Mechanism for flattening surface of door body during refrigeration of refrigerator

A technology with a flat surface and a door body, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problem of reducing the airtightness between the refrigerator cabinet and the door body, reducing the cooling effect of the refrigerator, and the air-conditioning outside the refrigerator. Leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

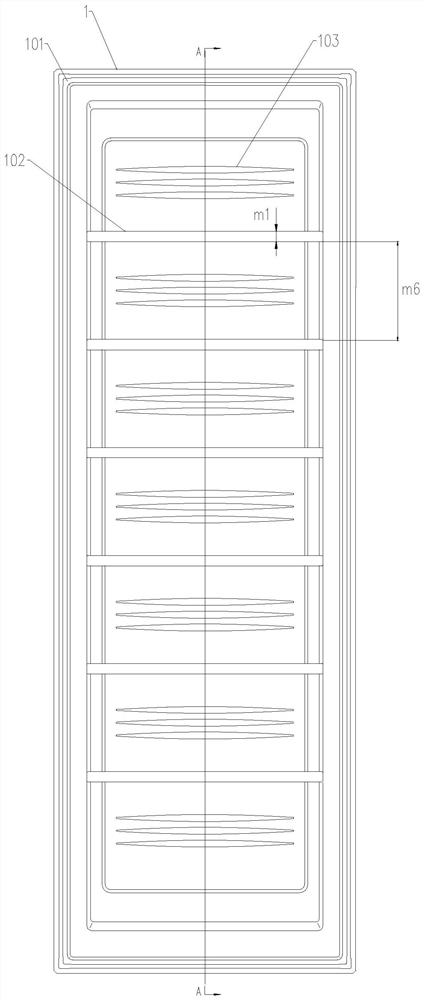

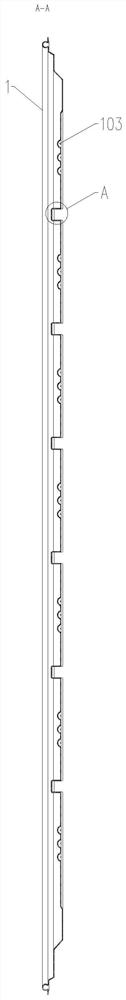

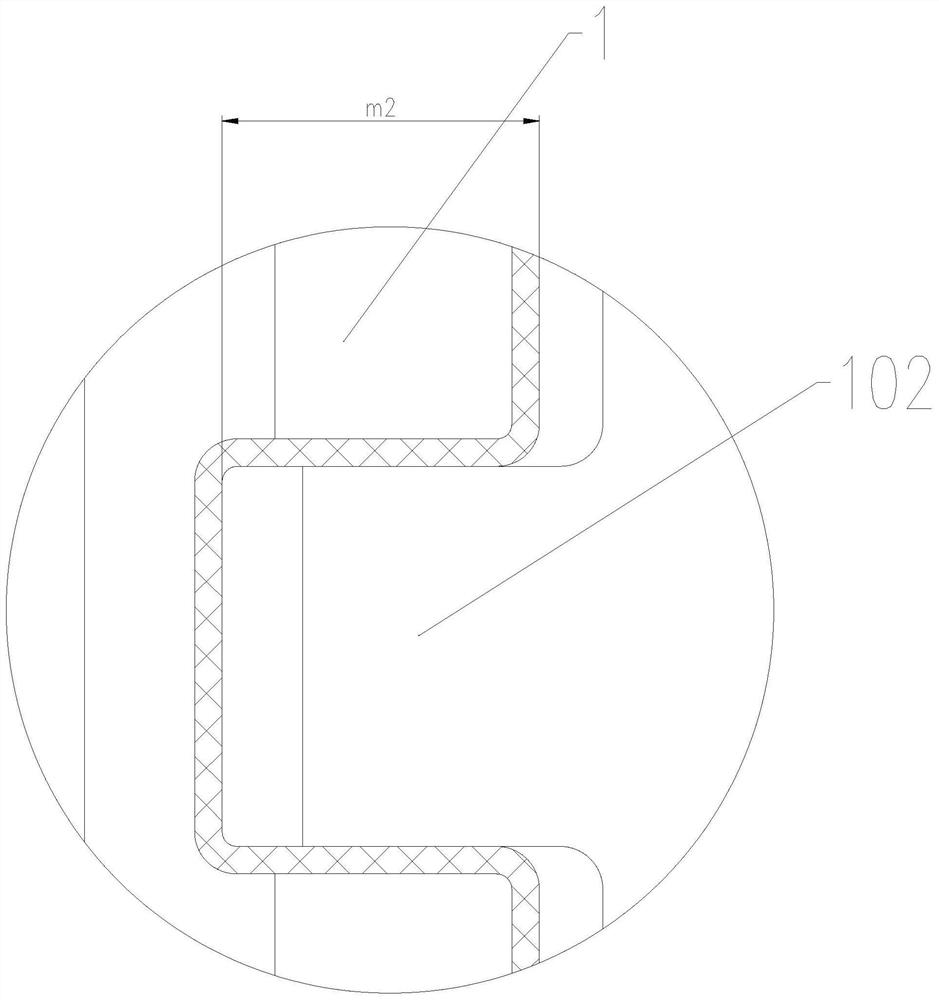

[0032] see Figure 1-10 , in the embodiment of the present invention, a mechanism for smoothing the surface of the door body when the refrigerator is refrigerated, comprising an inner tank body 1 and a door shell 5, the upper end of the door shell 5 is provided with an upper door bar 7, and the lower end of the door shell 5 is provided with There is a lower door strip 6, the inner container body 1 is clamped in the door shell 5, the upper door strip 7 is fixedly connected with the inner container body 1 and the lower door strip 6 and the inner container body 1 by a buckle 2, so The end of the upper door strip 7 far away from the liner body 1 is clamped in the door shell 5, the end of the lower door strip 6 away from the liner body 1 is clamped in the door shell 5, and one side of the liner body 1 is provided There are several first reinforcement grooves 102 and second reinforcement grooves 103 , and the two ends of the door shell 5 and the side close to the inner container bod...

Embodiment 2

[0043] see Figure 11 and Figure 12 The difference between this embodiment and Embodiment 1 is that it also includes a cabinet body 3 that is sealingly matched with the inner tank body 1, and the side of the inner tank body 1 close to the cabinet body 3 is provided with a fourth sealing groove 101, so The side of the cabinet body 3 close to the liner body 1 is provided with a sealing protrusion 302 inserted into the fourth sealing groove 101 . By setting the fourth sealing groove 101 for the sealing protrusion 302 to insert near the side of the cabinet body 3 of the inner container body 1, the sealing between the inner container body 1 and the cabinet body 3 can be guaranteed like this.

[0044]In this embodiment, the cabinet body 3 is provided with a first sealing groove 301 on a side close to the liner body 1 . By setting the first sealing groove 301 on the side of the cabinet body 3 close to the inner container, the first sealing groove 301 can be used to effectively imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com