Method for electrical heating continuous coal pyrogenation coking and coking furnace thereof

A technology of electric heating and coal pyrolysis, which is applied in the field of coking, can solve the problems that do not conform to the sustainable development plan, the recovery process of coking products is complicated, and the coke cannot be produced continuously, so as to increase the heat transfer time, increase the output value, reduce generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

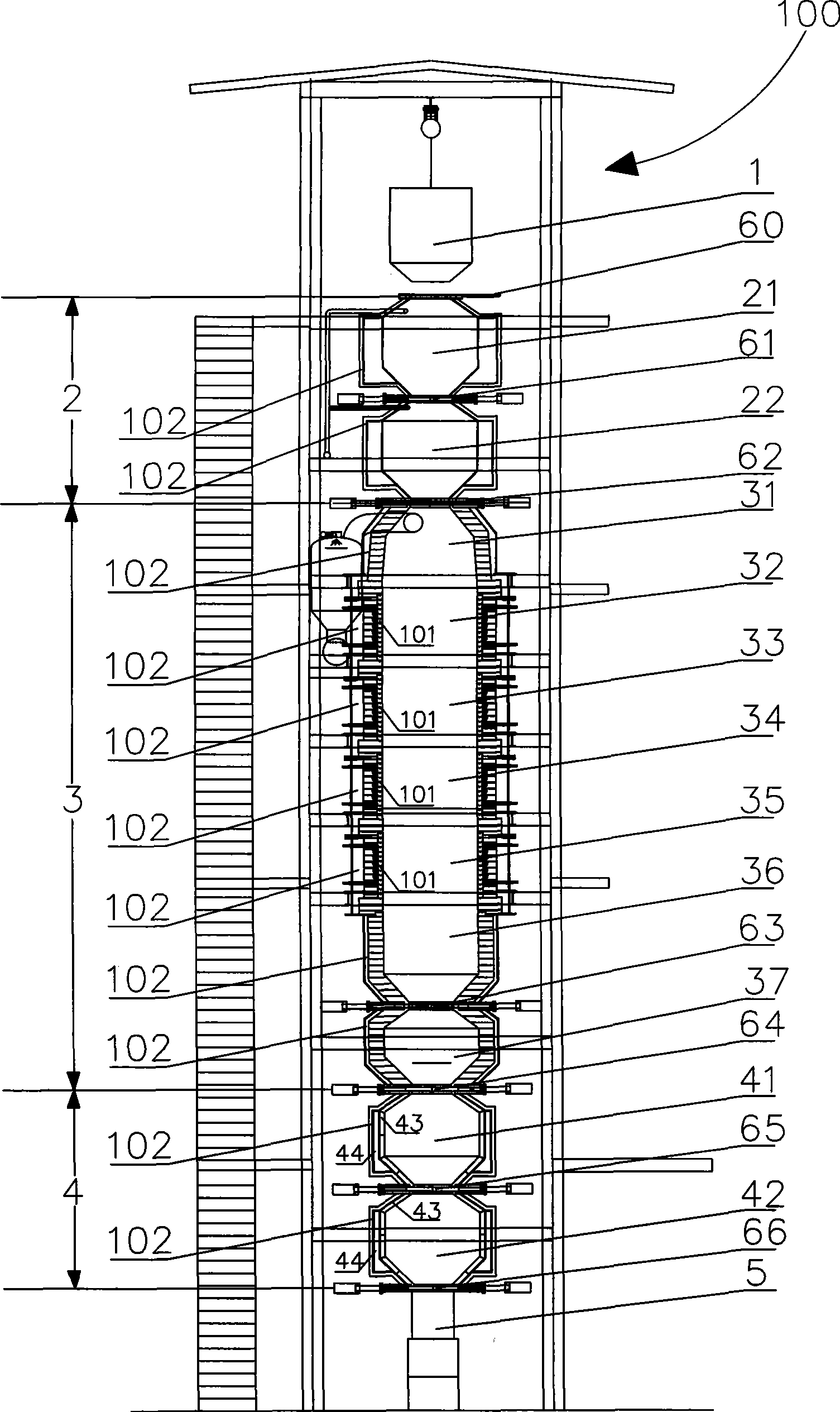

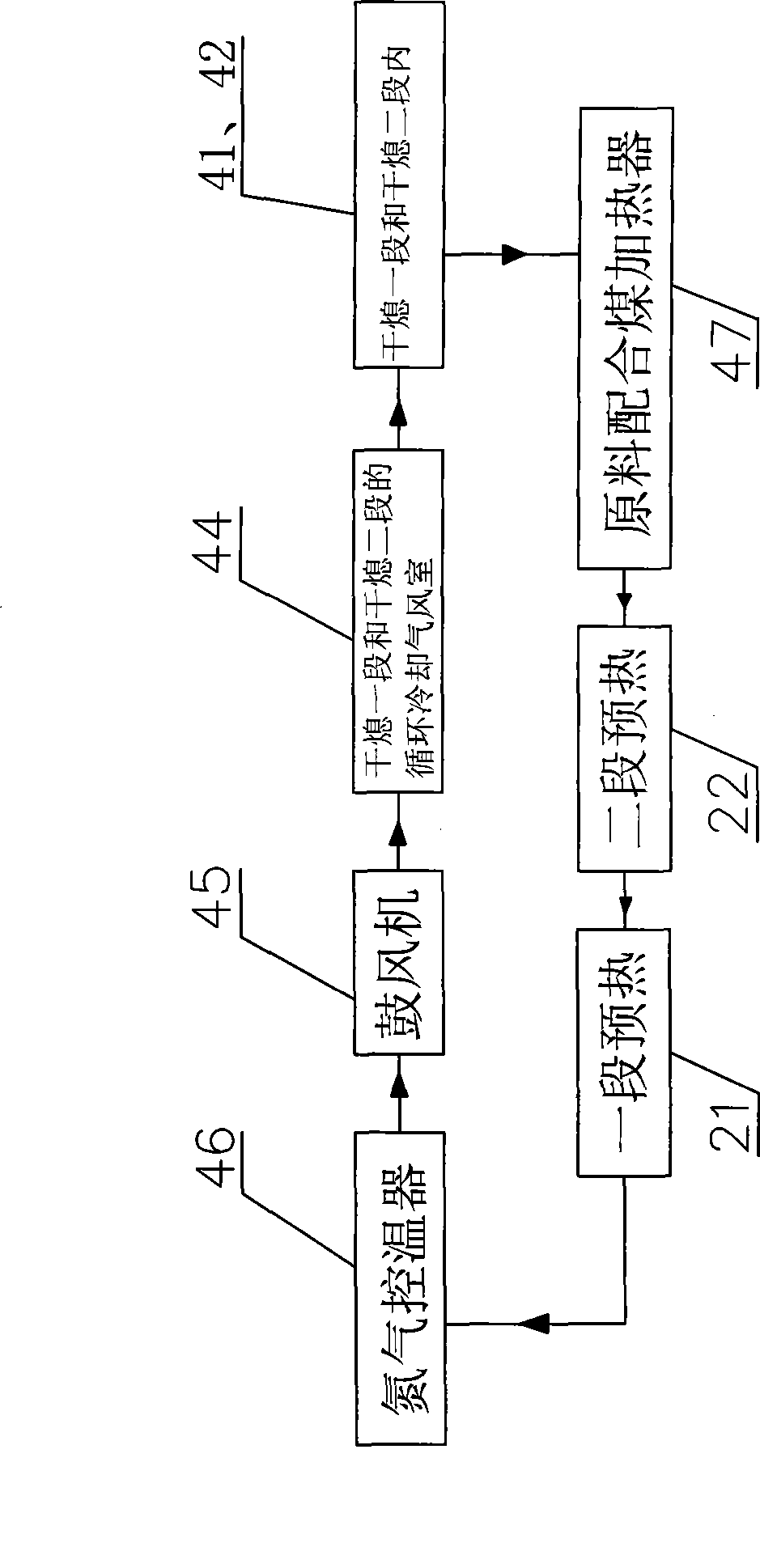

[0062] see figure 1 , 2 As shown, an electric heating continuous coal pyrolysis coking furnace includes a furnace body 100, and the furnace body is provided with a hopper 1, a preheating heating section 2, an electric heating main body section 3, a nitrogen circulation cooling section 4 and a coke discharge section 5 , a preheating section 2 is provided below the hopper 1, an electric heating main section 3 is provided below the preheating section 2, a nitrogen circulation cooling section 4 is provided below the electric heating main section 3, and the nitrogen circulation cooling A coke discharge section 5 is arranged below the section 4; the furnace lining heat conduction 101 part of the furnace body 100 adopts silicon carbide bricks. It is not easy to be damaged, has good thermal conductivity, and the maintenance cost of the coke oven is low; the external heat insulation material of the furnace body 100 is made of aluminum silicate cotton board 102, which has a good effect...

Embodiment 2

