Constant-temperature insulation steel silo

A constant temperature, steel plate technology, applied in the direction of heat preservation, fruit hanging devices, building components, etc., to achieve the effect of improving sealing, meeting fire protection requirements, and enhancing fire protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

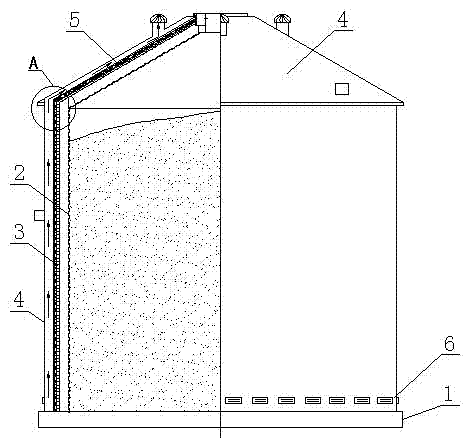

[0025] A steel silo with constant temperature and heat preservation, which consists of a foundation 1, a silo body 2 connected to the foundation, an insulation layer 3 fixed on the outside of the silo body through connectors, and the peripheral plate 4 fixed on the insulation layer or the silo body through brackets , the heat insulation layer and the peripheral board form an air heat insulation layer 5 .

Embodiment 2

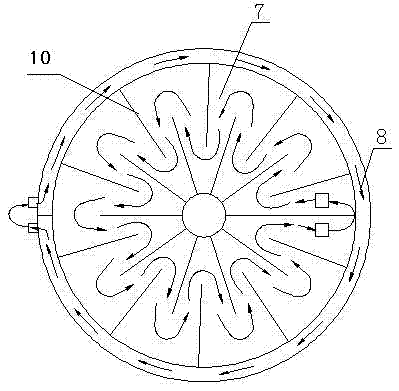

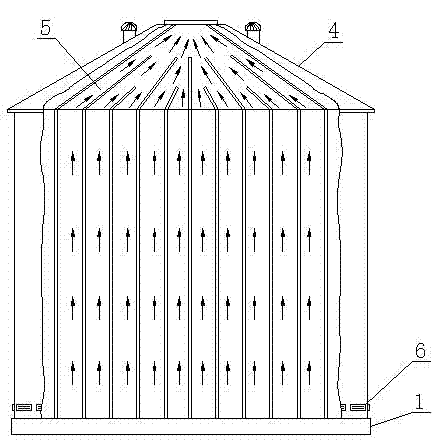

[0027] In the constant temperature and heat preservation steel silo described in Example 1, the support includes a cylinder support and a silo roof support, and the cylinder support is arranged longitudinally, and the vertical passages in the space are constructed in a high-altitude negative pressure environment. Under the suction, the respective chimney effect is formed. Similarly, the roof brackets are arranged radially corresponding to the cylinder brackets, and the cylinder brackets and the roof brackets play a role of blocking flow, so that the airflow can flow in an orderly manner, avoiding low-grade mixed flow from low-temperature areas to sun-exposed areas . Enhance air flow in the direction of sunlight.

Embodiment 3

[0029] In the constant temperature and heat preservation steel silo described in Example 1, the bottom of the peripheral plate has a rain-proof air inlet 6, and the top of the silo has an air outlet, and the air outlet is connected with a non-powered fan 9 to utilize the high-altitude strong wind As a driving force, it strengthens the suction effect on the bottom airflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com