Premixer structure of marsh gas fan heater burner

A premixer and heater technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of small burners, inability to adapt to the use of heating fans in large areas and large spaces, etc., to achieve enhanced mixing effect, The effect of saving high-quality energy and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The details of the present invention will be further described below in conjunction with the drawings.

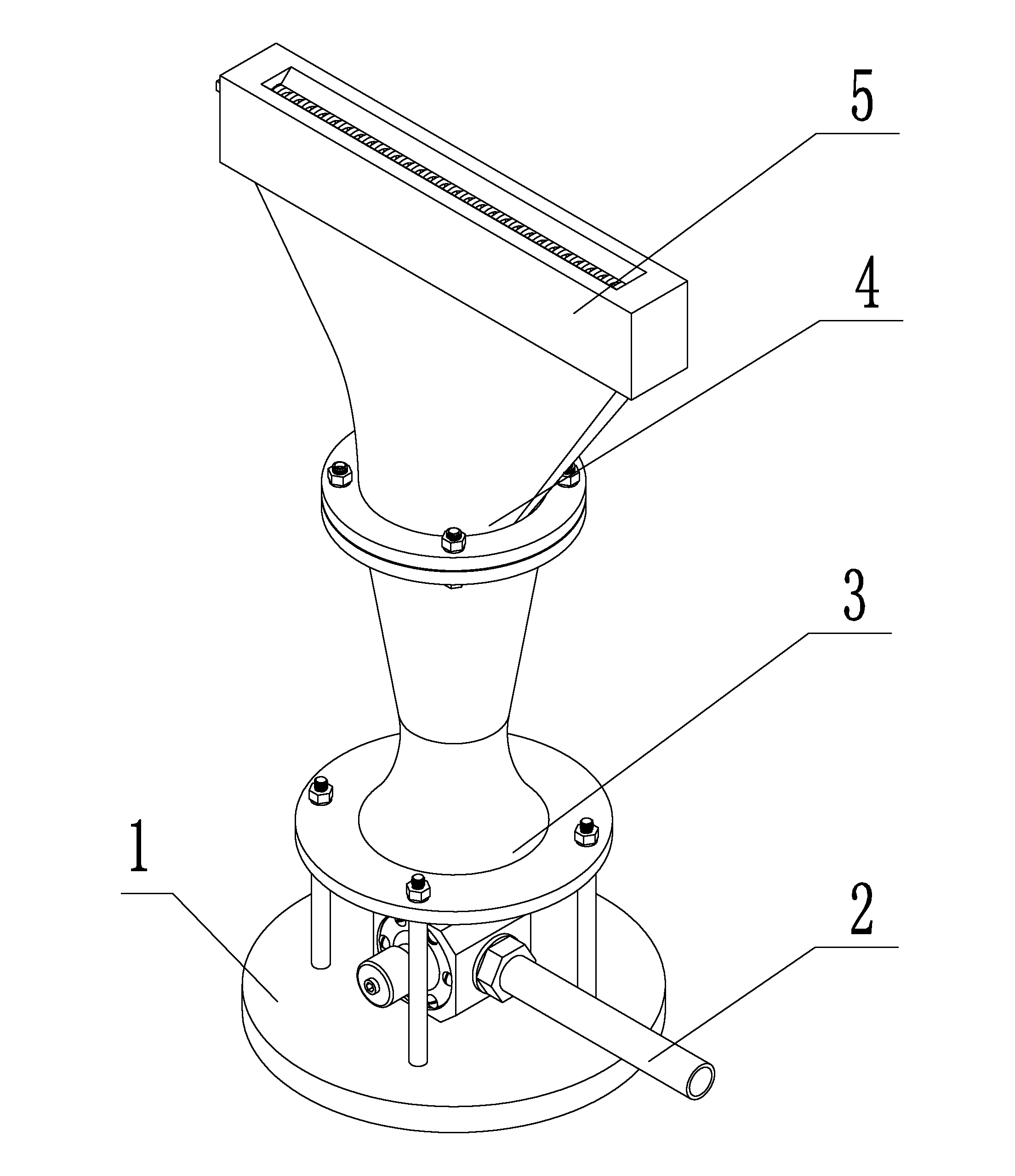

