Combustor structure of methane fan heater

A technology of burners and heaters, which is applied in the field of heat exchange, can solve the problems of being unable to adapt to the use of large-scale and large-space heating heaters, and small fire heads, so as to achieve the effects of saving high-quality energy, enhancing the mixing effect, and enhancing the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

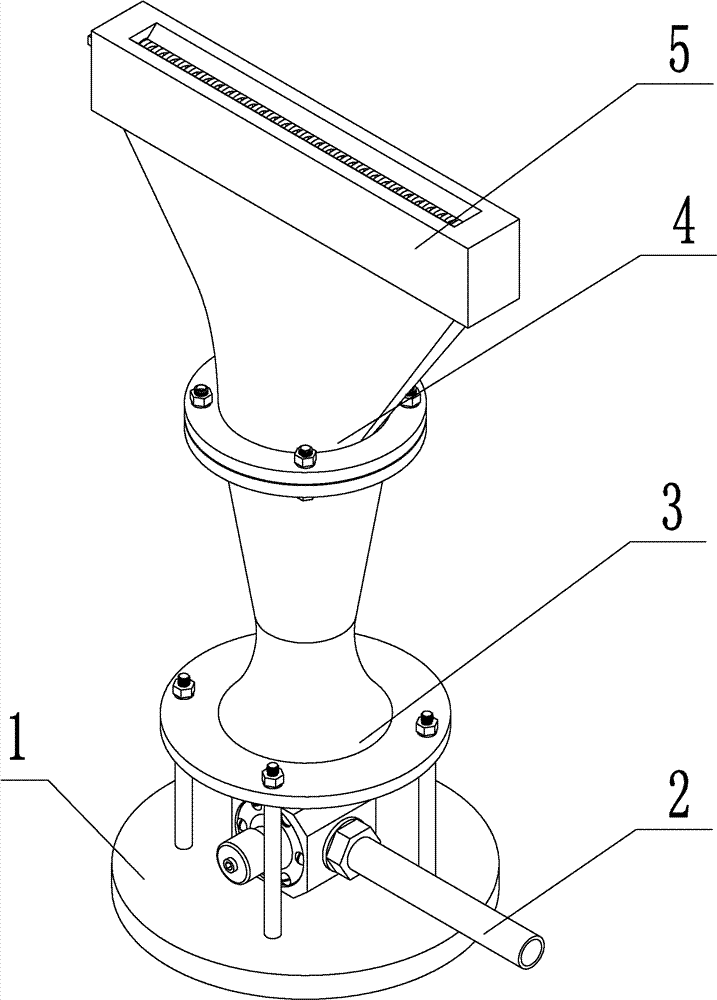

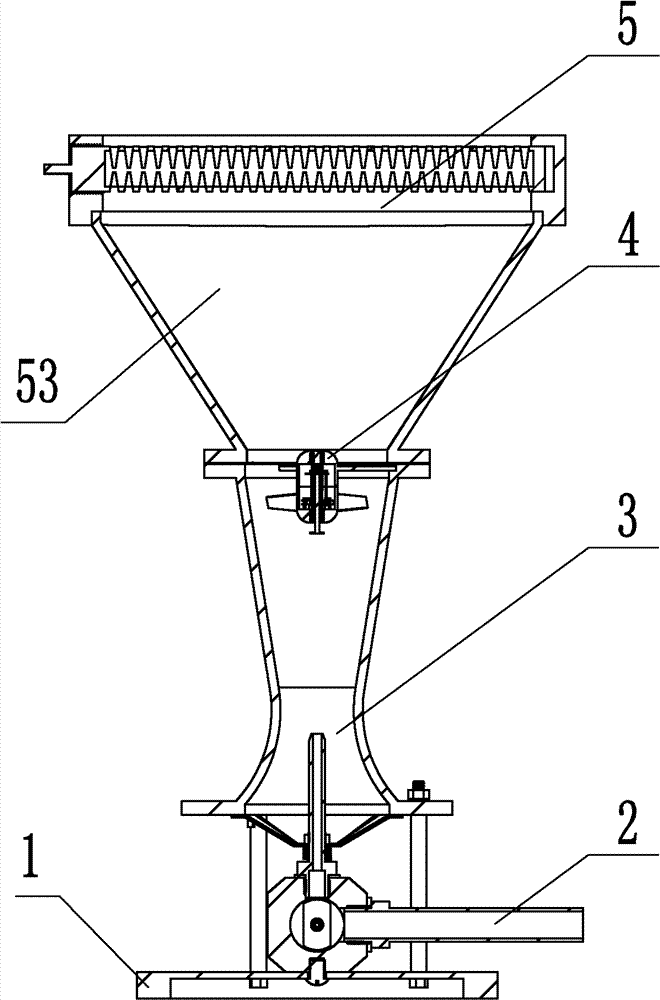

[0053] The details of the present invention will be further described below in conjunction with the accompanying drawings.

[0054] A burner structure for a biogas heater, in which a biogas nozzle device 2, a venturi tube 3, a premixer 4 and a biogas burner port 5 on the top are sequentially arranged on a base 1 from bottom to top,

