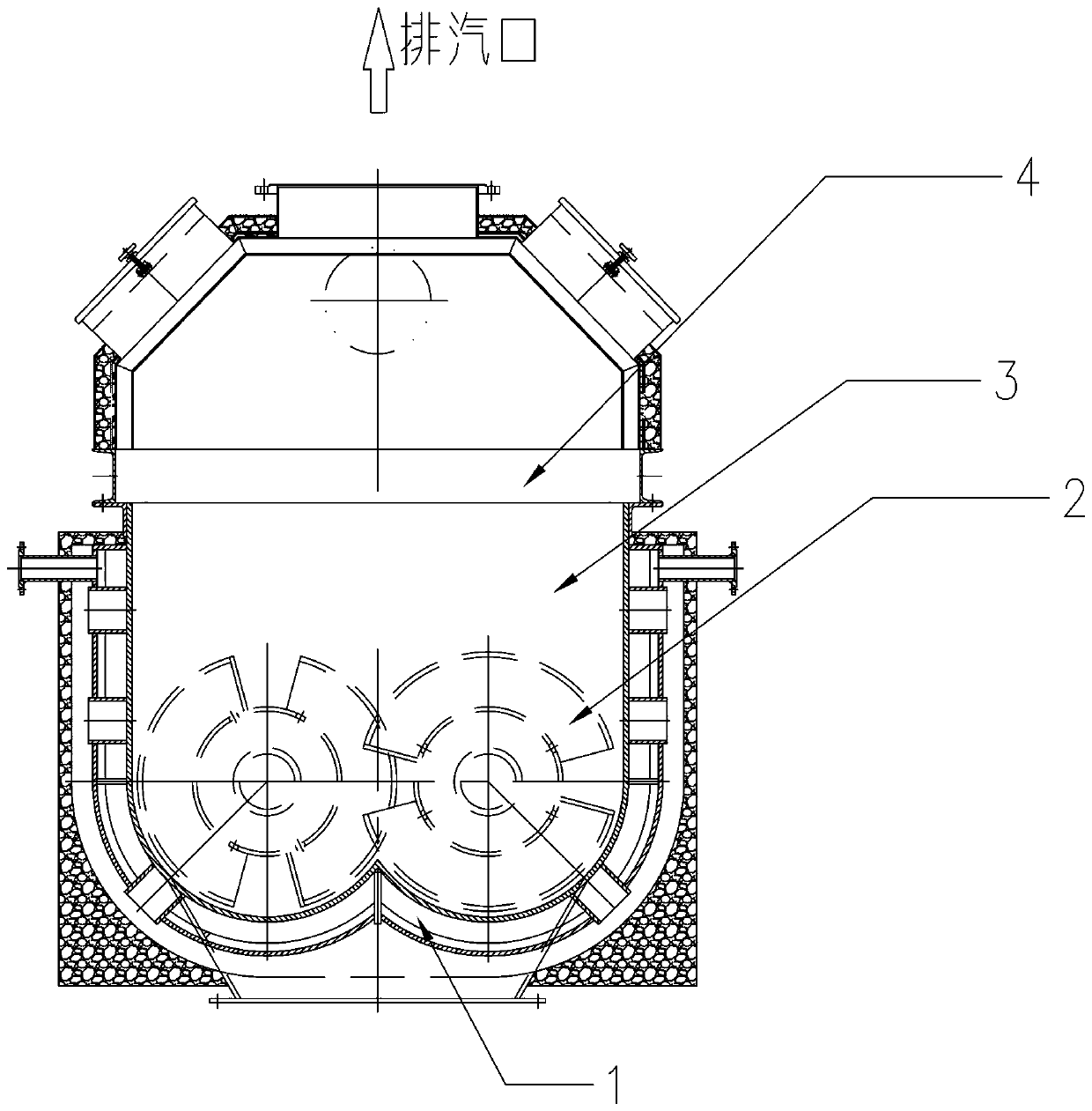

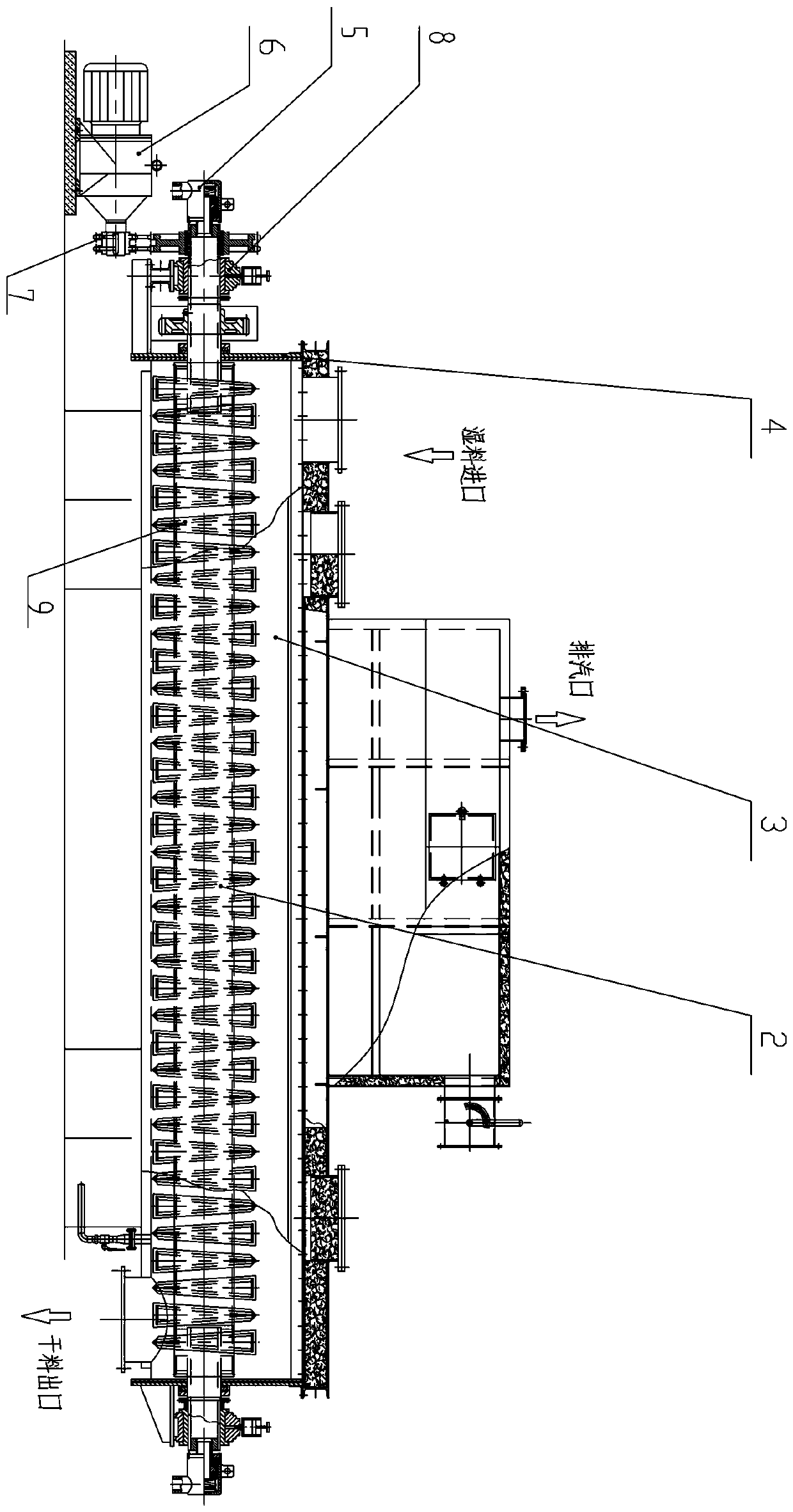

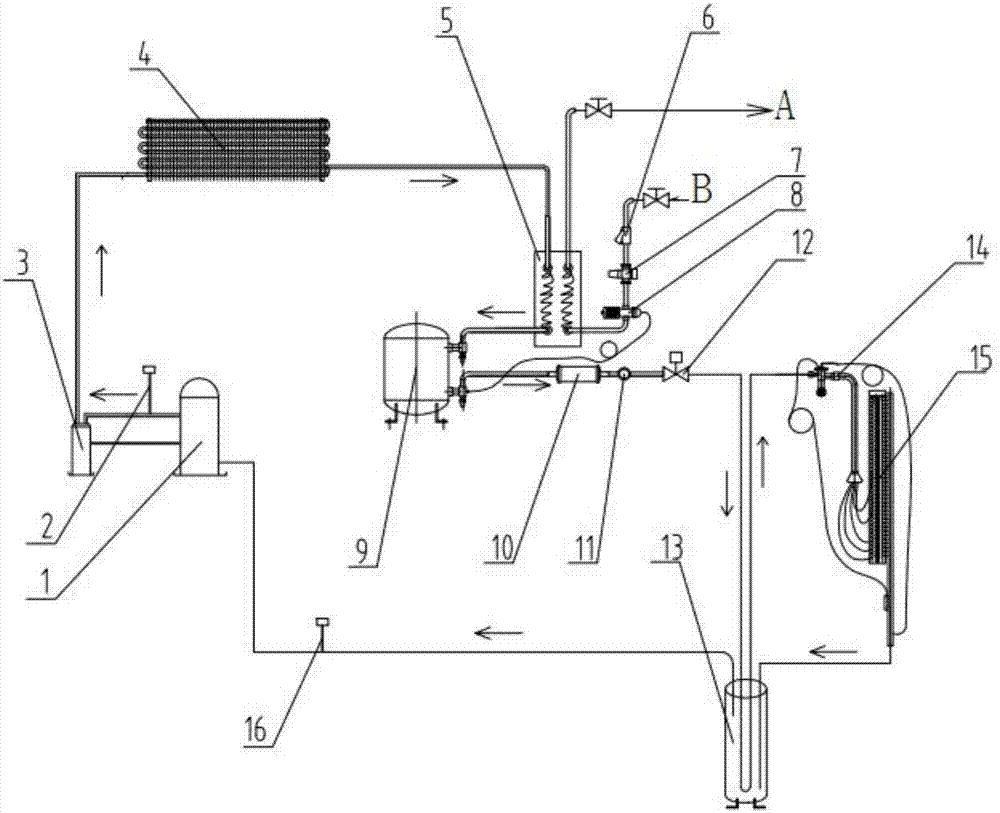

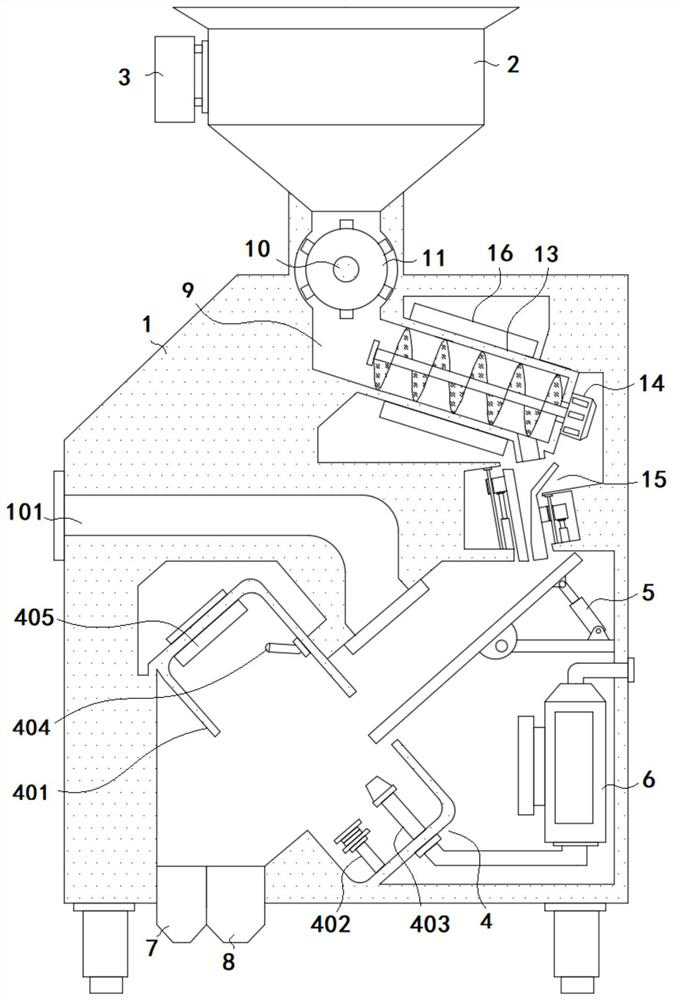

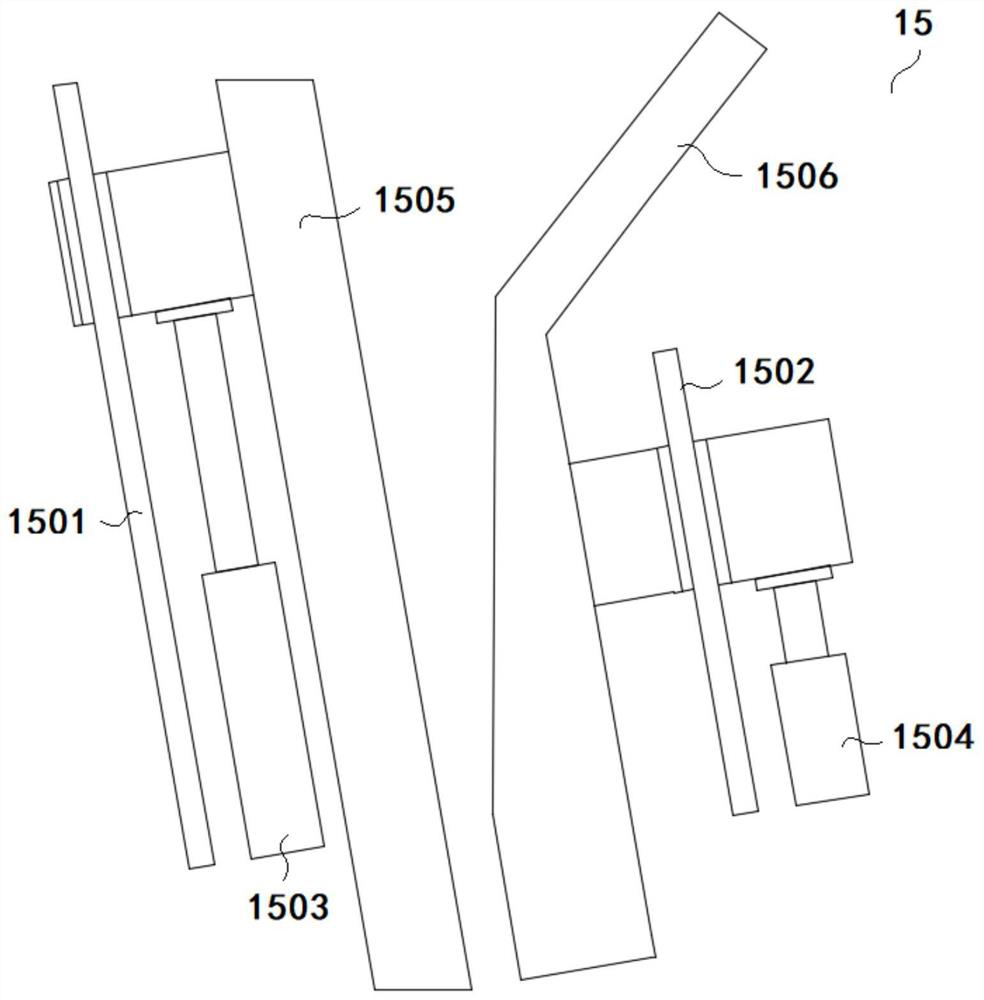

Production system for producing building plaster by using desulphurization gypsum and realization method of production system

The invention discloses a production system for producing building plaster by using desulphurization gypsum. The production system comprises a feeding system, a drying system, a calcining system, a dust removing system, a burning system and a material storing and packaging system, wherein the feeding system is used for feeding plaster materials; the drying system is used for drying the plaster materials; the calcimining system and the burning system are used for calcining the plaster materials into the building plaster; the material storing and packaging system is used for packaging the building plaster; the dust removing system is applied to all subsystems of the production system for removing dust in the production. The production system has the following advantages that the building plaster is prepared by a drying and calcining two-step method of a spiral dryer and a fluidized bed combustion boiler; the production system has remarkable advantages of low energy consumption, simple technology, stable quality of a product, easiness in control and the like.

Owner:山东海蓝阳光环境服务有限公司

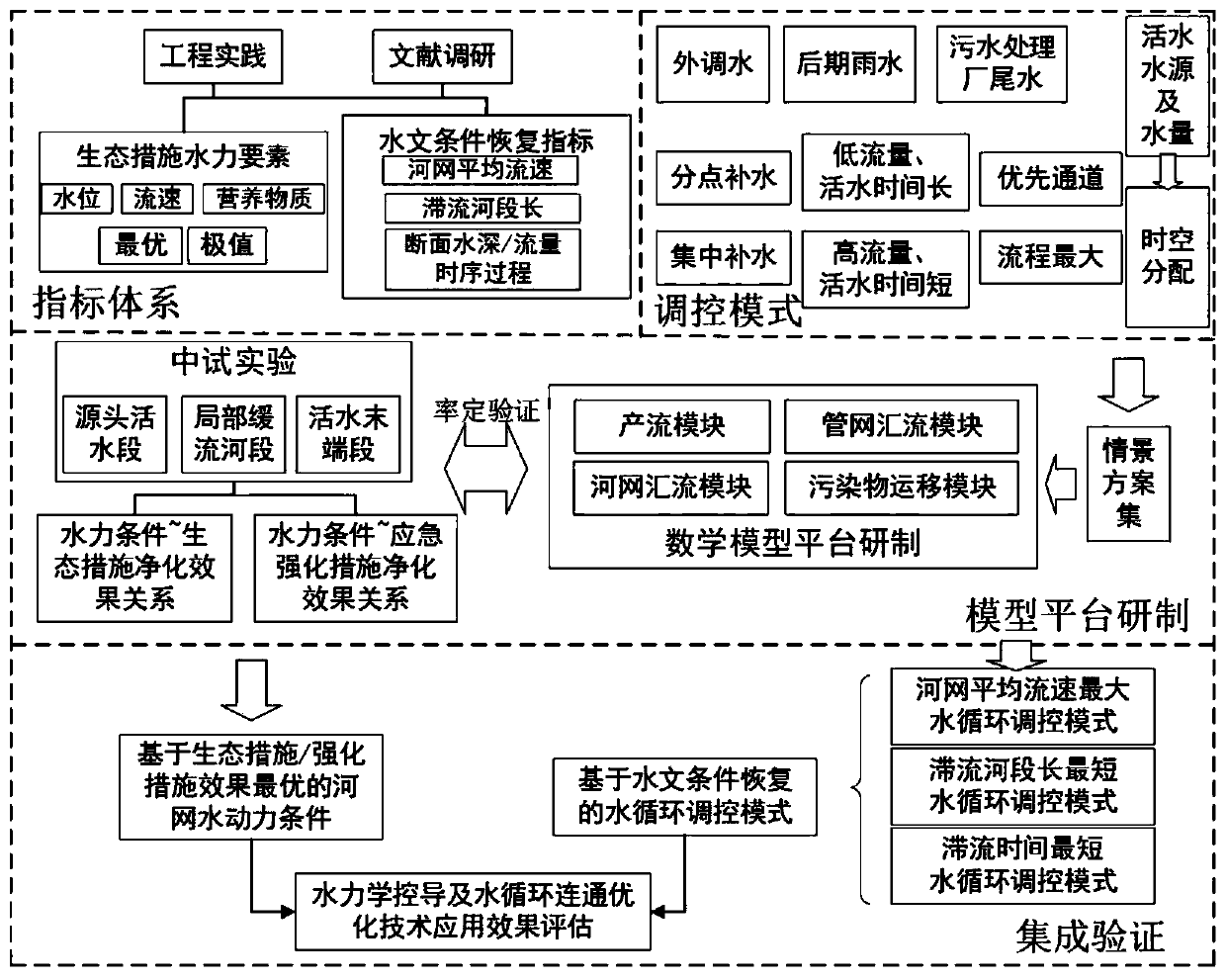

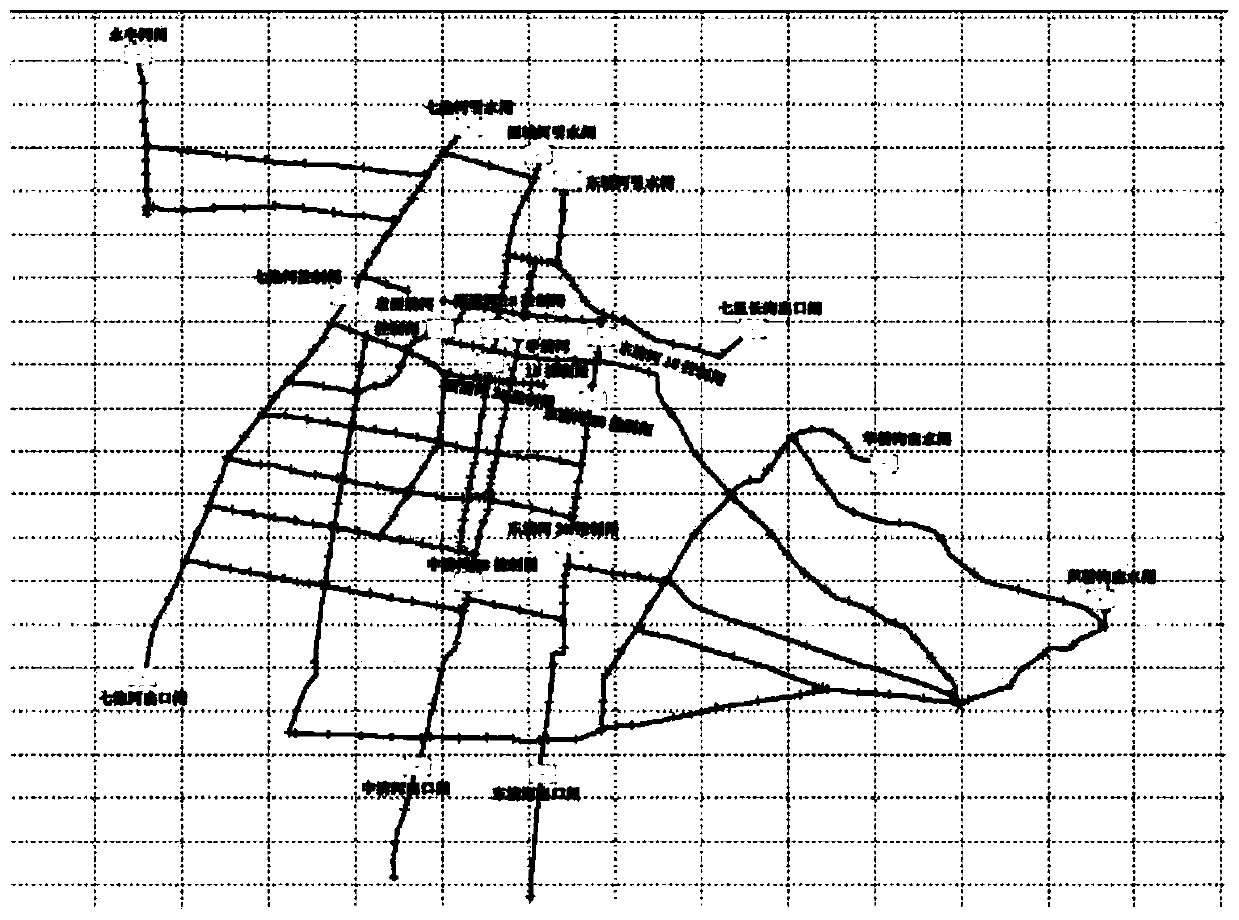

Plain area urban river network water circulation regulation and control method based on ecological restoration target

ActiveCN111027264AAchieve organic unityMaximize the environmental ecological effectWater resource protectionGeneral water supply conservationRiver networkWater source

The invention relates to a plain area urban river network water circulation regulation and control method based on an ecological restoration target, and the method comprises the steps: building a water volume-hydrodynamic force-water quality-water ecological index system through the investigation of the basic conditions of an urban river network and taking the aquatic organism diversity as the basic target of the urban river network water ecological restoration; constructing a river network hydraulics-water quality-water ecology refined simulation model, optimizing a flowing water engineeringregulation and control scheme by utilizing a hydrodynamic force-water quality simulation result of each scene scheme, constructing an urban river network large circulation system, and adjusting a section structure of a local end river segment to realize local small circulation; and comprehensively evaluating the flood control safety, the environment improvement benefit and the influence on the water supply source of the regulation and control scheme. Under an existing engineering system, a flowing water source and kinetic energy of the flowing water source are fully utilized, dispatching of hydraulic engineering such as gates and pumps serves as a main way, ordered movement of inland river water flow is promoted, and the inland river self-cleaning capacity is recovered and improved.

