A flue gas heat exchanger

A technology for flue gas heat exchangers and heat exchange fins, which is applied in the direction of heat exchangers, indirect heat exchangers, heat exchanger types, etc., and can solve the problem of dust accumulation on heat exchange fins, affecting heat exchange efficiency, air intake and output Short circulation paths and other issues, to achieve the effect of improving efficiency, increasing heat exchange circulation time, and effectively filtering and collecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make those skilled in the art better understand the technical solution of the invention, the present invention will be further described in detail below with reference to the specific embodiments.

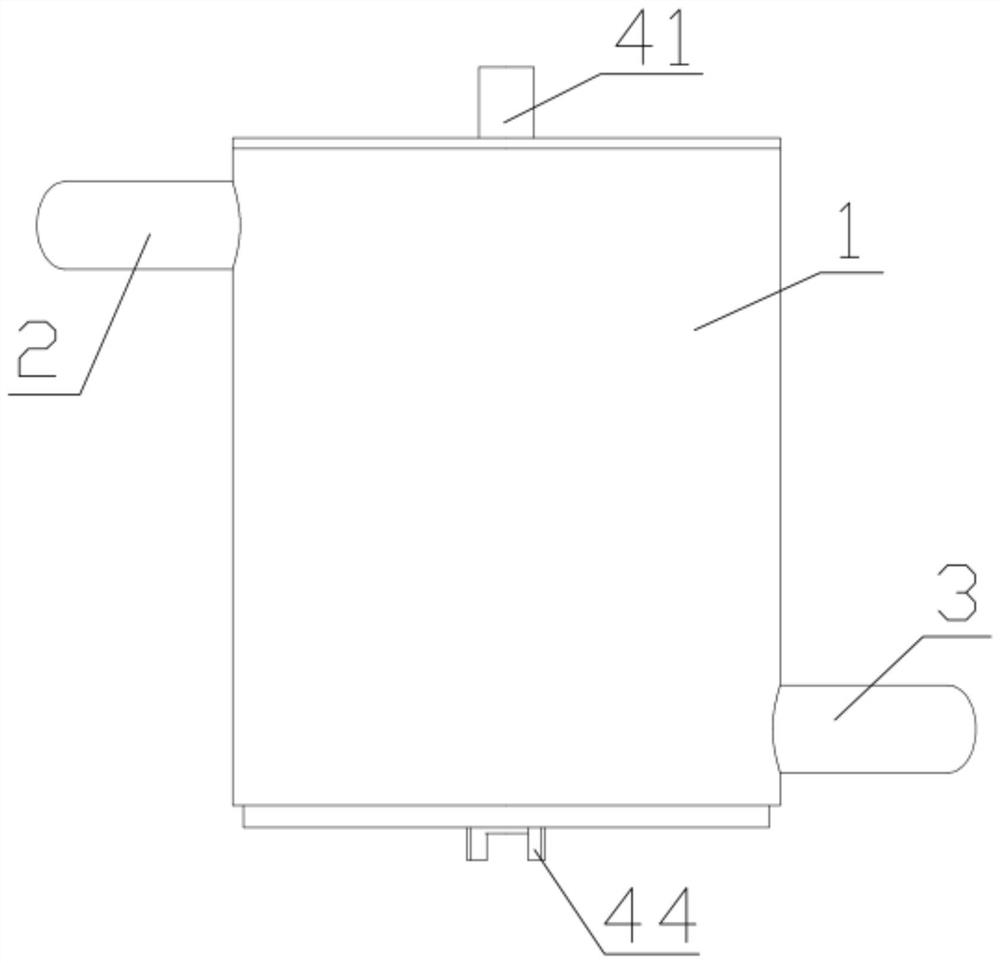

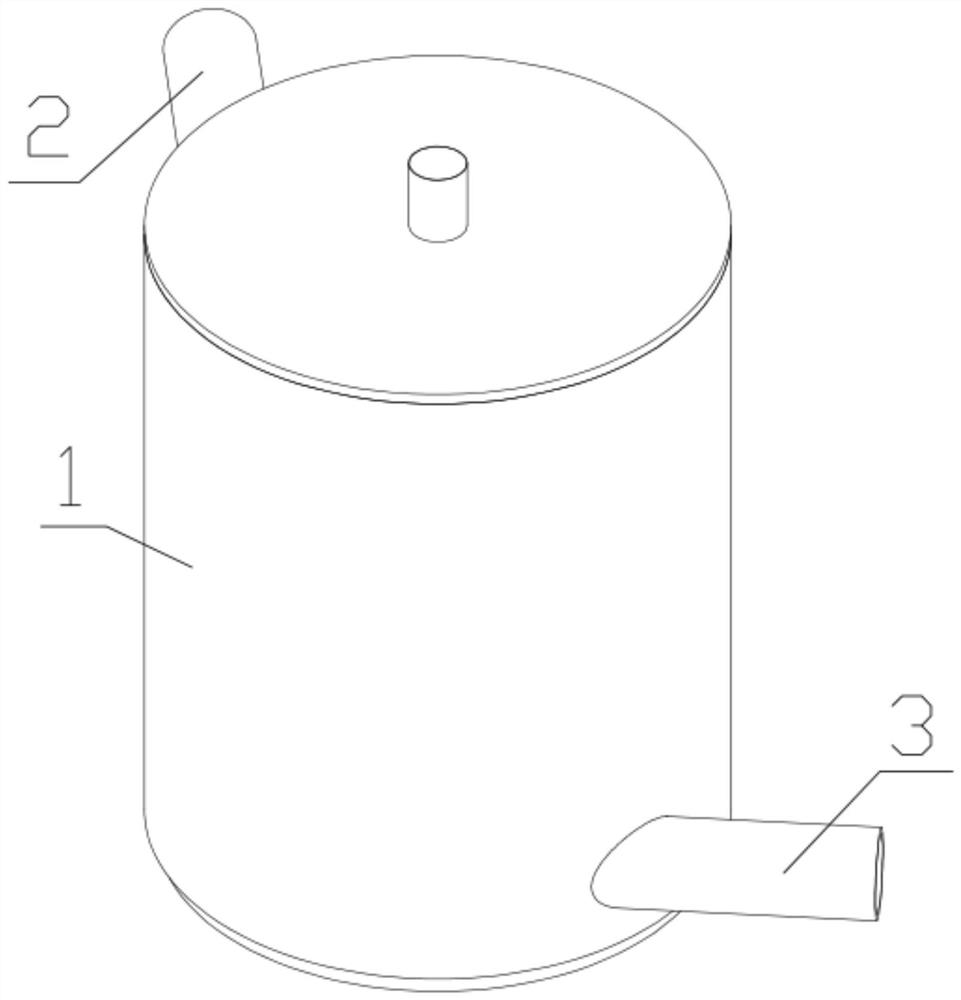

