A production line for in-situ mixed charging of ammunition

A technology of mixed charge and production line, applied in the direction of ammunition, offensive equipment, weapon accessories, etc., can solve the problems of many processes, large production volume, long process time, etc., and achieve the effect of ensuring reliable fixation and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

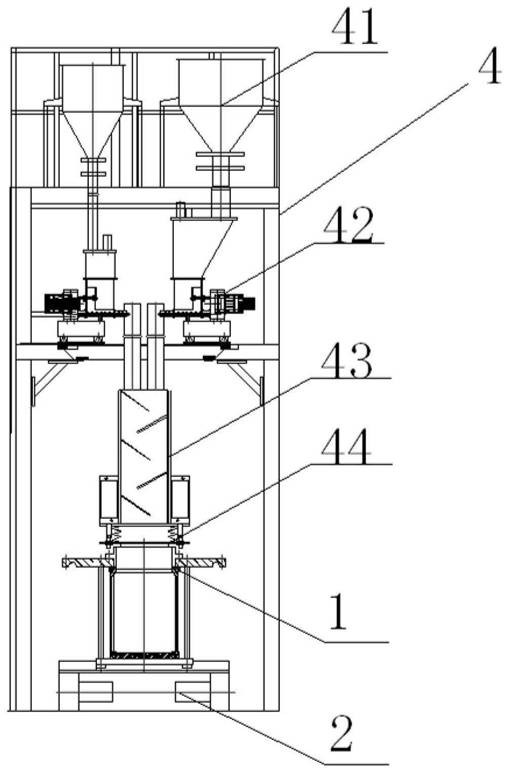

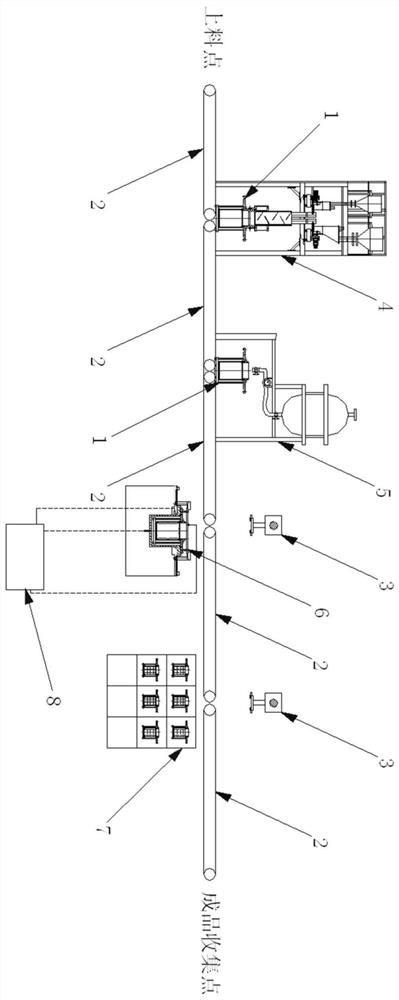

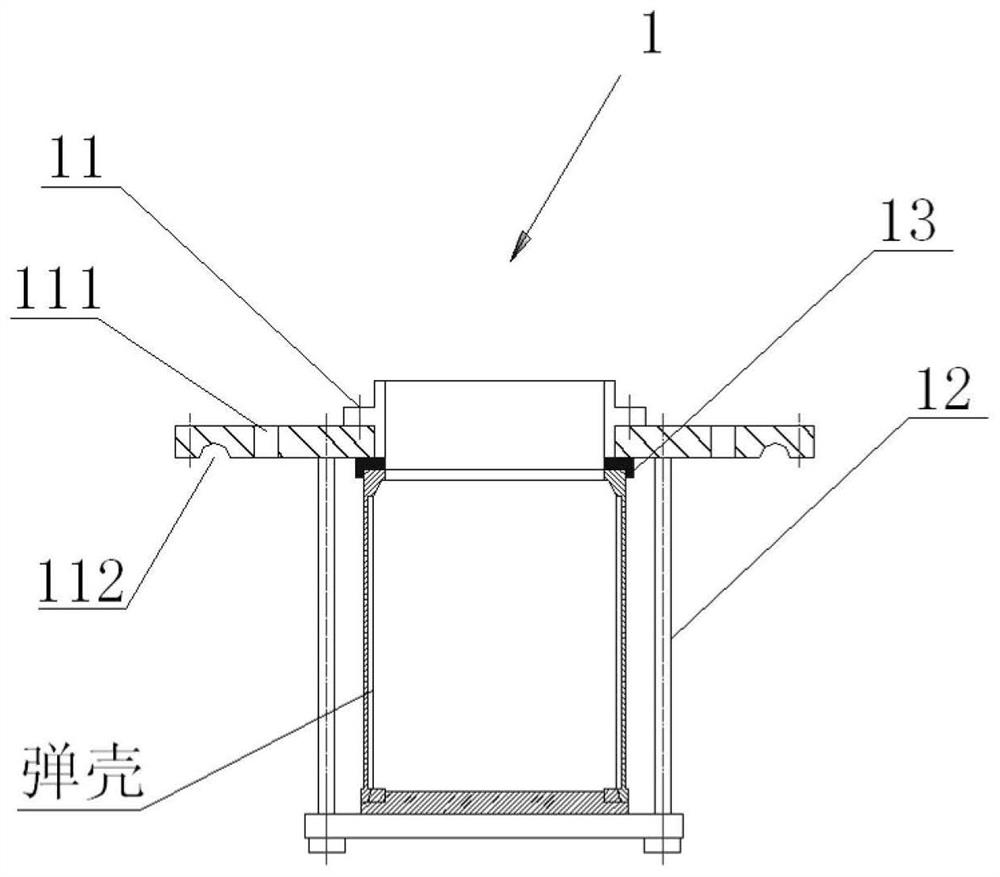

[0041] like figure 1 , an ammunition in-situ mixed charge production line, characterized in that it includes: a cartridge case fixing tool 1, a transfer unit 2, a transfer robot arm 3, a solid material feeding unit 4, a liquid material feeding unit 5, a mixing unit 6, and a curing unit 7. Auxiliary unit 8;

[0042] The cartridge case fixing tool 1 is an assembly with a cartridge case positioning structure, and after being assembled with the cartridge case, it is used for positioning the cartridge case, handling, and fixing and installing the cartridge case on the mixing unit 6;

[0043] The transmission unit 2 is a transmission mechanism with a positioning detection sensor, which is used to transmit the cartridge case fixing tool 1 at different stations;

[0044] The solid material feeding unit 4 is a mechanism with weighing, metering, feeding and batching, including 2-4 quantitative feeding machines, used for batching and feeding of 2-4 main component powders;

[0045] The ...

Embodiment 2

[0054] like figure 1 , an ammunition in-situ mixed charge production line, characterized in that it includes: a cartridge case fixing tool 1, a transfer unit 2, a transfer robot arm 3, a solid material feeding unit 4, a liquid material feeding unit 5, a mixing unit 6, and a curing unit 7. Auxiliary unit 8;