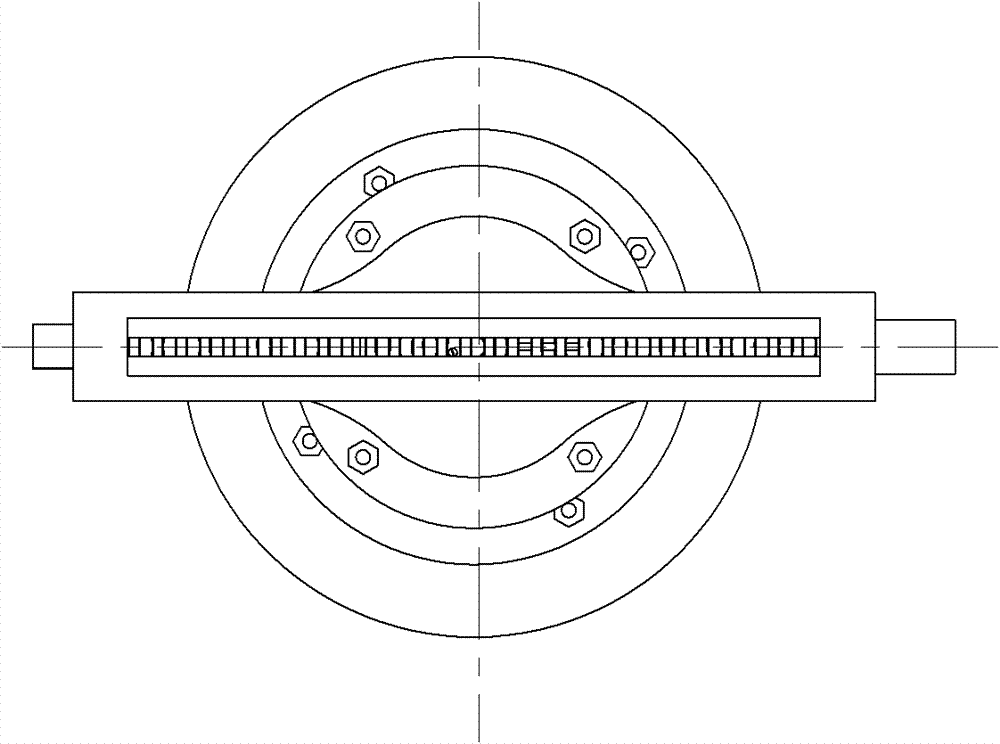

[0055] The venturi tube 3 is arranged vertically, the small bell mouth at the bottom of the venturi tube 3 is installed and covered on the upper surface of the nozzle base 25, and the big bell mouth at the top of the venturi tube 3 is docked with the air inlet of the biogas burner mouth 5 ;

[0056] The lower part of the biogas burner port 5 is a diffuser section 53 composed of a circular air inlet and a rectangular gas outlet, and the upper part is a biogas outlet composed of an oblong tubular burner outlet inner part 51 inserted into a long rectangular burner outlet outer part 52. Combination of burner outlet;

[0057] A pre-mixer 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com