[0035] like Figure 1-8 As shown, the present invention first provides a flue gas heat exchanger, comprising a casing 1, an air inlet 2 and an air outlet 3 on the side of the casing 1, and a heat exchange component 4 in the casing 1;

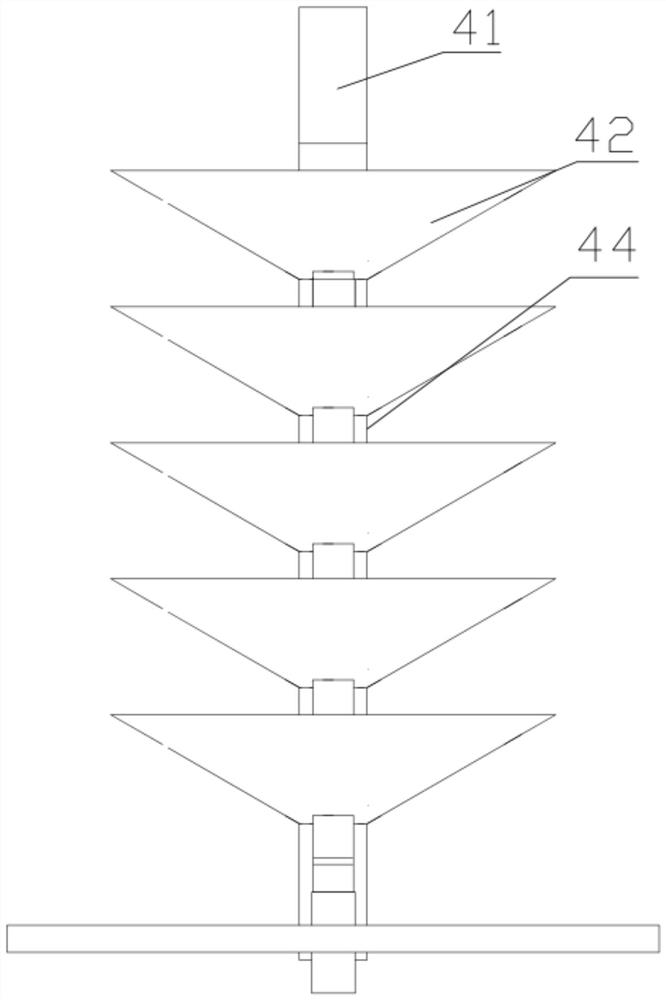

[0036] The heat exchange component 4 includes:

[0037] heat exchange columns 41 penetrating the upper and lower surfaces of the casing 1;

[0038] The heat exchange fins 42 arranged on the heat exchange column 41 in the circumferential direction;

[0039] an air guide fin 43 arranged in an arc shape on the heat exchange fin 42;

[0040] It is arranged on the outside of the heat exchange column 41 and penetrates the air extraction groove 44 of the heat exchange fin 42 from the bottom of the heat exchange fin 42;

[0041] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com