Patents

Literature

41results about How to "Reduce scrolling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

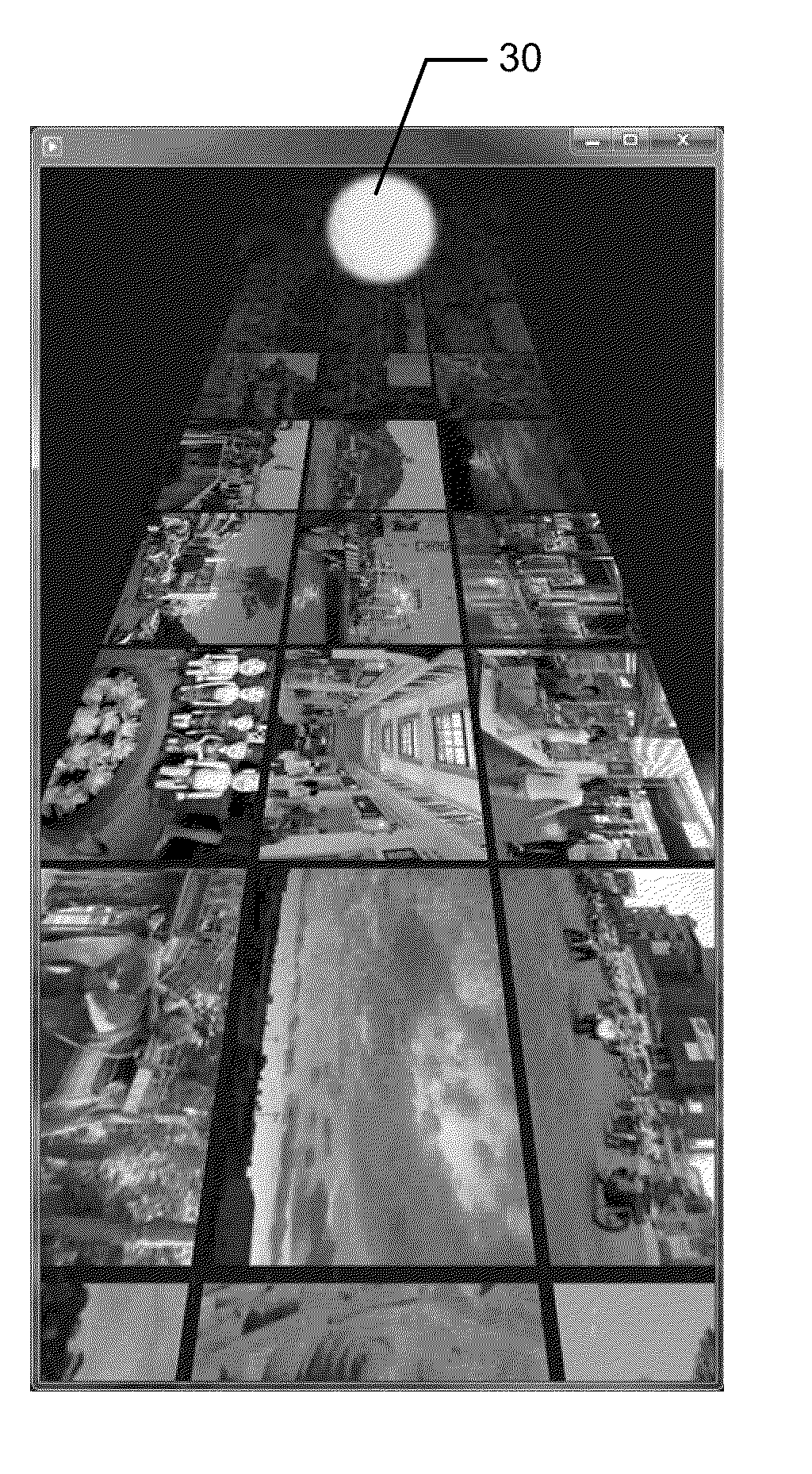

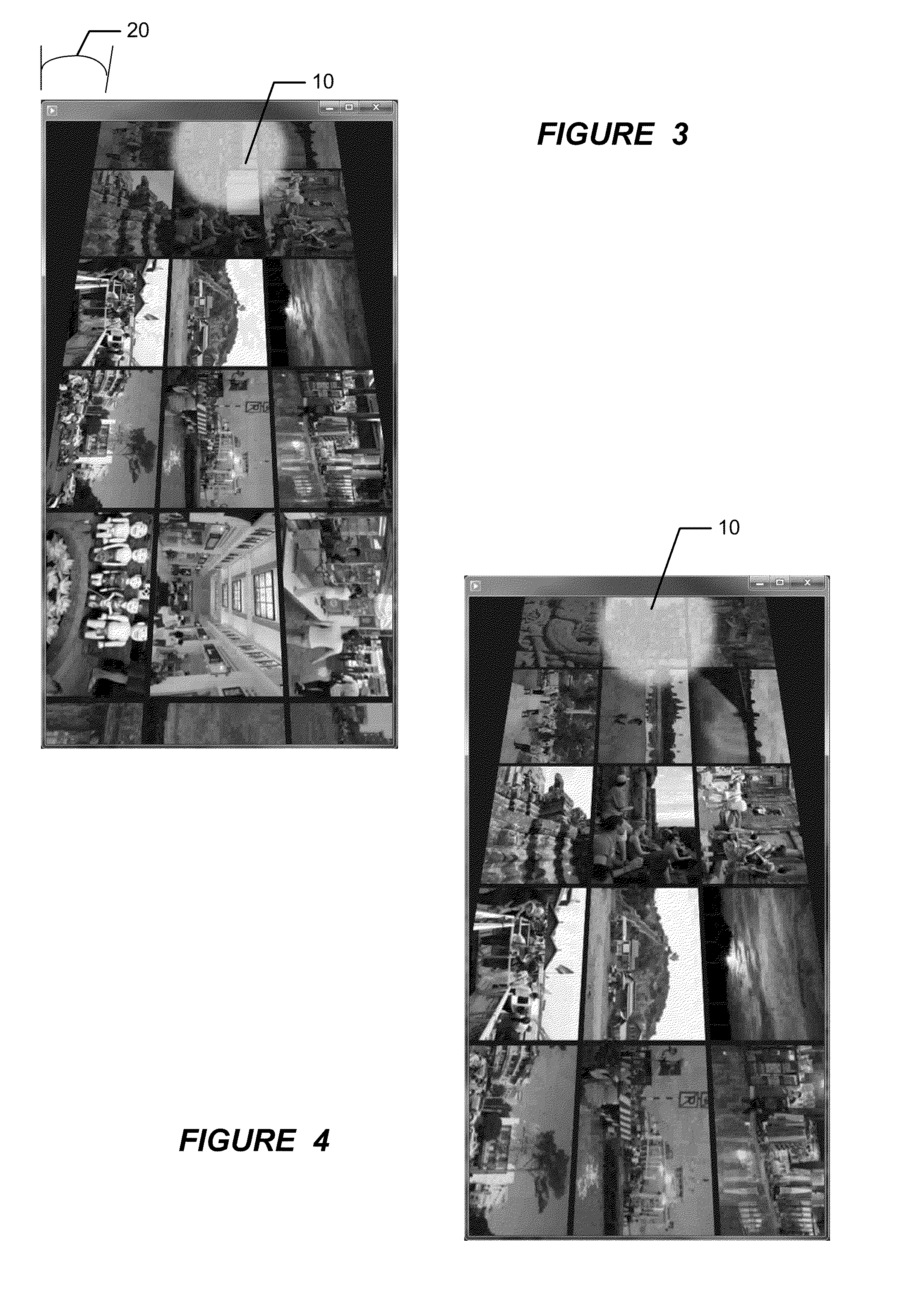

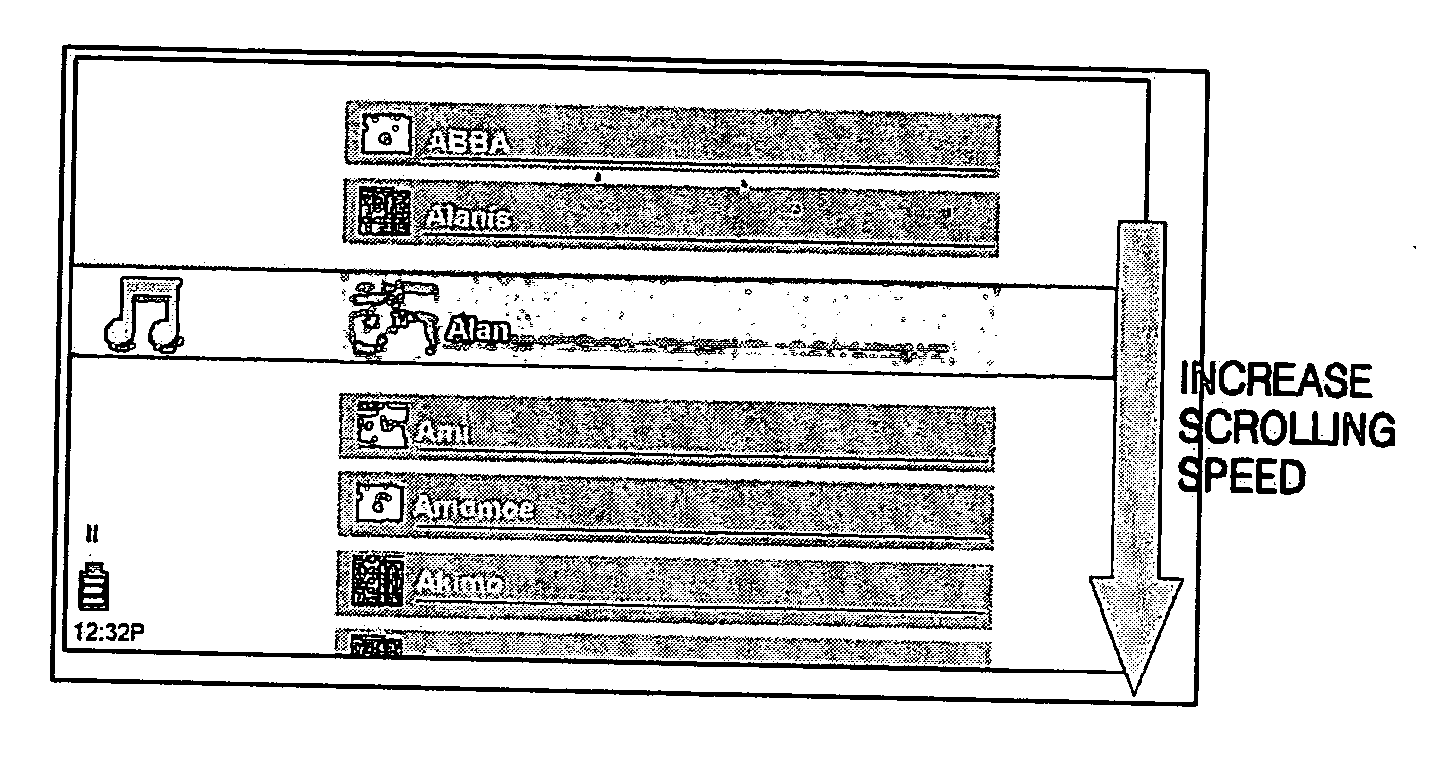

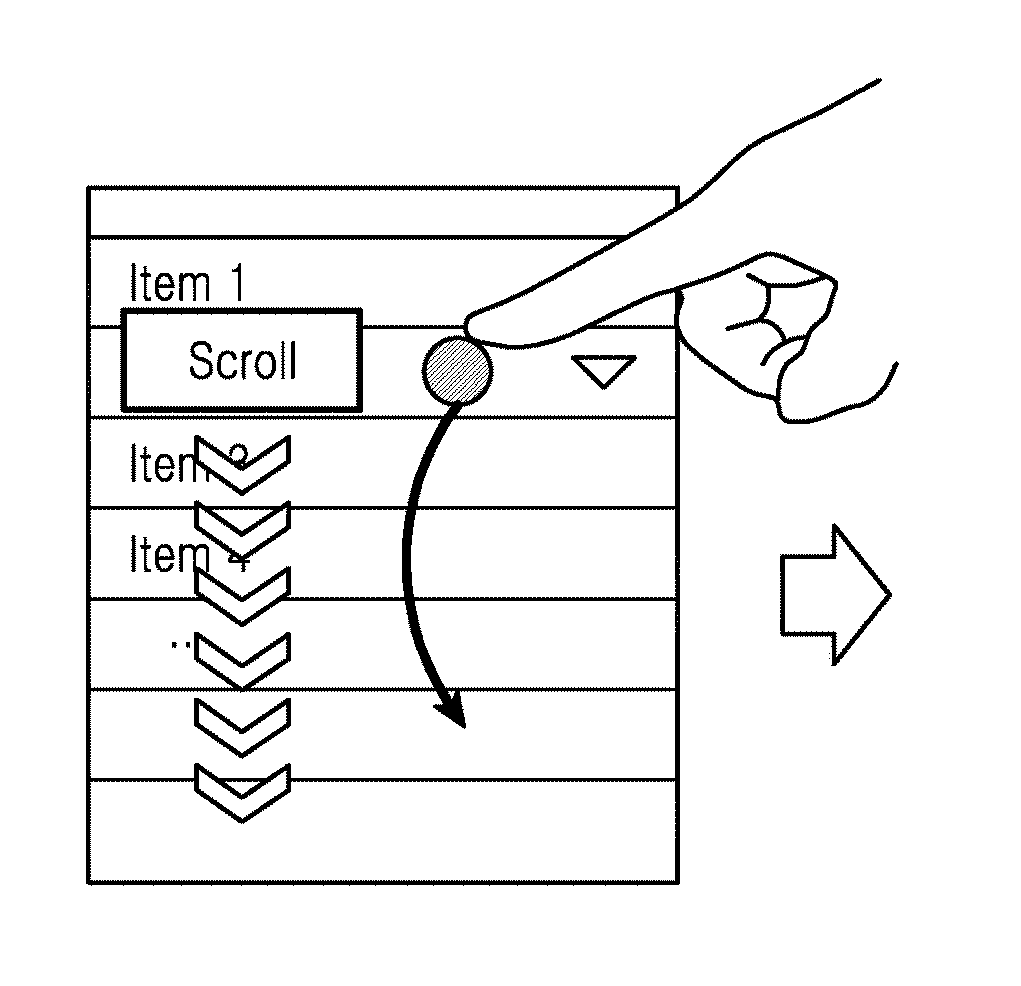

Regulation of navigation speed among displayed items and tilt angle thereof responsive to user applied pressure