[0055] The cartridge case fixing tool 1 is an assembly with a cartridge case positioning structure, and after being assembled with the cartridge case, it is used for positioning the cartridge case, handling, and fixing and installing the cartridge case on the mixing unit 6;

[0056] The transmission unit 2 is a transmission mechanism with a positioning detection sensor, which is used to transmit the cartridge case fixing tool 1 at different stations;

[0057] The solid material feeding unit 4 is a mechanism with weighing, metering, feeding and batching, including 2-4 quantitative feeding machines, used for batching and feeding of 2-4 main component powders;

[0058] The ...

Embodiment 3

[0068] like figure 1 , an ammunition in-situ mixed charge production line, characterized in that it includes: a cartridge case fixing tool 1, a transfer unit 2, a transfer robot arm 3, a solid material feeding unit 4, a liquid material feeding unit 5, a mixing unit 6, and a curing unit 7. Auxiliary unit 8;

[0069] The cartridge case fixing tool 1 is an assembly with a cartridge case positioning structure, and after being assembled with the cartridge case, it is used for positioning the cartridge case, handling, and fixing and installing the cartridge case on the mixing unit 6;

[0070] The transmission unit 2 is a transmission mechanism with a positioning detection sensor, which is used to transmit the cartridge case fixing tool 1 at different stations;

[0071] The solid material feeding unit 4 is a mechanism with weighing, metering, feeding and batching, including 2-4 quantitative feeding machines, used for batching and feeding of 2-4 main component powders;

[0072] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com