Owner:安徽省(水利部淮河水利委员会)水利科学研究院(安徽省水利工程质量检测中心站)

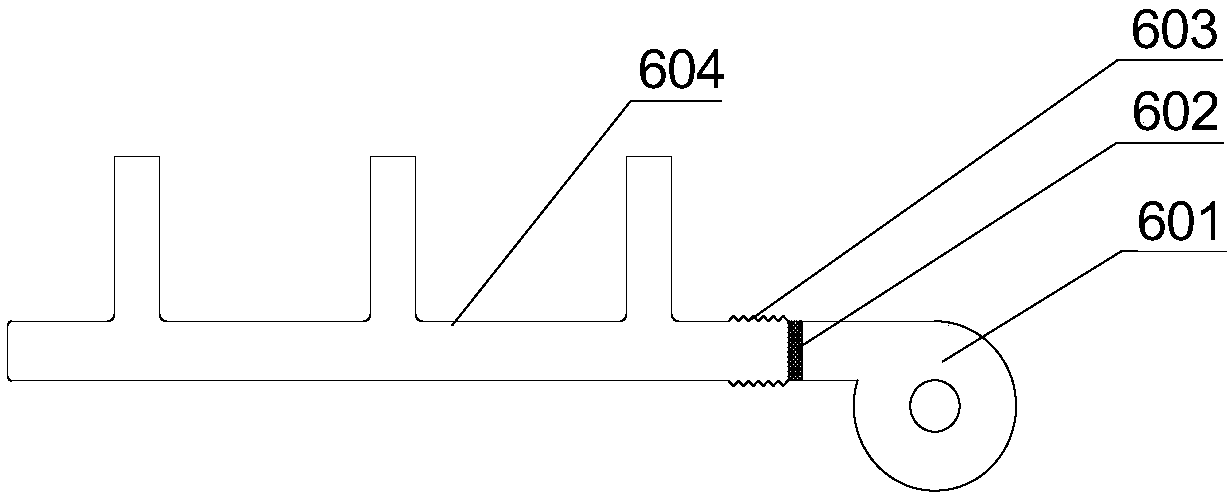

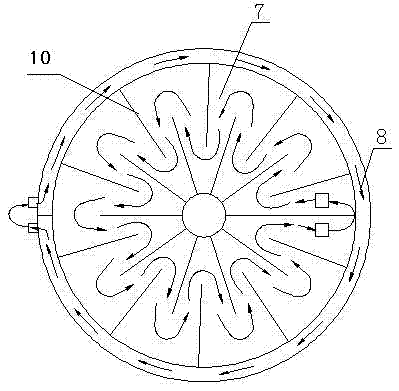

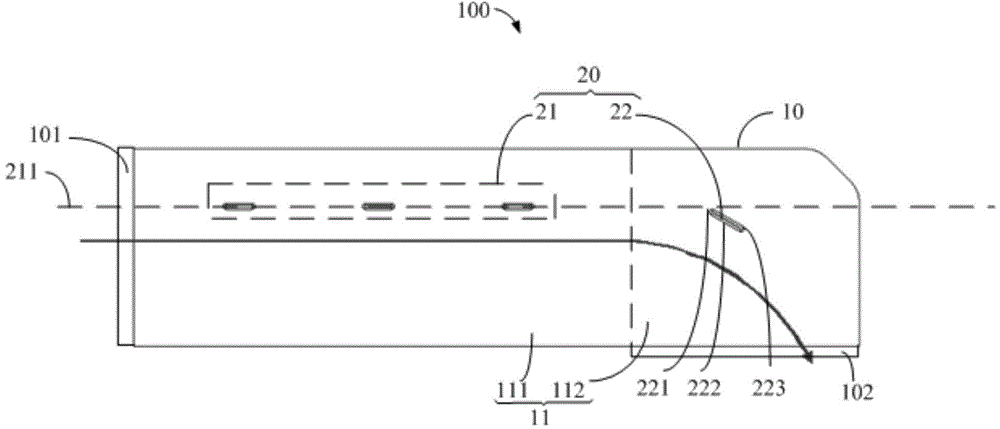

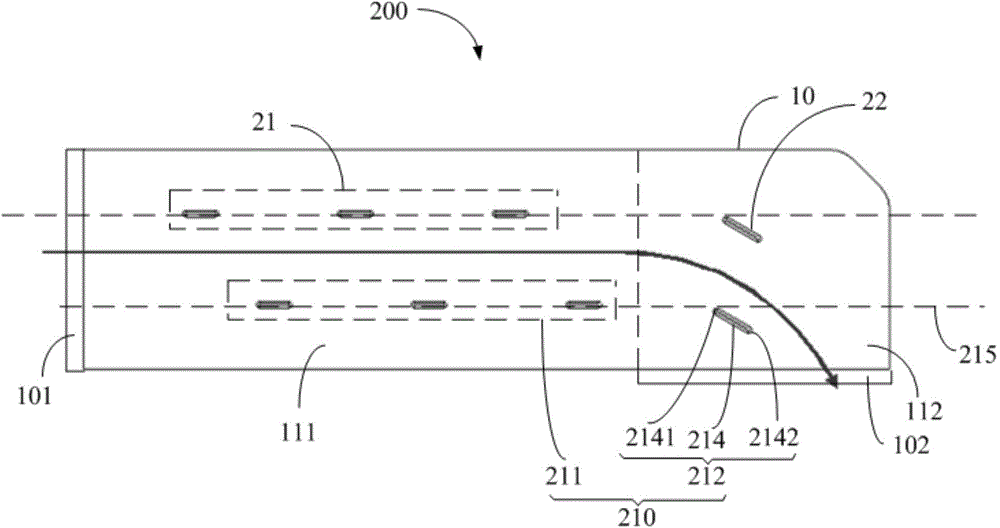

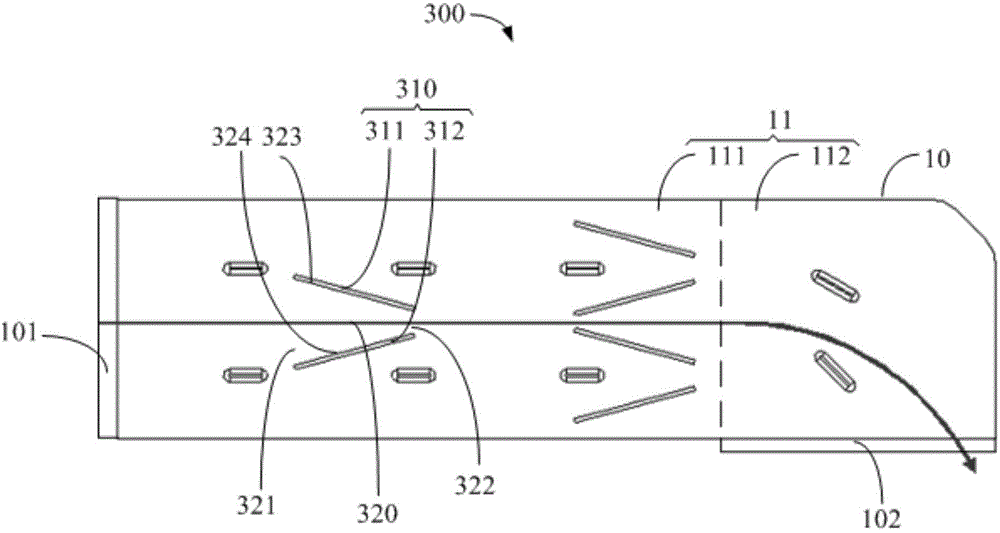

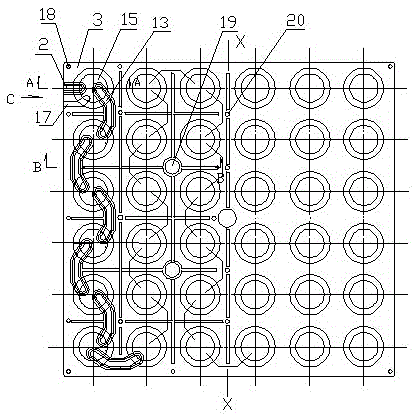

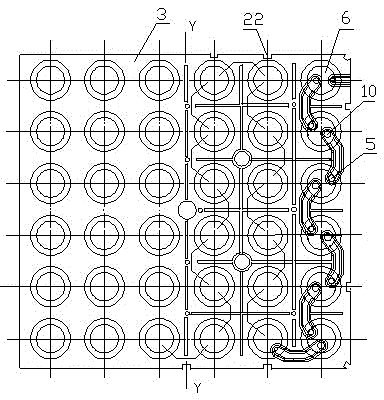

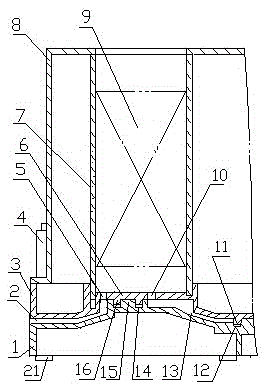

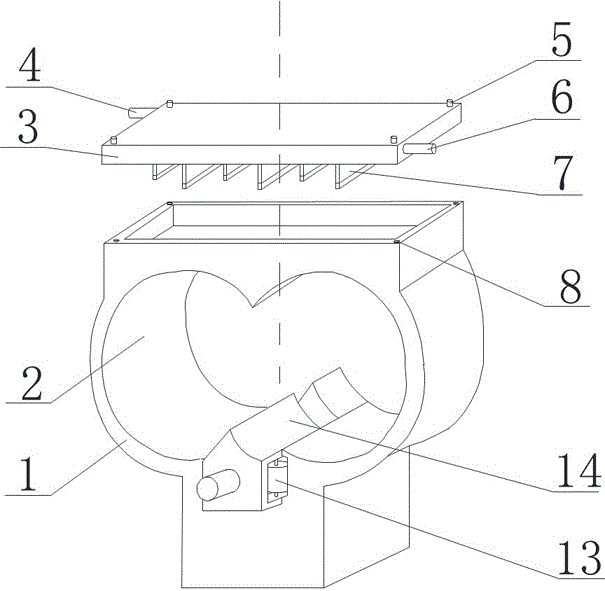

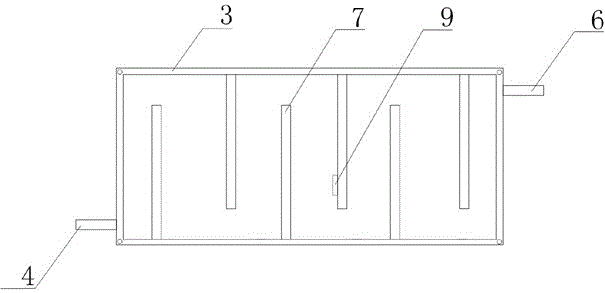

Liquid heat dissipation structure for motor controller

InactiveCN105392330AImprove closureOrderly flowCooling/ventilation/heating modificationsFlow diversionEngineering

A liquid heat dissipation structure for a motor controller comprises a heat dissipation plate main body and a cover plate arranged in parallel with the heat dissipation plate main body; wherein the heat dissipation plate main body comprises a heat dissipation substrate, a side plate with a liquid inlet and a liquid outlet, a plurality of flow baffles, and a plurality of diversion fin groups; the side plate is perpendicular to the heat dissipation substrate, a semi-closure containing cavity is enclosed by the side plate and the heat dissipation substrate; and the flow baffles and the diversion fin groups are arranged in the containing cavity. The liquid heat dissipation structure has the advantages that: with the design of at least two S-shaped main flow channels connected in series and the diversion fin groups, a flow diversion function is provided, and at the same time, dissipation of the heat in the motor controller is effectively accelerated; with the design of S-shaped bosses, which are in seamless connection with the S-shaped main flow channels on the heat dissipation substrate, on the cover plate, closure of the motor controller is improved, and at the same time, liquid having the heat dissipation effect can flow orderly between the main flow channels and secondary flow channels, so as to achieve the purpose of liquid heat dissipation.

Owner:WISDRI WUHAN AUTOMATION

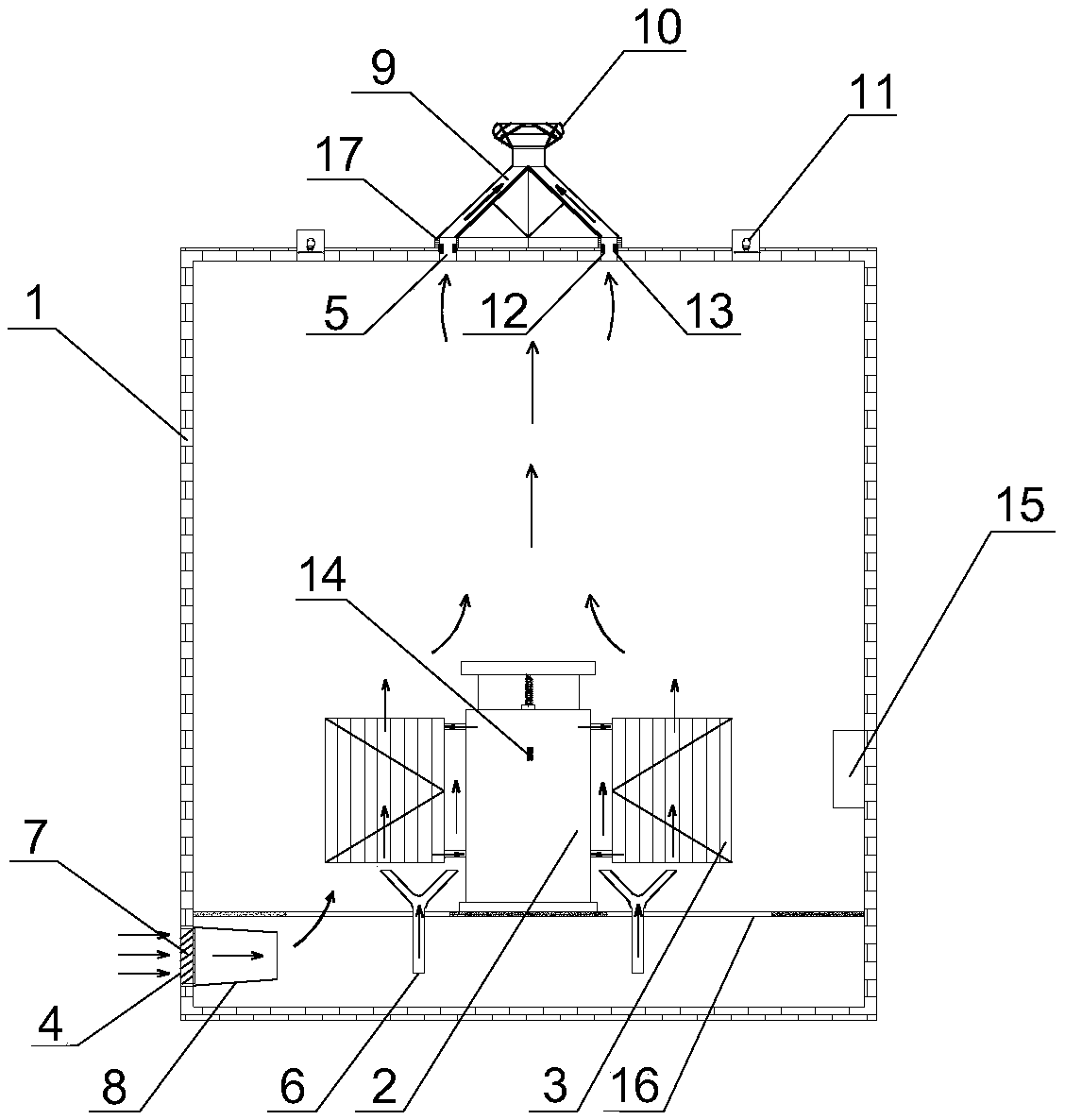

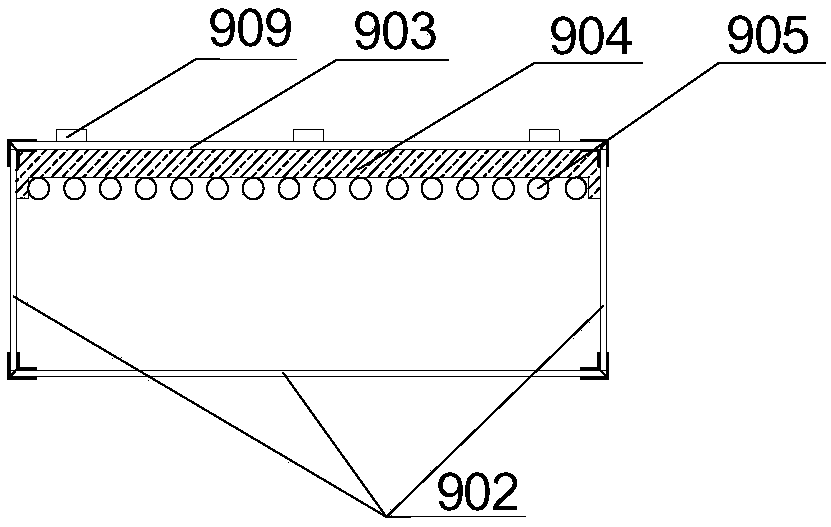

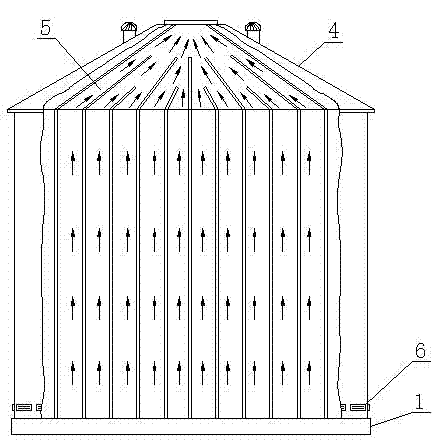

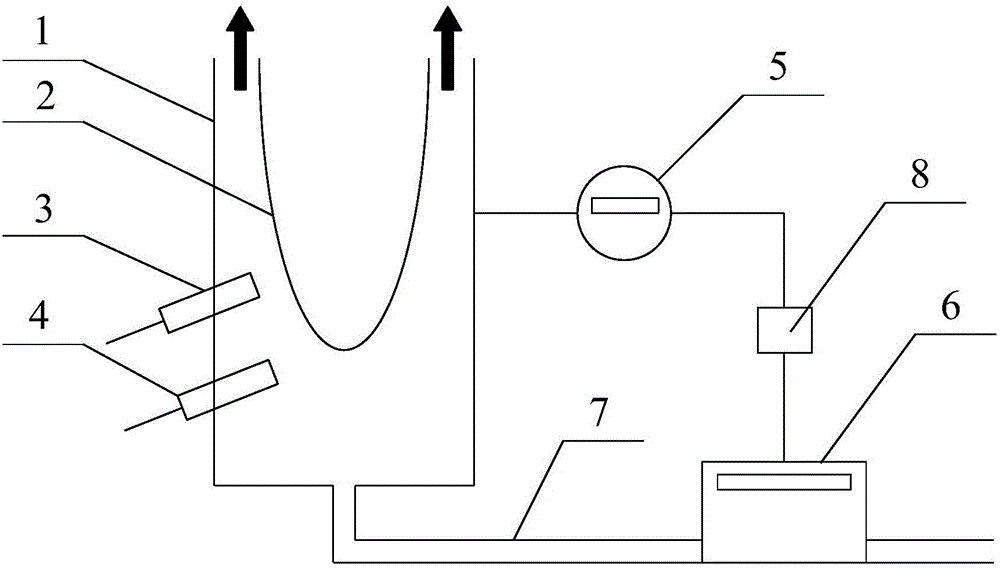

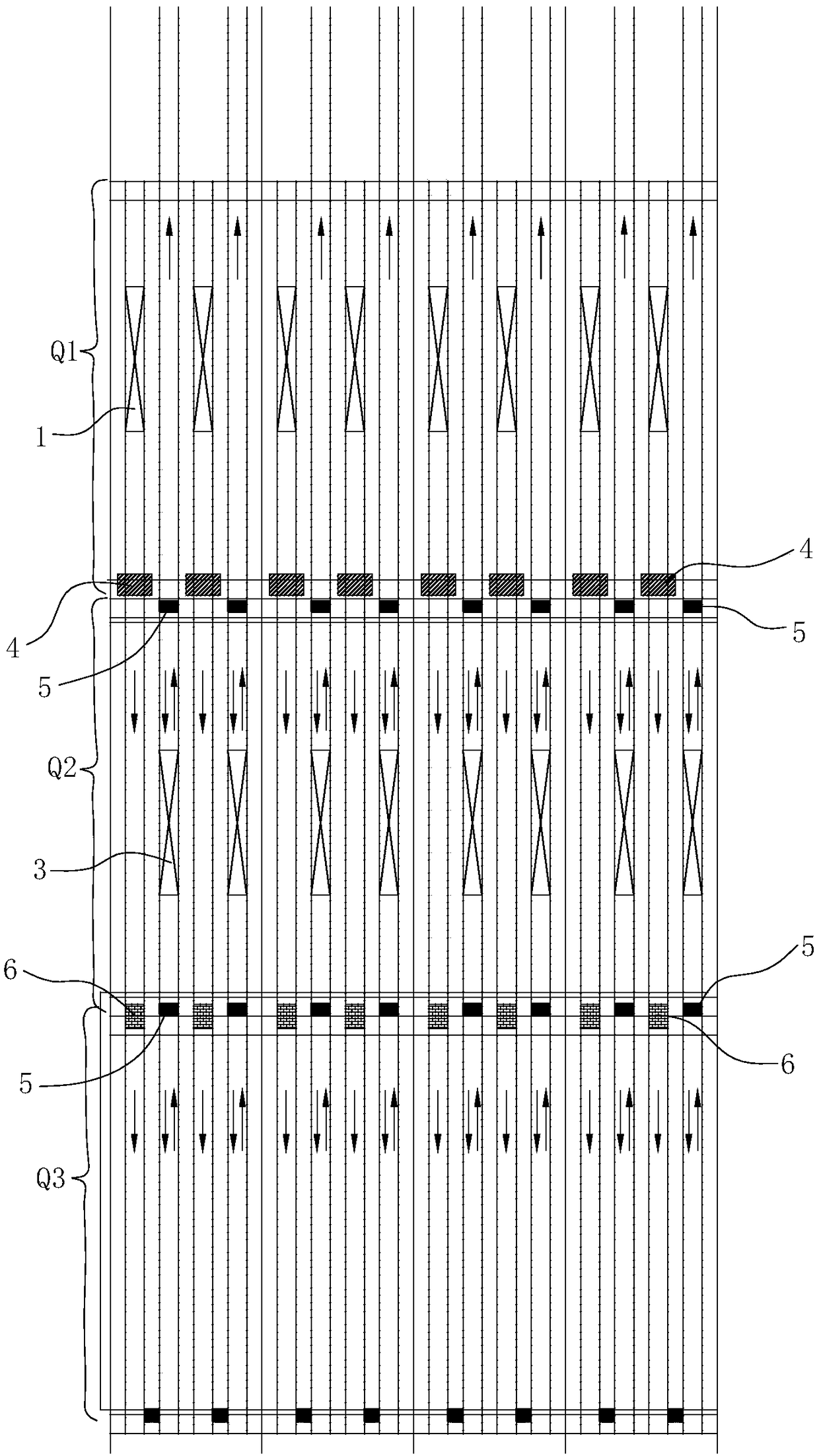

A composite ventilation cooling system of a main transformer room

InactiveCN109038303AImprove utilization efficiencyReduce usage timeSolar heating energySolar heat storageMechanical fanControl system

The invention discloses a composite ventilation cooling system of a main transformer room, including the main transformer room, an integrated oil-immersed transformer located in the center of the maintransformer roomroom, an air inlet system located below the integrated oil-immersed transformer and near the bottom of the main transformer room, an exhaust system located at the top of the main transformer room and a control system for intelligent control, the integrated oil-immersed transformer comprises a transformer body and radiators located on both sides of the transformer body, an air inlet is arranged at the bottom of one side wall of the main transformer room and an air outlet is arranged at the top of the main transformer room. The invention makes full use of external environmentalconditions to strengthen a ventilation effect, According to the operation of transformer and indoor ventilation condition, the ventilation mode can be adjusted dynamically, the indoor air flow can flow from bottom to top orderly, the utilization efficiency of cooling air can be improved, the service time of a mechanical fan is reduced, and the ventilation energy consumption can be reduced while the ventilation heat exchange effect of the transformer room can be improved.

Owner:SOUTHEAST UNIV

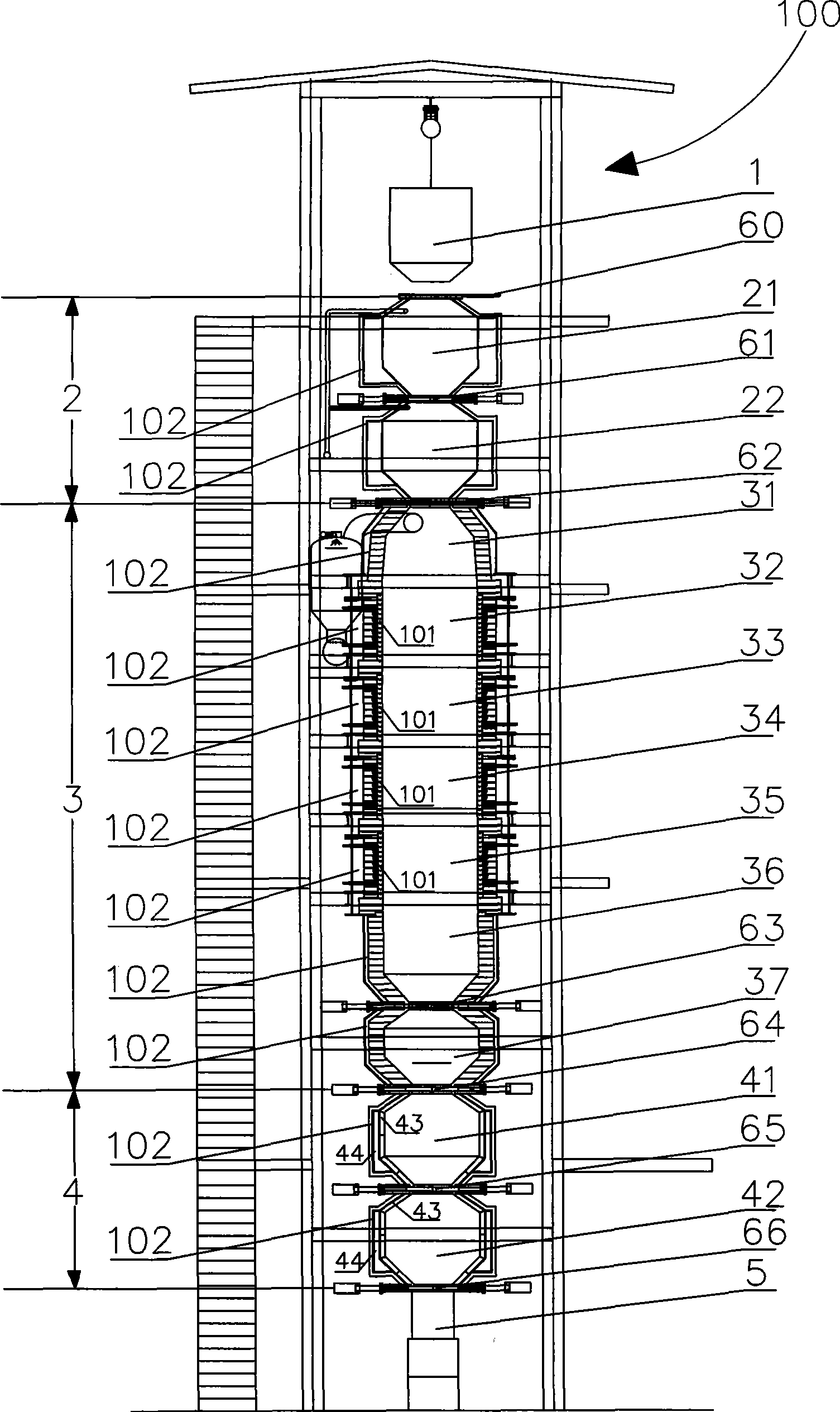

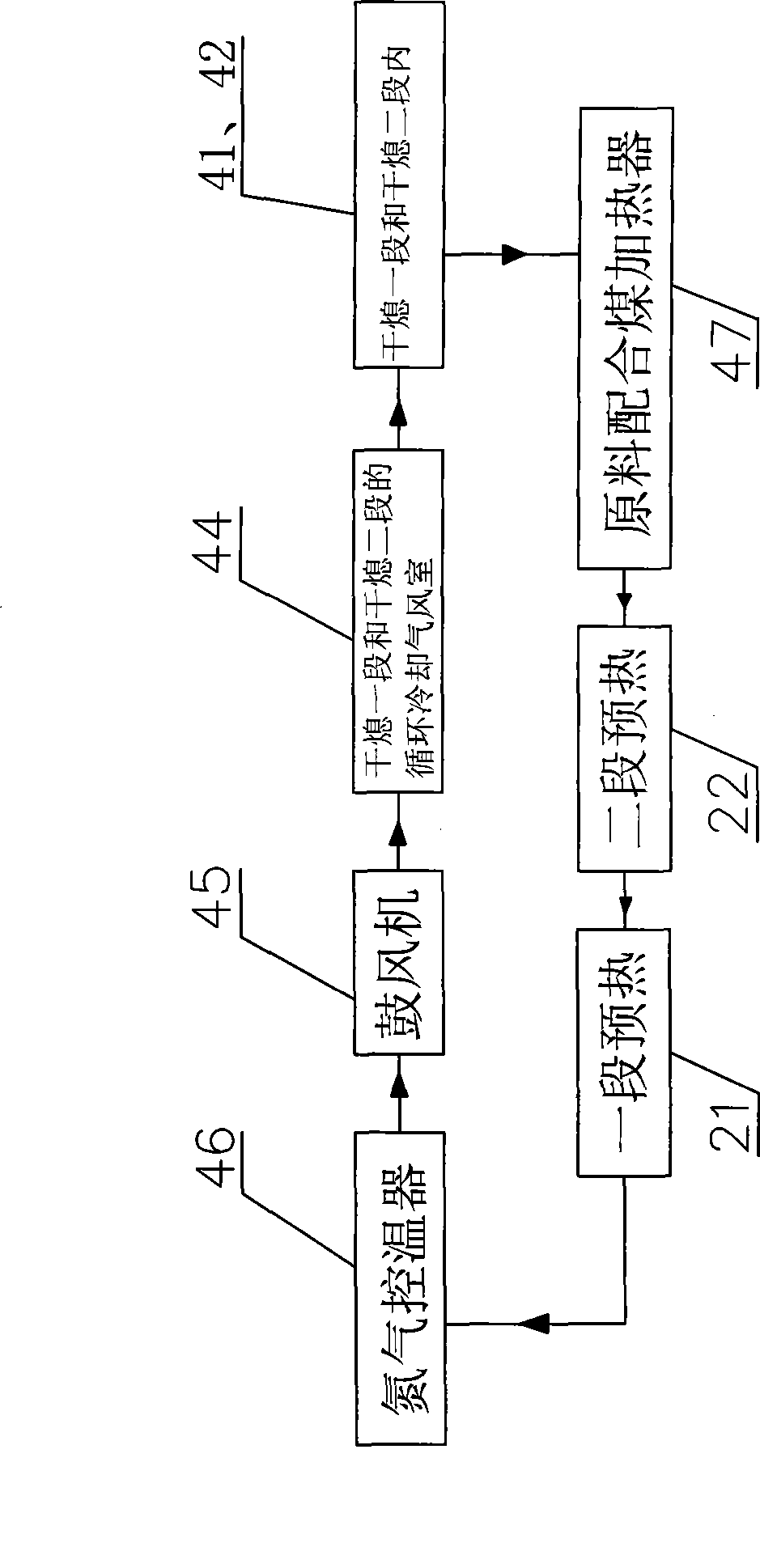

Method for electrical heating continuous coal pyrogenation coking and coking furnace thereof

InactiveCN101531906AIncrease heat transfer timeLow raw material costElectrical coke oven heatingIndirect heating destructive distillationBriquetteThermal energy

The invention provides an electrical heating continuous coal pyrogenation coking furnace which includes a furnace body, the furnace body is equipped with a hopper, a pre-heating segment, an electrical heating main body segment, a gas cycle cooling segment and a coke discharge segment orderly from upper to down; control valves are set among the hopper, the pre-heating segment, the electrical heating main body segment, the gas cycle cooling segment and the coke discharge segment. The coking furnace has advantages as follows: 1. the furnace can control rolling speed and heating effect of moulded coal efficiently in rolling process of coking coal; 2. the furnace solves temperature and environment atmosphere required by the coal pyrogenation coking; 3. the furnace changes traditional coke cooling method by water into inert gas cycle for realizing heat energy utilizing fully, is energy-saving and environmental-friendly; 4. the furnace reduces raw material cost, increases coke quality and reduces coke foam and coke particle generating; 5. the furnace can replace full coal gas by electrical heating which can solve smoke pollution efficiently.