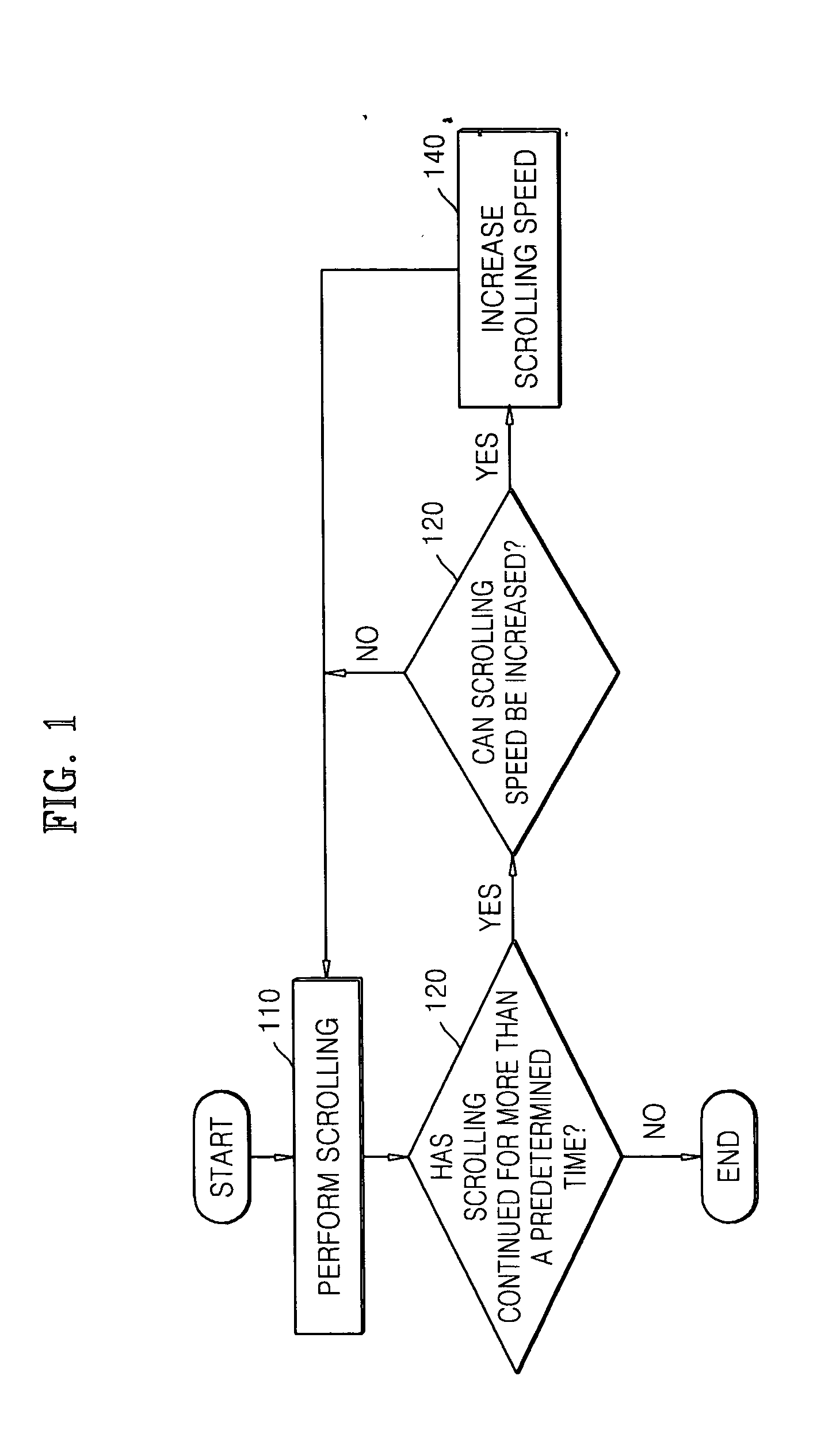

InactiveUS20110193881A1Increase scrolling speedReduce scrolling speedCathode-ray tube indicatorsInput/output processes for data processingMarine navigationGraphics

