A low-temperature sludge drying device

A sludge drying and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of insufficiency of equipment, secondary pollution of exhaust gas, large energy consumption of evaporation, etc. Large contact area and improved drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is specifically described below by the embodiment, and the present embodiment is only used to further illustrate the present invention, but can not be interpreted as the restriction to the protection scope of the present invention, some non-compliances made by those skilled in the art based on the content of the above-mentioned present invention Essential improvements and adjustments also belong to the protection scope of the present invention.

[0040] combine Figure 1 to Figure 7 .

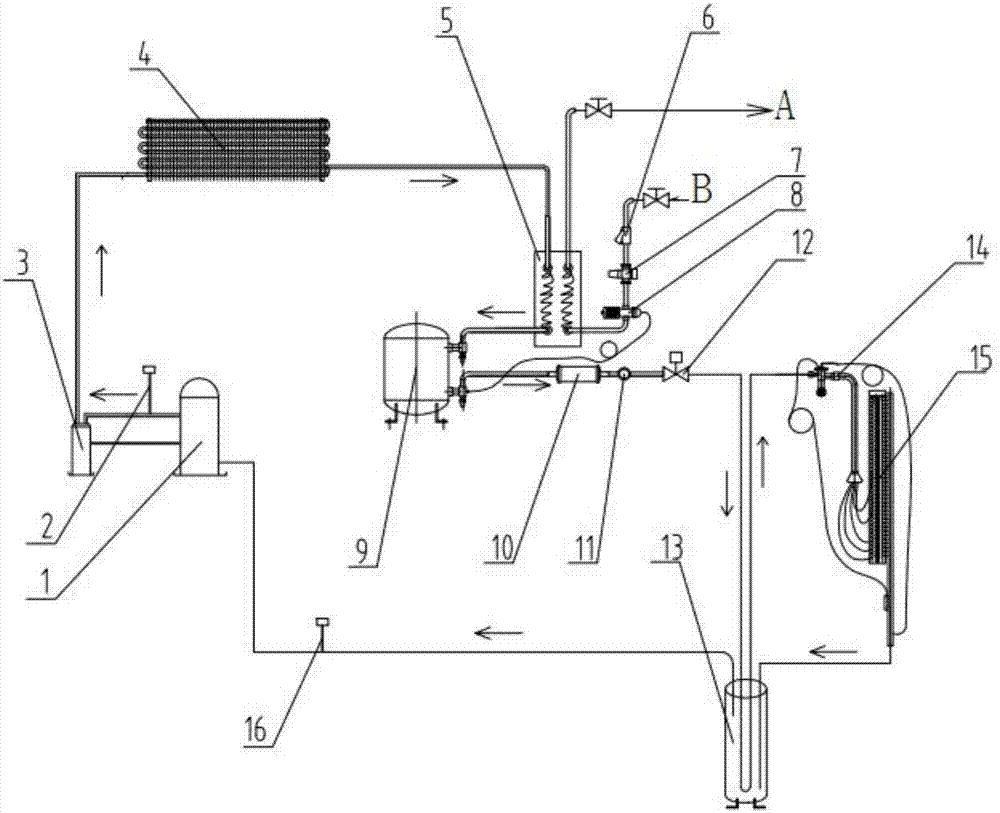

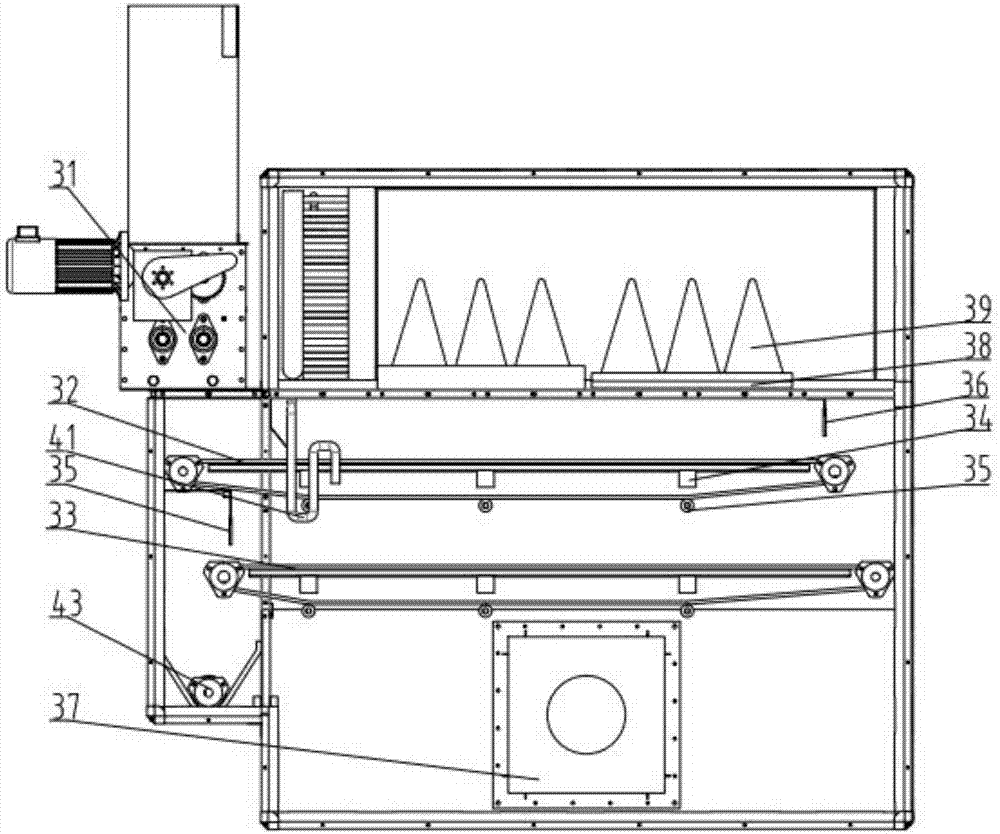

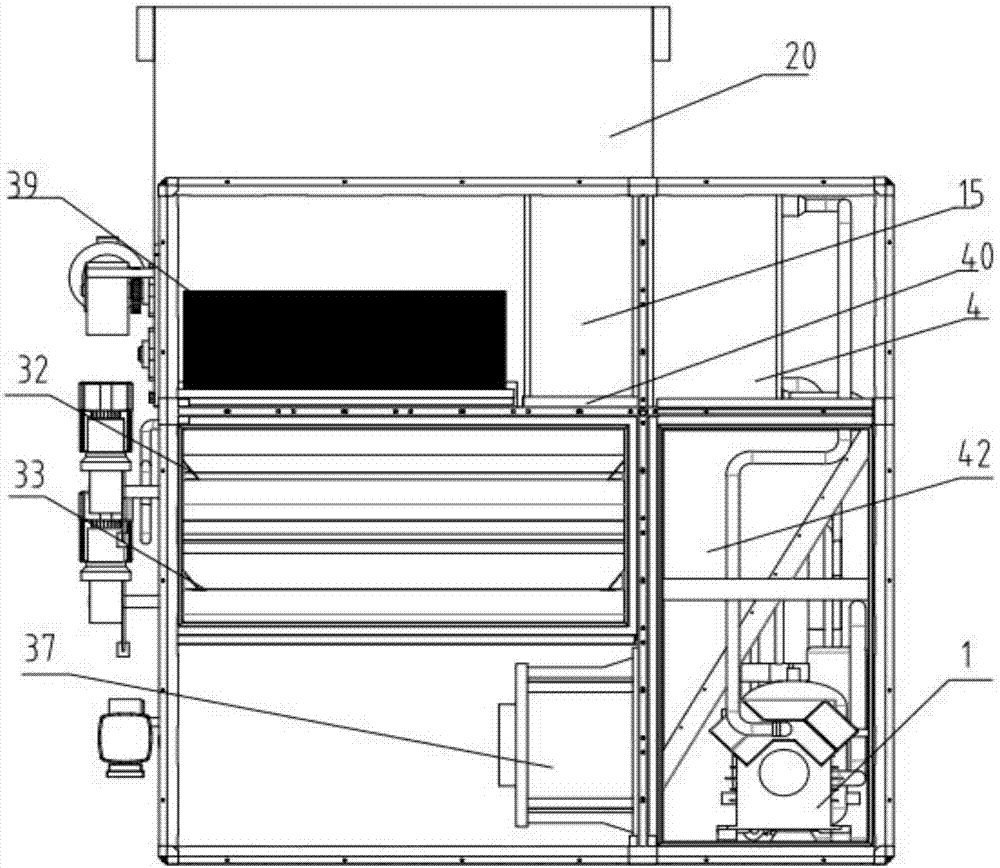

[0041]As shown in the figure, the sludge low-temperature drying device includes a sludge forming distributing machine 31, a sludge drying chamber containing two layers of conveying mesh belts, a heat pump system, a dry and hot air generating chamber, a fan 37 and a set at the sludge outlet. The sludge discharge screw 43; the sludge forming distributing machine 31 is arranged outside the sludge drying chamber and above the beginning end of the first conveying mesh b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com