Owner:山西华天新能源发展有限公司

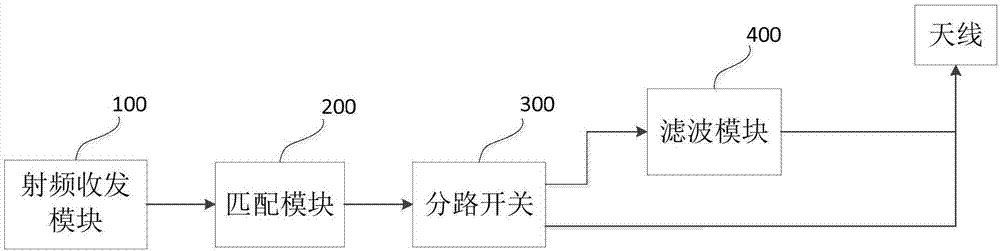

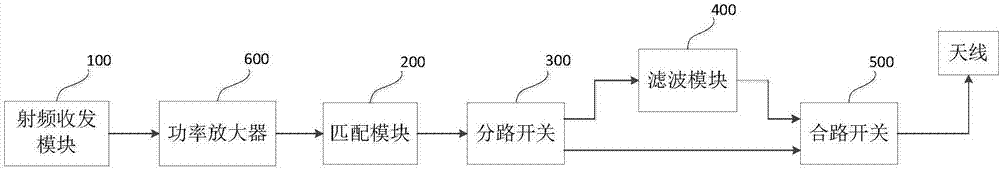

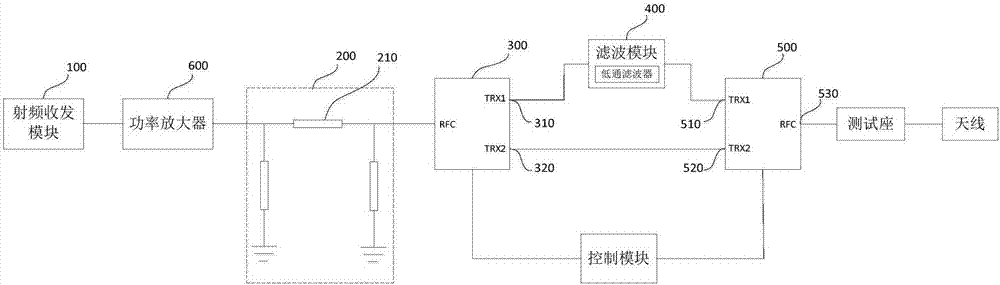

Radio-frequency circuit and method for reducing harmonic interference of radio-frequency circuit

The invention discloses a radio-frequency circuit and a method for reducing harmonic interference of the radio-frequency circuit. The circuit comprises a radio-frequency transceiving module, a matching module, a shunt switch and a filter module; one end of the matching module is connected with the radio-frequency transceiving module, and the other end is connected with the filter module via the shunt switch. The method comprises the following steps: S10, detecting the frequency of signals; and S20, selecting a signal channel according to the frequency detection result of the signals. The radio-frequency circuit can recognize signals and transmit the signals in different channels, and can further filter more harmonic interference generated therein, thus greatly reducing harmonic power no matter on conduction or coupling, and solving the problem of electromagnetic compatibility stray.

Owner:PHICOMM (SHANGHAI) CO LTD

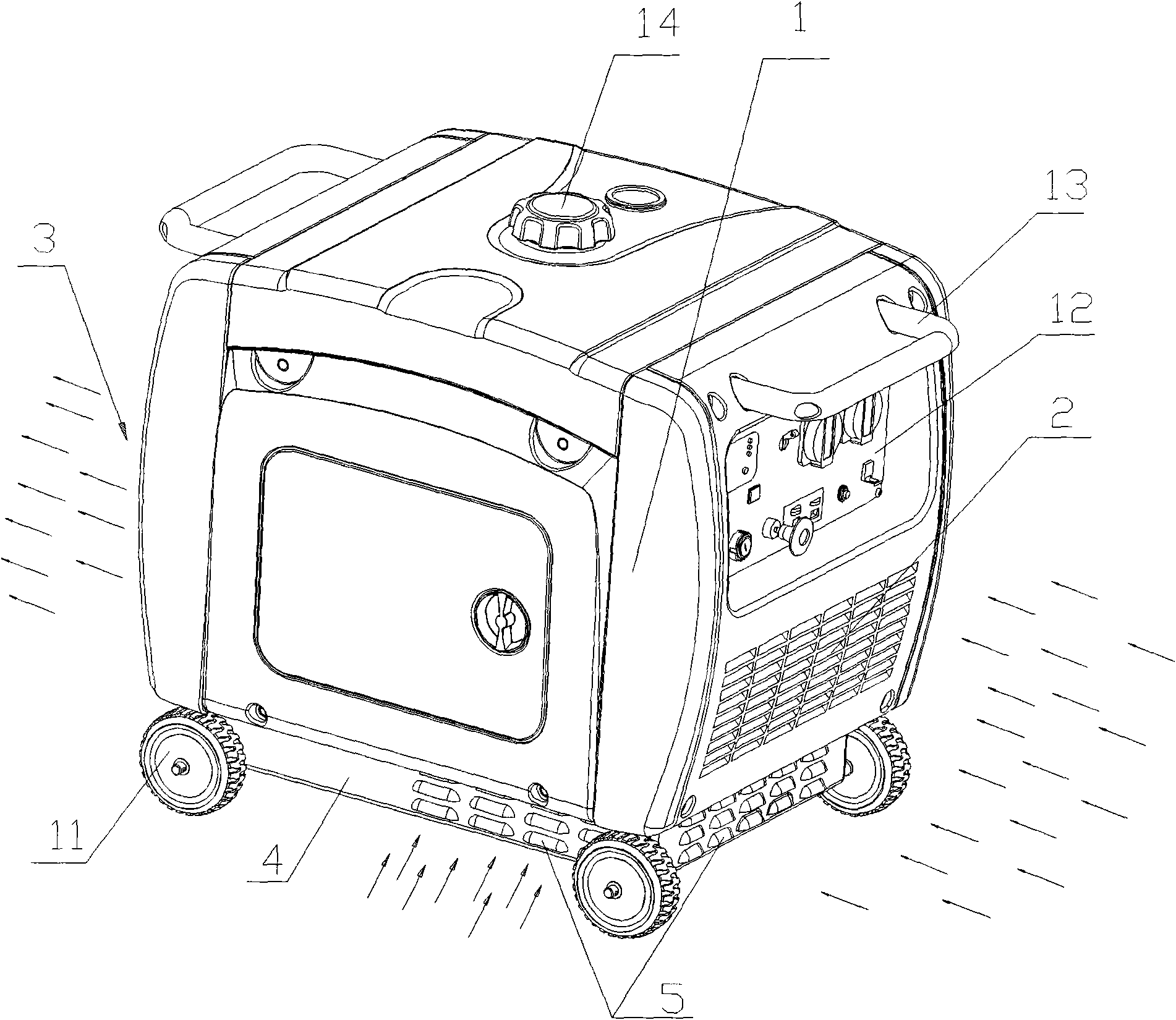

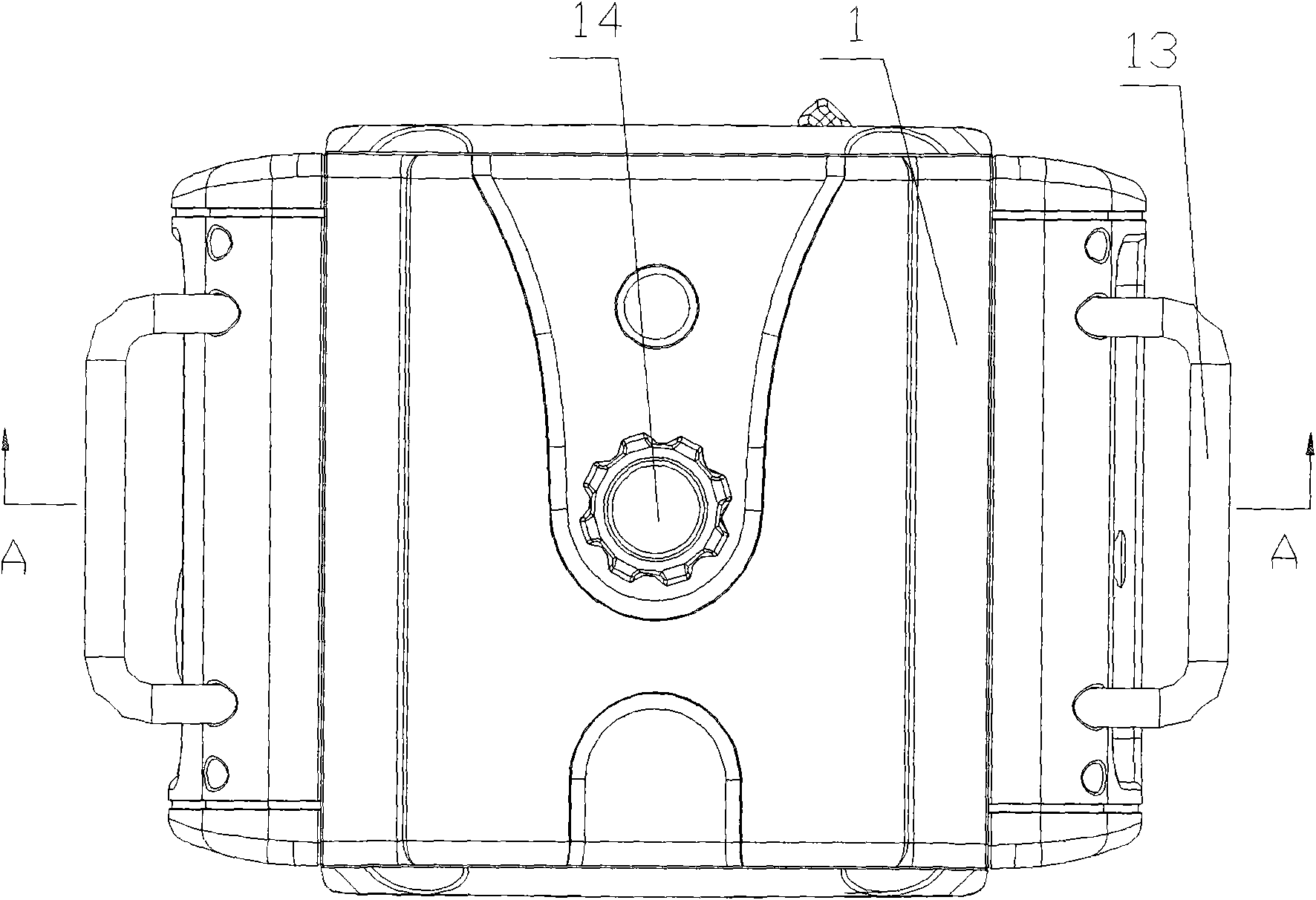

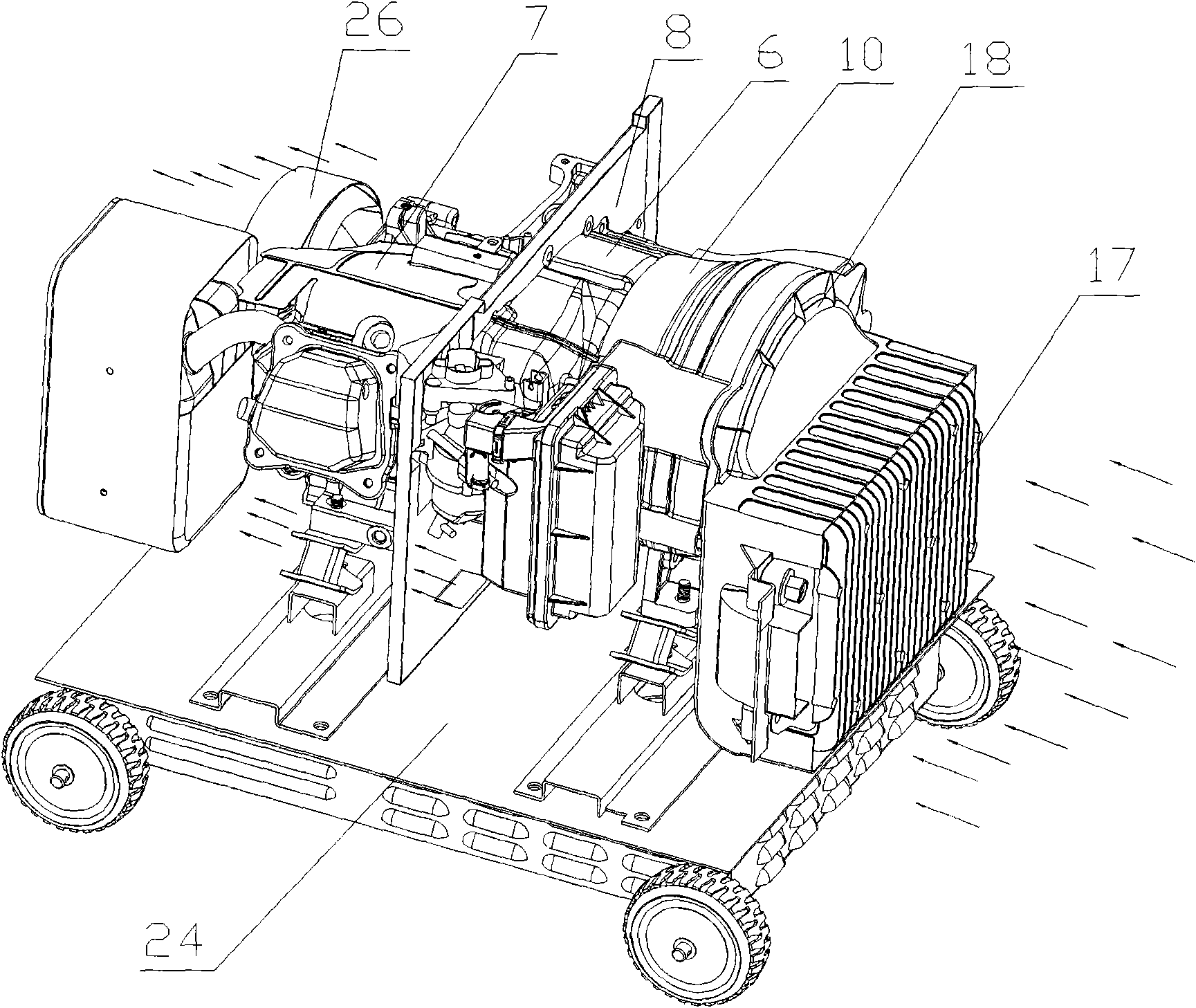

Generator of engine

InactiveCN101635486AOrderly flowImprove cooling effectCooling/ventillation arrangementFrequency changerElectric machine

The invention provides a generator of a gasoline engine. A generating set is mounted on a stand and is arranged in a closed outer shell. Two opposite sides of the outer shell are respectively provided with an air inlet and an air outlet; an engine is provided with a fan sleeve (6) and an air-guiding sleeve (7) which are respectively arranged at both sides of a cold-hot area separator (8); a motor stator is covered by another air-guiding sleeve (10); a gap is formed between the end surface of the fan sleeve (6) and an engine stator (9); and one end of the air-guiding sleeve (10) is connected with the fan sleeve (6). By the technical scheme of the invention, an air duct structure in the generator becomes more reasonable, an air flow direction becomes more regular and orderly and various heating parts in the generator are cooled well. The gasoline engine generator running at a room temperature can control the temperature of a transducer inductor to be lower than 60 DEG C and the oil temperature of the generator to be lower than 125 DEG C so that favorable ventilation and radiation effects are obtained.

Owner:LONCIN MOTOR

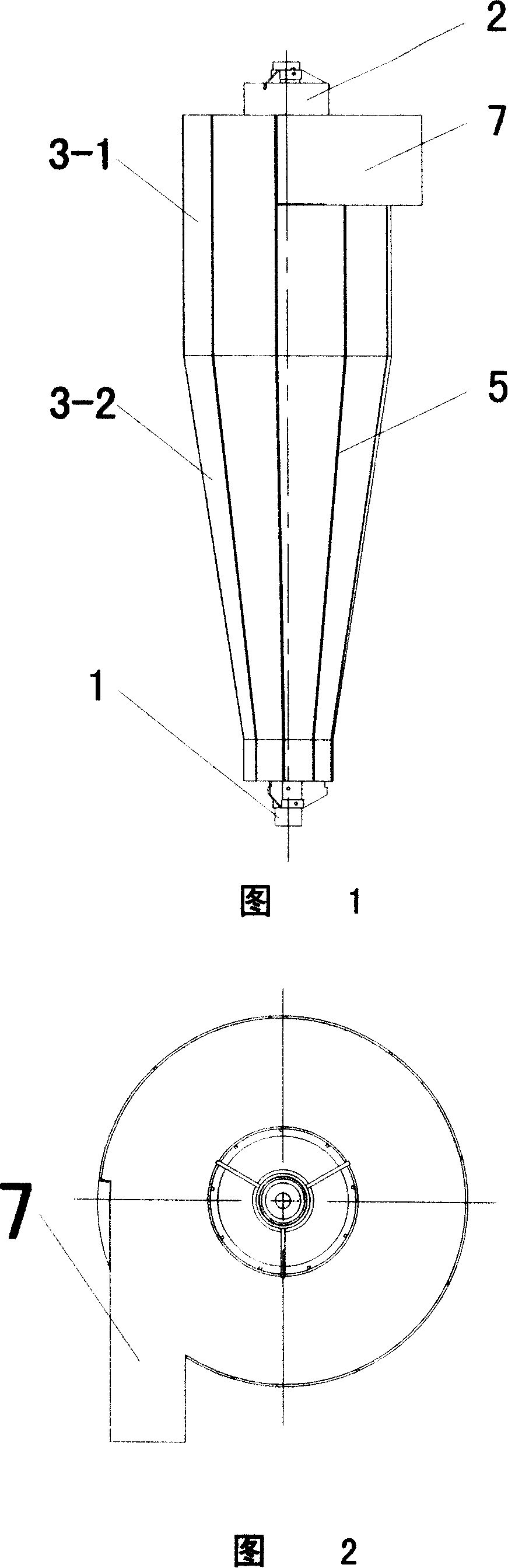

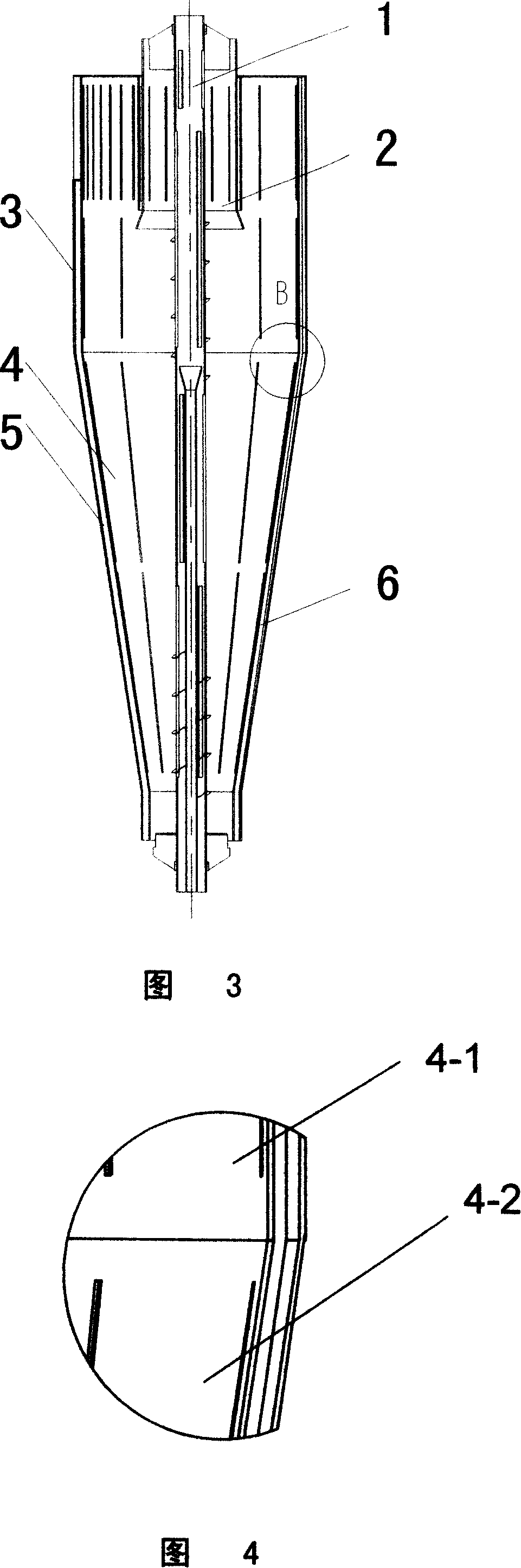

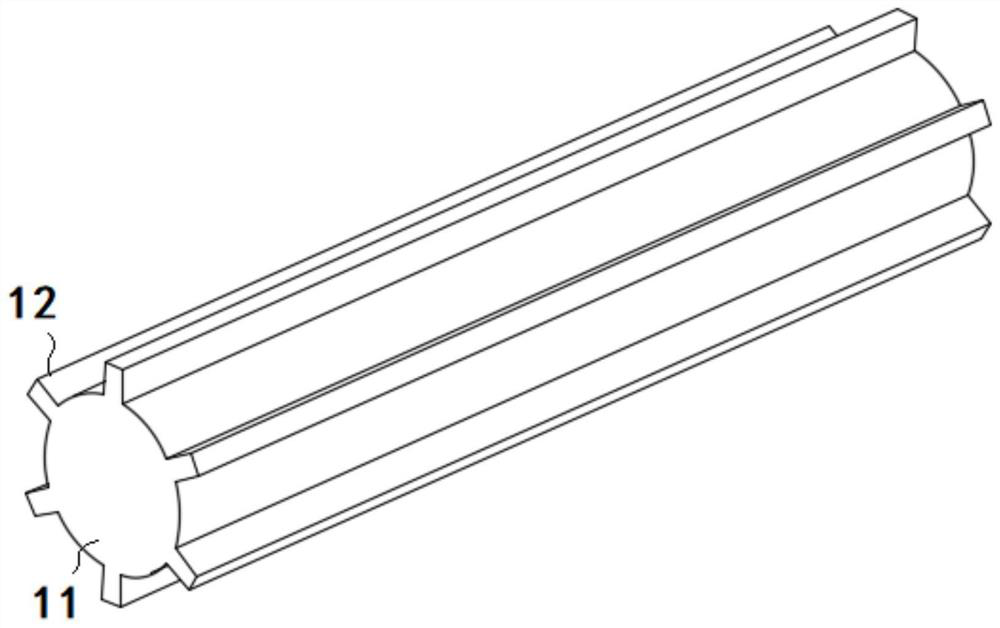

Cyclone type dust-cleaning device cyclone

InactiveCN101147895AReduce wearImprove dust removal efficiencyReversed direction vortexCycloneEngineering

The present invention relates to a concrete structure of cyclone rotor of cyclone dust collector. It includes an external cylindrical body whose external form is made into the form of column and is communicated with a conical body, an internal cylindrical body with tangential air inlet and an exhaust pipe placed in the central upper portion of said internal cylindrical body. It is characterized by that between the external cylindrical body and internal cylindrical body a supporting steel strip is arranged and connected on the surface of said internal cylindrical body from top to bottom, and the gap formed between external cylindrical body and internal cylindrical body can be divided into several powder dust channels from top to bottom by means of said supporting steel strip, and the described internal cylindrical body is formed from column-shaped upper cylindrical body and cone-shaped lower cylindrical body.

