Centrifugal concrete pile production line

A technology for concrete piles and production lines, which is used in strengthening molding, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as round-trip conflicts, and achieve the effect of reasonable layout and smooth mold removal line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

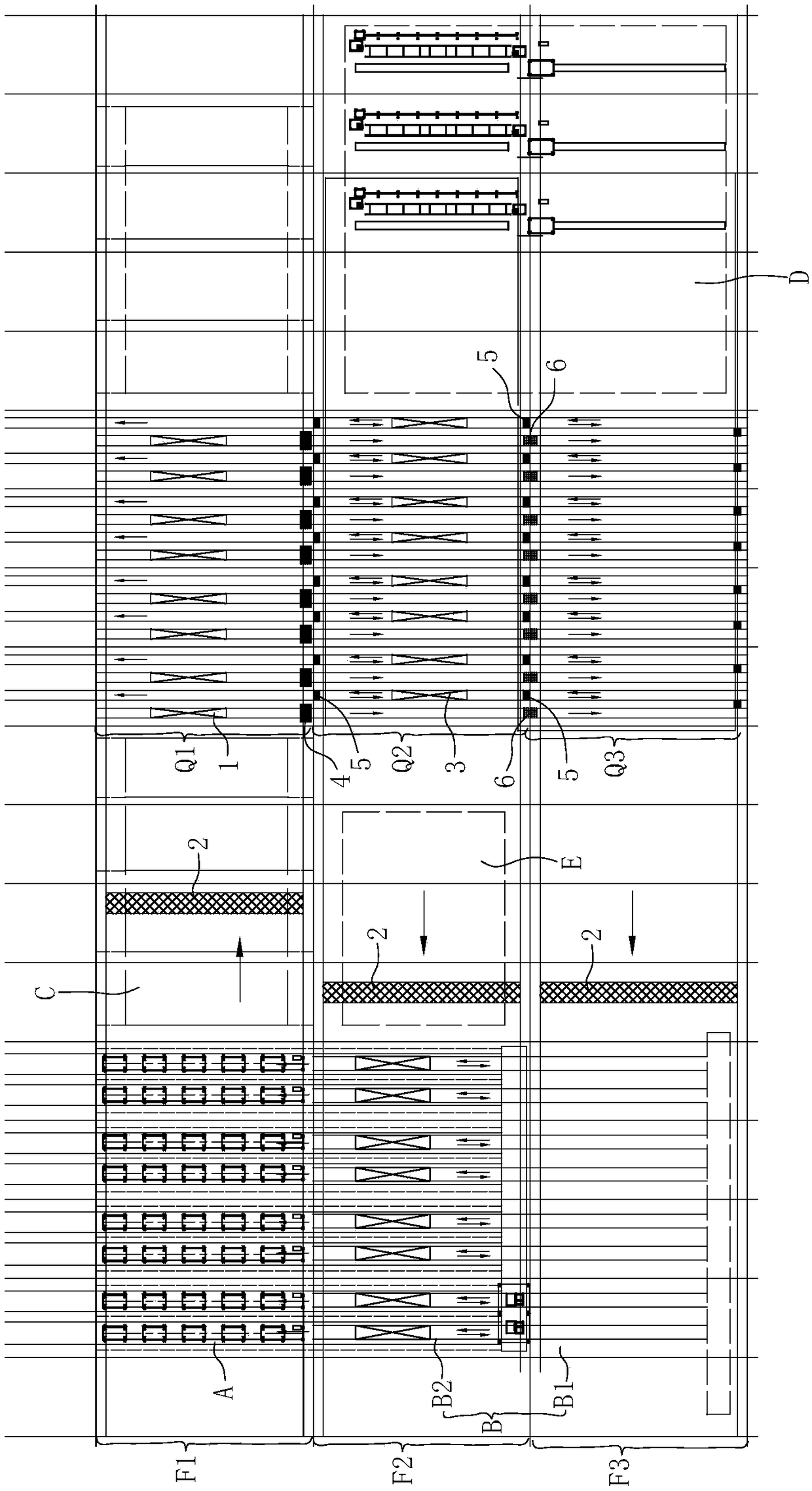

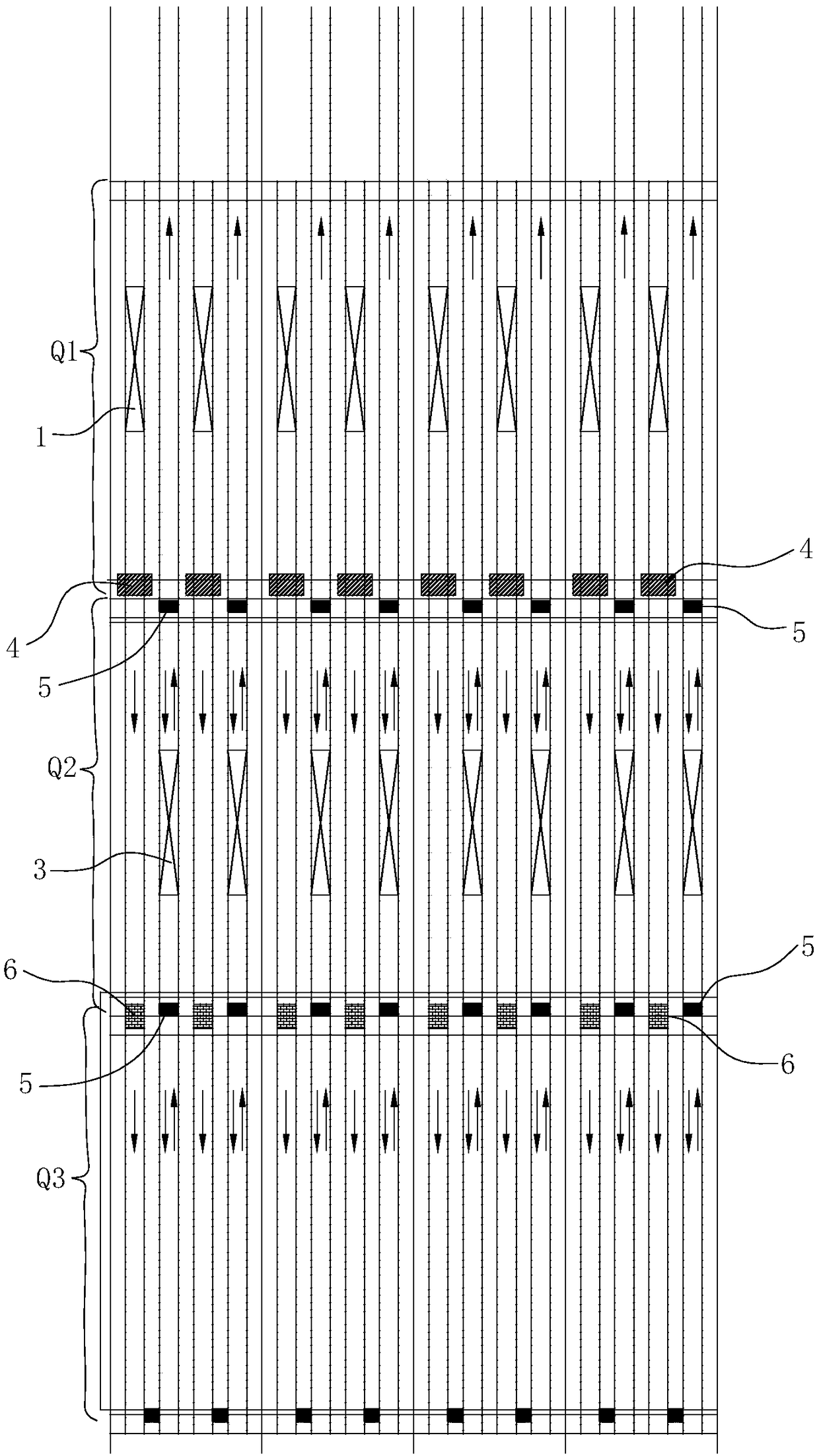

[0026] Such as figure 1 , 2 Shown is a preferred embodiment of the present invention.

[0027] A production line for centrifugal concrete piles, including a feeding mold-closing area B, a centrifugal area A, a curing area C, a mold transport vehicle 1, and successively adjacent first-span factory buildings F1, second-span factory buildings F2, and third-span factory buildings F3; centrifuge area A and maintenance area C are located in the first span factory building F1. On the side of the second area Q2, there is an upper mold half cleaning area E. The upper half-mold cleaning area E is preferably set between the second area Q2 and the feeding mold clamping area B. A reinforcement cage processing area D is provided on one side of the third area Q3.

[0028] In the first span factory building F1, there is a first area Q1 for dismantling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com