[0083] see figure 1 , 2 As shown, an electric heating continuous coal pyrolysis coking furnace includes a furnace body 100, and the furnace body is provided with a hopper 1, a preheating heating section 2, an electric heating main body section 3, a carbon dioxide circulation cooling section 4 and a coke discharge section 5 A preheating heating section 2 is arranged below the hopper 1, an electric heating main body section 3 is arranged under the preheating heating section 2, a carbon dioxide circulation cooling section 4 is arranged under the electric heating main section 3, and the carbon dioxide circulation cooling A coke discharge section 5 is arranged below the section 4; the furnace lining heat conduction 101 part of the furnace body 100 adopts silicon carbide bricks. It is not easy to be damaged, has good thermal conductivity, and the maintenance cost of the coke oven is low; the external heat insulation material of the furnace body 100 is made of aluminum silicate cott...

Embodiment 3

[0104] see figure 1 , 2 As shown, an electric heating continuous coal pyrolysis coking furnace includes a furnace body 100, and the furnace body is provided with a hopper 1, a preheating heating section 2, an electric heating main body section 3, a nitrogen circulation cooling section 4 and a coke discharge section 5 , a preheating section 2 is provided below the hopper 1, an electric heating main section 3 is provided below the preheating section 2, a nitrogen circulation cooling section 4 is provided below the electric heating main section 3, and the nitrogen circulation cooling A coke discharge section 5 is arranged below the section 4; the furnace lining heat conduction 101 part of the furnace body 100 adopts silicon carbide bricks. It is not easy to be damaged, has good thermal conductivity, and the maintenance cost of the coke oven is low; the external heat insulation material of the furnace body 100 is made of aluminum silicate cotton board 102, which has a good effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com