Owner:SHANGHAI UNIV OF ENG SCI

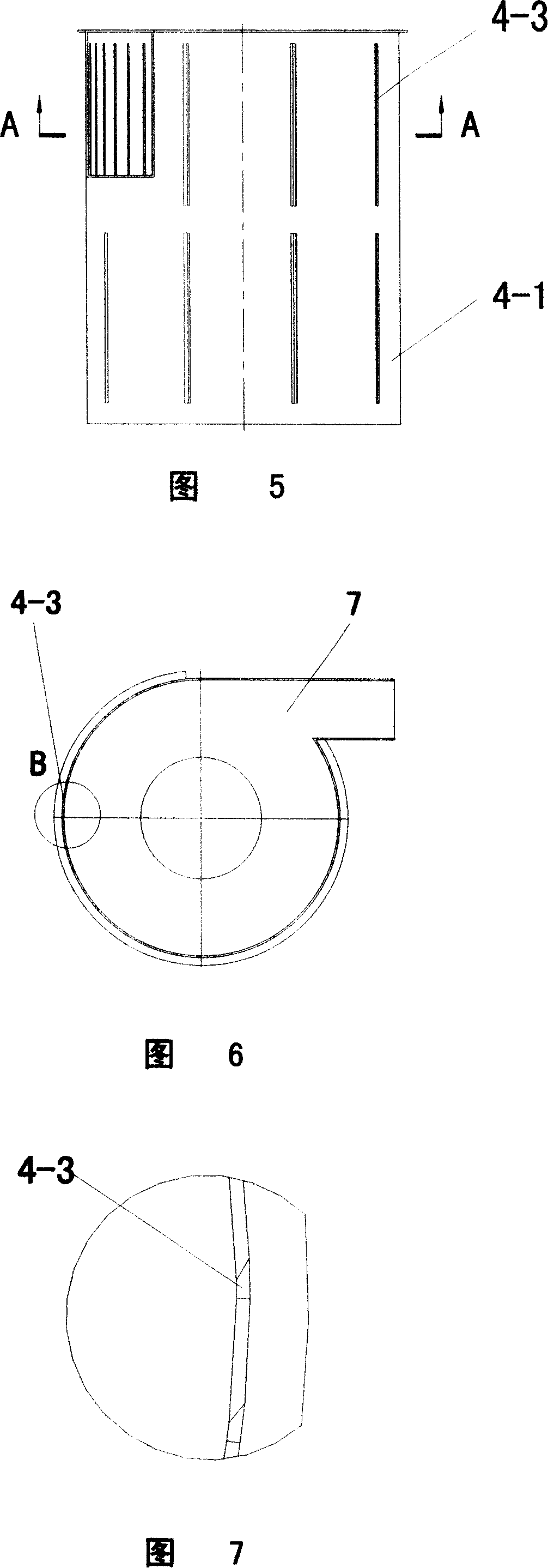

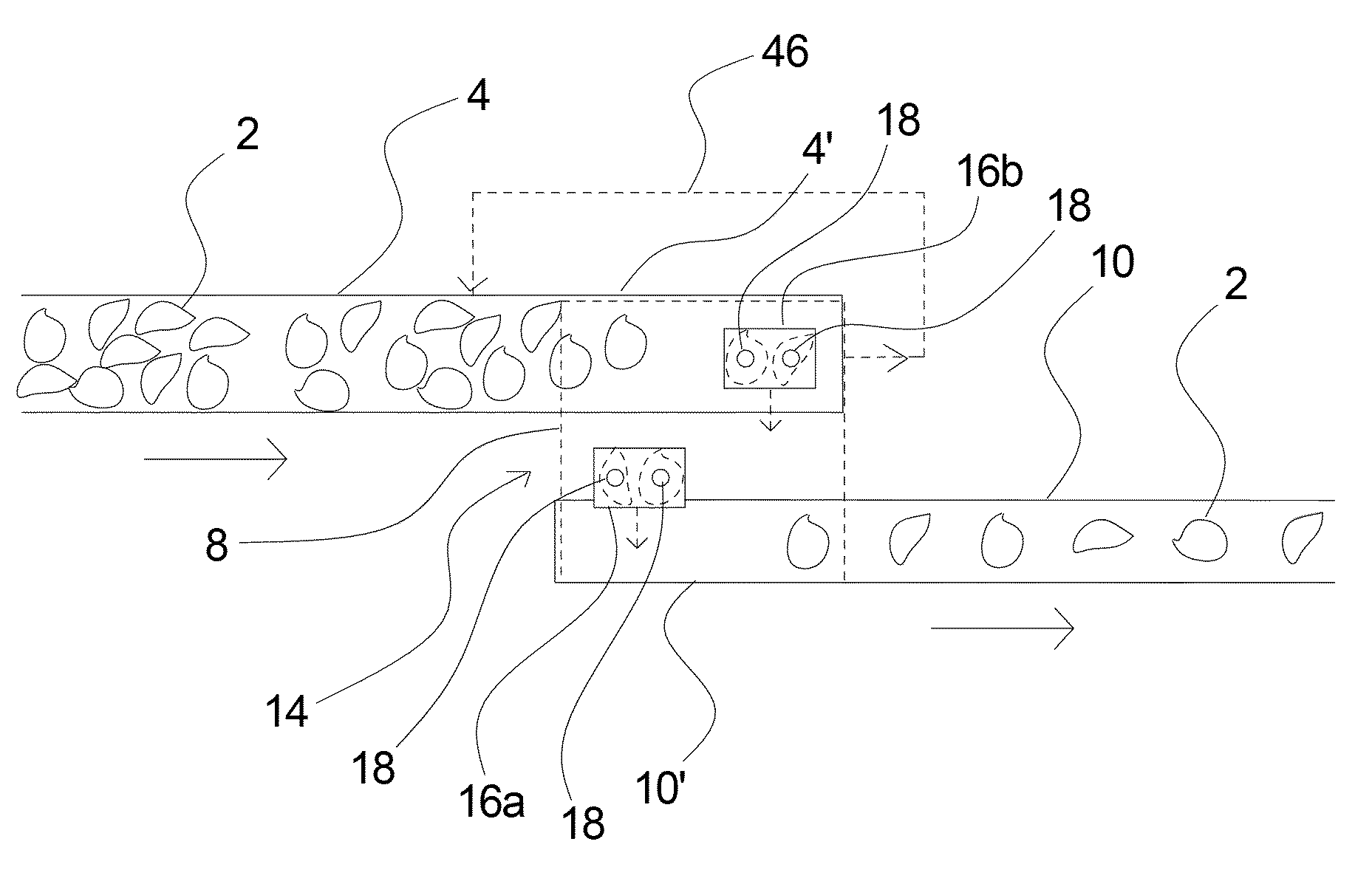

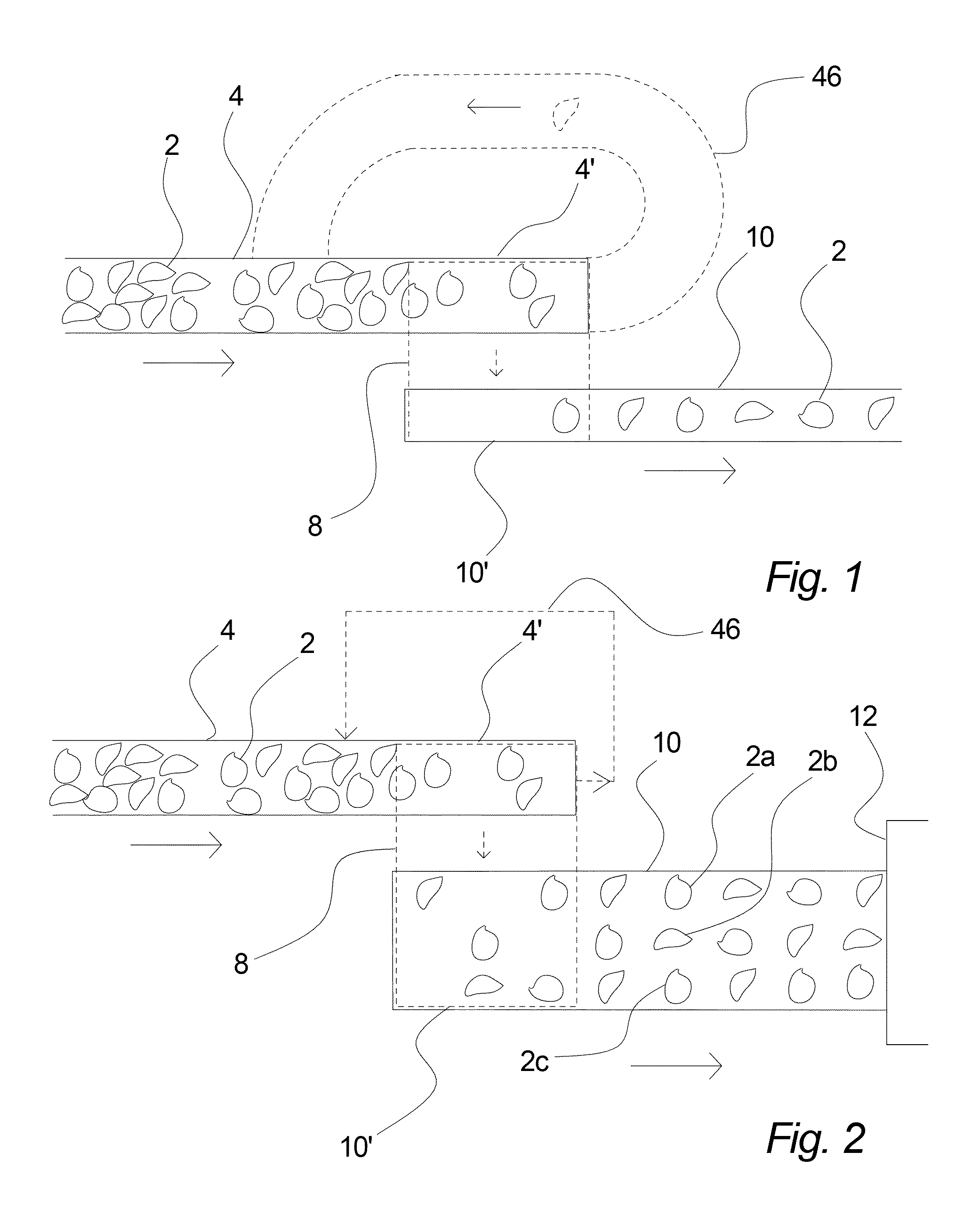

Method and a system for transferring of items

ActiveUS20090129910A1Decreases its movabilityIncreased need for cleaningSemiconductor/solid-state device manufacturingPackagingIndustrial engineering

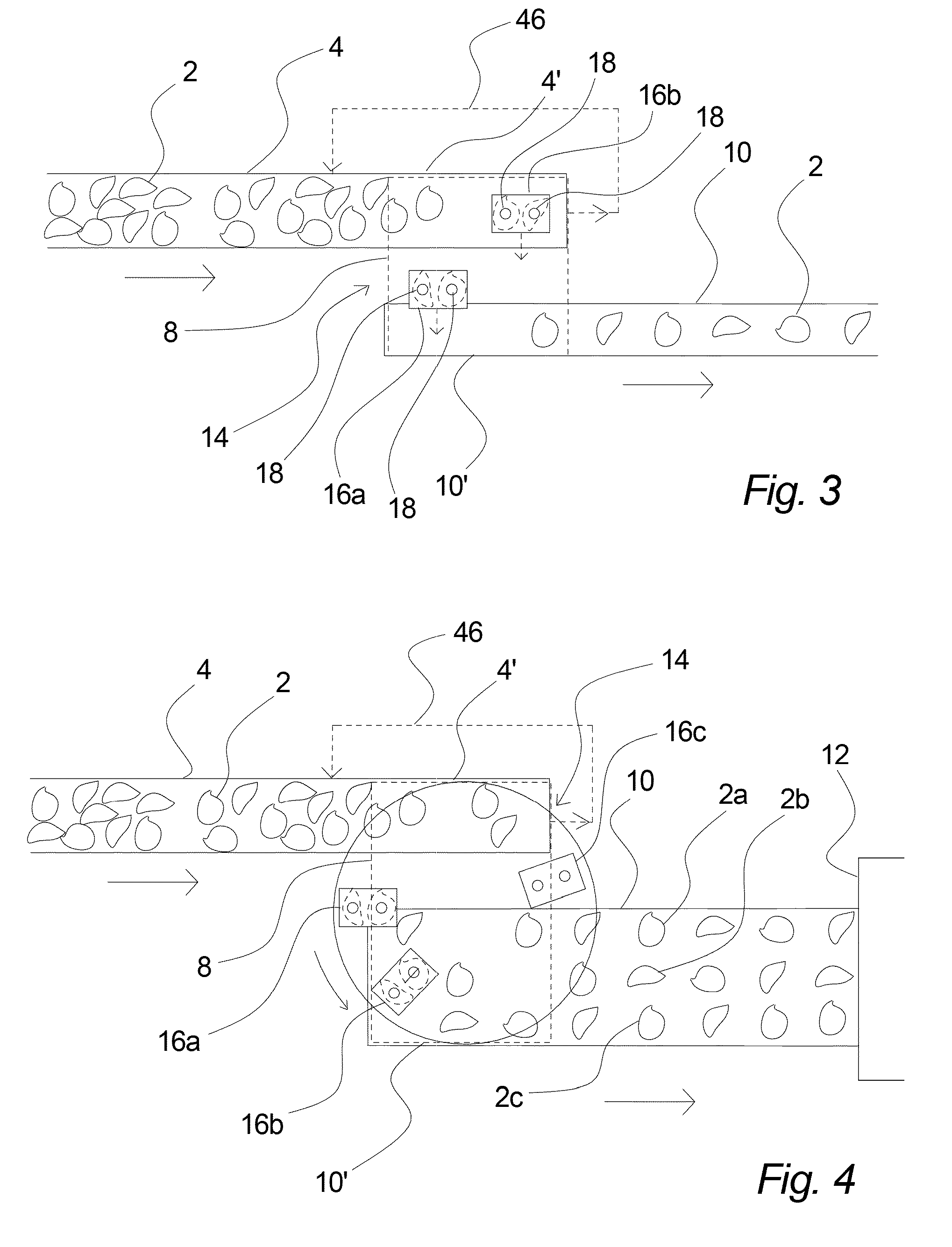

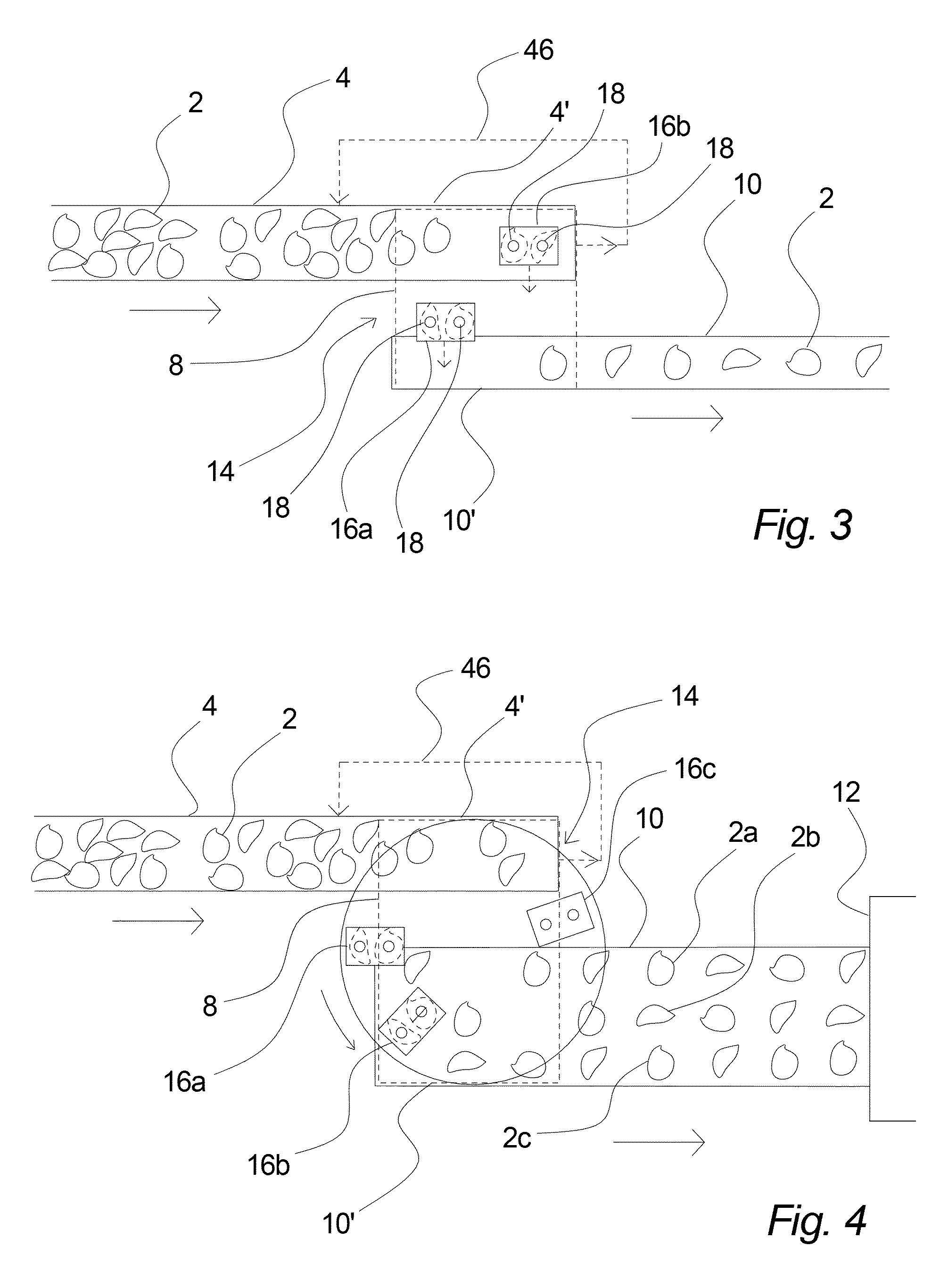

Method and system for transferring items (2) from an inlet flow or a bulk of items at a first area to a second area, from which the items are transferred in an orderly flow of items,whereby a plurality of gripping means (18) are used for transferring said items andwhereby said method comprises the steps ofmoving at least one of said plurality of gripping means (18) towards at least part of said first area or vice versa,engaging one of said items by said at least one of said plurality of gripping means (18),moving said engaged item away from said first area, or vice versa,placing said engaged item at a selected position, and wherebysaid item is moved away from said second area in an orderly flow with at least one further item handled by another of said plurality of gripping means.

Owner:SCANVAEGT INT AS

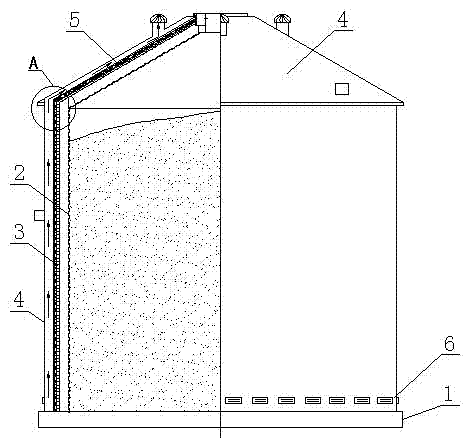

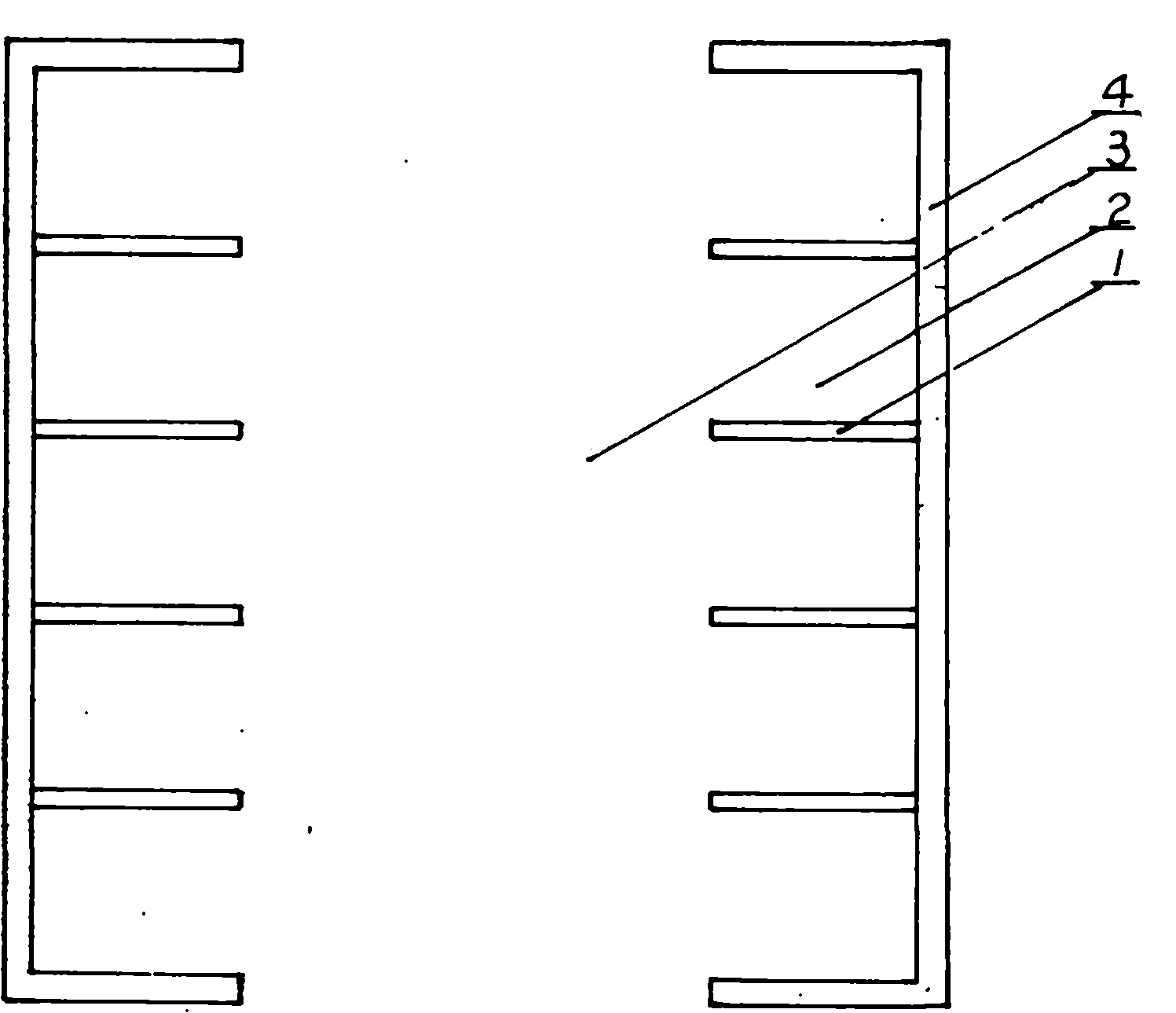

Constant-temperature insulation steel silo

ActiveCN104847151AAvoid conductionAvoid enteringAgriculture tools and machinesClimate change adaptationInsulation layerThermal break

Disclosed is a constant-temperature insulation steel silo. A common steel silo is already widely used as being low in cost and fast in construction and is unsuitable for long-term storage of grain and only suitable for revolving as not having an insulation function. The constant-temperature insulation steel silo is composed of a foundation (1) and a silo body (2) connected with the foundation, an insulation layer (3) is fixed to the outer side of the silo body through connectors, a peripheral plate (4) is fixed on the insulation layer or the silo body through supports, and the insulation layer and the peripheral plate form an air heat-insulation course. The constant-temperature insulation steel silo is used as a granary for long-term grain preservation.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

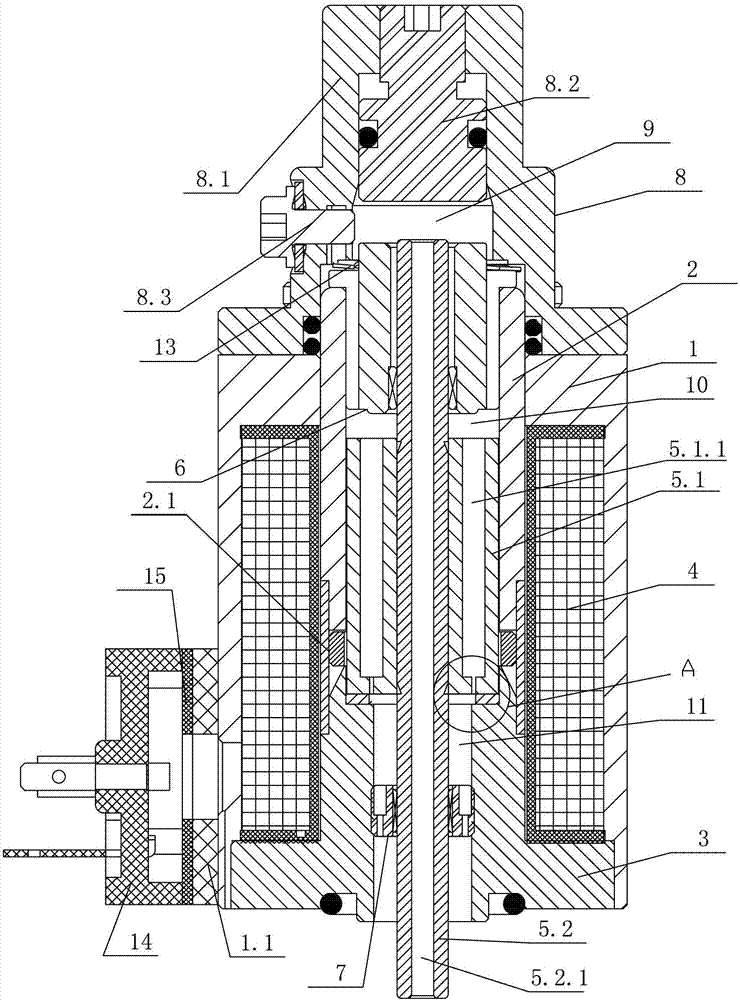

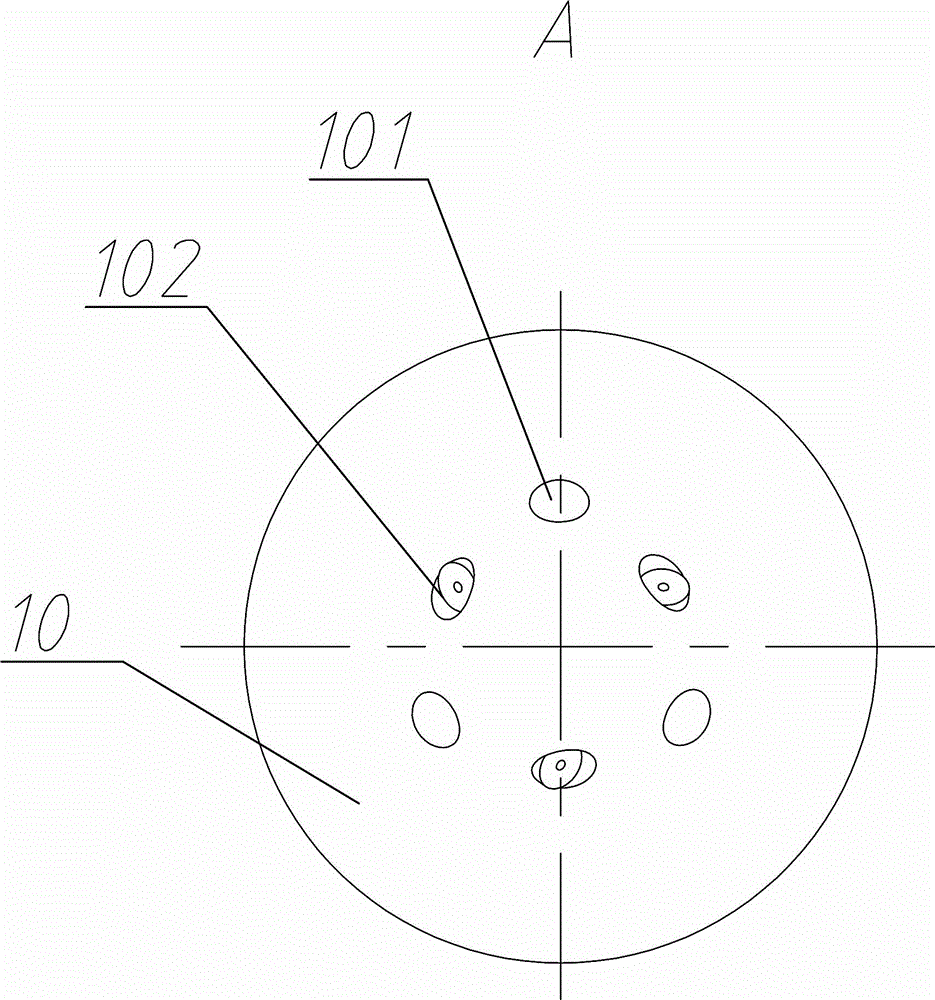

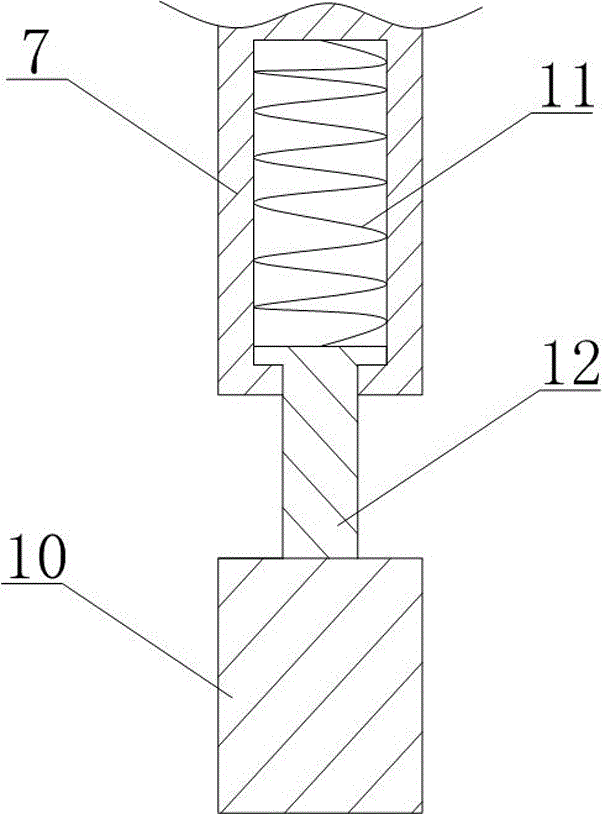

Proportional electromagnet for controlling position of valve core of hydraulic valve

ActiveCN102788186AEliminate hydraulic disturbancesOrderly control flow rateOperating means/releasing devices for valvesHydraulic equipmentEngineering

The invention discloses a proportional electromagnet for controlling a position of a valve core of a hydraulic valve. The proportional electromagnet comprises an electromagneticinduction component and an armature component, wherein the armature component is arranged in the electromagneticinduction component and is in sliding fit with the electromagneticinduction component; the proportional electromagnet is also provided with a hydraulic passage which is communicated with an upper end face and a lower end face of the armature component and forms a hydraulic loop with a valve core cavity of the hydraulic valve; a hydraulic loop is formed between the upper end face as well as the lower end face of the armature component and the valve core cavity of thehydraulic valve, so that the upper end face as well as the lower end face of the armature component and the valve core cavity of thehydraulic valve are hydraulically balanced, hydraulic disturbance is effectively eliminated, the output power of the proportional electromagnet is stably output, and the positional relation of the valve core and a valve seat of the hydraulic valve is effectively controlled; and thus, the flow velocity of oil in the hydraulic valve is controlled, the hydraulic pressure of the oil in an executing element of the hydraulic system is stably adjusted, and the hydraulic equipment stably works.

