High speed mixer

A mixer, high-speed technology, applied in the direction of mixers, mixer accessories, dissolution, etc., can solve the problem of limited mixing speed, to achieve the effect of prolonging the service life, increasing the mixing speed, and being easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

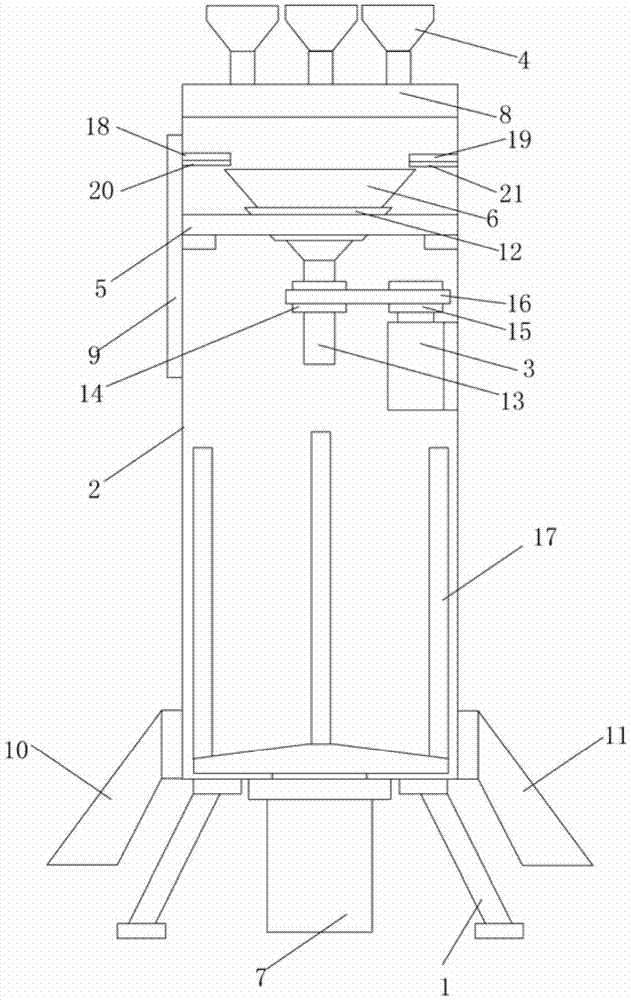

[0020] Such as figure 1 As shown, a high-speed mixer includes a frame 1, a tank body 2, a first motor 3, a feed hopper 4, a fixed frame 5, a premix hopper 6, and a second motor 7, and the tank body 2 is fixed on the frame 1, the top of the tank body 2 is provided with a tank cover 8, one side of the tank body 2 is provided with an observation window 9, one side of the bottom of the tank body 2 is provided with a first discharge port 10 and the other side is provided with a second Outlet 11, the quantity of feeding hopper 4 is more than two and it is fixed on the top of tank cover 8, and fixing frame 5 is fixed on the top of tank body 2, and premixing hopper 6 is arranged on fixing frame 5, and premixing hopper 6. Anti-friction pads 12 are arranged between the fixed frames 5, the bottom of the premix hopper 6 is connected with a feeding pipe 13, the outside of the feeding pipe 13 is fixed with a first runner 14, and the first motor 3 is fixed on the tank body 2 and it is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com