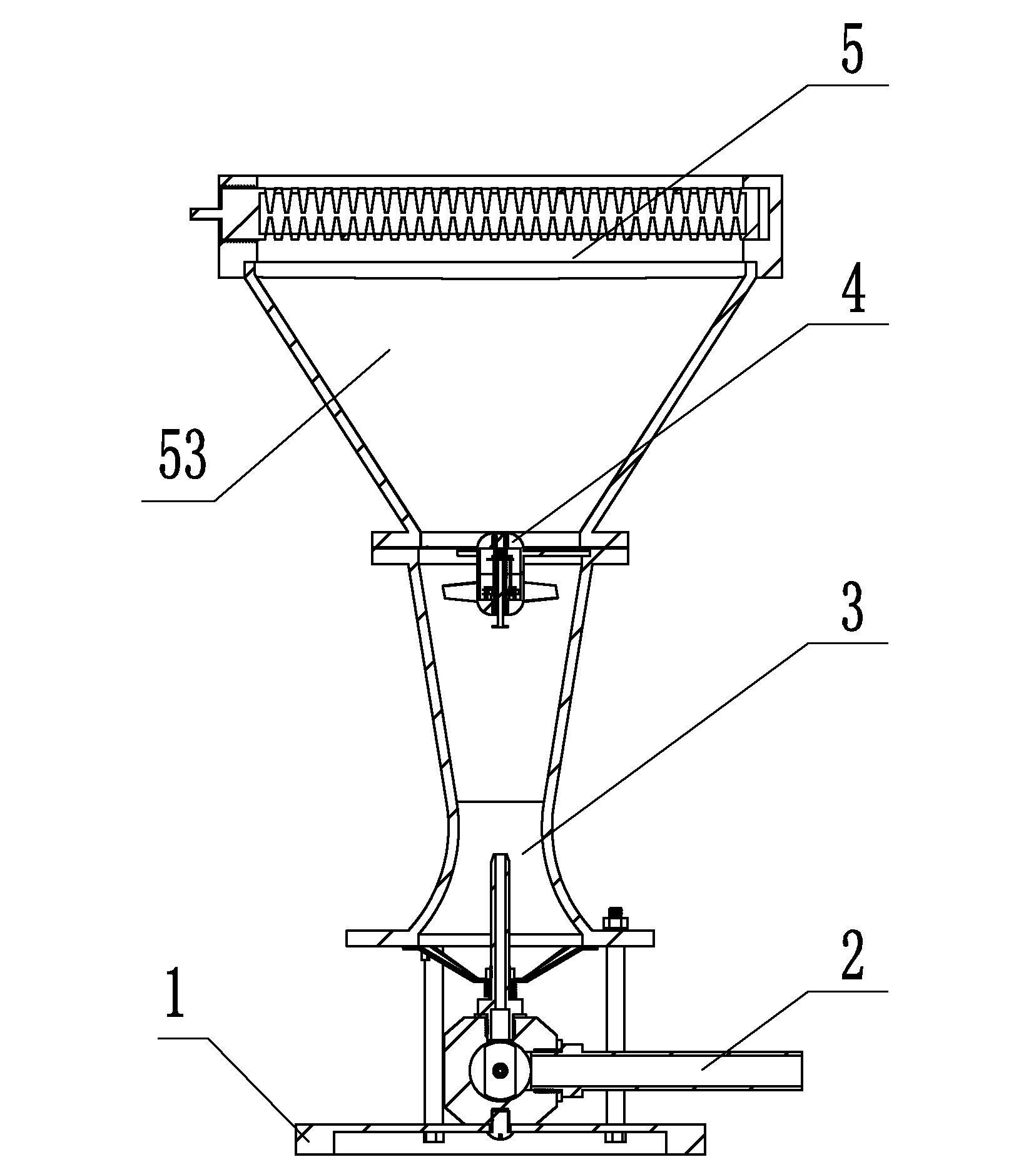

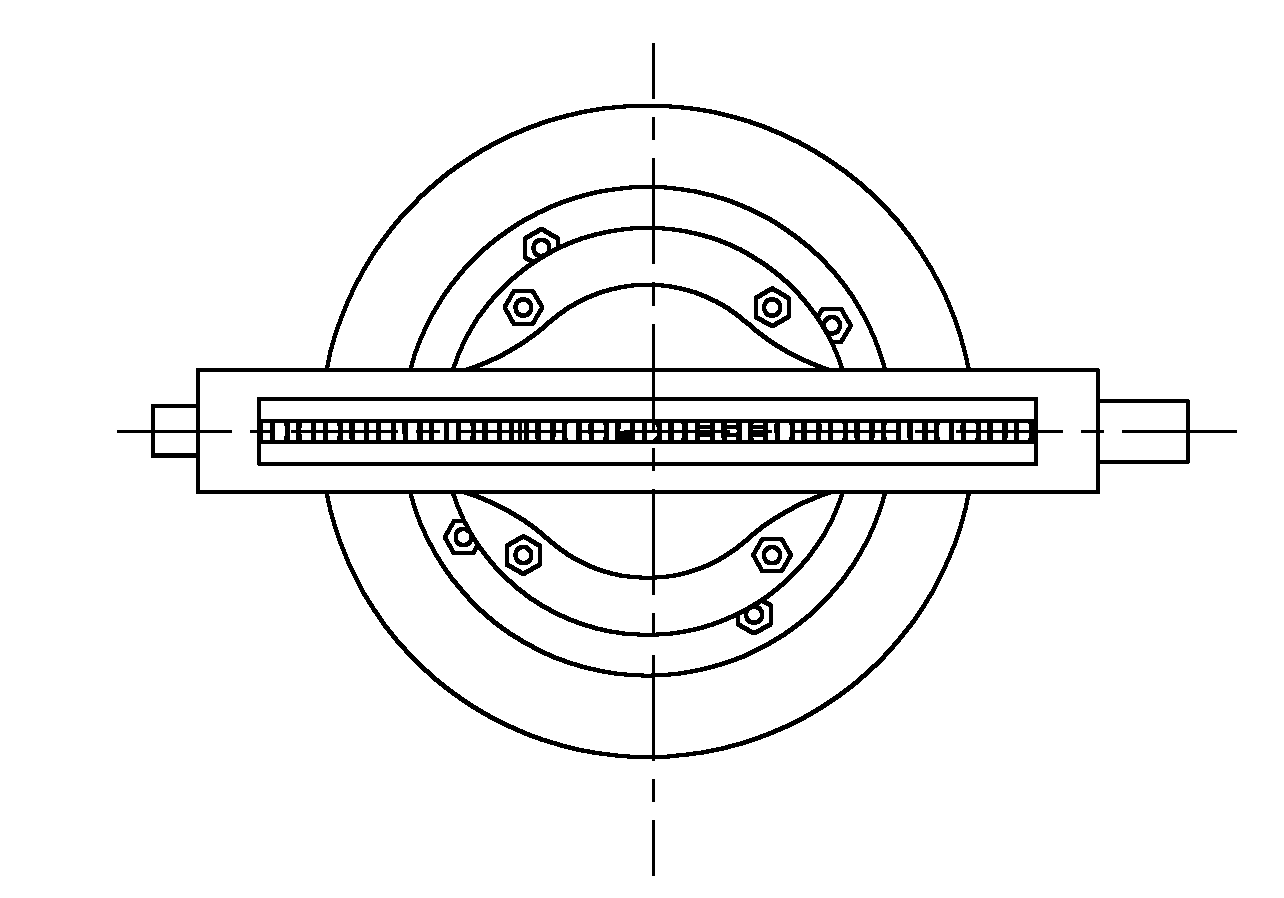

[0057] A premixer structure of a biogas heater burner. A biogas nozzle device 2, a venturi 3, a premixer 4, and a biogas burner 5 on the top are arranged on a base 1 from bottom to top.

[0058] In the premixer, the main body premixer shell 41 is in the shape of a capsule, and M radial connecting rods 48 extend radially from the upper end, which are fixedly connected to the inner wall of the biogas diffusion section of the venturi tube 3, and the The shaft center of 41 is equipped with a top rod member 46 that can move up and down from bottom to top. The top end of the top rod member 46 abuts a horizontal balance plate 43. The top of the balance plate 43 is pressed downward by an upper support spring 49. On 43, N connecting thin rods 44 with the same diameter are evenly distributed in the circumferential direction. The lower ends of the N connecting rods 44 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com