Owner:宁波市鄞州通力液压电器厂

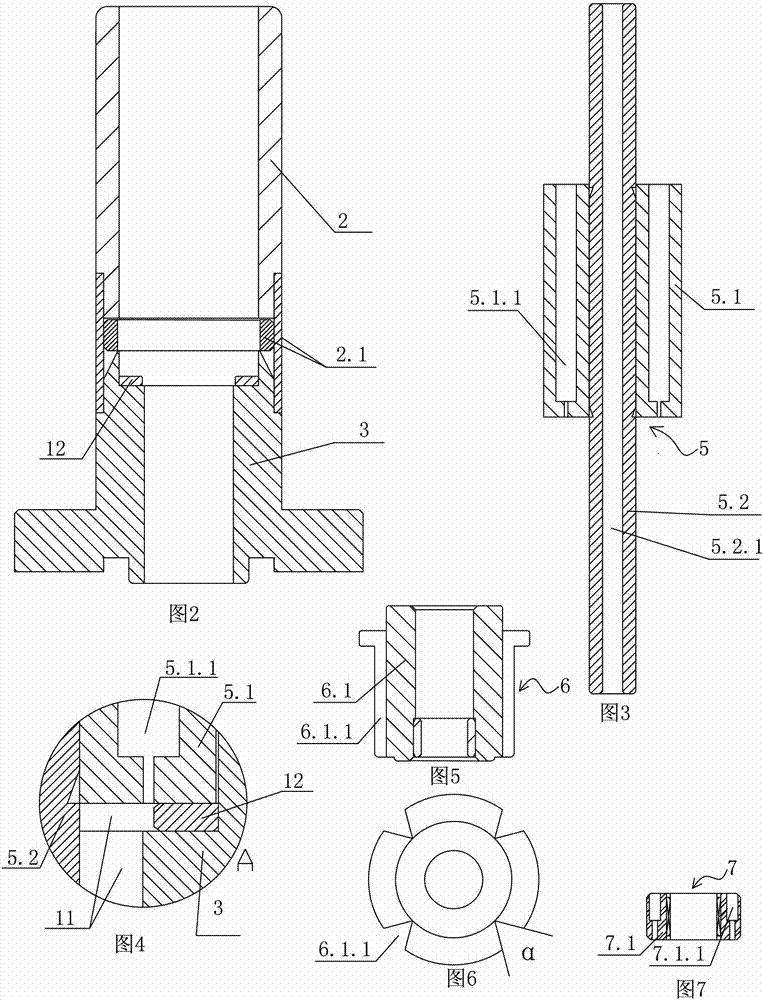

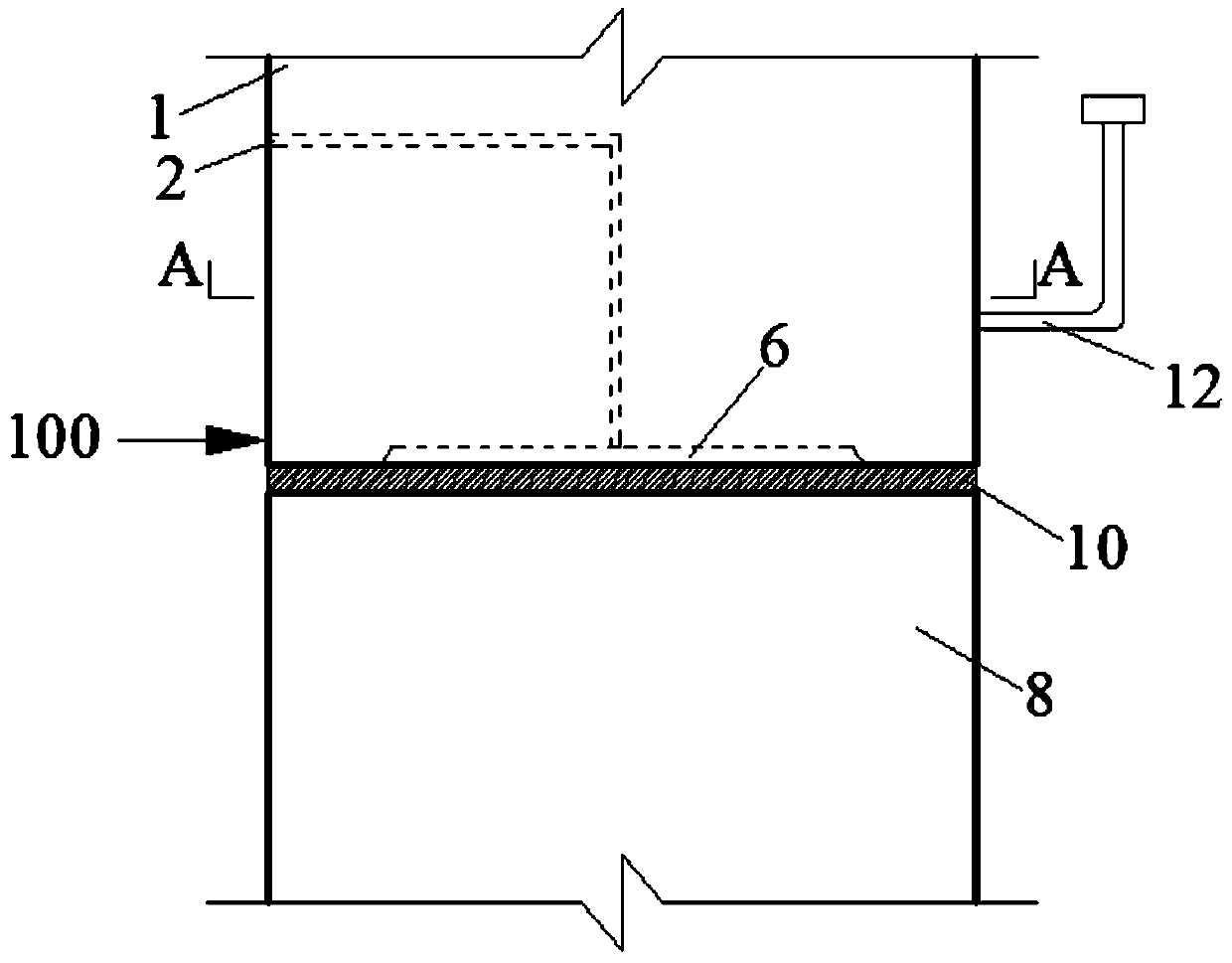

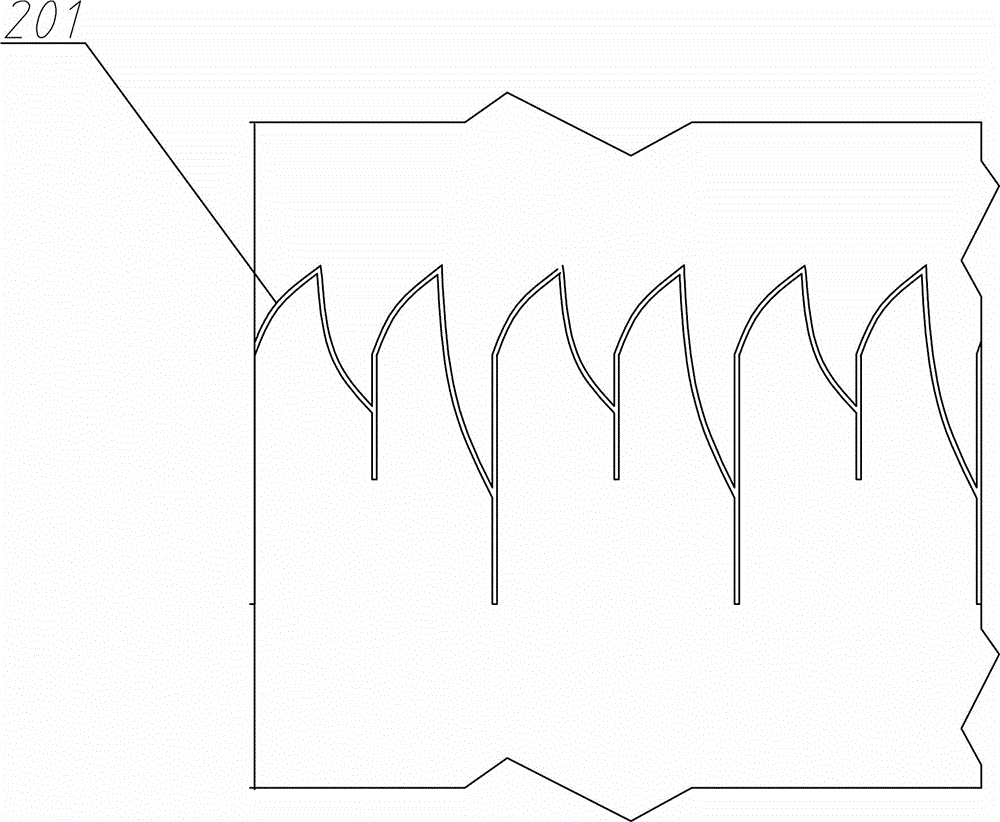

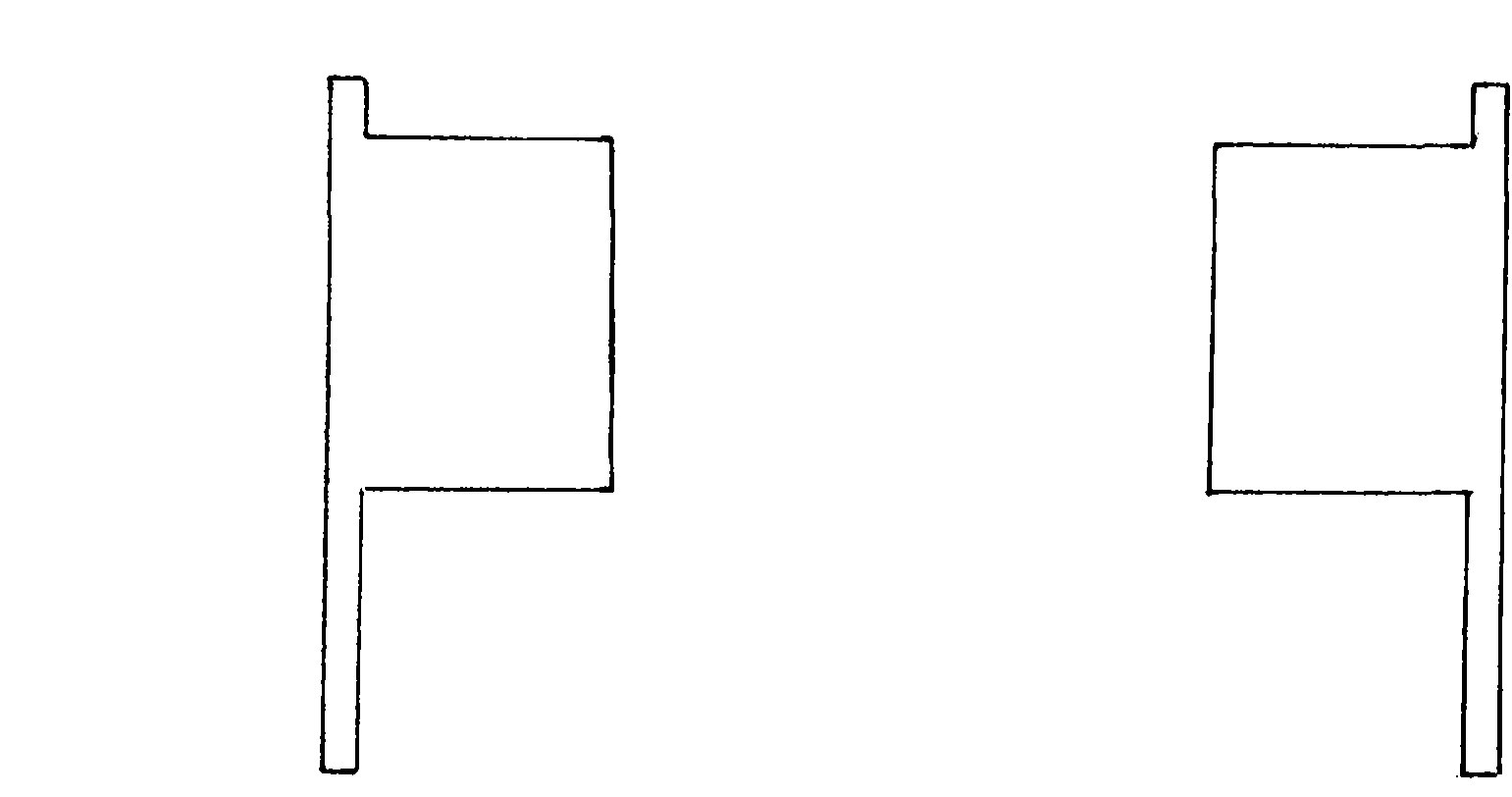

Assembly prefabricated component series-connection sleeve connecting structure and grouting method thereof

PendingCN109853862AEasy constructionSimplify internal structureBuilding reinforcementsSingle pointEngineering

The invention relates to an assembly prefabricated component series-connection sleeve connecting structure and a grouting method thereof, and belongs to the field of residential PC industrialization.The assembly prefabricated component series-connection sleeve connecting structure comprises one or more sets of series-connection sleeves and connecting pipes; a gap is formed between an assembly prefabricated upper component and an assembly prefabricated lower component; each set of series-connection sleeves is formed by a plurality of sleeves which are connected in series through the corresponding connecting pipe, and the two ends of the connecting pipes are connected with upper openings and lower openings of the adjacent sleeves correspondingly; and a shear key forming groove is formed inthe bottom end of the upper component, communicates with the gap between the upper component and the lower component and is poured with a primary grouting material, and the series-connection sleeves are poured with secondary grouting materials. The grouting method of the assembly prefabricated component series-connection sleeve connecting structure comprises the steps: primary pouring, still standing and secondary pouring. The assembly prefabricated component series-connection sleeve connecting structure is improved based on a single-point grouting method, and has the characteristics of beingeasy to construct, excellent in performance and free of grouting defects.

Owner:河北冀科工程项目管理有限公司

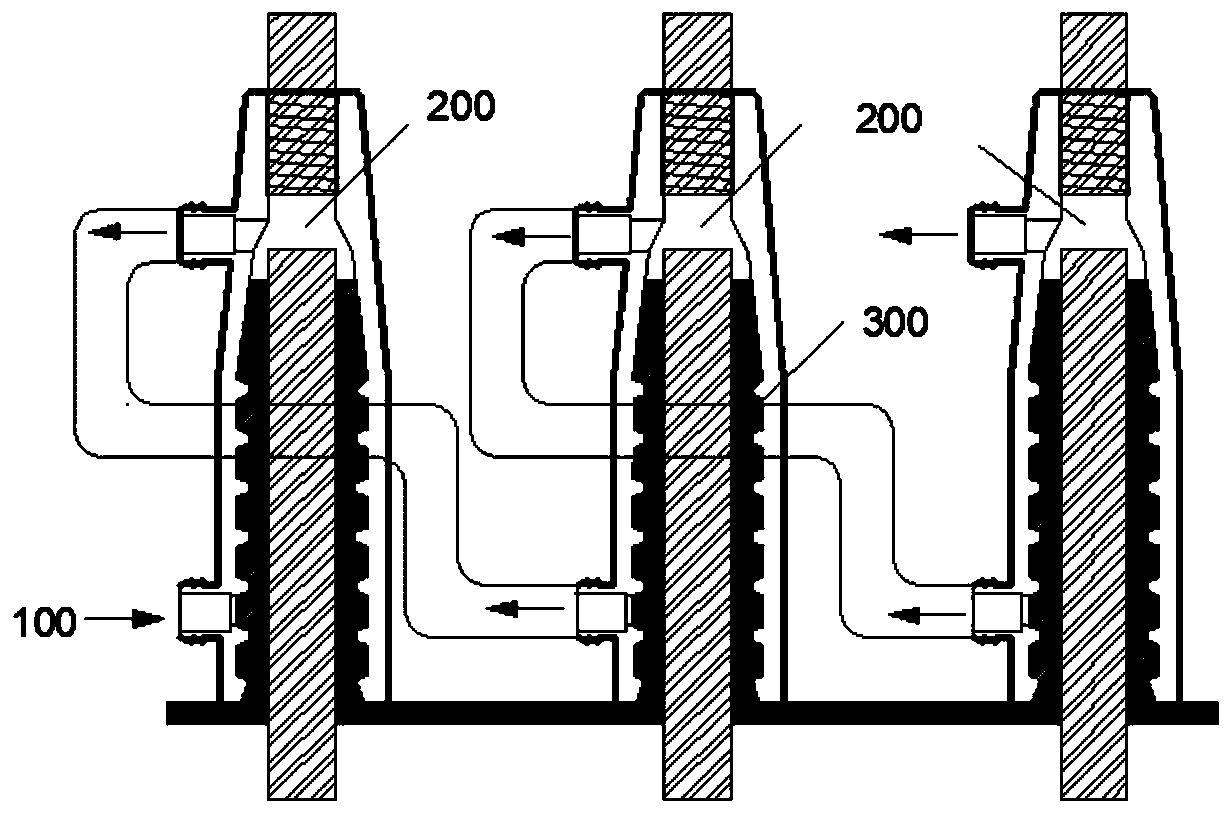

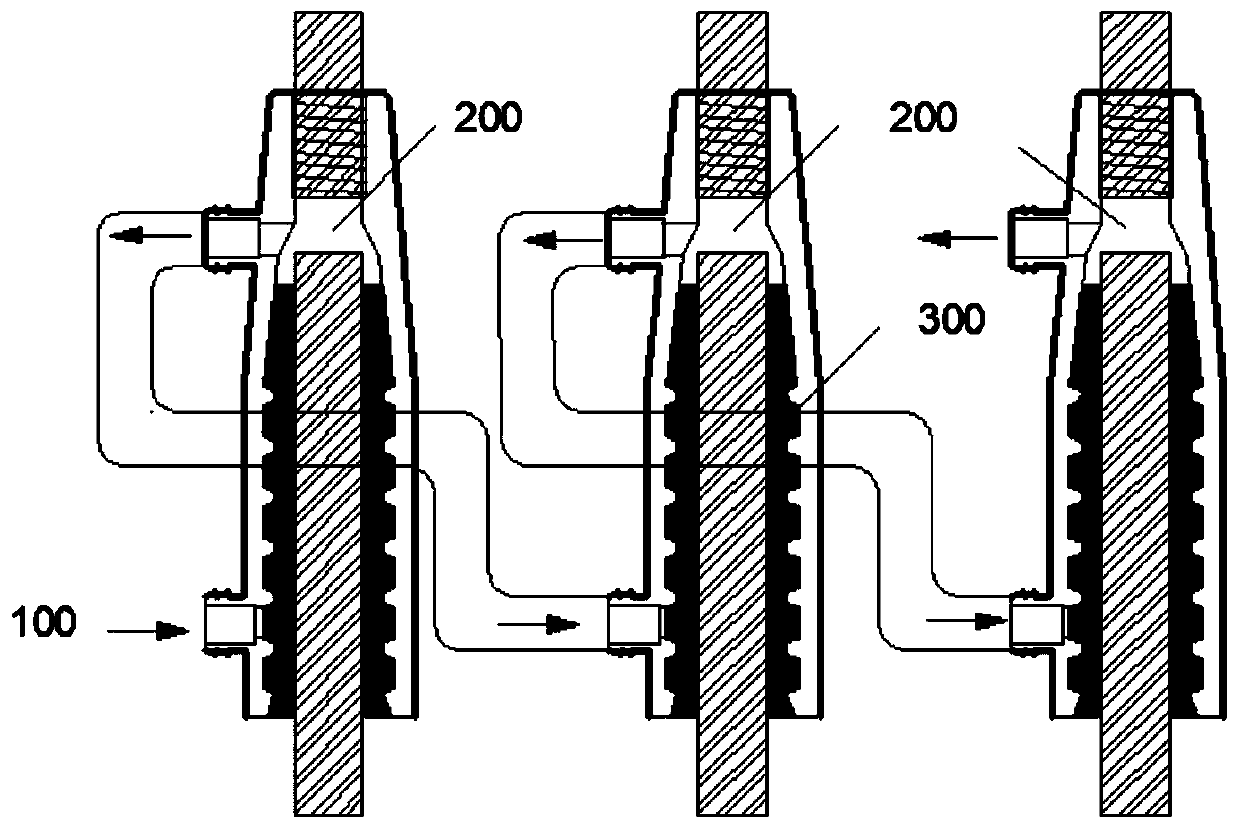

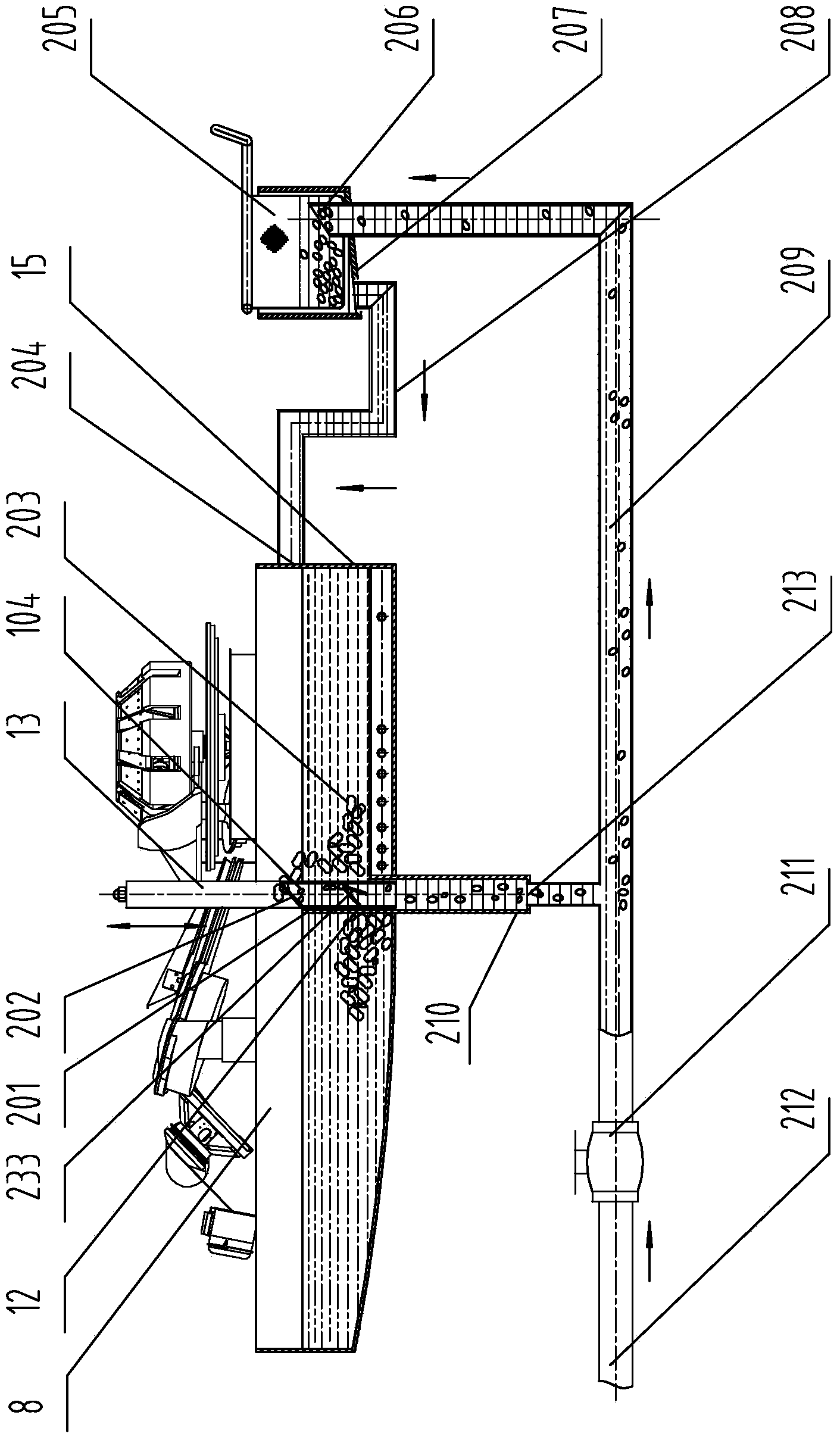

Comprehensive treatment method and comprehensive treatment device for cocoons without ends and basinetto silks on end neatening and groping head of automatic silk reeling machine

ActiveCN103614782ARaise and secure the logicImprove and guarantee cocooning working conditionsSilk reelingWater flowWater circulation

The invention provides a comprehensive treatment method for cocoons without ends and basinetto silks on an end neatening and groping head of an automatic silk reeling machine. By the comprehensive treatment method, the working conditions of the end neatening and groping head can be comprehensively treated systematically by taking environment-friendly and energy-saving measures. According to the comprehensive treatment method for the cocoons without the ends and the basinetto silks on the end neatening and groping head of the automatic silk reeling machine, fluid of an end neatening pot at a hopper for feeding cocoons with correct ends returns and rushes out from a slope of the bottom of the end neatening pot in front of an opening for feeding the cocoons with the correct ends in the end neatening pot to form water flow through a first water pressing valve by using the descending action of the hopper for feeding the cocoons with the correct ends on the end neatening pot, the cocoons without ends on the slope on the bottom of the end neatening pot are washed away from the opening for feeding the cocoons with correct ends and are fed in running water flow of a hopper for lifting the cocoons without the ends, and the hopper for lifting the cocoons without the ends is a conveying mechanism for feeding the cocoons without the ends to an end groping pot from the end neatening pot. By using water circulation, the structure is simple, the comprehensive treatment method is multipurpose, cocoons can be discharged, and water in the end groping pot can be heated, and negative effects on cocoons in the end groping pot due to the fact that the fluid in the end groping pot is directly heated by steam are avoided.

Owner:ZHEJIANG SCI-TECH UNIV

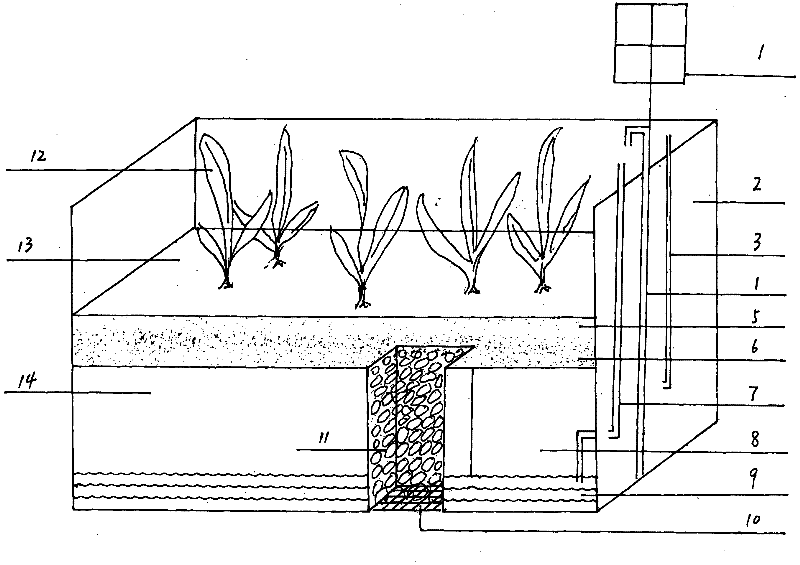

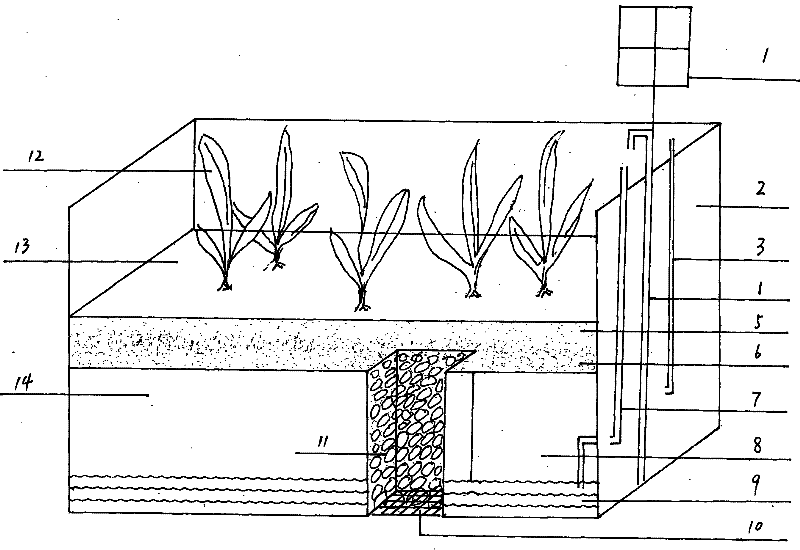

a paddy field

InactiveCN102257928AActive self-purificationOrderly flowCultivating equipmentsReceptacle cultivationSludgeDigestion

The invention provides a floating bed with a frame structure that can be suspended in water for a long time, and a paddy field equipped with a water lifting device powered by natural energy. The water lifting device lifts water from the outside of the paddy field and sends it into the paddy field. Under the action, the water in the paddy field will seep and flow from the soil and sand in the paddy field from top to bottom and return to the external water area, using the soil, sand and its cultivated organisms to intercept the sludge and bacteria in the water body, Digest the pollutants in the water body and sludge to achieve the purpose of purifying the water body; adjust the ratio of the water level to the air in the lower buoyancy chamber, so that the conversion between the water pool and the dry land can be shown in the upper material chamber, realizing the use of water space, The purpose of creating cultivated land, green land and wetland provides an infrastructure for the sustainable development of human society in harmony with the natural environment.