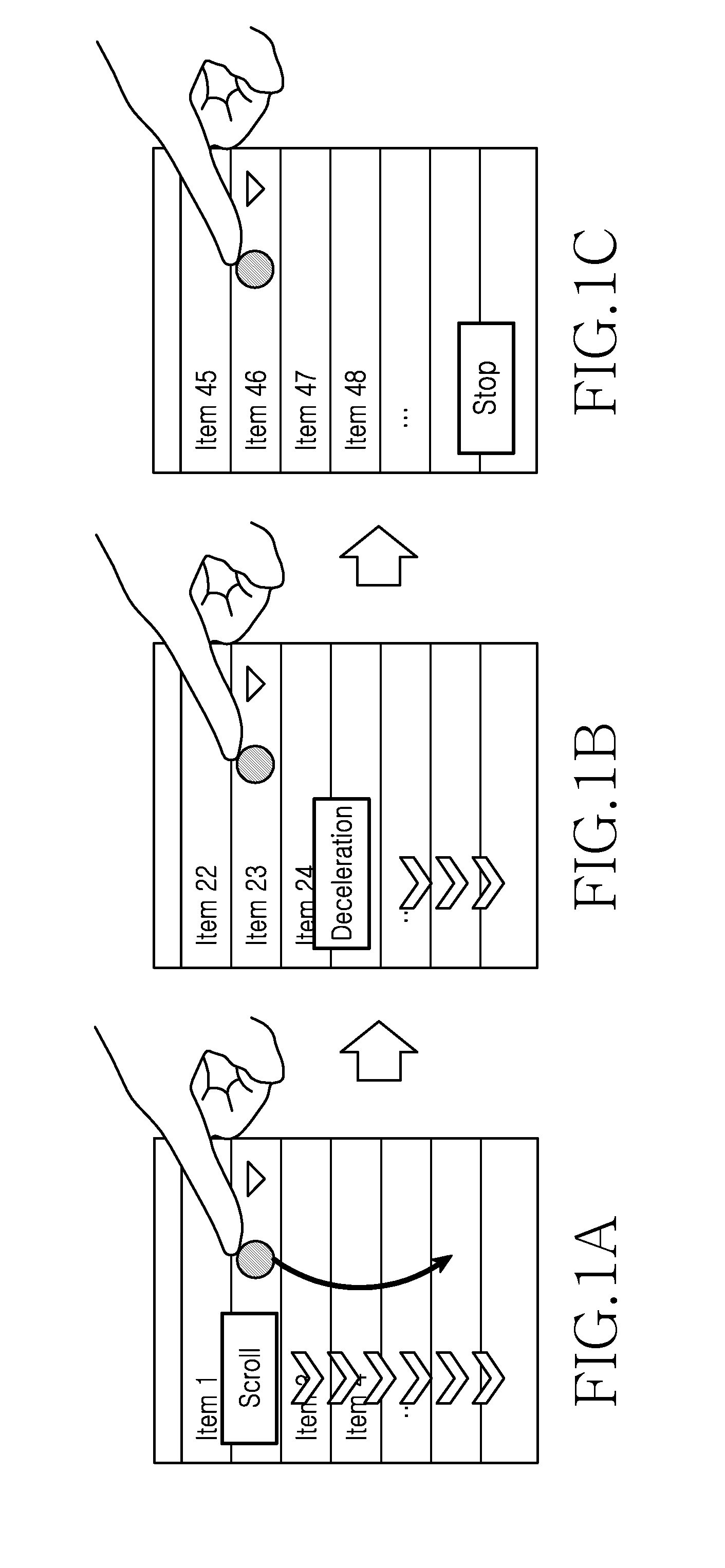

An electronic device can include a touch sensitive display screen and a controller circuit. The touch sensitive display screen identifies a location where a user is pressing and generates a force signal that indicates how hard the user is pressing. The controller circuit controls a speed at which information items are scrolled across the screen and controls a tilt angle of the displayed information items responsive to the force signal. The controller circuit graphically renders the tilt angle on the screen by tapering width of the displayed information items in a defined direction and regulates the tapered width responsive to the force signal. No tilt angle is rendered when the force signal indicates that the user is not pressing the screen. The scrolling speed and the tilt angle of the displayed information items are increased, to provide a visual indication to the user of the increased scrolling speed, responsive to the force signal indicating that the user is pressing harder against the screen.

