Generator of engine

An engine and generator technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of high temperature engine oil temperature, wind resistance, poor ventilation and heat dissipation effect, etc., to achieve good ventilation and heat dissipation effect, flow direction rules are The effect of reasonable sequence and air duct structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

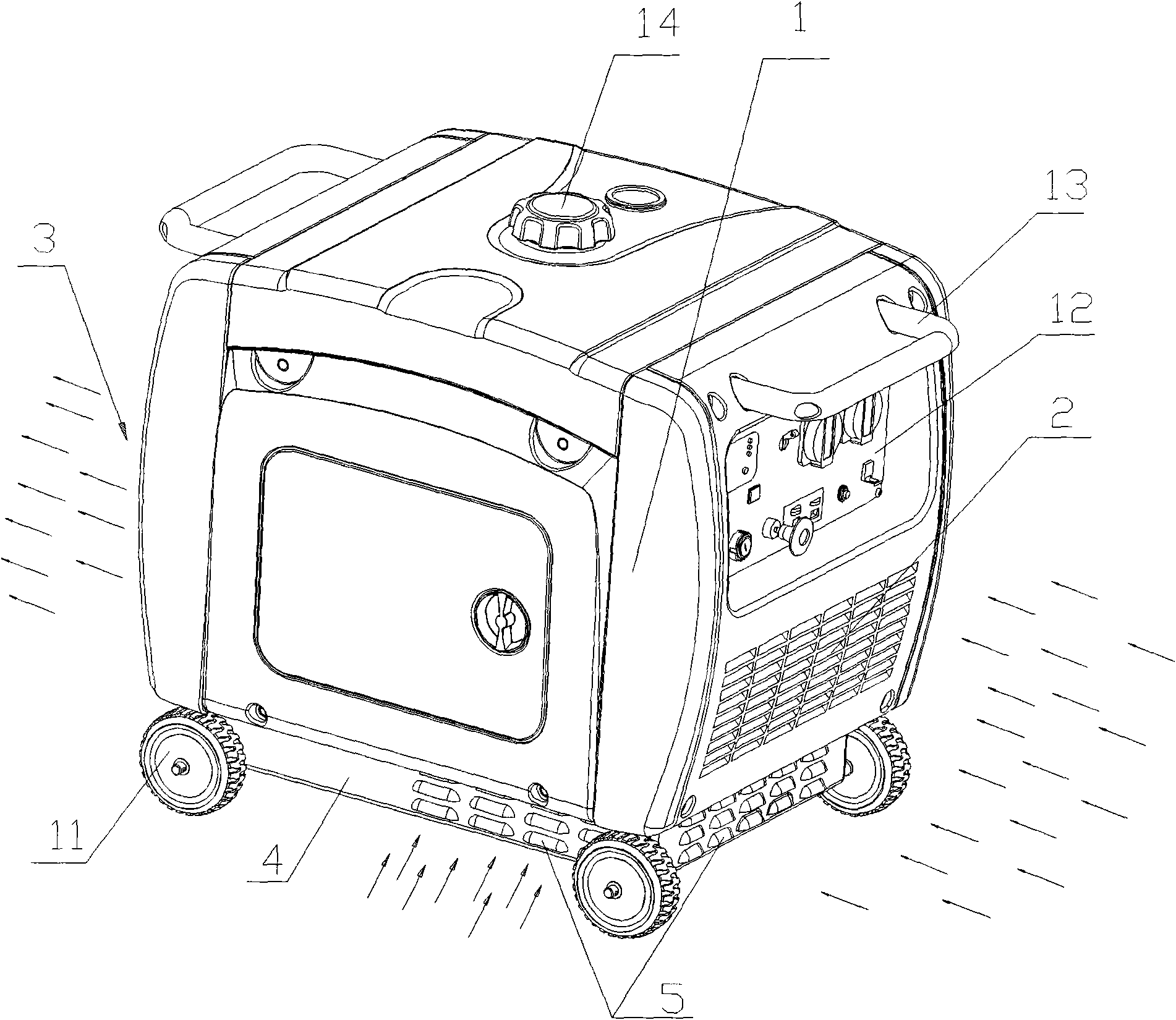

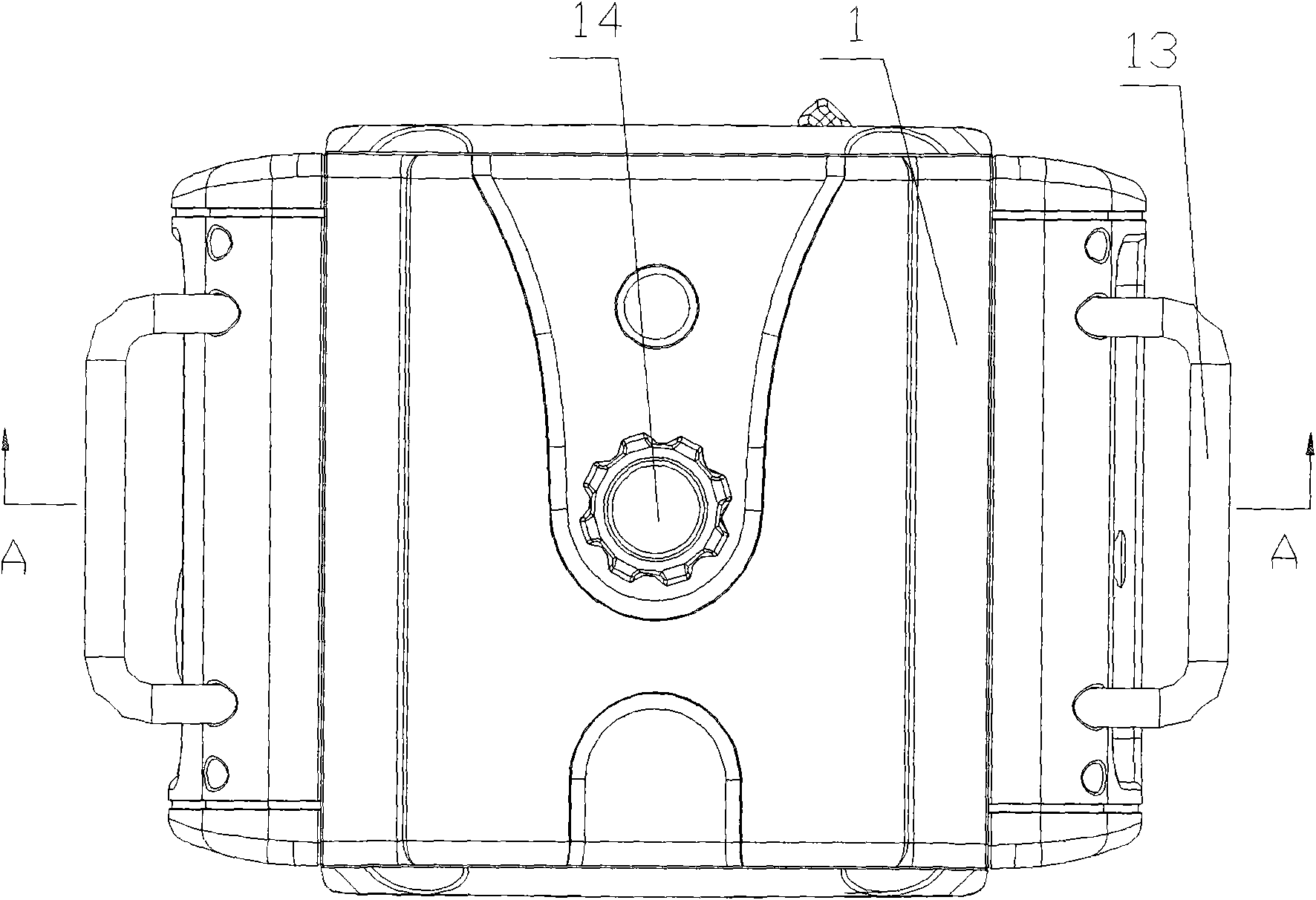

[0024] like figure 1 , figure 2 As shown, the gasoline engine generator in the embodiment of the present invention adopts a closed casing 1, wherein two opposite sides of the casing 1 are respectively provided with a louvered air inlet 2 and an air outlet 3, and the side plates of the frame 4 are also provided with Ventilation port 5 of louver type is arranged, and wheel 11 is equipped with at four corners of frame 4 bottoms, and the side of shell 1 is provided with control panel 12, and label 13 is handle pipe, and 14 is fuel cap.

