Device for detecting air tightness of dissipative muffler

A resistive muffler and inspection device technology, applied in the field of air compressors, can solve the problems of increasing the operator's work intensity, inconvenience, and reducing the service life of the casing, and achieves the advantages of convenient cleaning, prolonging service life and ensuring cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

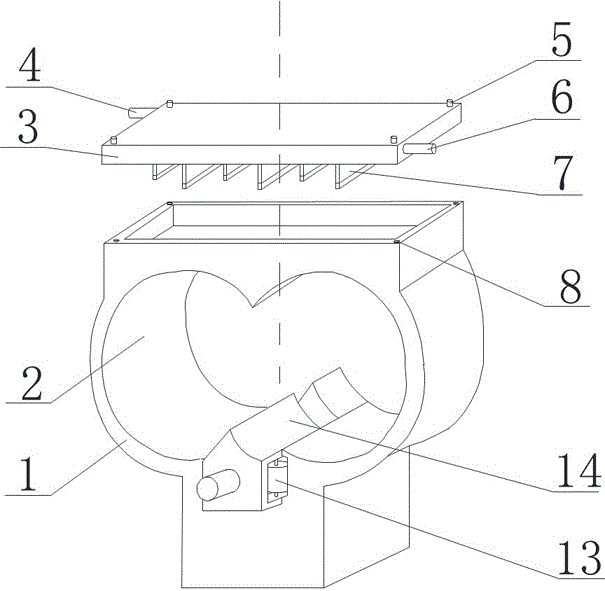

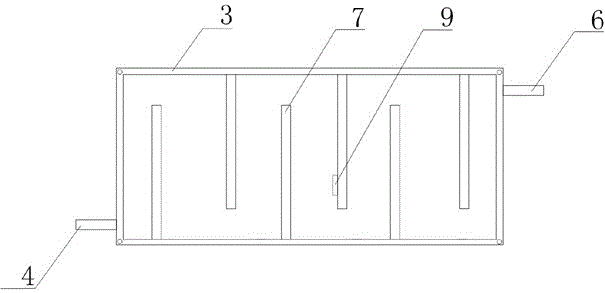

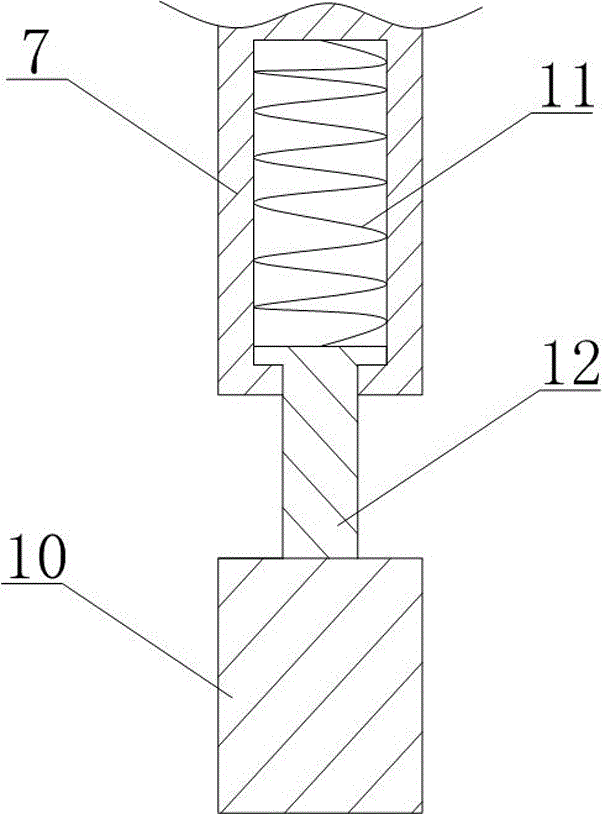

[0031] Such as figure 1 , figure 2 with image 3 As shown, the present invention is an inspection device for the airtightness of a resistive muffler, including a casing 1, a working chamber 2 is arranged inside the casing 1, a slide valve 14 is arranged at the bottom of the working chamber 2, and a second slide valve 14 is arranged on the side of the slide valve 14. A groove, the first groove is provided with a rotating roller 13 and a rotating shaft that runs through the upper and lower bottom surfaces of the rotating roller 13, the side of the rotating roller 13 is in contact with the casing 1, and the surroundings of the top surface of the casing 1 are raised upwards. The top of the part is provided with a screw hole 8, and a cooling water cover 3 matching with the casing 1 is provided above the casing 1, and a through hole is provided on the cooling water cover 3, and a screw 5 is also included, and the screw 5 passes through the through hole Inserted into the screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com