Protective conveying mechanism for high-cleanliness working spaces

A work space, high cleanliness technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as insufficiency, achieve reasonable structural design, avoid polluting the surrounding environment and materials, and increase manufacturing difficulty and production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

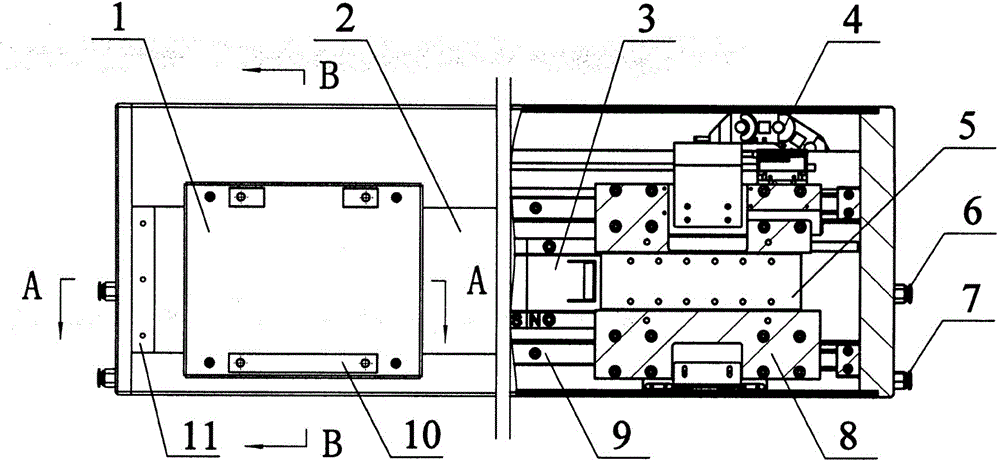

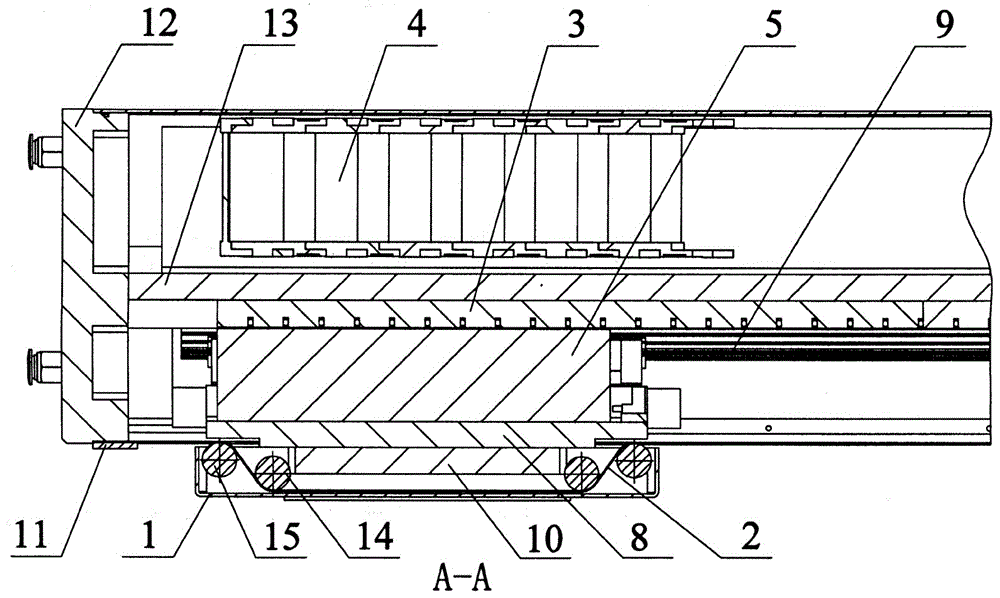

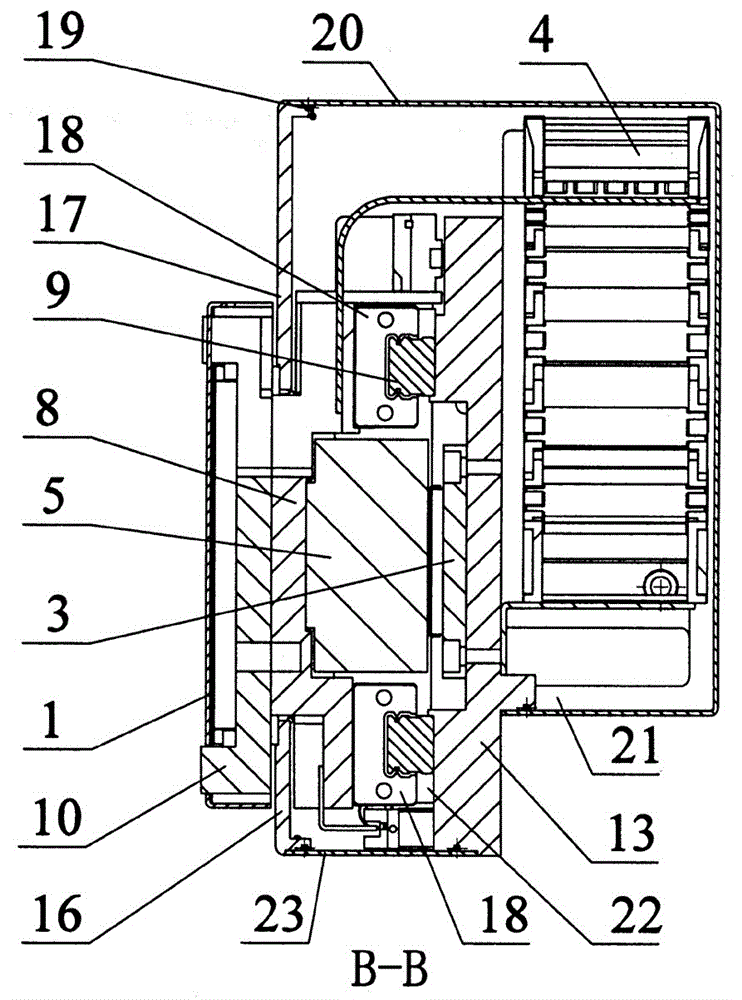

[0025] according to Figure 1~6The specific structure of the present invention will be described in detail. The conveying mechanism used in the high-cleanliness space includes a base body composed of a base plate 13 and a side plate 12 provided with an upper guard plate 17, a lower guard plate 16, an upper cover plate 20, and a lower cover plate 23. A linear motion device that is matched by a linear motor and a linear guide rail 9, the towline cavity air outlet 6 and the guide rail that are provided on the side plate 12 and communicate with the inner cavity of the substrate for connecting to an external negative pressure source (not shown in the figure) Cavity gas outlet 7 etc. pieces. In this embodiment, a linear motor is used as the driving body, and the base plate 13 and the side plates 12 mounted on both sides of the base plate 13 are used as the basic structure of the base of the linear motion device. The stator 3 and the linear guide rail 9 of the linear motor are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com