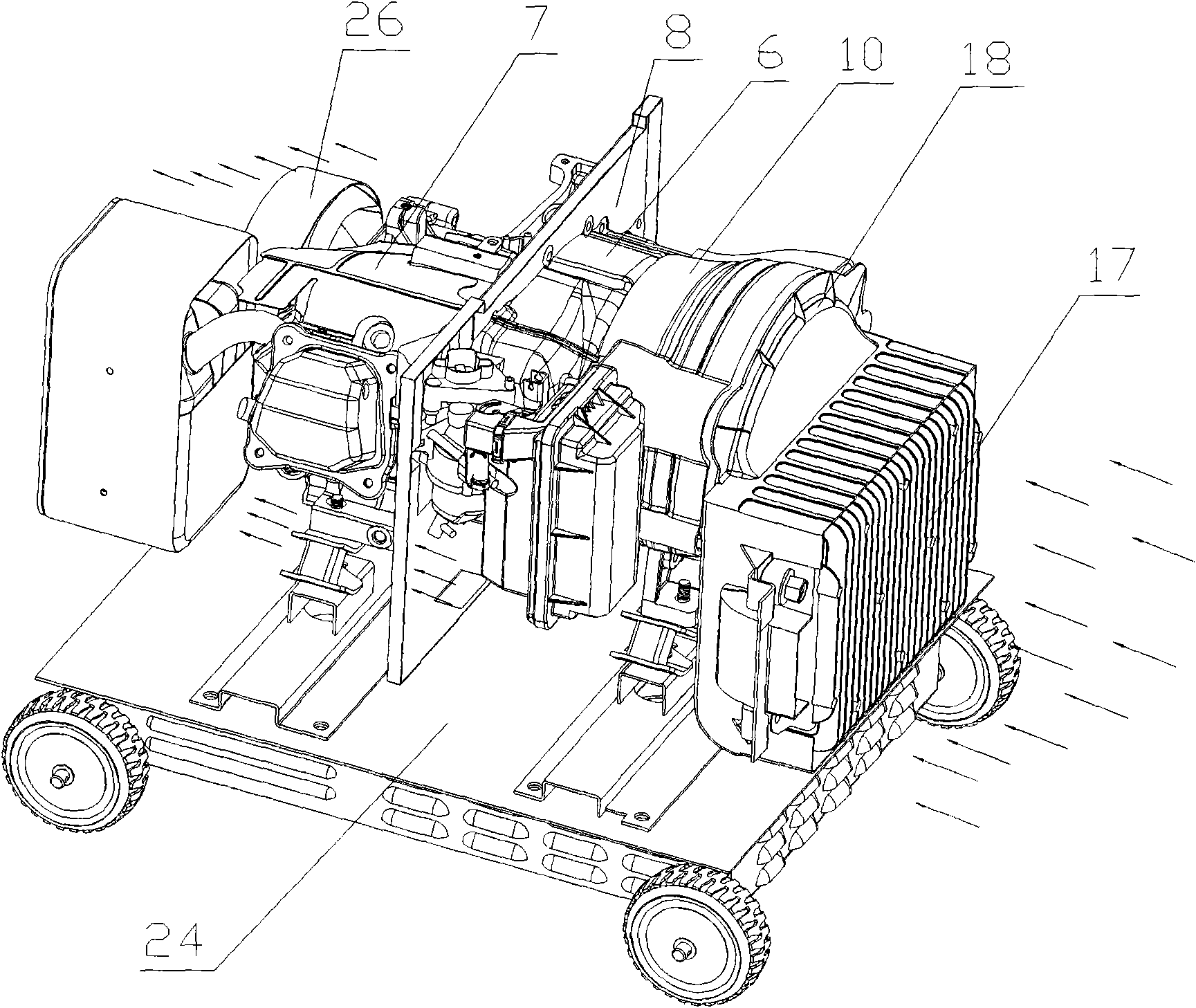

[0025] like image 3 , Figure 4 As shown, the engine is equipped with a fan cover 6 and an air guide cover 7, the fan cover 6 and the air guide cover 7 are respectively located on both sides of the hot and cold zone partition plate 8, the fan cover 6 covers the engine flywheel and the fan, and the air guide Cover 7 is posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com