Gob sealing structure

A closed structure and goaf technology, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as high gas density, potential safety hazards, gas gushing, etc., to increase the sealing distance, ensure the sealing quality, improve The effect of the closure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

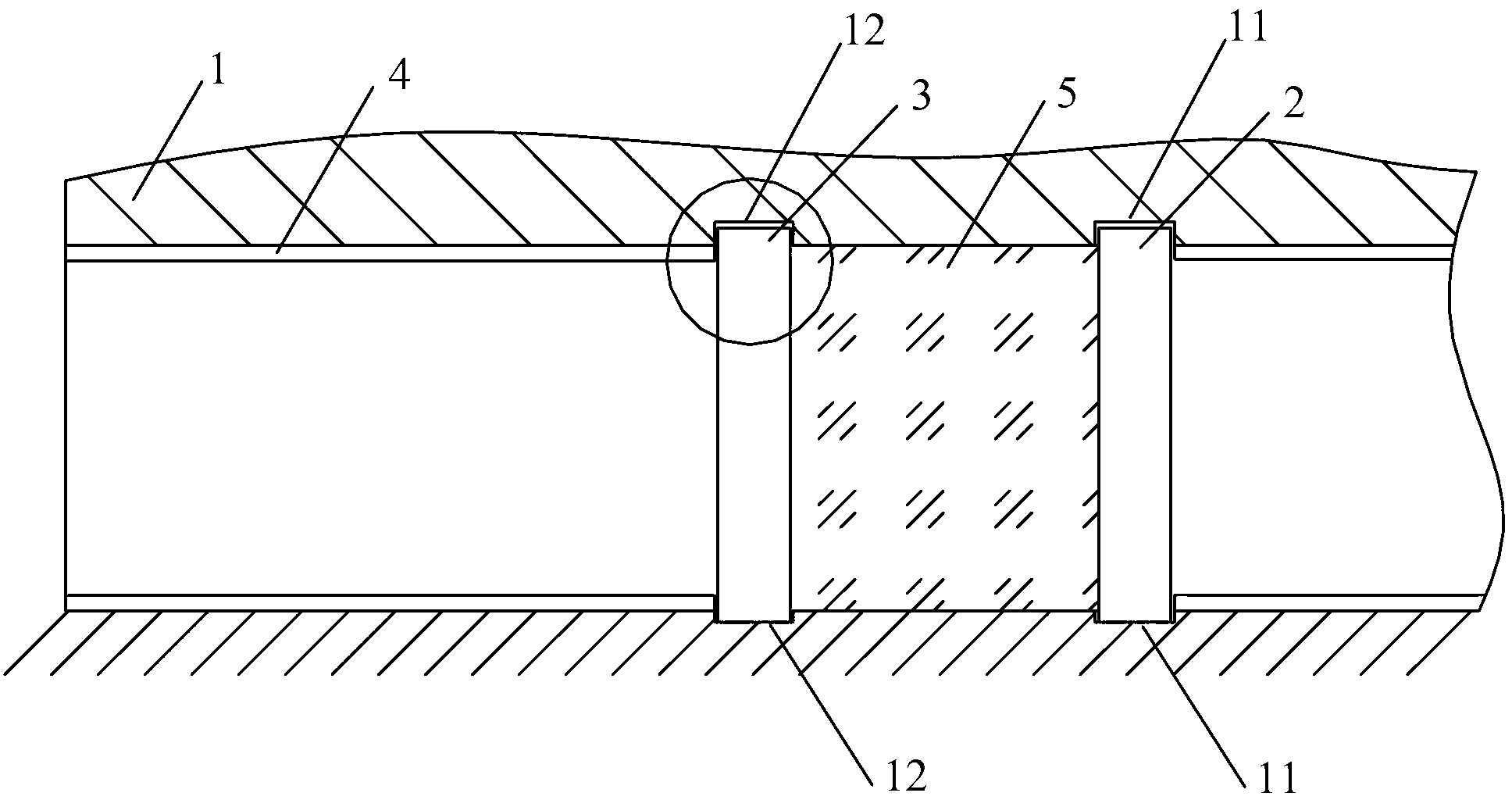

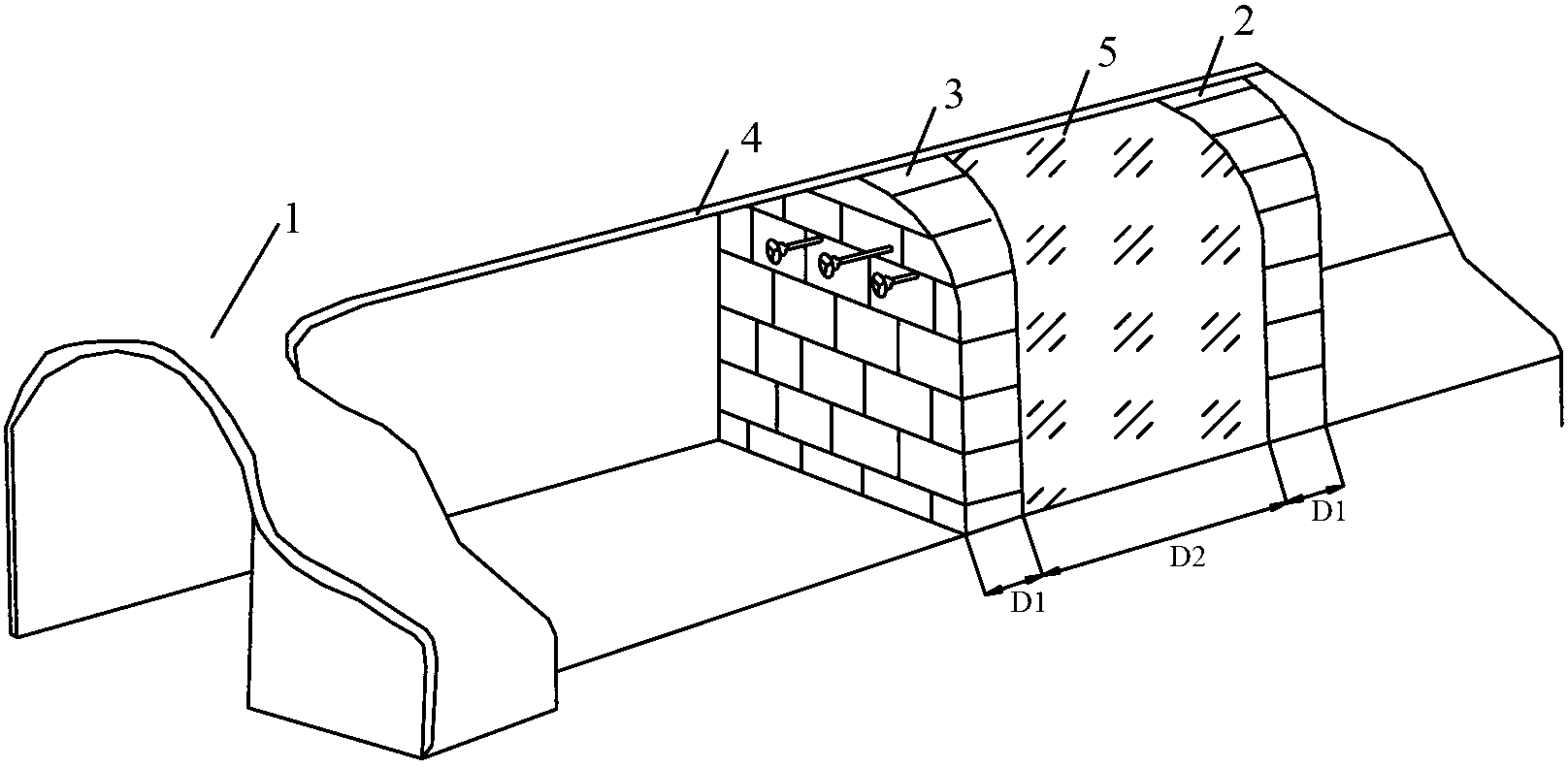

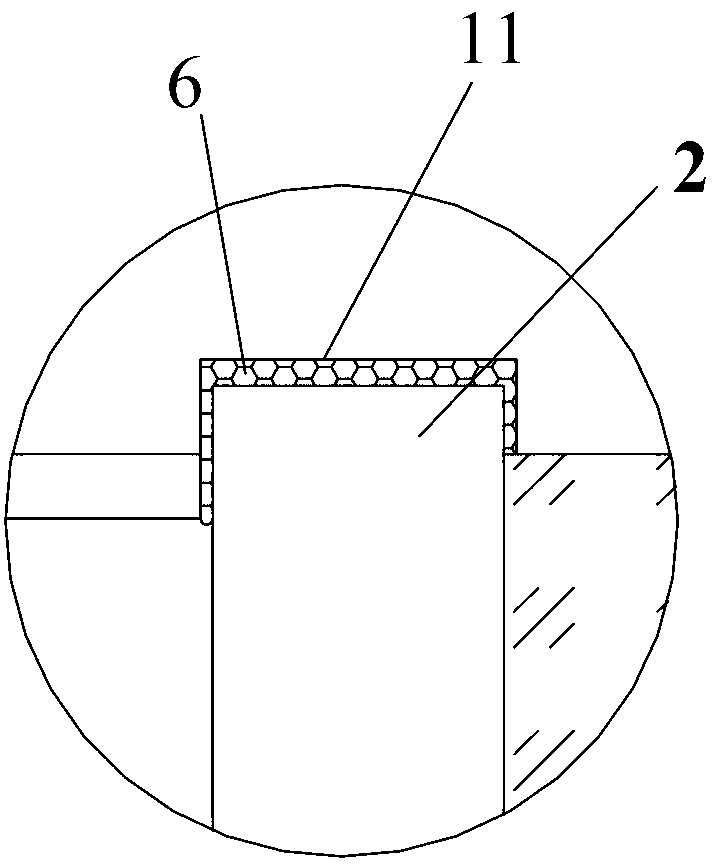

[0021] Such as figure 1 and 2 As shown, the structural schematic diagram of Embodiment 1 of the goaf sealing structure provided by the present invention. As shown in the figure, the goaf closure structure described in the first embodiment includes: a first wall 2 and a second wall 3 arranged in the goaf roadway 1 . The distance D2 between the first wall 2 and the second wall 3 is not less than 2 meters, and the thickness D1 of the first wall 2 and the second wall 3 is not less than 0.6 meters. Such as figure 2 As shown, the inner wall of the goaf roadway 1 is provided with a roadway shotcrete layer 4 formed by at least two spraying processes, and the total thickness of the roadway shotcrete layer 4 is not less than 0.1 meters. Such as figure 1 As shown, the inner wall of the goaf roadway is provided with a first ring wall groove 11, the edge of the first wall 2 is embedded in the first ring wall groove 11, and the first wall 2 The thickness is adapted to the groove width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com