Environment-friendly firework launching rack capable of being filled repeatedly

An environmentally friendly fireworks and launcher technology, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems that the discharge cannot be carried out in sequence, affect the quality of fireworks products, and reduce production efficiency, so as to improve the quality of fireworks products and benefit ecological resources. Protects, saves paper and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

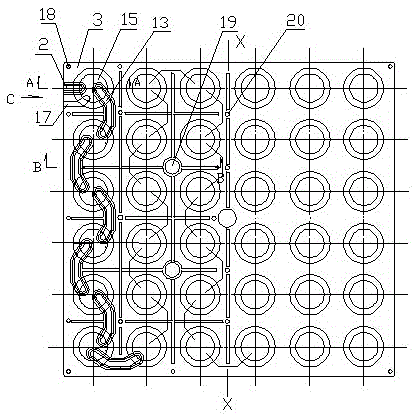

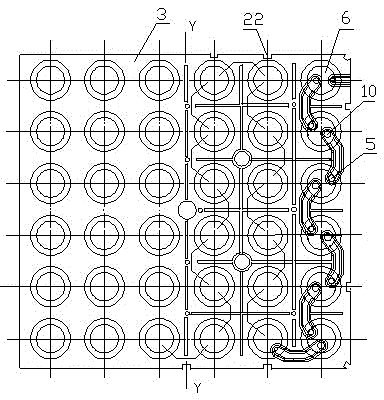

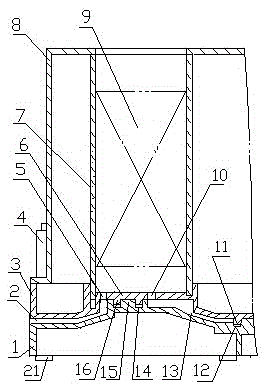

[0023] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Among them, the launch frame that can refill environmentally friendly fireworks includes a lower mold base 1 and an upper mold base 3, and 36 support platforms 15 are arranged at intervals on the lower mold base, and the support platforms can be higher than the upper surface of the lower mold base or A cylindrical or conical shape that is flush with the upper surface of the lower mold base. The support platform is arranged in a single row, double rows or multiple rows to form fireworks tubes of several specifications. The upper mold base is provided with a sinking platform that matches the support platform. hole (not marked in the figure), there is an air channel between the upper mold base and the lower mold base, which can connect the support platform in series, figure 1 In X-X line for symmetry, figure 2 The Y-Y line is symmetrical in the center. After the upper mold base, the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com