Semi-active dynamic vibration absorber for magneto-rheological elastomers and selection and installation method

A technology of magnetorheological elastomer and dynamic vibration absorber, which is applied in the functional characteristics of spring/shock absorber, spring/shock absorber, spring, etc., can solve the problems of high manufacturing cost and complex structure of active dynamic vibration absorber, etc. Achieve the effect of improving work reliability, ensuring magnetic circuit, and suppressing vertical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with accompanying drawing.

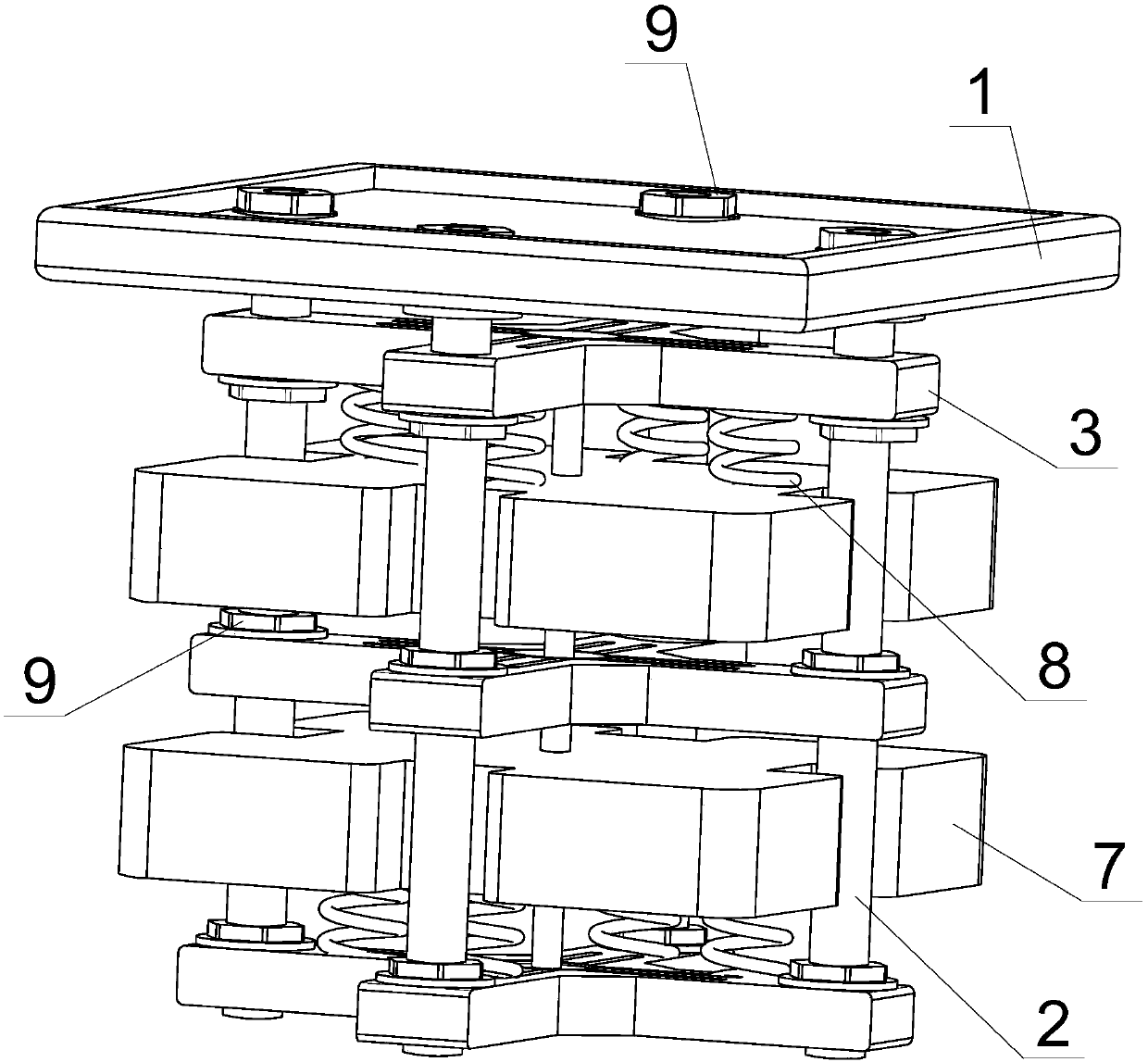

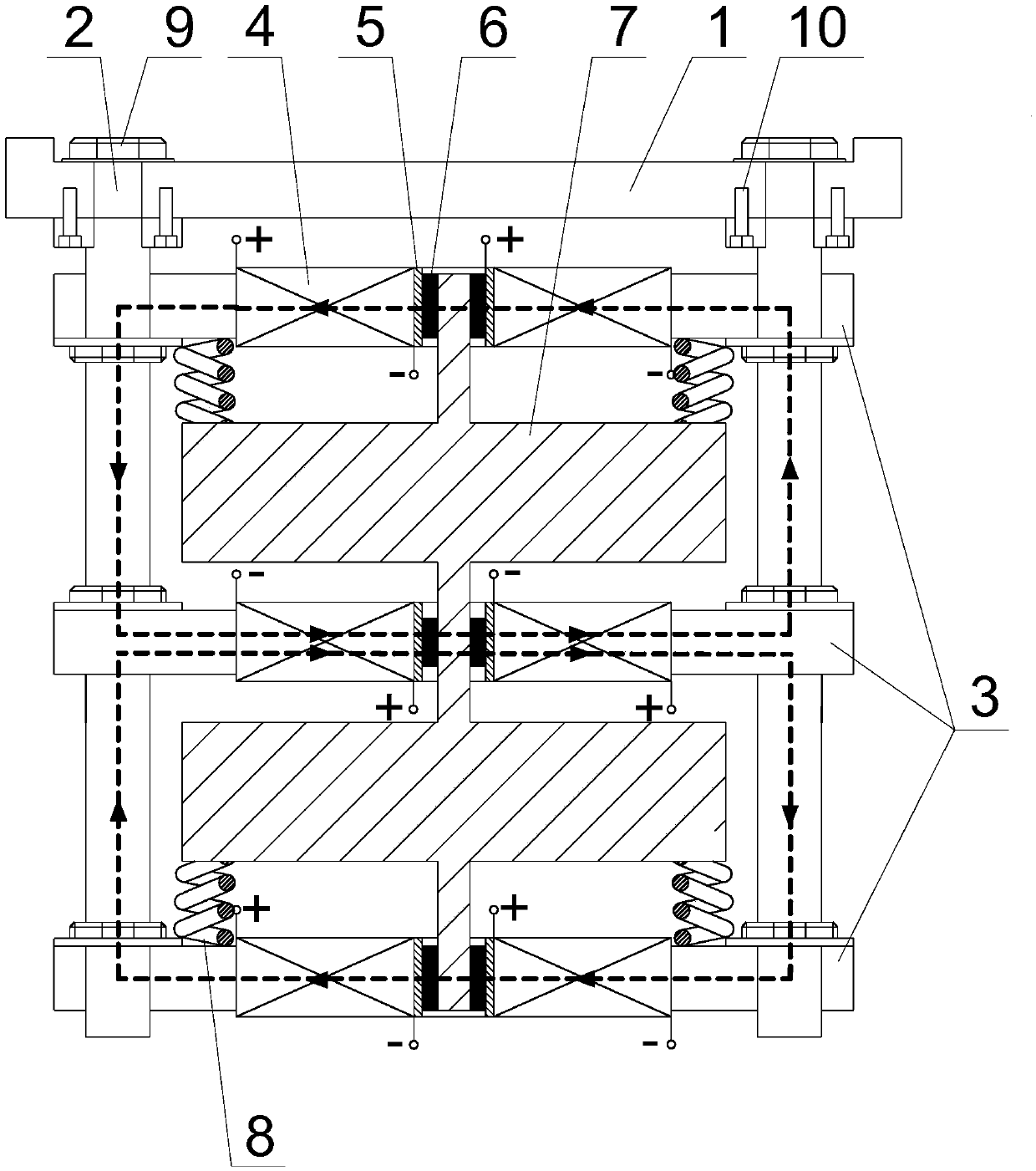

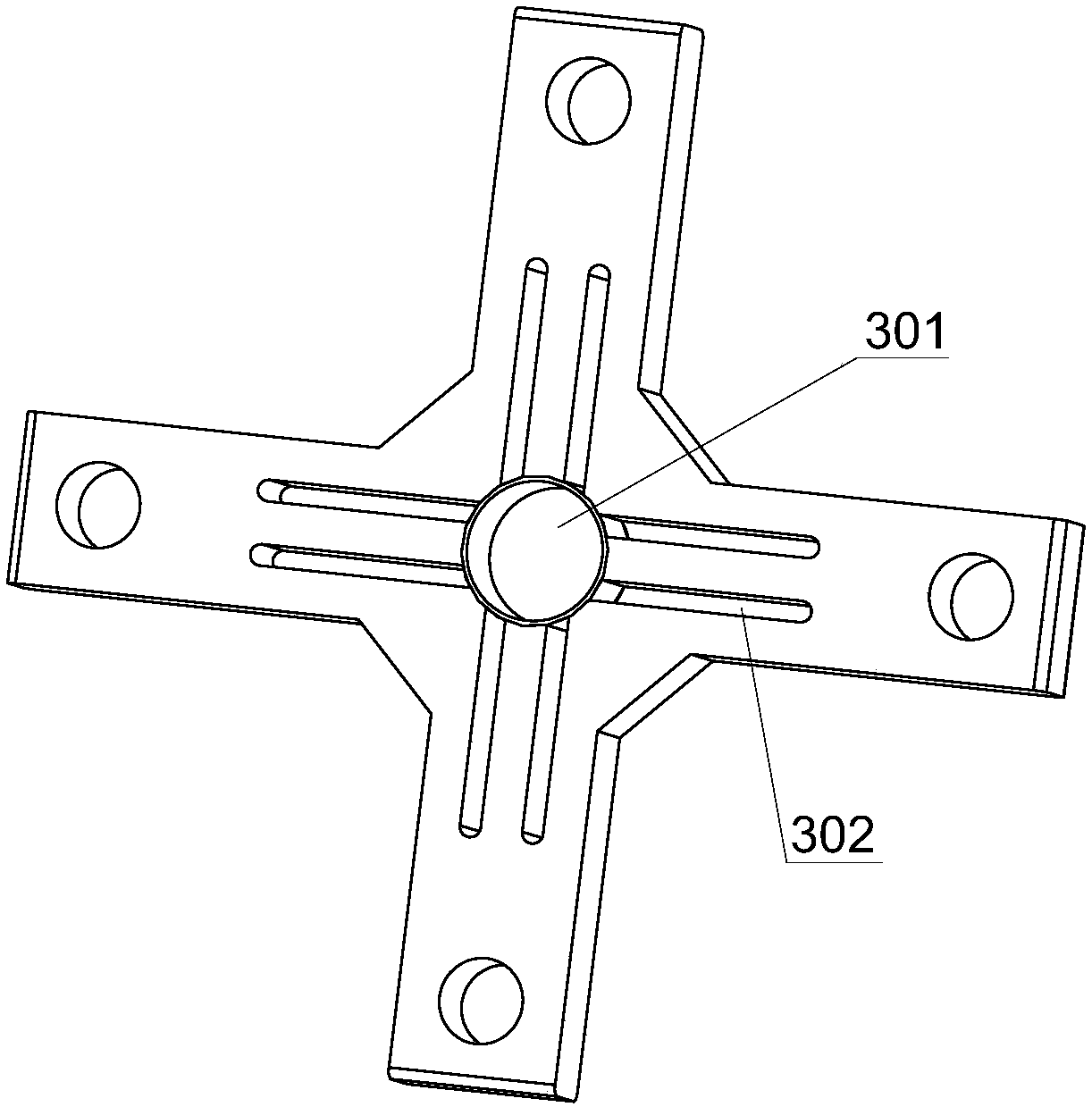

[0073] like Figure 1~2 As shown, three layers of cross-shaped beams 3 arranged in parallel up and down are suspended and fixed on the chassis base at the bottom of the rail vehicle through four vertically arranged vertical magnetic guide rods 2 that run through the four ends of the "ten" beam arms. 1, which constitutes the outer frame of the dynamic vibration absorber;

[0074] like Figure 4 , figure 2 As shown, the multi-layer slotted vibrator 7 is in the shape of a "string", including two layers of vibrators parallel to each other up and down and a connecting shaft 701 located in the center of the vibrator to connect and fix the two layers of vibrators as a whole. Each layer of vibrator is square. Located between two adjacent layers of cross-shaped beams 3, the multi-layer slotted vibrator 7 and the cross-shaped beam 3 form a five-layer superposition structure space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com