Liquid heat dissipation structure for motor controller

A technology of motor controller and heat dissipation structure, which is applied to the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., to achieve the effect of accelerating heat loss and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

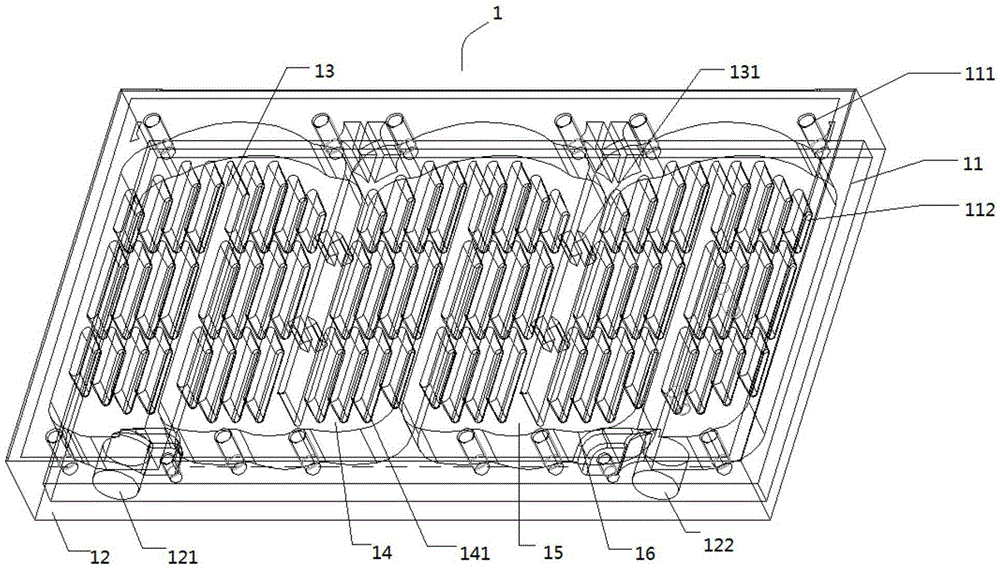

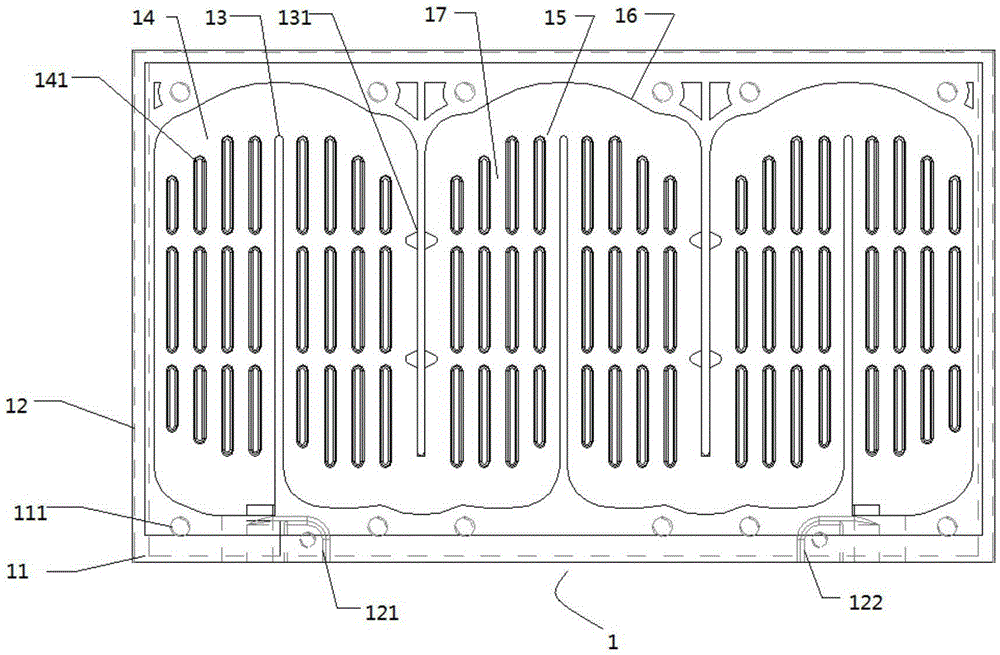

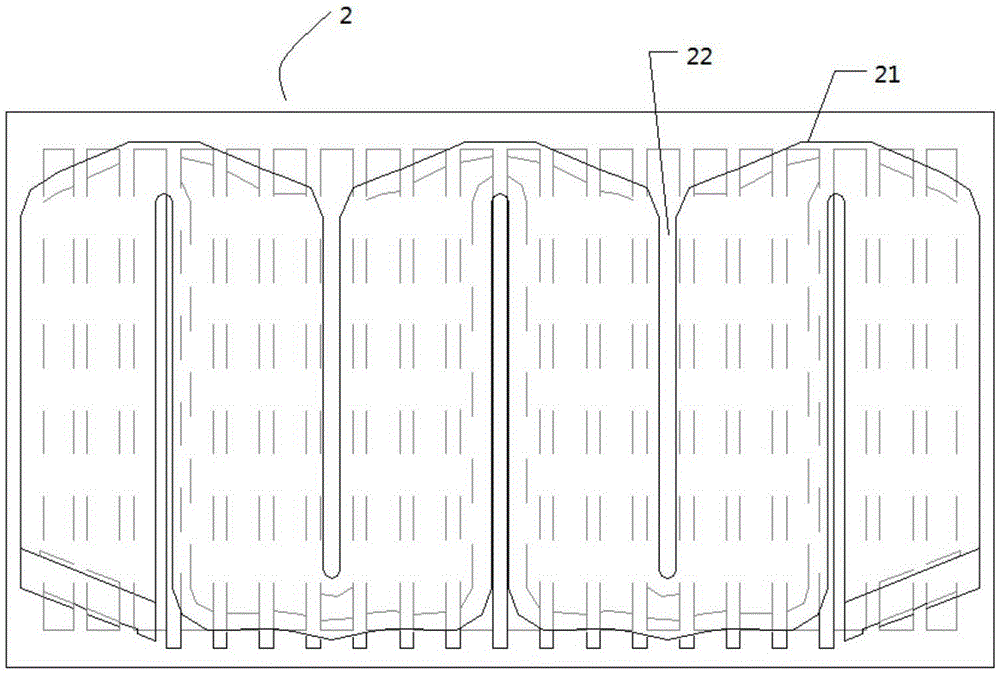

[0020] according to Figure 1 to Figure 2 Shown: a liquid heat dissipation structure of a motor controller, including a heat dissipation plate main body 1 and a cover plate 2 arranged parallel to the heat dissipation plate main body 1; the other side of the heat dissipation plate main body 1 is used to fix the power module unit, and then The heat generated during the working process of the power module unit is taken away through the liquid in the liquid heat dissipation structure, so as to achieve the purpose of heat dissipation, so as to speed up the heat dissipation efficiency of the power module unit and improve the service life.

[0021] Preferably, the heat dissipation plate main body 1 includes: a heat dissipation substrate 11, a side plate 12 with a liquid inlet 121 and a liquid outlet 122, a plurality of baffles 13, a plurality of guide fin groups 14, and the heat dissipation substrate 11 The side plate 12 enclosing a semi-closed accommodating cavity 15 is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com