Complete abrator for locomotive

A shot blasting machine and locomotive technology, which is applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of narrow range of shot blasting and cleaning of car body workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

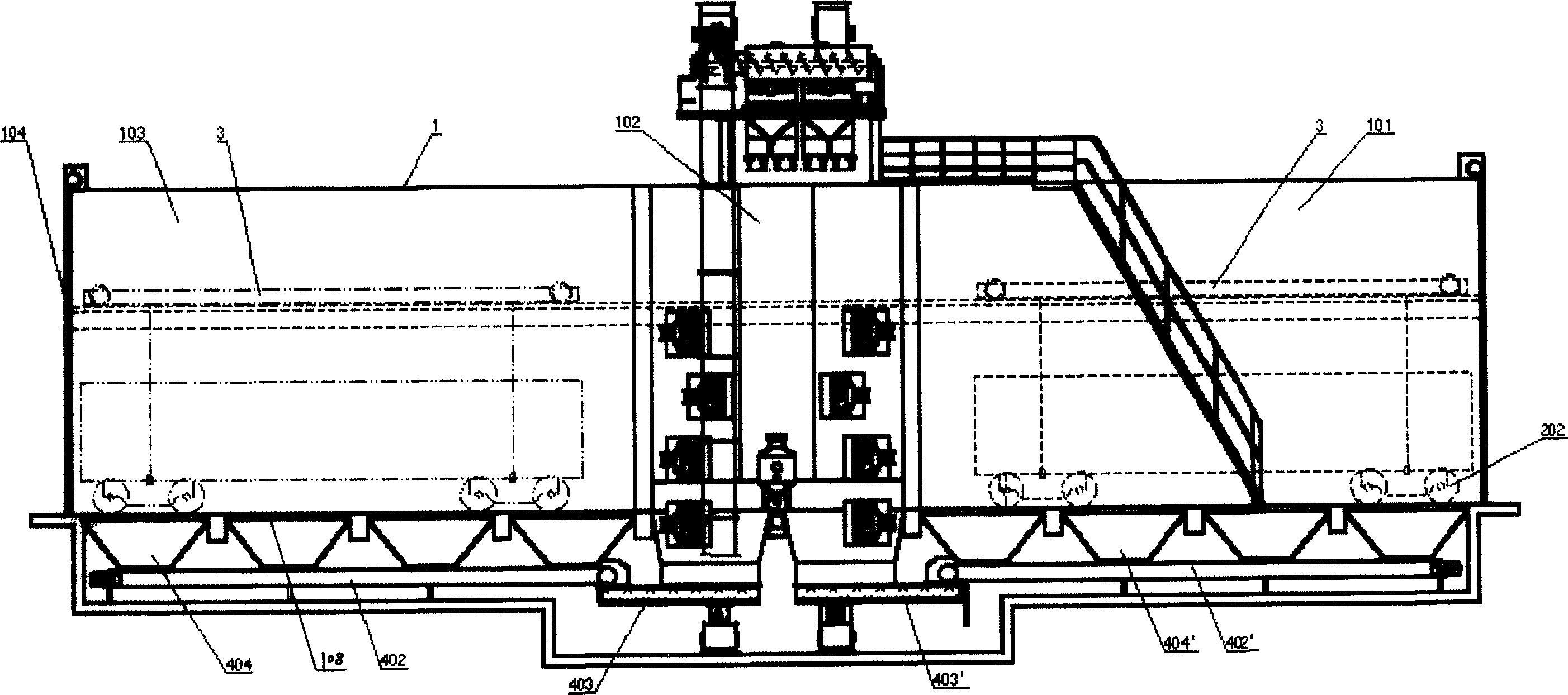

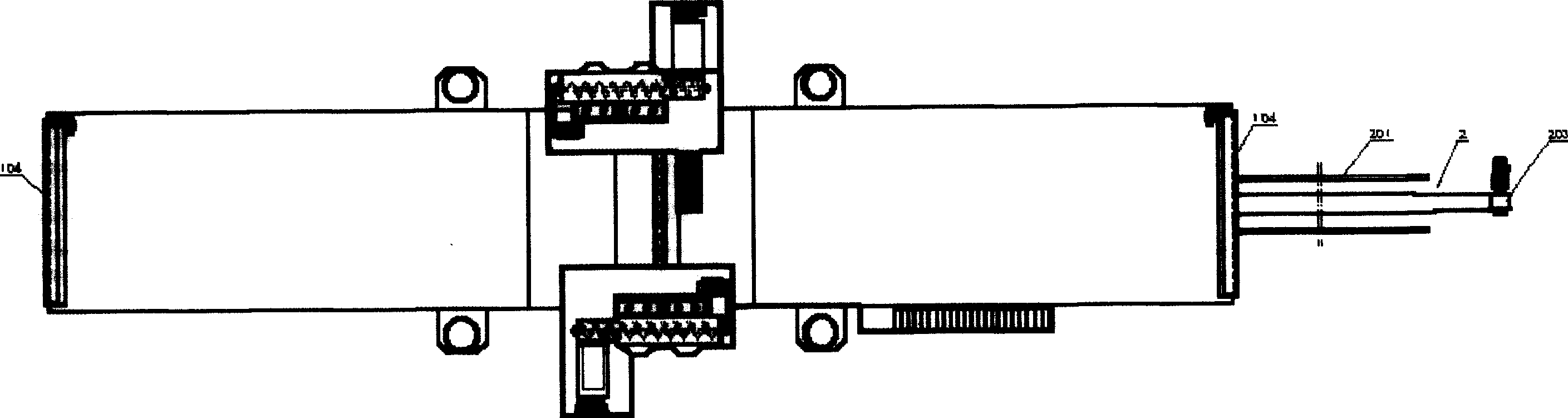

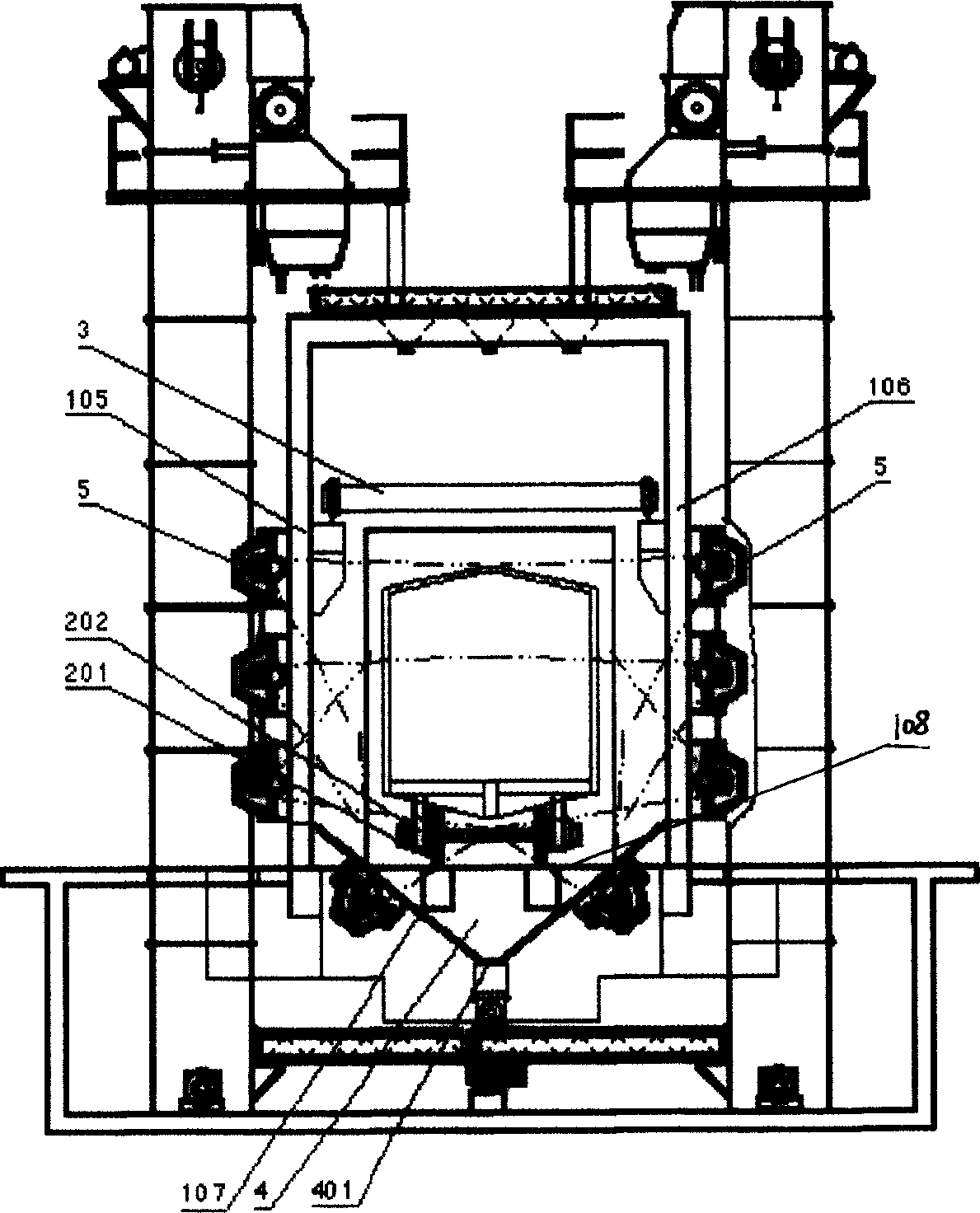

[0021] combined reference Figure 1 to Figure 4 , the locomotive vehicle shot blasting machine of the present invention, the working length of cleaning chamber 1 is generally better than the sum of the lengths of two car body workpieces (i.e. 2 times of a single car body workpiece), and at the same time at its front and rear ends or at the One of the ends is provided with the entrance and exit of the car body workpiece, and the entrance and exit of the car body workpiece is equipped with a door body 104 that can open and close the entrance and exit. The door body 104 can be selected as an automatic rolling shutter door. Work area 102 and rear auxiliary work area 103, also can lay the pedal platform 108 that is convenient for the operator to enter and exit the cleaning room in the bottom of cleaning room, if enter the direction of cleaning room with car body workpiece as forward pointing, then car body workpiece first After entering the auxiliary working area 103, the relevant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com