Owner:陈国柱

Method and a system for transferring of items

Method and system for transferring items (2) from an inlet flow or a bulk of items at a first area to a second area, from which the items are transferred in an orderly flow of items,whereby a plurality of gripping means (18) are used for transferring said items andwhereby said method comprises the steps ofmoving at least one of said plurality of gripping means (18) towards at least part of said first area or vice versa,engaging one of said items by said at least one of said plurality of gripping means (18),moving said engaged item away from said first area, or vice versa,placing said engaged item at a selected position, and wherebysaid item is moved away from said second area in an orderly flow with at least one further item handled by another of said plurality of gripping means.

Owner:SCANVAEGT INT AS

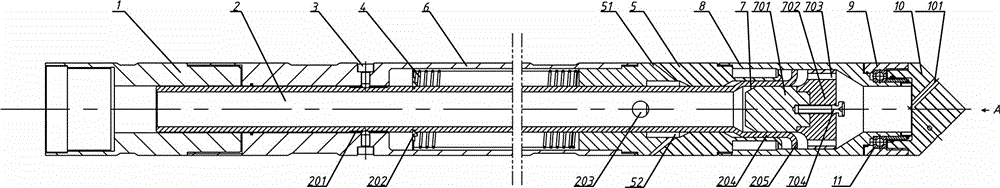

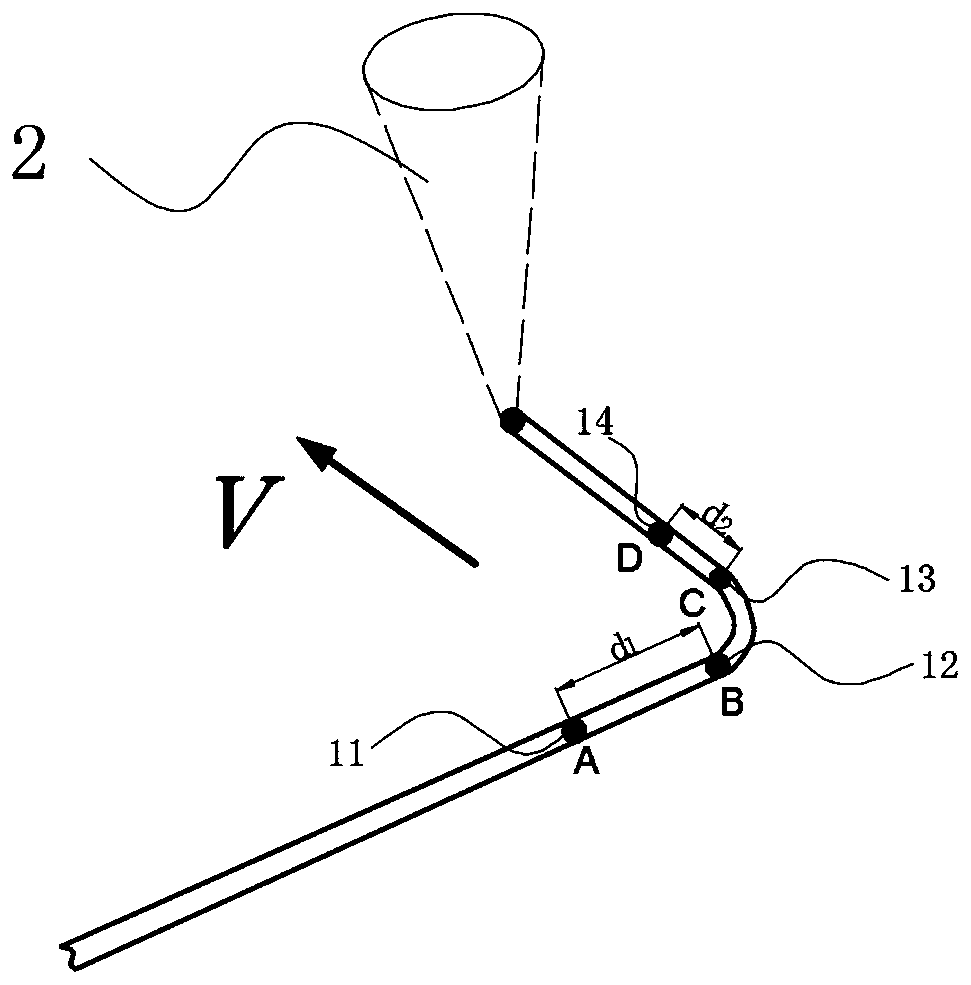

Swirling sand removing device and method

The invention provides a swirling sand removing device and a swirling sand removing method. A hollow center pipe is arranged in a connecting pipe in a sliding manner, the front end of the connecting pipe is connected with a rotary front nozzle component, and a rear nozzle component is arranged at the side wall of the connecting pipe; a side through hole is formed in the side wall of the center pipe, and the side through hole is communicated with a rear nozzle of the rear nozzle component when the center pipe is located at an axial position; a piston component is arranged in the connecting pipe, a piston through hole is formed in the piston component, and the piston through hole is communicated with a front nozzle of the front nozzle component; when the central pipe moves axially, the piston is closed or started by the central pipe; a spring which enables the center pipe to be far away from the front nozzle component is further arranged between the central pipe and the connecting pipe. By adopting the structure and the method provided by the invention, the axial movement of the central pipe can be controlled by feeding fluid supply pressure of the connecting pipe, and the forwards rotary liquid injection of the front nozzle component and the backwards liquid injection of the rear nozzle component can be realized, therefore the sand can flow orderly in a shaft bottom, the turbulence is low in the sand removing process, and the sand cleaning effect of the shaft bottom can be improved.

Owner:YANGTZE UNIVERSITY

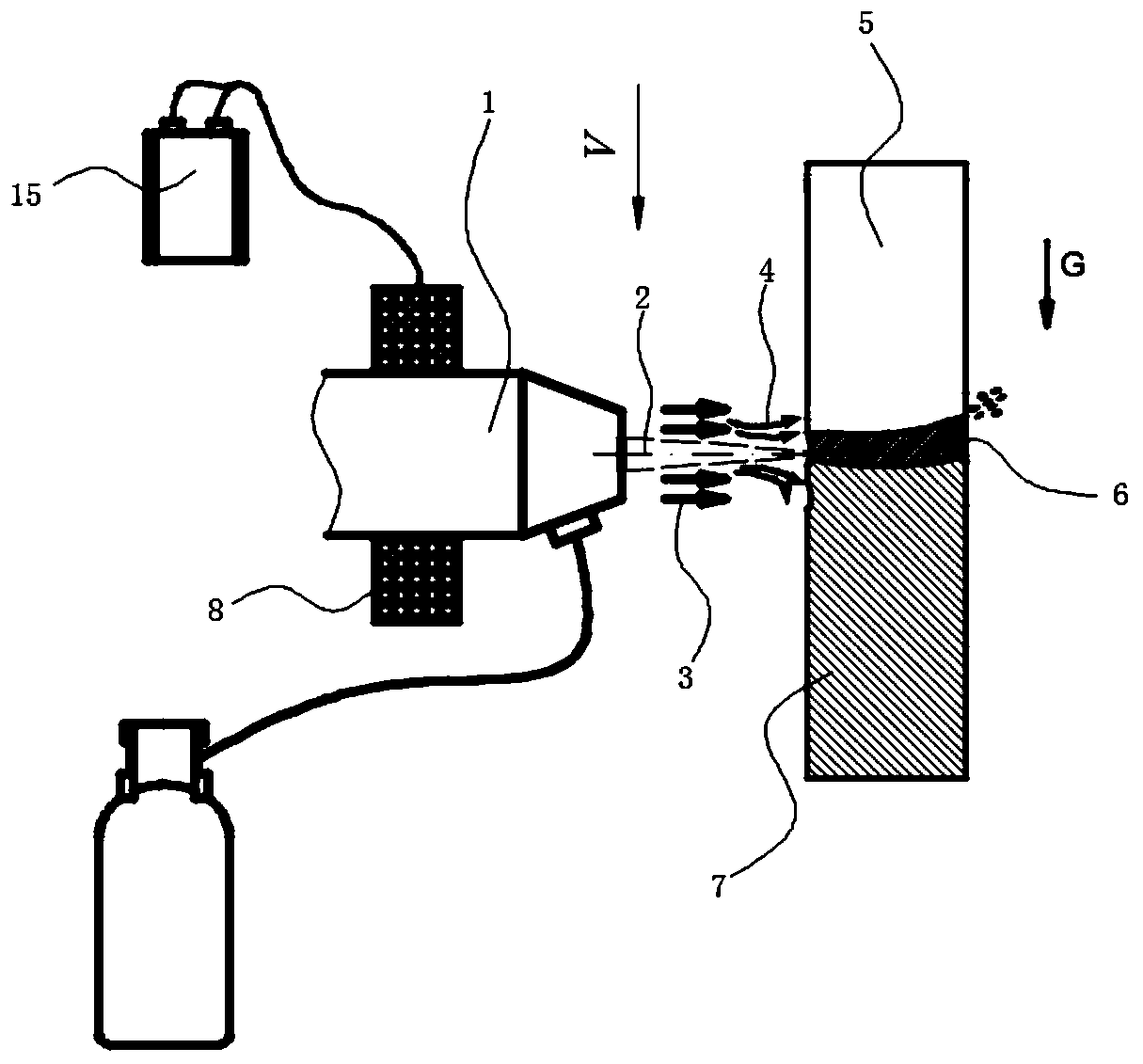

Deposition reaction device for manufacturing low-loss optical fiber preform rod and pressure adjusting method

InactiveCN105776843AUniform depositionLow content of metal impuritiesGlass making apparatusEngineeringMetal impurities

The invention discloses a deposition reaction device for manufacturing a low-loss optical fiber preform rod and a pressure adjusting method, and relates to the technical field of manufacturing of optical fiber preform rods. The device comprises a pressure gauge, a controller and a reaction vessel with an open top, wherein the pressure gauge and the reaction vessel are connected, and high-purity inert gas with purity higher than 99 percent circulates in the reaction vessel; a first blast burner for making a cladding layer and a second blast burner for making a core layer are arranged on one side of the reaction vessel, and the second blast burner is located between the first blast burner and a plane of the bottom of the reaction vessel; the bottom of the reaction vessel is connected with a matching pipe, the matching pipe is communicated with the inside of the reaction vessel, a flow adjuster is arranged on the matching pipe and the flow adjuster is connected with the pressure gauge through the controller. According to the deposition reaction device for manufacturing the low-loss optical fiber preform rod and the pressure adjusting method, metal impurities can be effectively prevented from entering glass micro-particle sedimentary bodies, the content of metal impurities in the manufactured optical fiber preform rod is low and the impurity absorption loss is smaller.

Owner:TENGCANG FENGHUO PHOTOELECTRIC MATERIAL TECH CO LTD

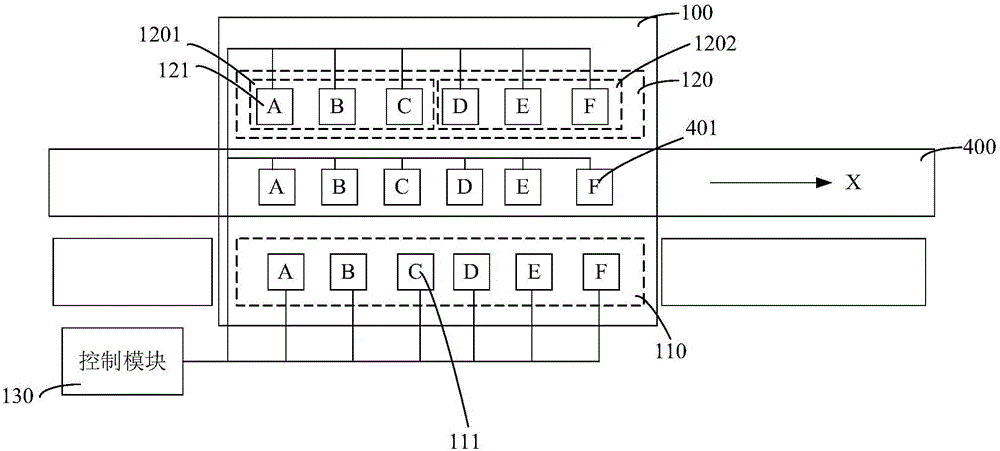

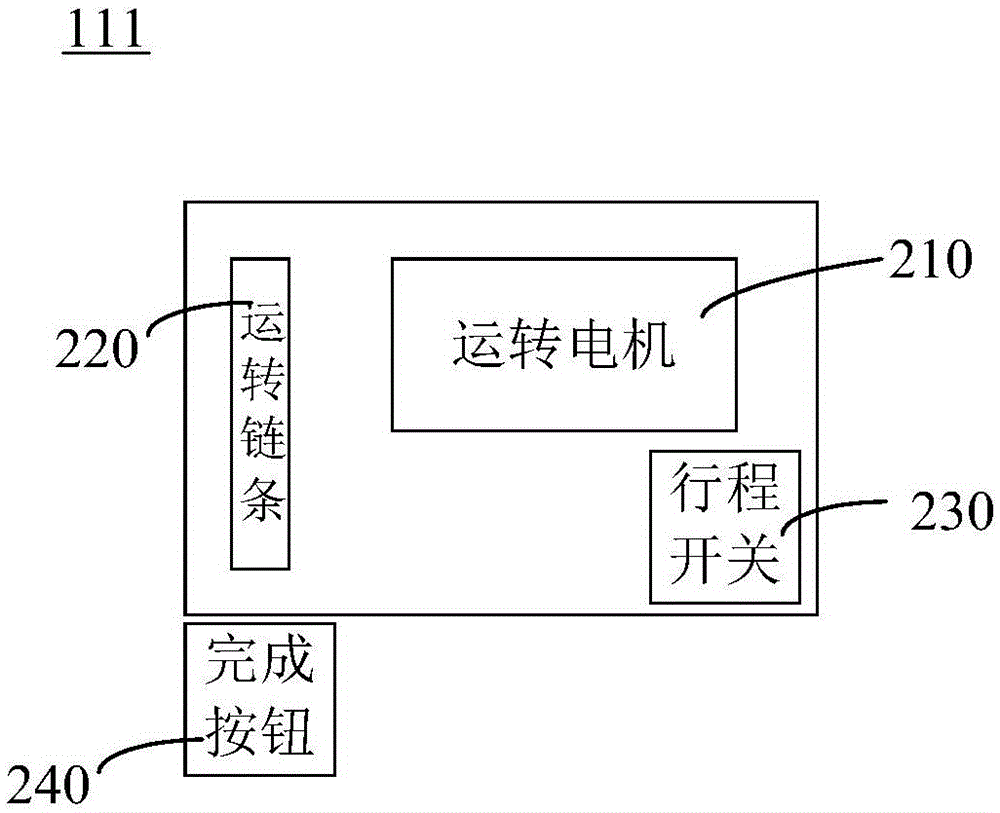

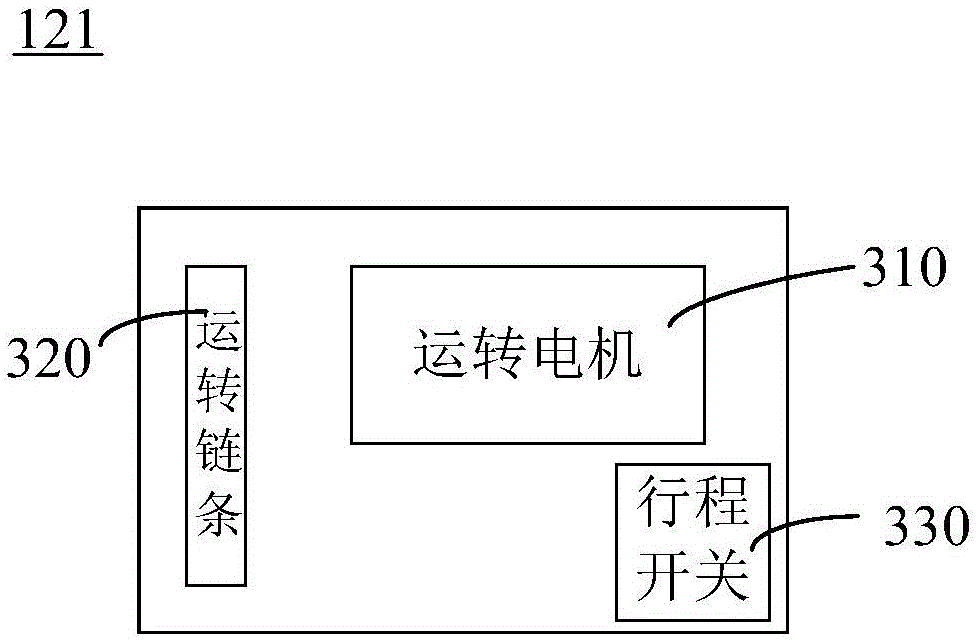

Assembly line station storage structure and control method thereof

ActiveCN105035679AAvoid accumulationShorten the lengthControl devices for conveyorsMechanical conveyorsComputer moduleAssembly line

The invention relates to an assembly line station storage structure and a control method which are used in cooperation with a main assembly line. The assembly line station storage structure comprises a work region and a control module. The main assembly line comprises bearing and moving devices used for moving products on the main assembly line out of the main assembly line. The work region comprises work tables, the storage structure further comprises a storage region, and the storage region comprises storage tables. The storage region and the work region are arranged on the two sides of the main assembly line respectively so that the bearing and moving devices can horizontally move the products to the storage tables or the work tables. The control module is connected with the bearing and moving devices, the work tables and the storage tables. The assembly line station storage control method includes the steps that the state of the work region is judged; whether the products to be input are conveyed to the work tables or the storage tables is judged according to the state of the work region. Through the adoption of the assembly line station storage control method and structure, the length of the assembly line can be shortened and space can be saved.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

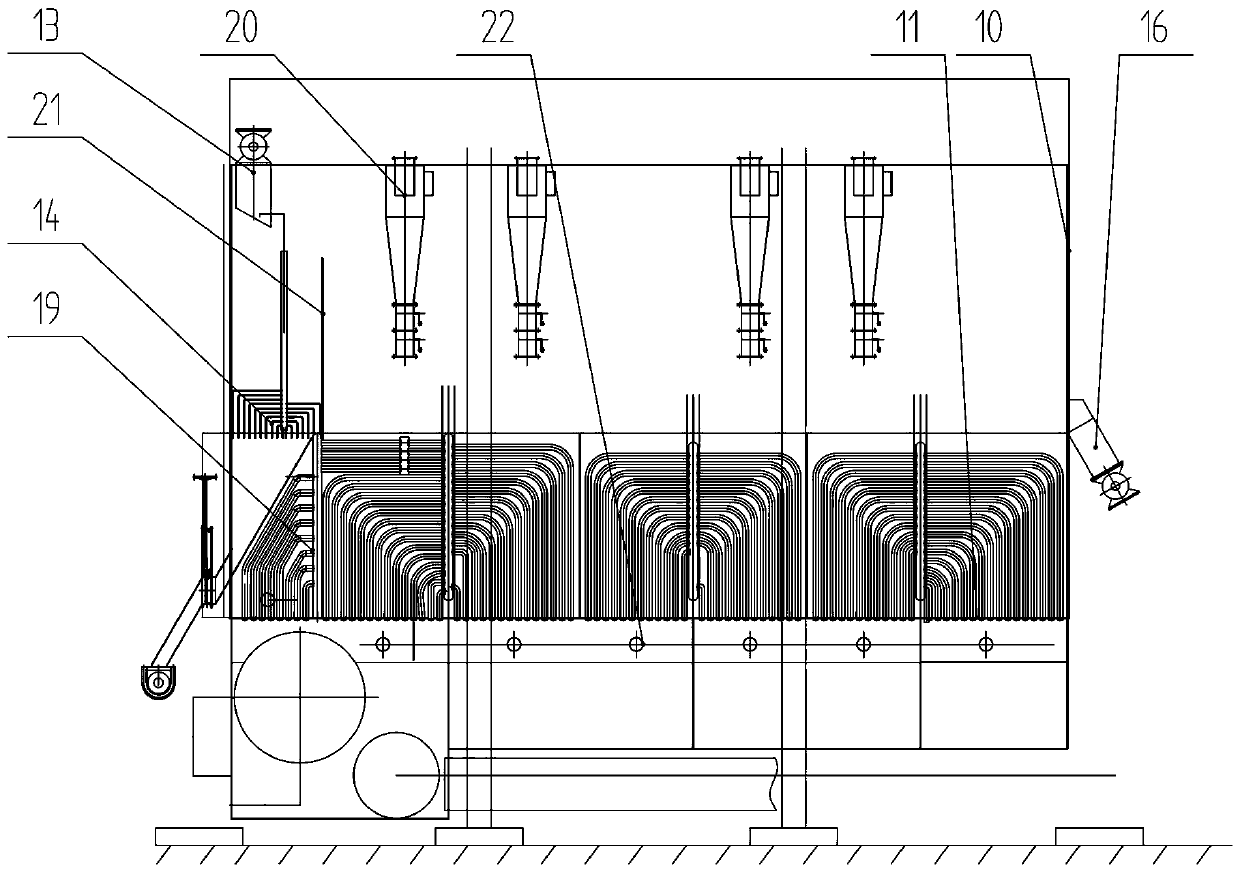

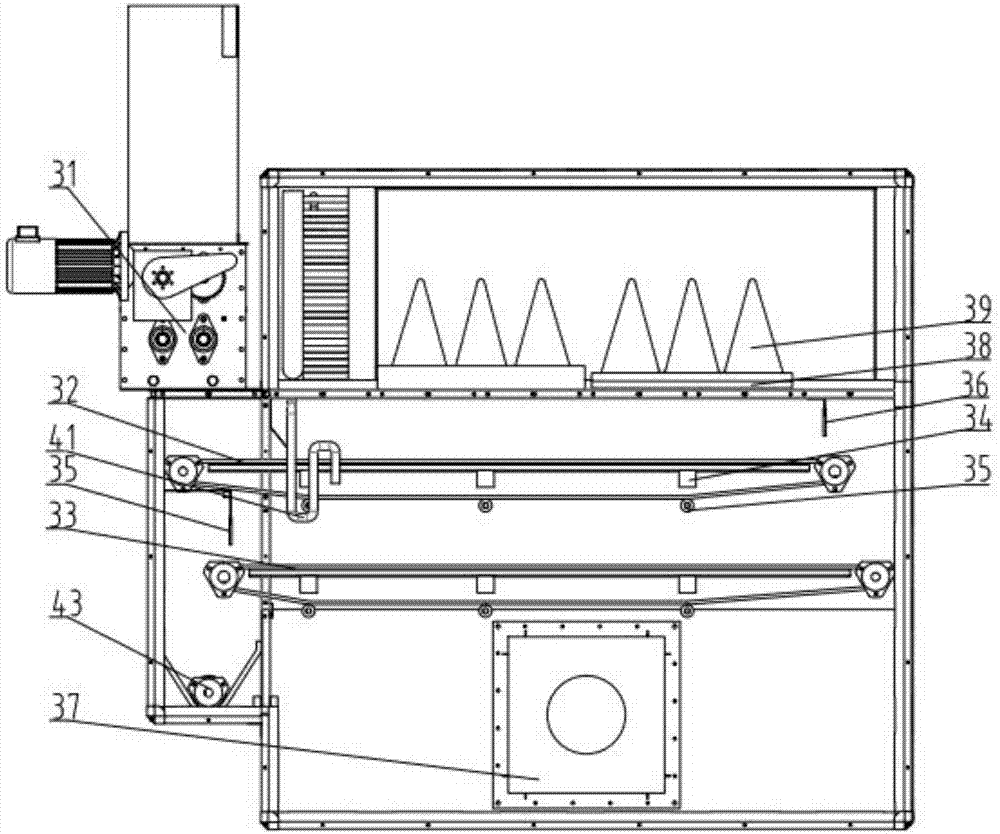

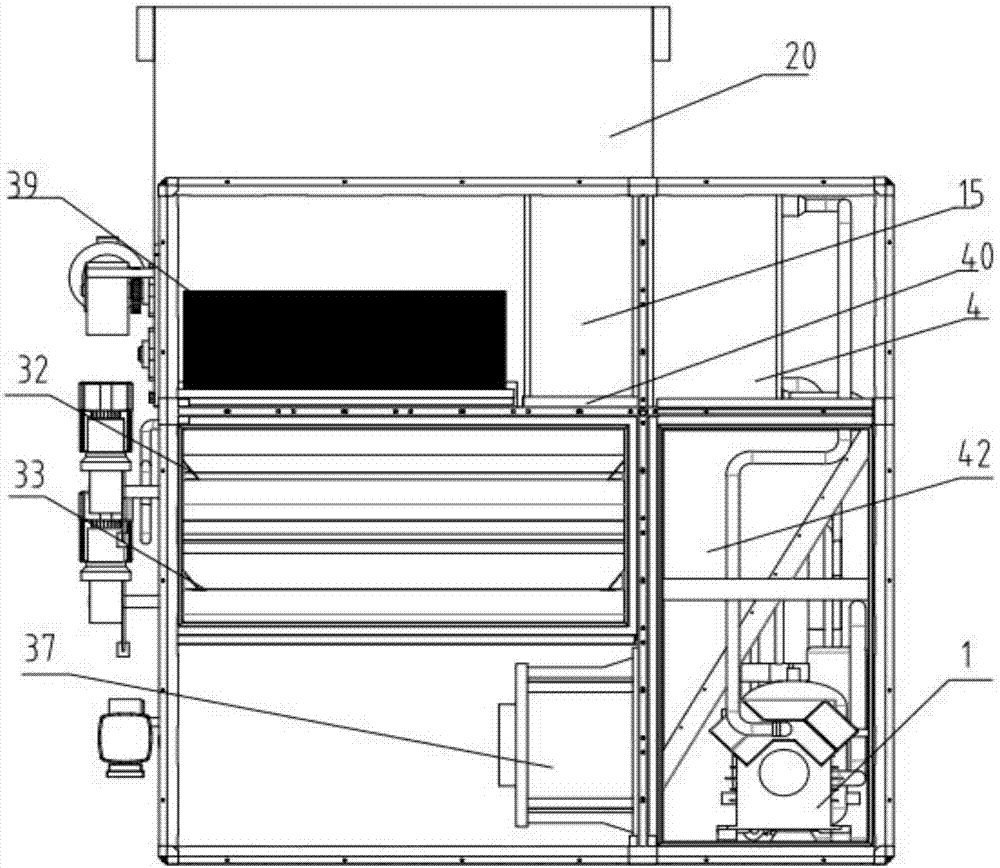

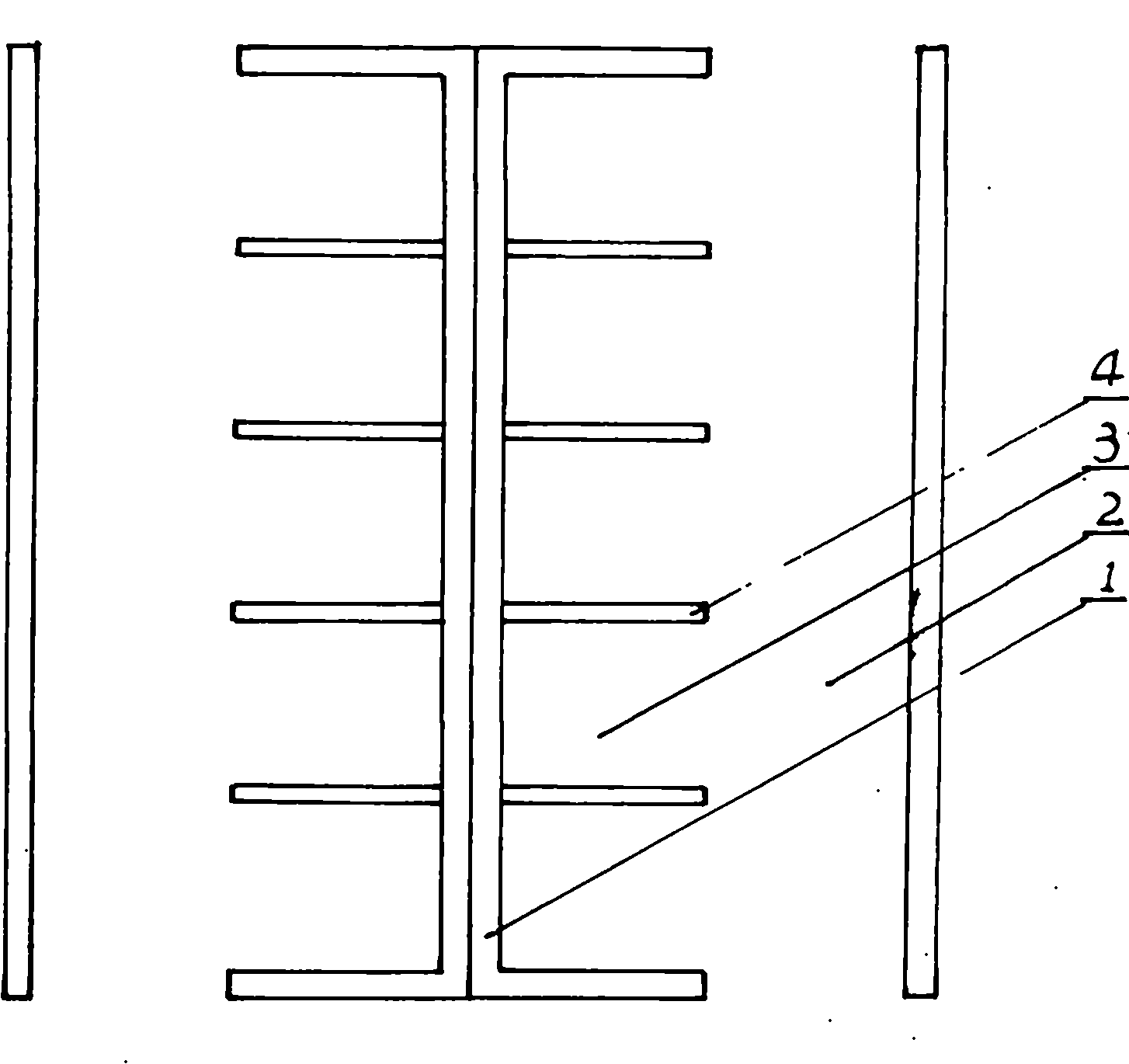

A low-temperature sludge drying device

ActiveCN106630539BReduce energy consumptionAdjust drying timeSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention discloses a low-temperature drying device for sludge. The low-temperature drying device comprises a sludge running system and a heated dry air running system, wherein the sludge running system consists of a totally enclosed sludge drying chamber; the sludge drying chamber comprises a sludge inlet, multiple layers of conveying mesh belts which are jointed end to end and a sludge outlet, which are arranged from top to bottom; the heated dry air running system consists of a heat pump system, a heated dry air generating chamber and a fan, and forms a circulating drying air current which is from bottom to top in the sludge drying chamber. According to the low-temperature drying device, the sludge drying chamber, the heated dry air generating chamber, the fan and a discharge screw conveyer are all in one totally enclosed box body; the escape of a smell is avoided; the secondary pollution is not caused to the environment; the effective disintegration and molding are carried out on the sludge, which is not dried, through a molding spreader; strip sludge which does not mutually adhere and is good in air permeability is formed; the drying effect on the sludge is greatly promoted; the safe reliability of an appliance is ensured through a drying condition of a lower temperature; the low-temperature drying device has the advantages of being low in energy consumption, good in effect, safe, reliable, free from the secondary pollution, wide in scope of application and long in service life.

