Weaving method of multilayer three-dimensional fabric

A three-dimensional and three-dimensional fabric technology, which is applied in fabrics, textiles, papermaking, textiles, etc., can solve the problems of large beating strokes, reduce the number of frictions, reduce the rate of broken ends, and improve operating efficiency and fabric quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

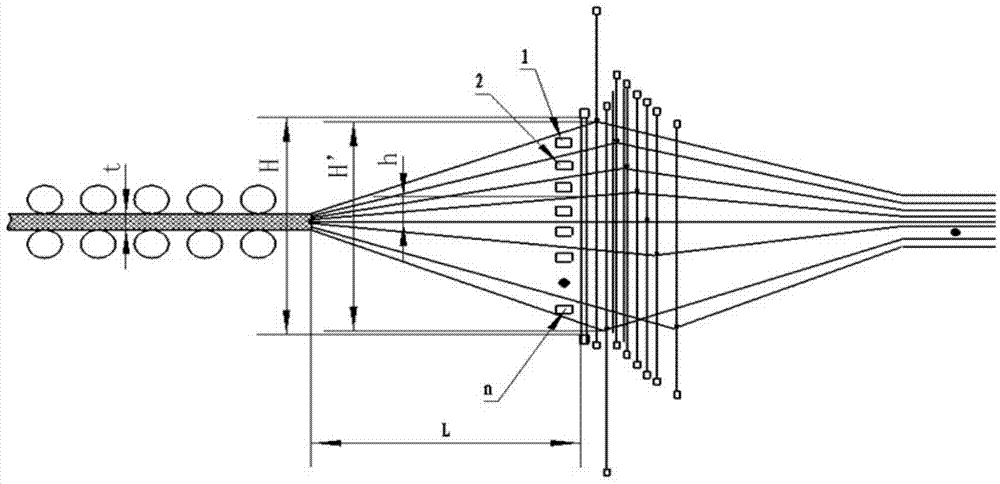

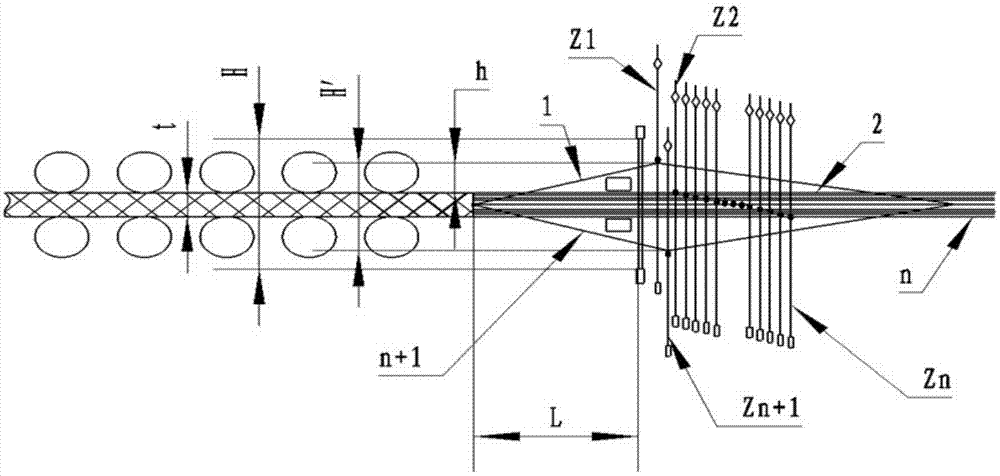

[0056] like figure 2 As shown, the present invention uses the three-position double shed opening of the warp yarn and the double weft insertion layer by layer as the means, and by changing the warp passing mode and the law of shedding and weft insertion, the maximum distance H between the uppermost warp yarn and the lowermost warp yarn when shedding is ′=2h+t<<n×h, which can greatly increase the number of weaving layers of various three-dimensional fabrics.

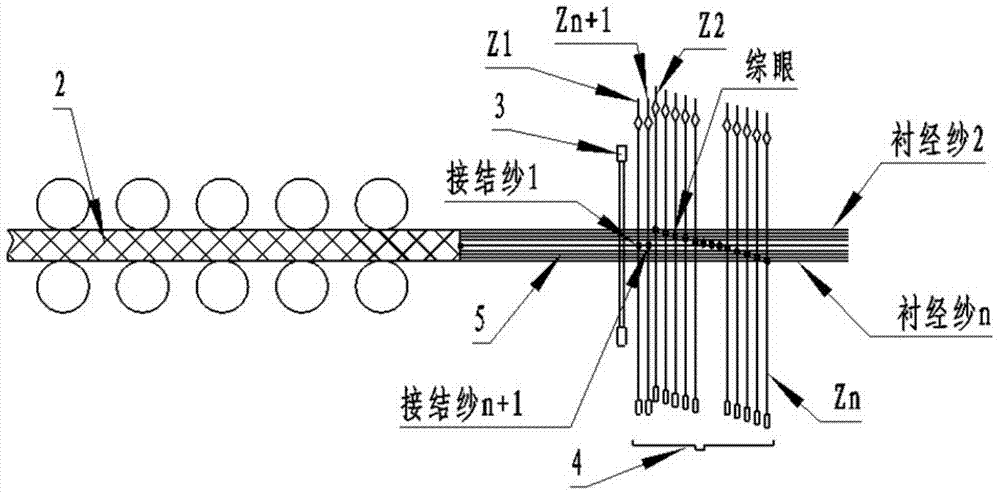

[0057] Orthogonal fabric warp threading method is attached image 3 As shown, there are multi-layer three-dimensional fabric 2, reed 3, heddle 4, warp yarn 5 as shown in the figure. The heddle 4 is provided with a heald eye. The numbers of the heddles are arranged as Z1, Zn+1, Z2, Z3...Zn-1, Zn, which are respectively used to drive the warp yarns 1, n+1, 2, 3,...n-1 arranged in sequence from top to bottom , n. The warp yarn 5 is divided into a binding yarn and a lining warp yarn. The binding yarn is a warp yarn conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com