Deposition reaction device for manufacturing low-loss optical fiber preform rod and pressure adjusting method

A technology of optical fiber preform and deposition reaction, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems such as adverse effects of light attenuation characteristics, and achieve the effects of less metal impurity content, uniform deposition, and low impurity absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

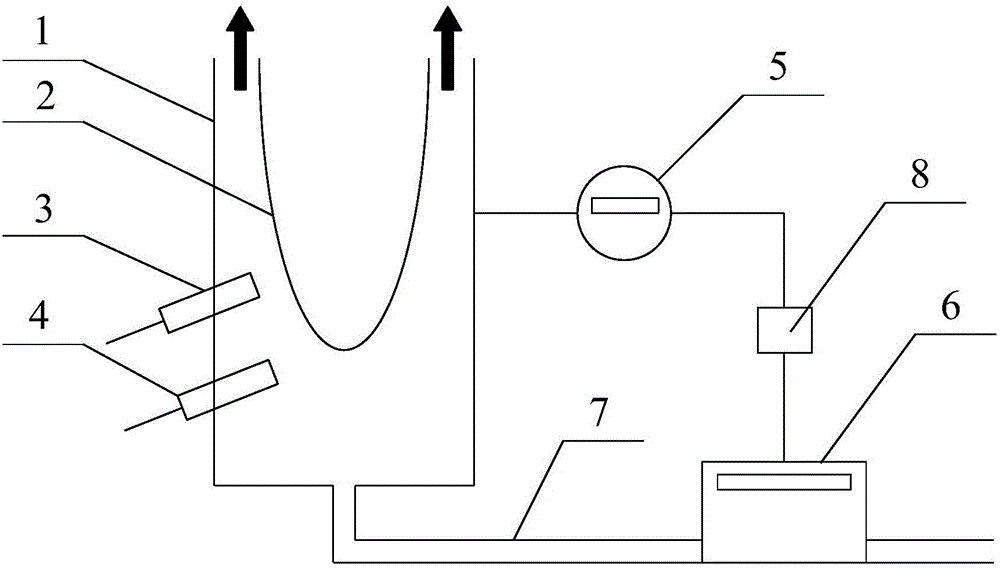

[0022] see figure 1 As shown, the embodiment of the present invention provides a deposition reaction device for preparing a low-loss optical fiber preform, the device includes a reaction vessel 1 with an open top, and the device also includes a pressure gauge 5, a controller 8, and the pressure gauge 5 and the reaction vessel 1. The containers 1 are connected, and a high-purity inert gas with a purity higher than 99% circulates inside the reaction container 1; a first torch 3 for preparing a cladding layer and a second torch 4 for preparing a core layer are arranged on one side of the reaction container 1, The second blowtorch 4 is positioned between the plane where the first blowtorch 3 and the bottom of the reaction vessel 1 are located; the bottom of the reaction vessel 1 is connected with a piping 7, and the piping 7 communicates with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com