Tungsten inert gas shielded welding torch capable of compressing electric arc

A tungsten electrode inert gas, tungsten electrode technology, applied in arc welding equipment, electrode clip cooling, electrode support devices, etc., can solve the problems of large electrode loss, poor cooling effect, random deviation between actual position and design position, etc. The effect of convenient replacement of electrodes, improved heat exchange efficiency, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

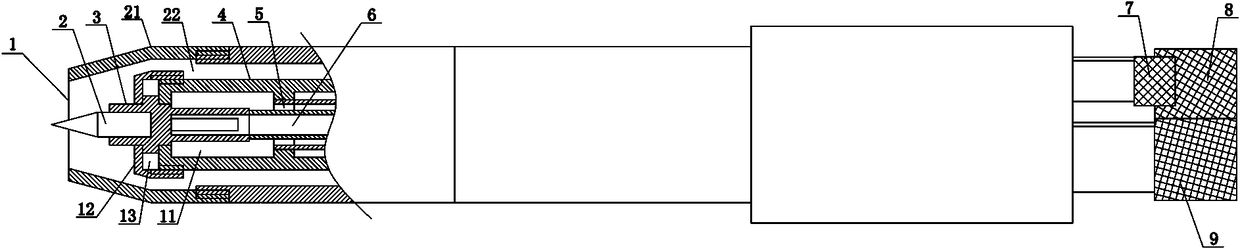

[0040] A tungsten inert gas shielded welding torch with a compressible arc, including a torch shell 21, and a coaxially arranged tungsten electrode 2, electrode handle 3, electrode holder 4, water inlet pipe 6, water outlet pipe 5, gas nozzle 1, gas Nozzle 1 is an annular nozzle, and the inert gas ejected from the annular nozzle can protect the electrode to work in an inert atmosphere during operation, so that the electrode will not be burned due to high temperature or slow down the electrode's burning at high temperature. It also includes an electrode cap 12 and a sealing gasket 13 for sealing between the electrode handle 3 and the electrode holder 4 . The welding torch shell 21 is also provided with a water inlet connector 9 , a water outlet connector 8 , an air inlet connector 7 , and a cable connector 10 . The electrode handle 3, the electrode seat 4, the water inlet pipe 6, the water outlet pipe 5, the electrode cap 12, and the sealing gasket 13 form a water cooling heat ...

Embodiment 2

[0050] A tungsten inert gas shielded welding torch with a compressible arc, including a torch shell 21, and a coaxially arranged tungsten electrode 2, electrode handle 3, electrode holder 4, water inlet pipe 6, water outlet pipe 5, gas nozzle 1, gas Nozzle 1 is an annular nozzle, and the inert gas ejected from the annular nozzle can protect the electrode to work in an inert atmosphere during operation, so that the electrode will not be burned due to high temperature or slow down the electrode's burning at high temperature. It also includes an electrode cap 12 and a sealing gasket 13 for sealing between the electrode handle 3 and the electrode holder 4 . The welding torch shell 21 is also provided with a water inlet connector 9 , a water outlet connector 8 , an air inlet connector 7 , and a cable connector 10 . The electrode handle 3, the electrode seat 4, the water inlet pipe 6, the water outlet pipe 5, the electrode cap 12, and the sealing gasket 13 form a water cooling heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com