Owner:四川天润德环境工程有限公司

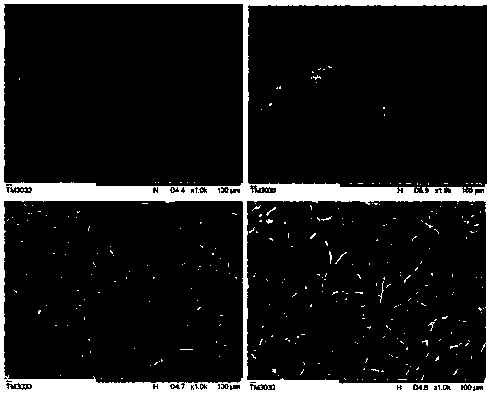

Polyurethane/liquid crystal compound biological material, and preparation method and application thereof

ActiveCN107674409ALiquidExcellent Mechanical ConductivityAdditive manufacturing apparatusElectro-spinningCrystallographyBiological property

The invention discloses a polyurethane / liquid crystal compound material, and a preparation method and application thereof. The preparation method of the polyurethane / liquid crystal compound biologicalmaterial comprises the following steps: (1) preparing side-chain high-molecular liquid crystals; and (2) preparing the polyurethane / liquid crystal compound material through a solvent volatilization method or a 3D printing method or an electrostatic spinning method. For the polyurethane / liquid crystal compound material, the tensile modulus of elasticity is 0.025-0.53 MPa, the compressive modulus of elasticity is 1.67-4.10 MPa, and the maximum elongation percentage of the film material is up to 700-900%. The compound material disclosed by the invention has favorable elastic properties, favorable liquid crystal properties, favorable biological properties and an adjustable degradation rate, and can be favorably used for mechanical conduction and used for research on a mechanical microenvironment.

Owner:JINAN UNIVERSITY

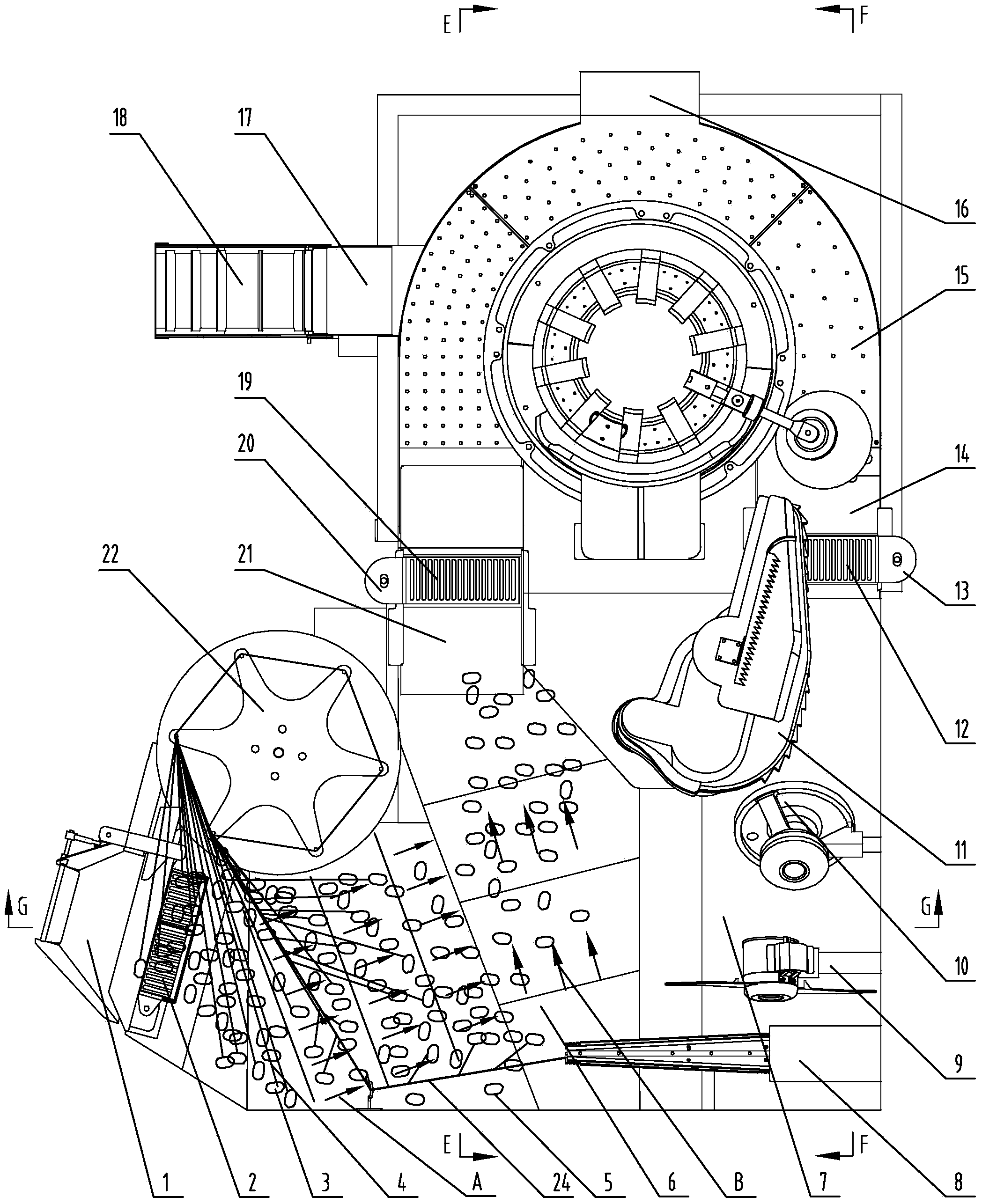

A color sorter for rice processing

ActiveCN110614235BReduce the probability of cloggingReduce error rateSortingAgricultural engineeringElectric machinery

Owner:宁夏昊帅粮油有限责任公司

Guardrail

ActiveCN102061669AOrderly queueOrderly flowTraffic restrictionsRoadway safety arrangementsPublic placeCrowding

The invention discloses a guardrail which is suitable for a public place for assisting queuing people to wait and pass, such as a passage guardrail arranged by corresponding to a bus door at a public transit stop. In the invention, a plurality of transverse guardrails are longitudinally arrayed to form a plurality of buffer areas and correspond to each person at the passage queue, and when the queue changes, for example, when people continuing to waiting need to avoid migrant people, the people continuing to waiting can stand in the buffer areas, thereby mutual crowding is avoided; and in a long waiting queue, a part is divided to be a special area for vulnerable people needing help so that the vulnerable people are safer and more comfortable, thereby the purposes of ordered waiting queue of people, ordered flowing and avoiding and smoothness without blockage are achieved.

Owner:田生

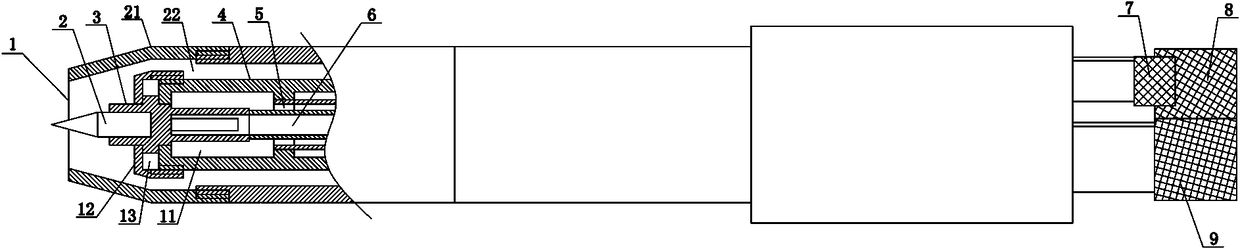

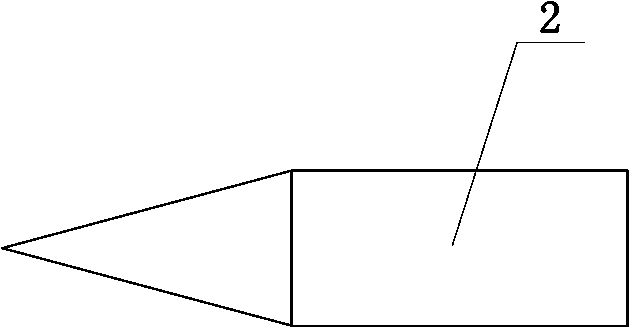

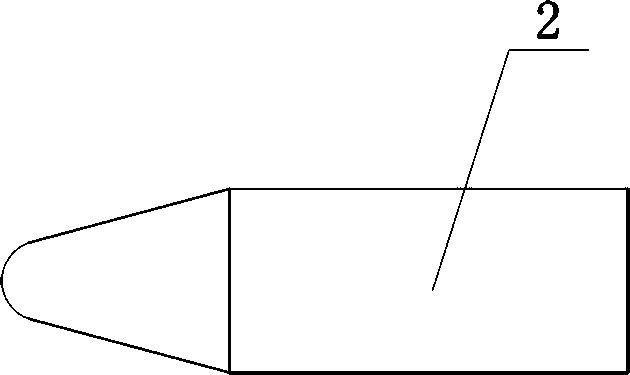

Tungsten inert gas shielded welding torch capable of compressing electric arc

PendingCN109434256AEasy to replace electrodesGood reproducibilityCooled electrode holdersElectric arcGasket

The invention discloses a tungsten inert gas shielded welding torch capable of compressing electric arc, and a water cooling heat dissipation device composed of an electrode handle, an electrode seat,a water inlet pipe, a water outlet pipe, an electrode cap and a sealing gasket. The head part of the electrode handle is a tungsten electrode seat for installing tungsten electrodes, a positioning table is arranged on the middle part of the electrode handle, the tail part of the electrode handle is a heat dissipation cylinder, the tungsten electrodes are in interference fit with the tungsten electrode seat, and the tungsten electrodes and the electrode handle are integrated through hard connection, namely a combined electrode. The electrode handle enables the combined electrode and the electrode seat to be accurately connected through the positioning table and the electrode seat. An air passage is formed between a welding torch shell and the electrode seat, a cooling water cavity is formed between the heat dissipation cylinder and the electrode seat, the water inlet pipe and the water outlet pipe are both connected with the cooling water cavity, the water inlet pipe is arranged in thewater outlet pipe, a plurality of guide holes are formed in the peripheral wall of the heat dissipation cylinder, and an opening of the heat dissipation cylinder is opposite to a nozzle of the waterinlet pipe. The tungsten inert gas shielded welding torch capable of compressing the electric arc has good cooling effect, large welding penetration depth, convenient electrode replacement and no influence on the welding effect after each electrode replacement.

Owner:成都国泰景程科技有限公司

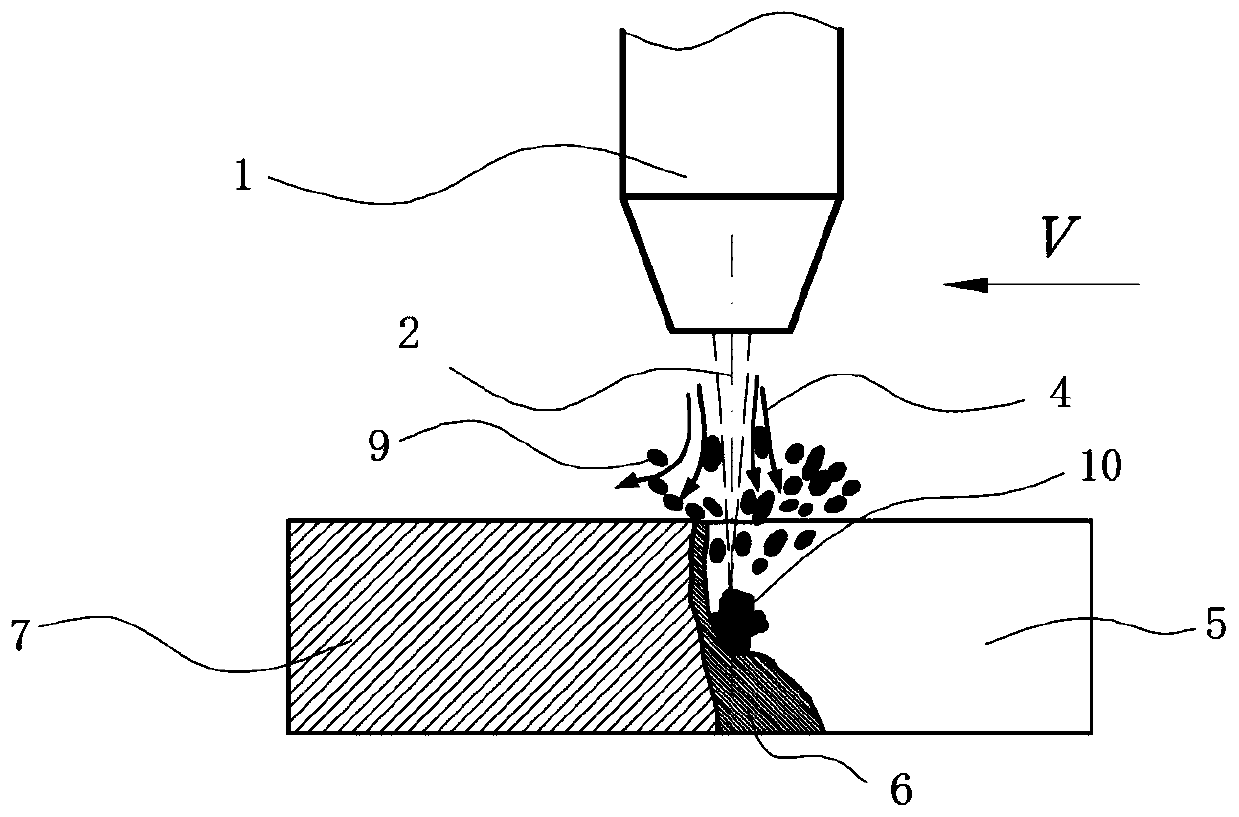

Thick plate laser cutting method

ActiveCN110293325AAvoid "reverse spray" phenomenonImprove cutting effectLaser beam welding apparatusThick plateEngineering

The invention relates to a thick plate laser cutting method. The thick plate laser cutting method is characterized by comprising the following steps of 1, fixing an electromagnetic coil onto a laser cutting head, wherein the electromagnetic coil can move along with the laser cutting head; 2, vertically placing and fixing a workpiece to be cut; 3, defining a corner cutting leading-in section and aleading-out section in a laser cutting track; 4, activating a laser cutting system, cutting auxiliary gas and an electromagnetic field power source, perpendicularly irradiating the surface of the workpiece to be cut by laser beams to realize laser cutting of a thick plate; 5, adjusting the electromagnetic field power source when the laser beams move to a starting point of the corner cutting leading-in section to start corner region cutting; 6, adjusting the electromagnetic field power source when the laser beams move to an end point of the corner cutting leading-out section to finish corner region cutting; and 7, turning off a laser generator, the electromagnetic field power source and the cutting auxiliary gas to complete the cutting process when a cutting tail end point is reached. Compared with the prior art, the thick plate laser cutting method is good in cutting effect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

