Fume treatment unit for selective laser melting

A laser melting and processing device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of smoke and dust removal, achieve effective processing, convenient use, and high automatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

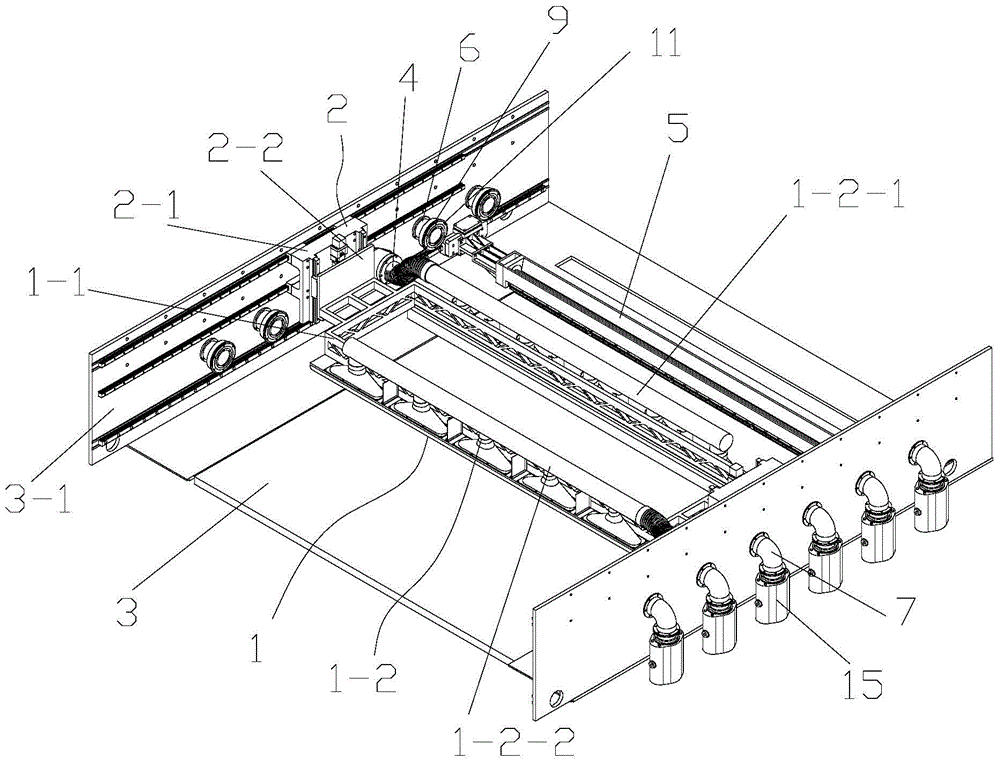

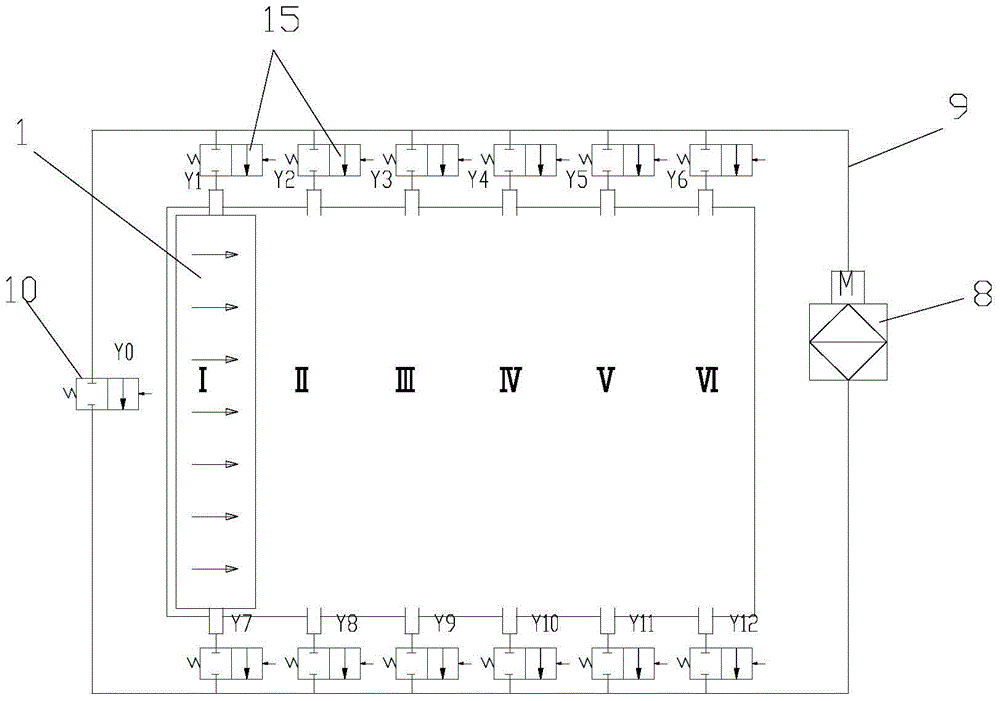

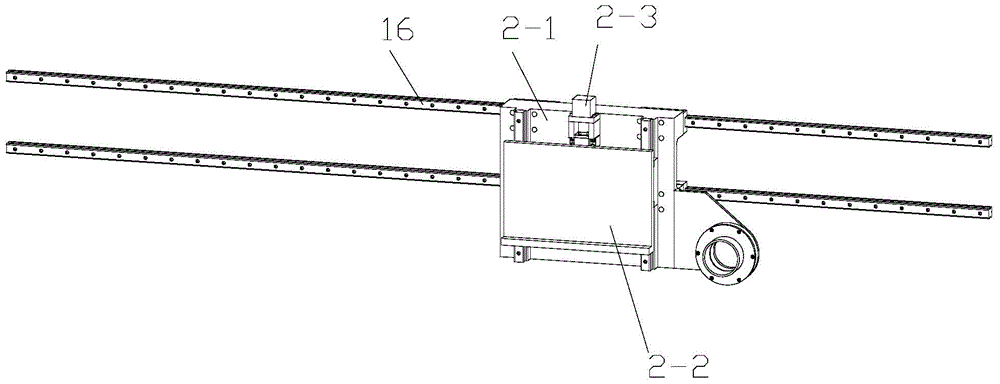

[0029] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic diagram of the principle of the gas circulation system in the present invention, image 3 It is a structural schematic diagram of the hanging plate driving assembly in the present invention, Figure 4 It is a structural schematic diagram of the pipe joint unit in the present invention, Figure 5 It is a schematic diagram of the variable-diameter airway structure in the present invention, as shown in the figure: the fume treatment device for selective laser melting in this embodiment includes a blowing and smoking device 1 and a laser scanning unit for driving the blowing and smoking device 1 . Synchronously move to the drive assembly 2 of each station;

[0030] The blowing and smoking device 1 includes a frame body 1-1, a gas convection unit 1-2 which is arranged on the frame body 1-1 and is used to form convection gas and is arranged on the processing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com