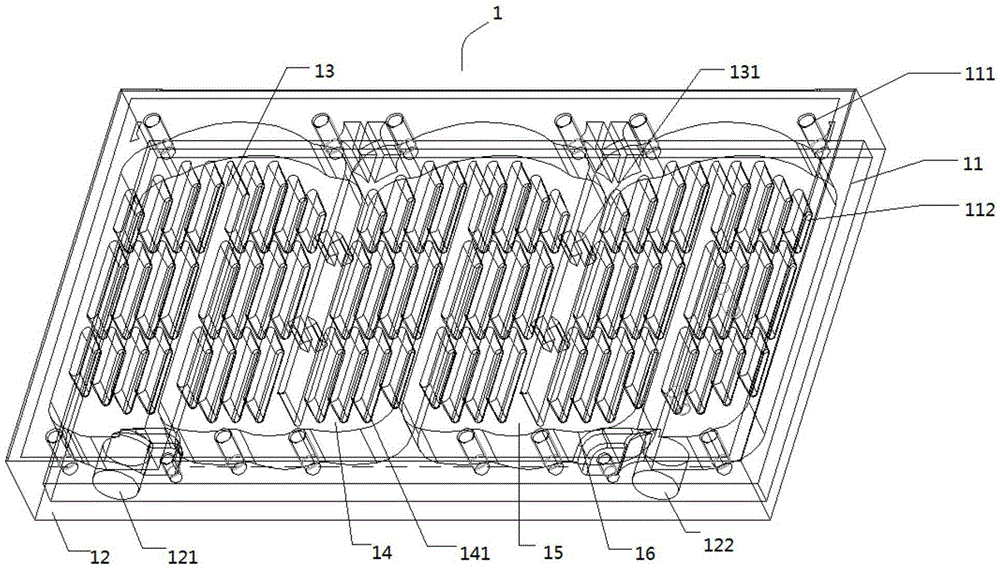

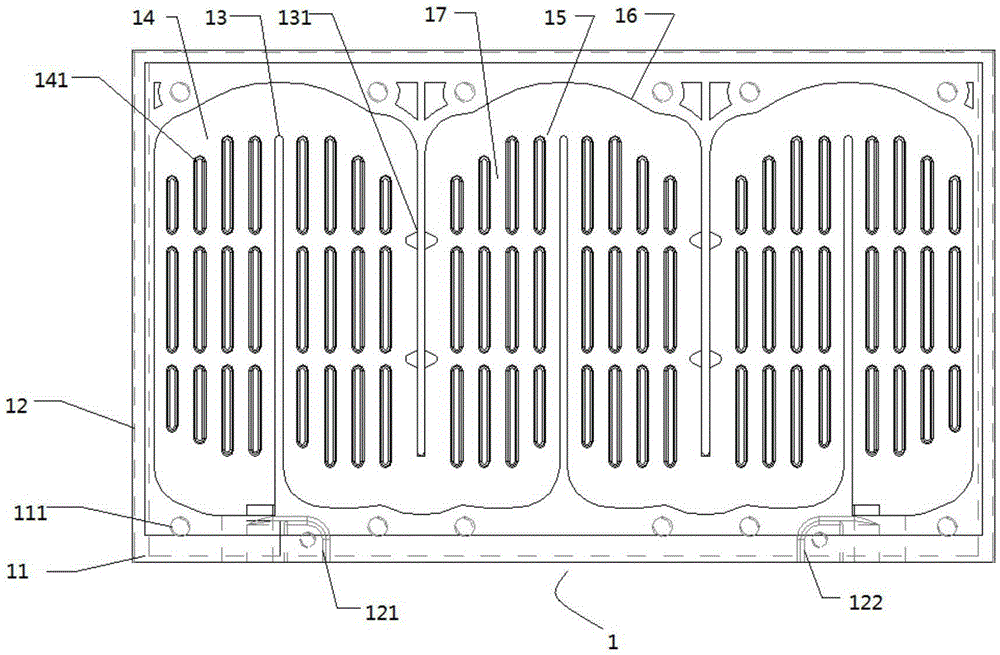

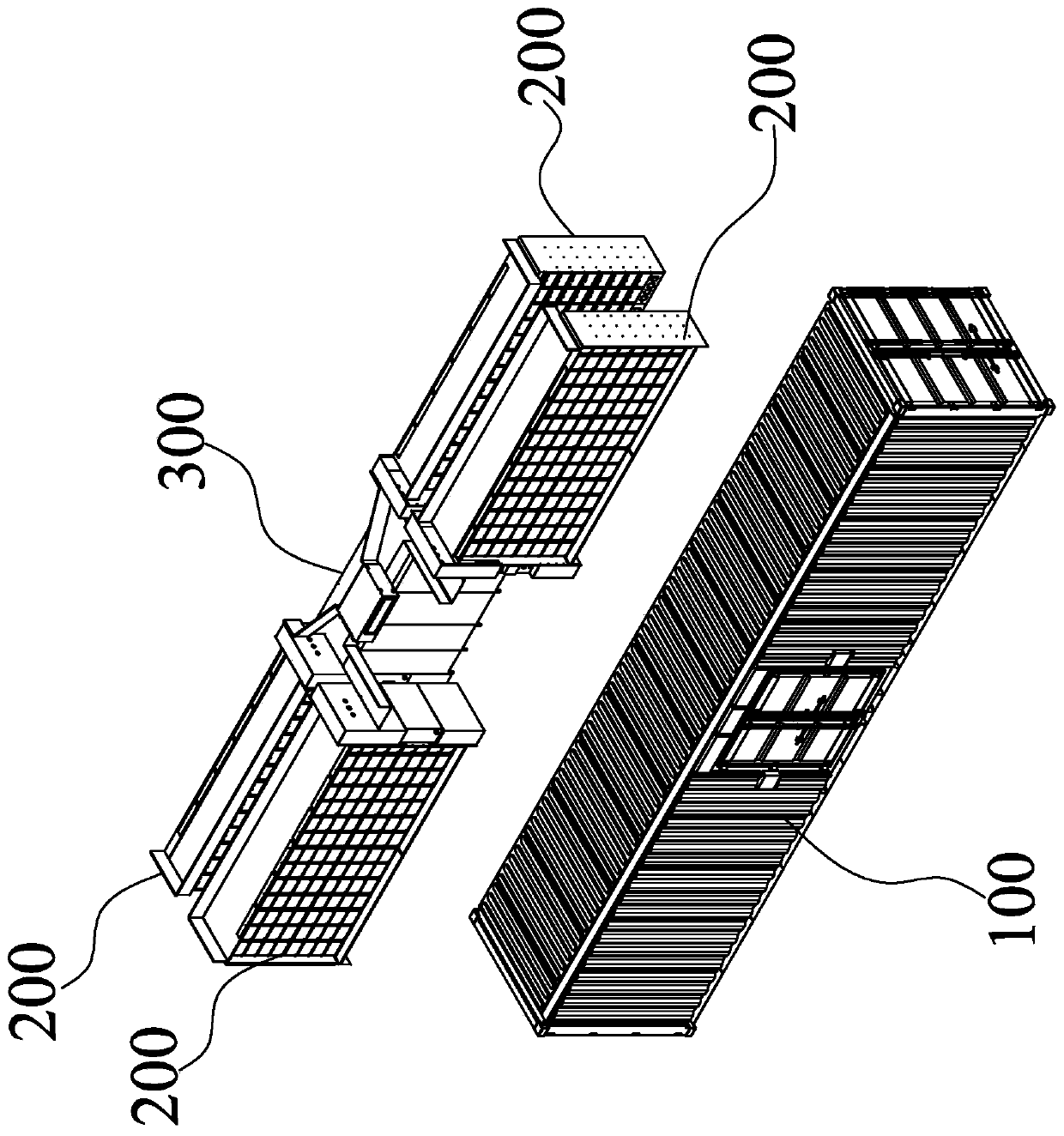

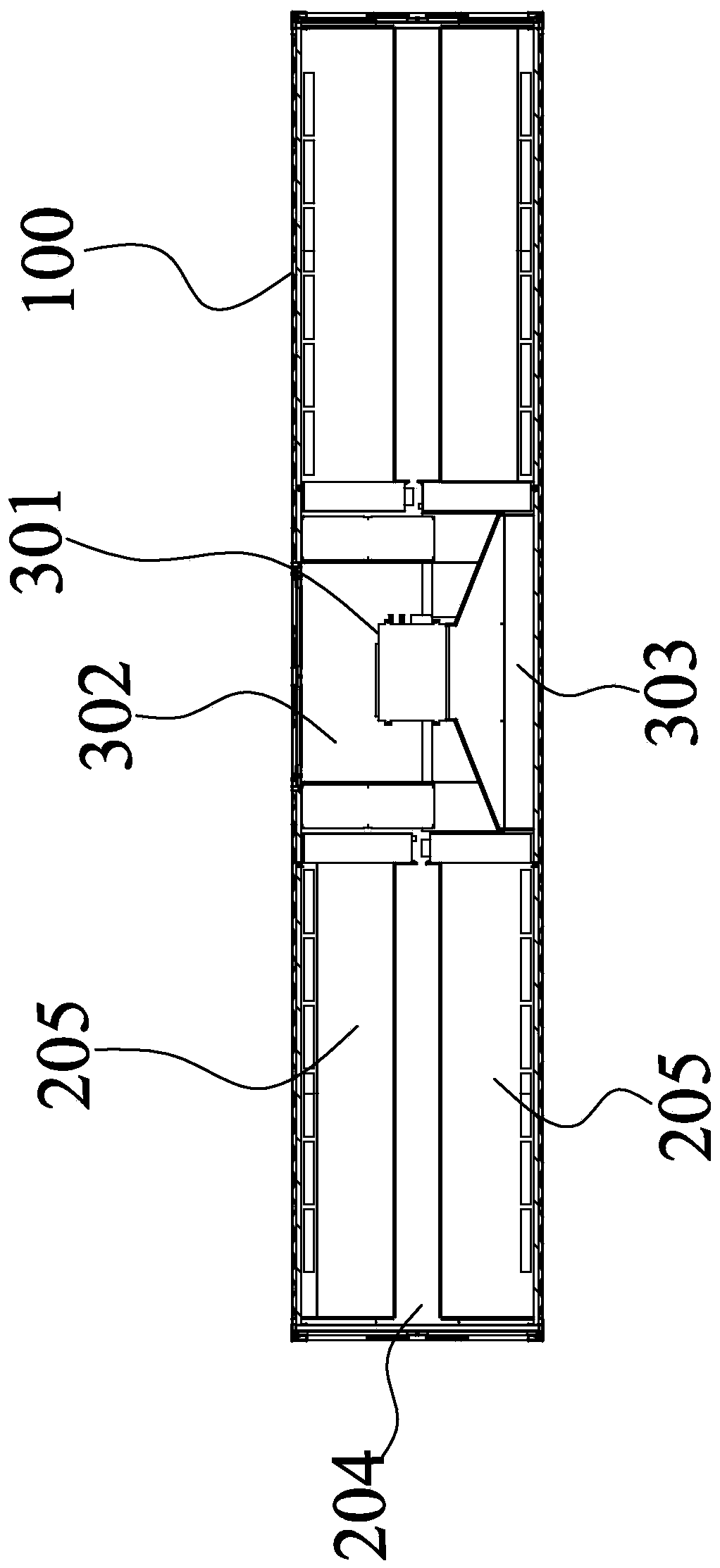

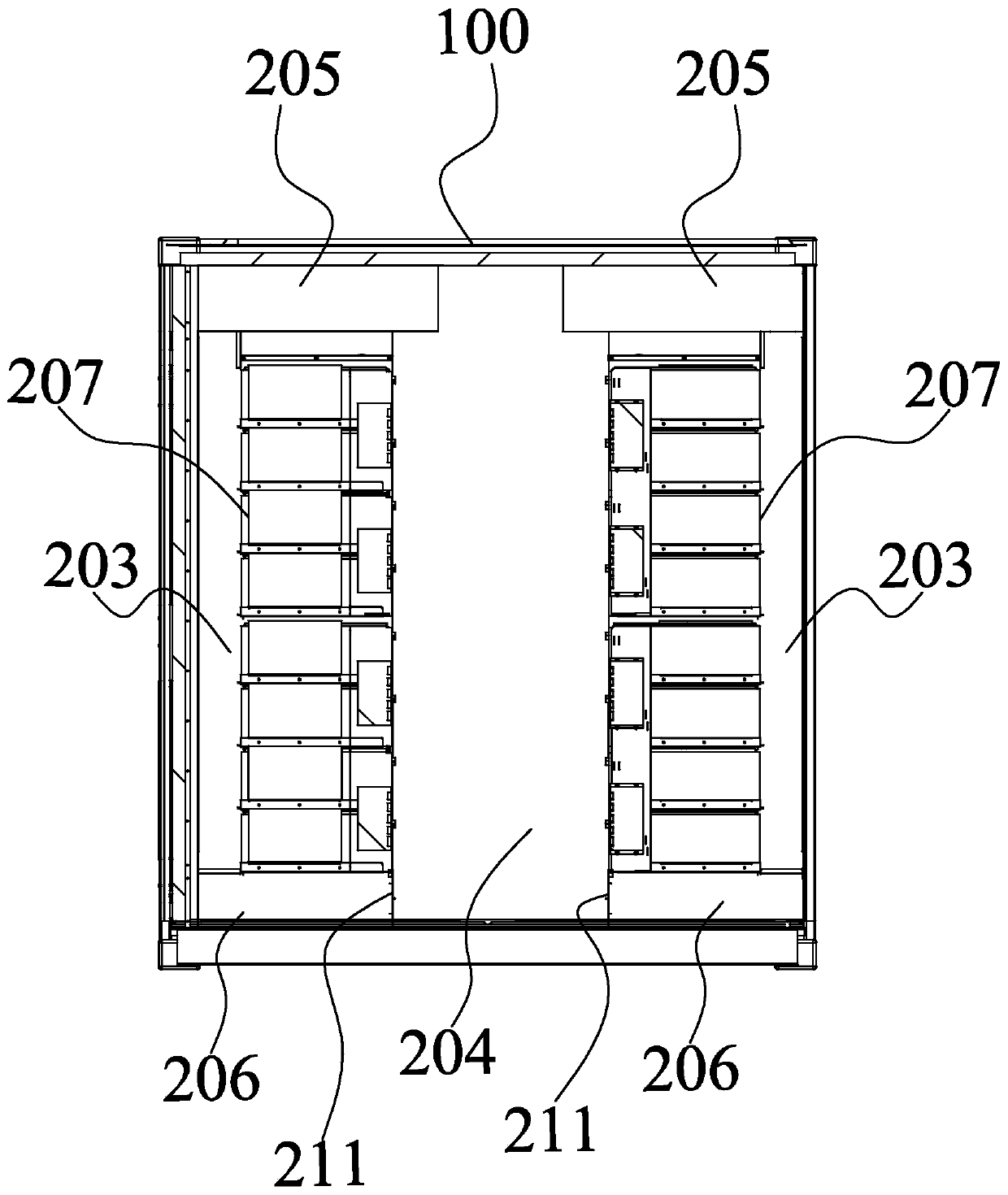

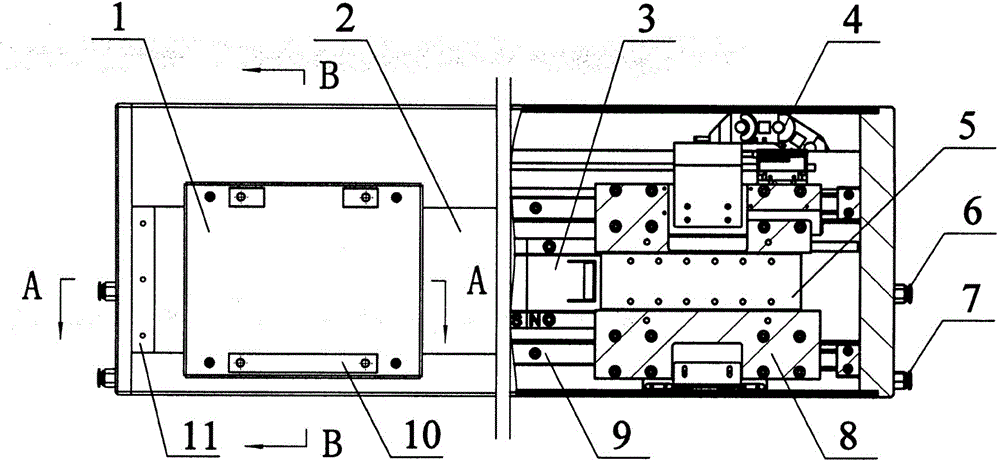

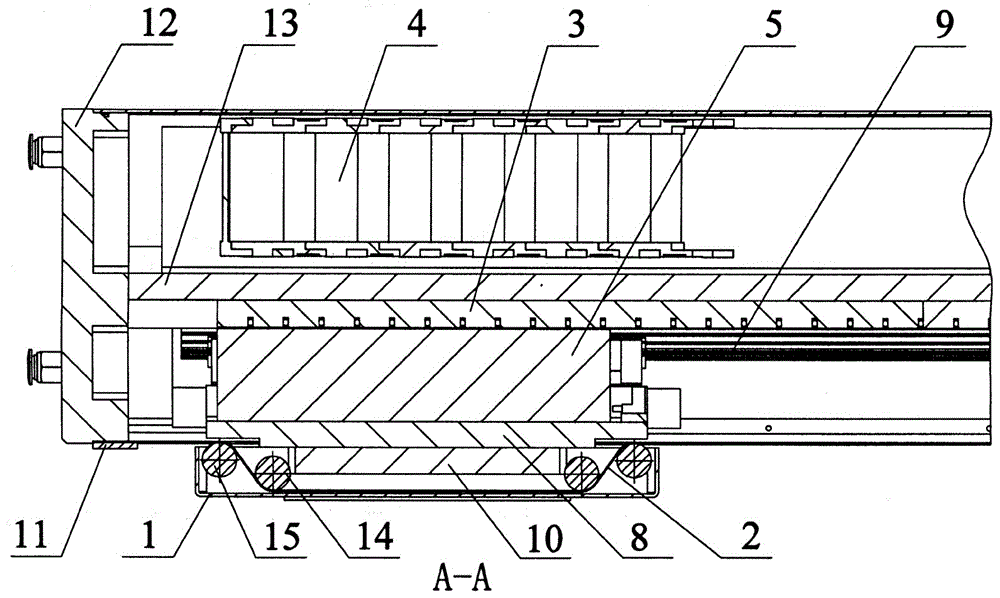

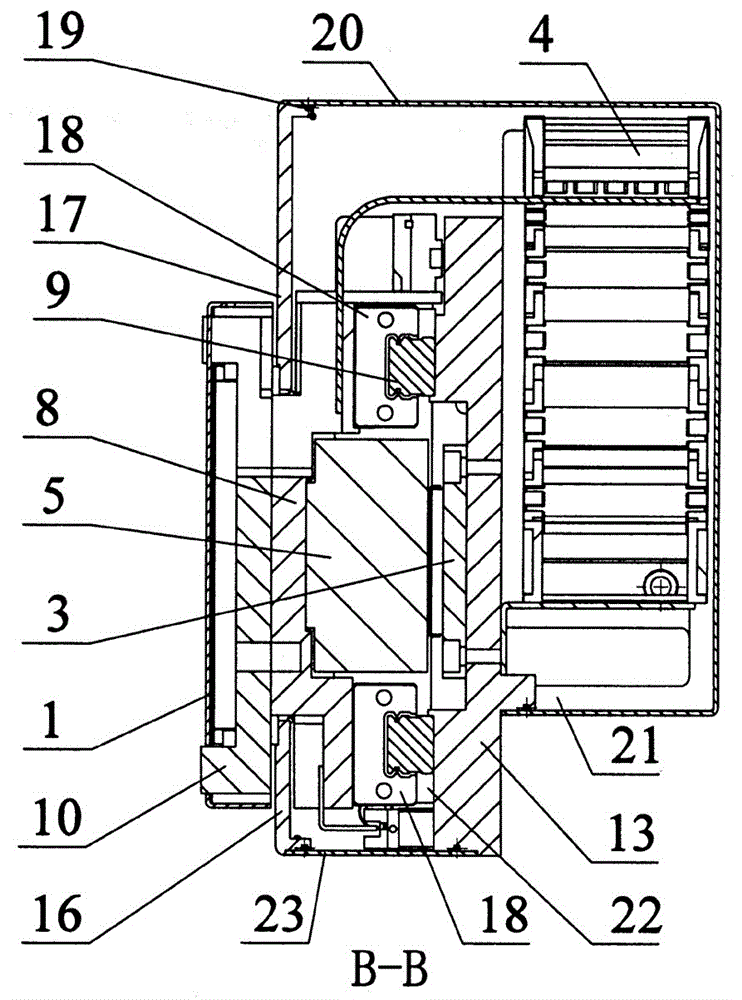

Battery PACK cooling assembly, energy storage container and cooling method

PendingCN110581328AGuaranteed cooling effectSmall unit volumeSecondary cellsAutomotive engineeringCooling methods

The invention relates to the technical field of energy storage equipment, and particularly relates to a battery PACK cooling assembly, an energy storage container and a cooling method. The battery PACK cooling assembly makes the cold air flow into a first air supply cavity and flows into a first air collection cavity from a gap between battery PACKs to cool the battery PACKs. The battery PACK cooling assembly has the effects of ordered flow of a wind field, small temperature difference in the box and stable cooling effect. The energy storage container comprises at least two battery PACK cooling assemblies. The first air supply cavities of two adjacent battery PACK cooling assemblies are communicated or the first air collection cavities of the two adjacent battery PACK cooling assemblies are communicated, so that the unit design volume of the energy storage container is reduced, and the occupied area of the energy storage container is also reduced. According to the cooling method, cooling is achieved by making the cold air pass through the space between the two adjacent battery PACKs, so that the cooling effect is good; and the first air collection cavity and the first air supply cavity separate the two sides of a battery rack, the air field flows orderly, and the temperature difference in the energy storage container is small.

Owner:珠海科创电力电子有限公司

Protective conveying mechanism for high-cleanliness working spaces

Provided is a protective conveying mechanism for high-cleanliness working spaces. The defect that an existing Cartesian-coordinate robot cannot be used for high-cleanliness working spaces is overcome. The protective conveying mechanism for high-cleanliness working spaces is technically characterized in that a unique structure combining sealing and negative pressure adsorption is adopted, that is, a channel opening needed for movement of a rotor of a linear motor and an external standby fixing plate assembled together with a positioning supporting connecting plate is sealed by a dustproof belt; a sealed chamber is formed by an inner cavity of a base body, and a whole driving main body is packaged in the inner cavity of the base body; under the action of negative pressure adsorption in the sealed chamber communicating with an external negative pressure source, generated airflow flows in sequence and is exhausted through a corresponding exhaust opening in the closed chamber, and the effect that micro dust produced by all movement units is not leaked out of the sealed chamber of the base body is guaranteed. The protective conveying mechanism for high-cleanliness working spaces is reasonable in structural design, wide in operation range, high in operation speed, accurate in positioning accuracy and capable of meeting the requirement of various high-cleanliness working spaces, the micro dust produced by the movement units is not leaked out, and the ambient environment and materials are prevented from being polluted.

Owner:SHANGHAI FORTREND TECH CO LTD

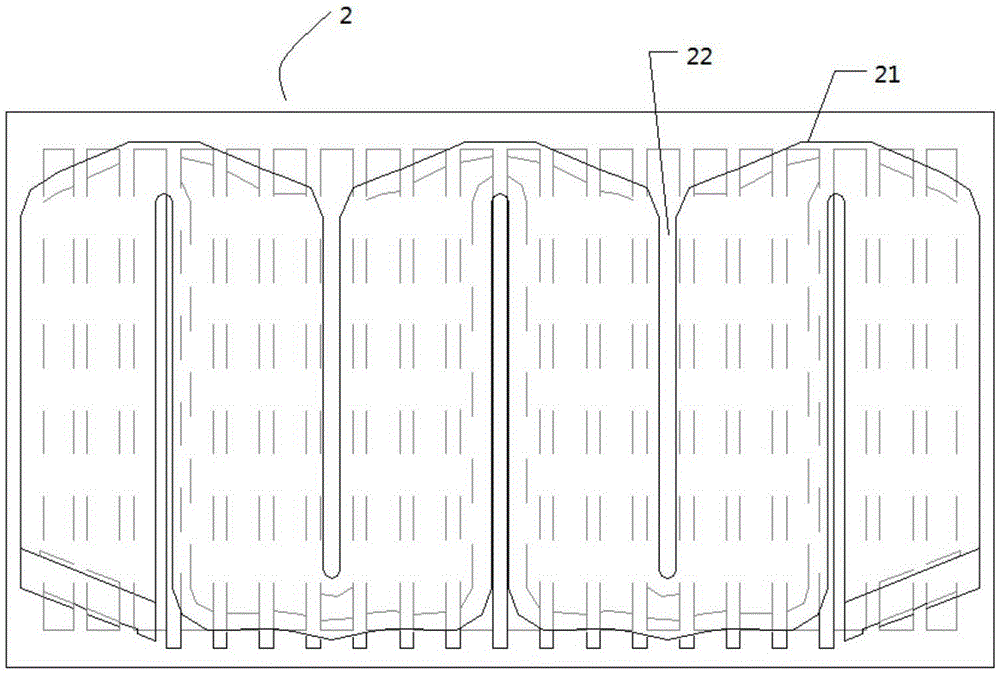

Heat exchange plate, heat exchanger and cabinet of communication base station

ActiveCN104582443AImprove air efficiencyOrderly flowCooling/ventilation/heating modificationsEngineeringMicro heat exchanger

An embodiment of the invention provides a heat exchange plate applied to a heat exchanger. The heat exchange plate is characterized by comprising a body and a first guide assembly, wherein the first guide assembly is arranged on the upper surface of the body to guide a fluid flowing through the upper surface of the body to flow. The heat exchange efficiency of the heat exchange plate is improved. The invention further provides the heat exchanger and a cabinet of a communication base station.

Owner:HUAWEI TECH CO LTD

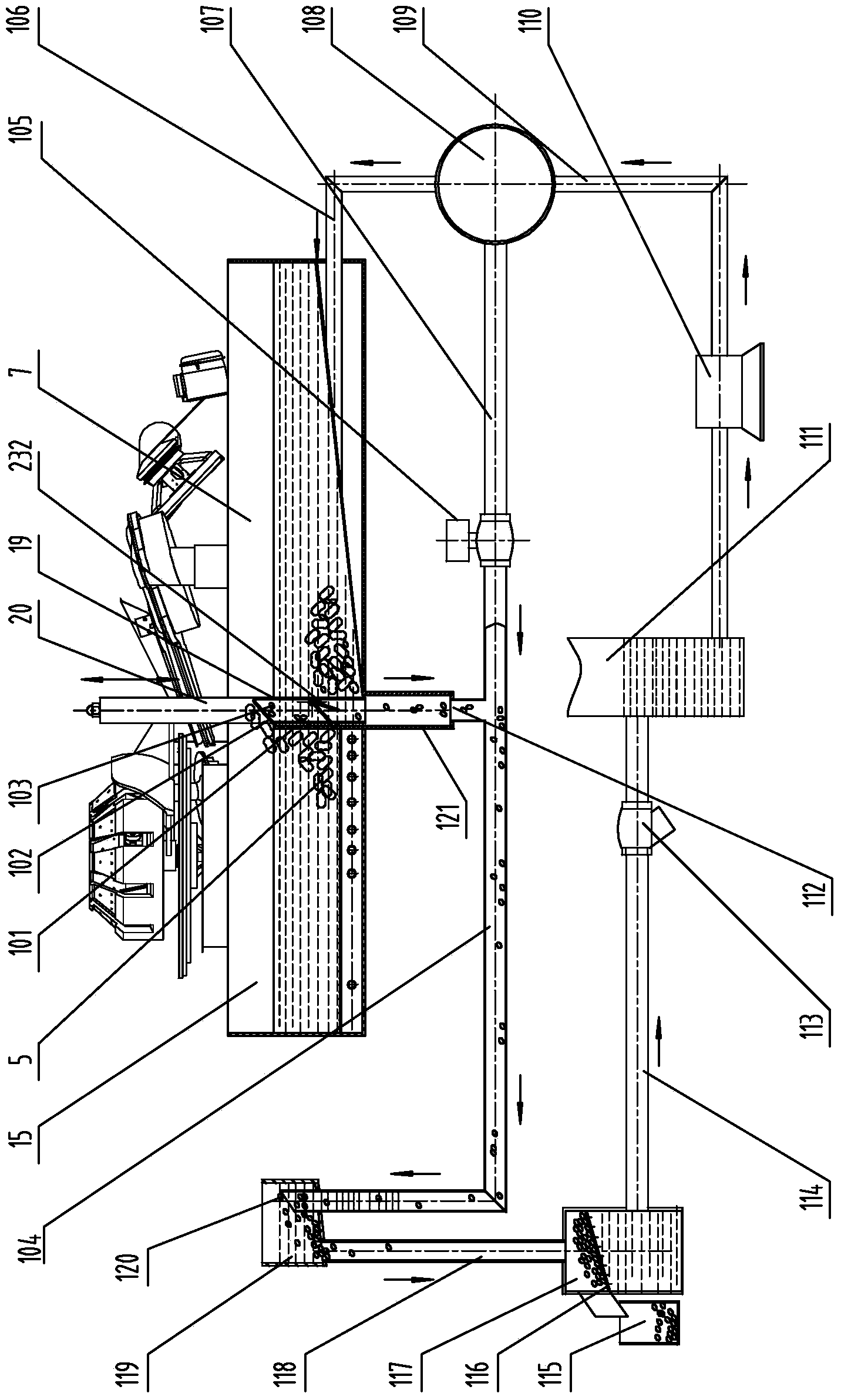

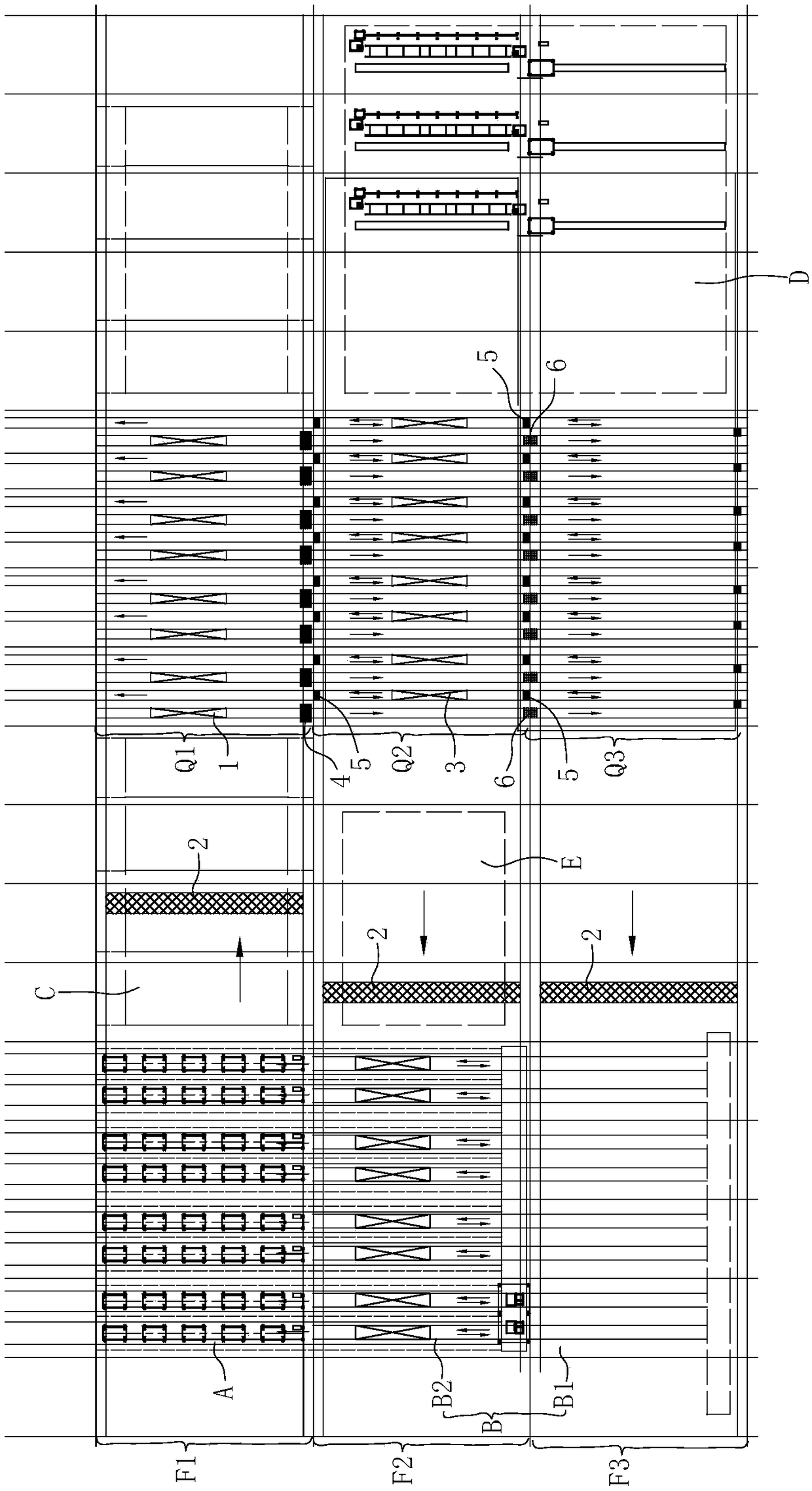

Centrifugal concrete pile production line

PendingCN109227920AReasonable layoutUnobstructed demoulding lineCeramic shaping plantsShaping reinforcementsEngineeringManufacturing engineering

The invention relates to a centrifugal concrete pile production line which comprises a feeding and die locking area, a centrifugal area and a curing area. The centrifugal concrete pile production lineis characterized by additionally comprising a die conveying vehicle, a first span of a factory building, a second span of the factory building and a third span of the factory building; the first spanof a factory building, the second span of the factory building and the third span of the factory building are orderly arranged in a neighboring manner; a first area used for placing cured dies containing piles is arranged in the first span of the factory building, a second area used for lifting upper half die sections of the dies is arranged in the second span of the factory building, and a thirdarea used for mounting steel reinforcement cages on lower half die sections of the dies is arranged in the third span of the factory building; or the third area used for mounting the steel reinforcement cages on lower half die sections of the dies is arranged in the second span of the factory building, and the second area used for lifting the upper half die sections of the dies is arranged in thethird span of the factory building; the die conveying vehicle can move to and fro between the first span of the factory building and the second span of the factory building, and the die conveying vehicle can move to and fro between the second span of the factory building and the third span of the factory building. The centrifugal concrete pile production line is reasonable in layout and capable of ensuring orderly operation of die disassembling and manufacturing, and improvement of an automation level of concrete pile production can be facilitated.

Owner:俞向阳

Environment-friendly firework launching rack capable of being filled repeatedly

ActiveCN106568349AOrderly flowEnsure normal dischargeFireworksElectrical and Electronics engineering

The invention discloses an environment-friendly firework launching rack capable of being filled repeatedly. The environment-friendly firework launching rack comprises a lower die holder (1) and an upper die holder (3); supporting platforms (15) are arranged on the lower die holder at intervals; platform sinking holes matched with the supporting platforms are formed in the upper die holder; an air duct capable of connecting and communicating with the supporting platforms in series is formed between the upper die holder and the lower die holder; the side edge of the first supporting platform is provided with a fire-leading channel (17) capable of being filled with a detonating fuse head; the periphery of the air duct is correspondingly provided with a sealing device capable of sealing the air duct; and the sealing device comprises sealing grooves (14) located in the lower die holder and sealing stripes (16) which are located on the upper die holder and can be embedded into the sealing grooves. According to the environment-friendly firework launching rack capable of being filled repeatedly, as the periphery of the hot airflow air duct is provided with the sealing device, thus, hot airflow can be controlled to be not leaked outwards, so that the hot airflow is enough to be subjected to ignition discharging, moreover, the hot airflow can flow orderly, and normal discharging of fireworks is ensured. The launching rack is compact in structure, convenient to manufacture, lightweight and high in durability.

Owner:JIANGXI CROWN TECH CO LTD

Device for detecting air tightness of dissipative muffler

ActiveCN106089720AGuaranteed cooling effectExtended flow timeRotary/oscillating piston pump componentsLiquid fuel engine componentsAir tightnessMuffler

The invention discloses a device for detecting the air tightness of a dissipative muffler. The device comprises an engine case, a working cavity and a sliding valve, wherein a rotating roll is arranged on a side surface of the sliding valve; the periphery of the top surface of the engine case is bulged upward; screw holes are formed in the bulged part; a cooling water cover is arranged above the engine case; through holes are formed in the cooling water cover; bolts penetrate through the through holes and are inserted into the screw holes; a plurality of baffle plates are arranged under the cooling water cover; cavities are formed in the baffle plates; springs and supporting plates are arranged in the cavities; the lower parts of the supporting plates are connected with bases; a water inlet and a water outlet are respectively mounted on two mutually parallel side surfaces of the cooling water cover; when the cooling water is mounted on the engine case, the bottoms of the baffle plates are in contact with the engine case, and the baffle plates are perpendicular to side surfaces of the bulged part; and the baffle plates are parallel to one another, and every two adjacent baffle plates are connected onto the different side surfaces of the bulged part. The device not only is convenient to clean, but also has the advantage that the engine case assembly is prevented from being repeatedly dismounted from and mounted in a screw rod compressor, so that the working strength of operating personnel can be reduced and the service life of the engine case can be prolonged.

Owner:ENGINEERED EXHAUST SYST B T INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com