Owner:SONY ERICSSON MOBILE COMM AB

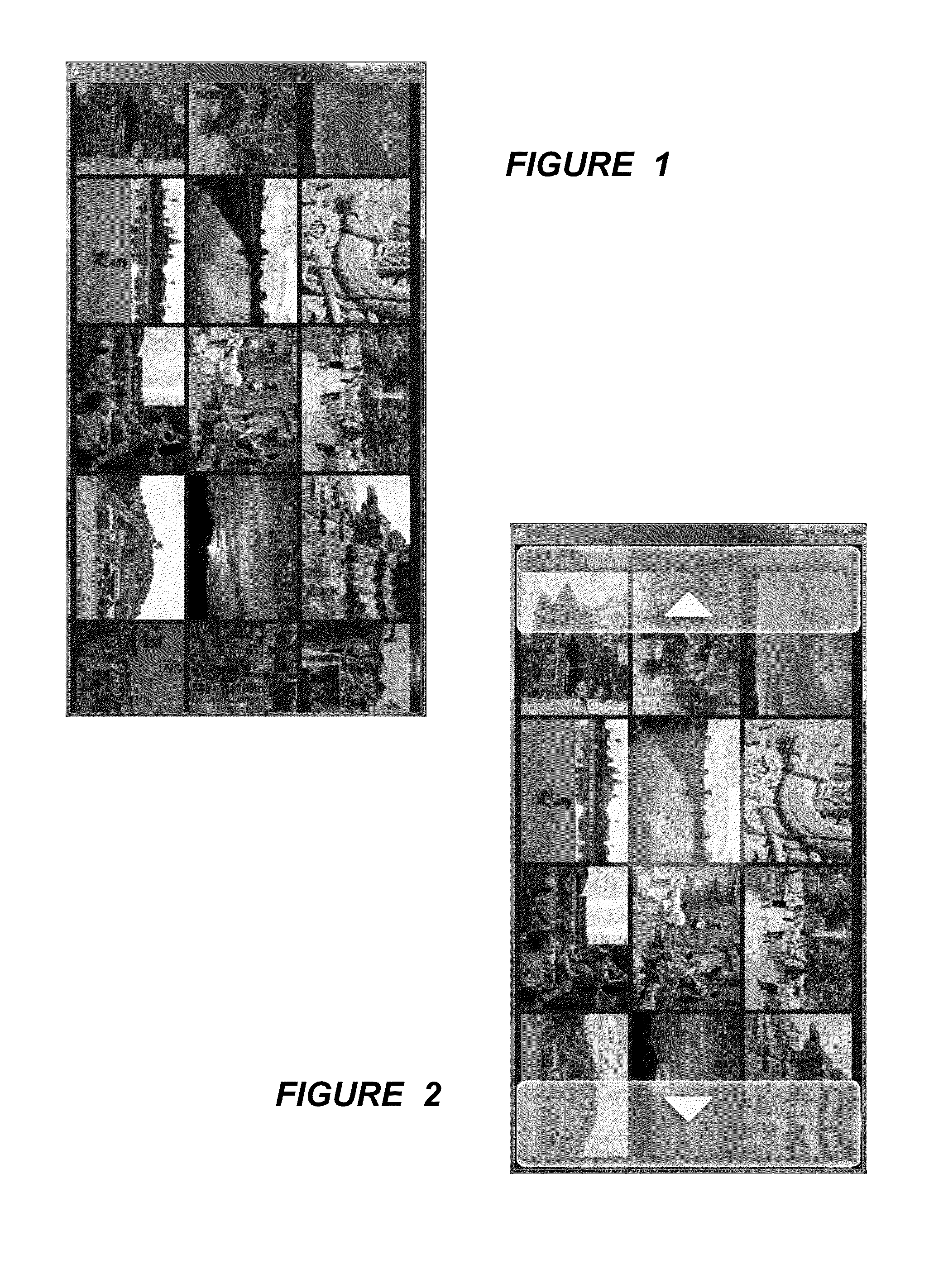

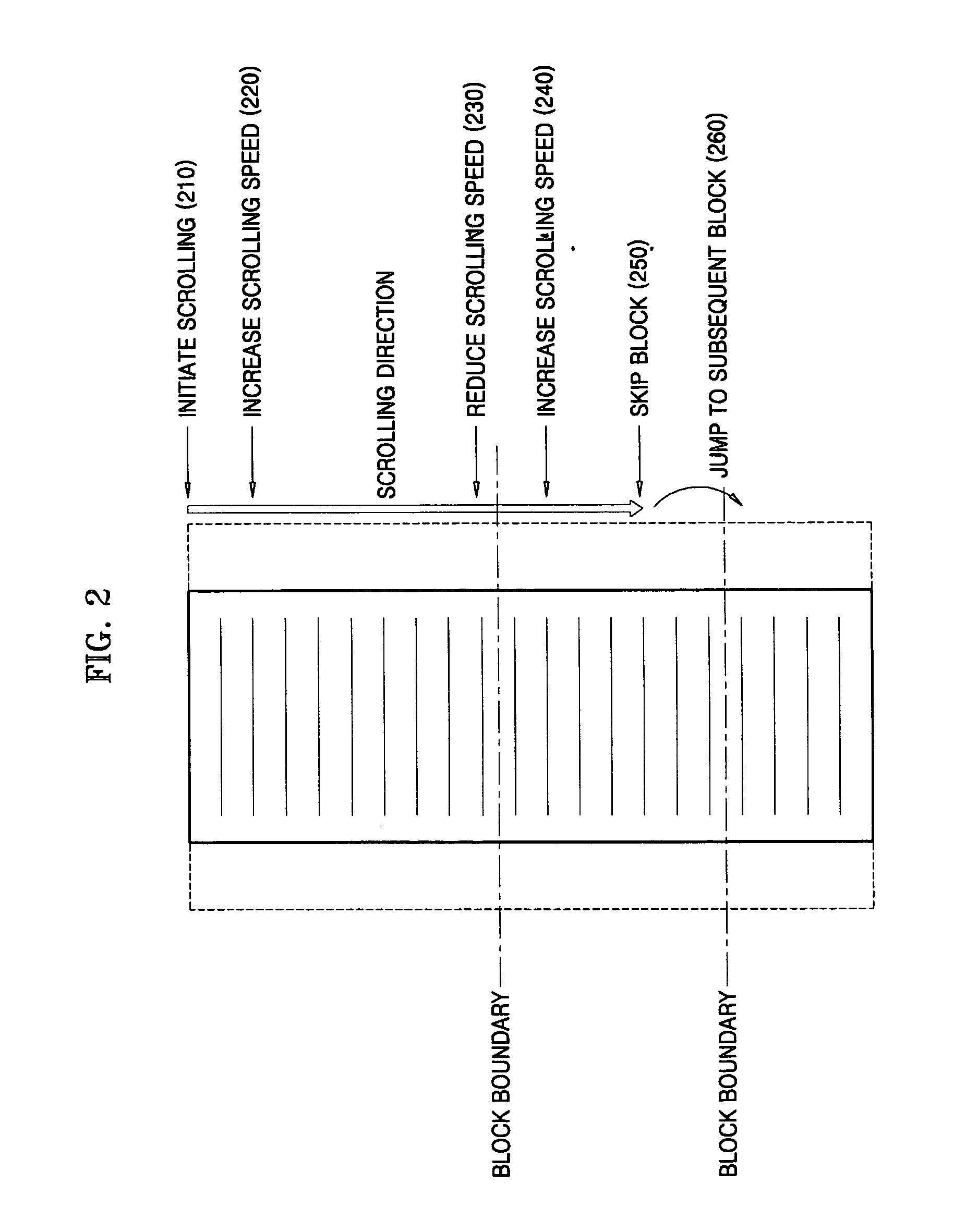

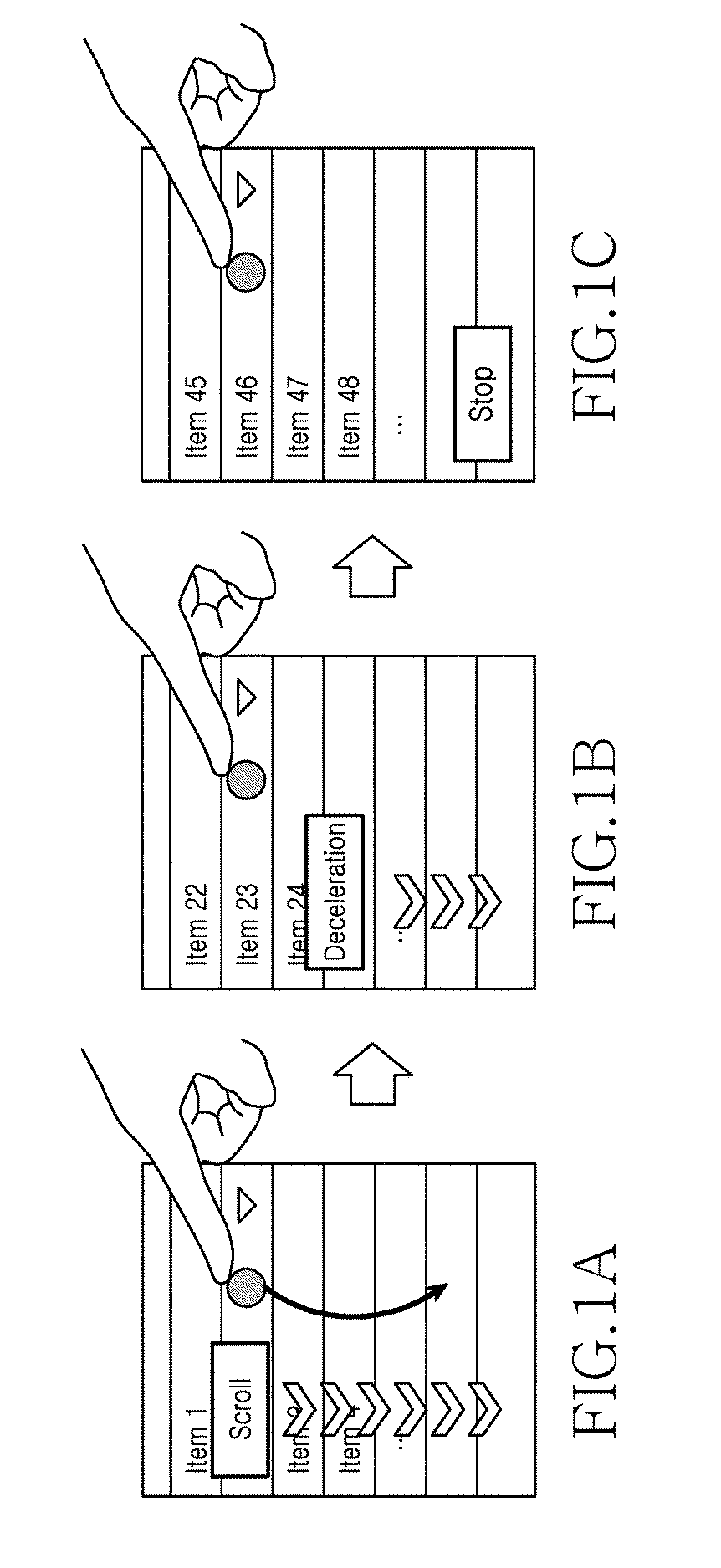

Scrolling method and apparatus using plurality of blocks into which items are classified

InactiveUS20060268020A1Increase scrolling speedReduce scrolling speedCathode-ray tube indicatorsInput/output processes for data processingScrolling

A method and apparatus for adjusting scrolling speed according to the location of an item currently being highlighted on a screen in a block containing the item. The method includes: measuring a distance between the item currently being highlighted on the screen and a last item of the block containing the item; and reducing the scrolling speed if the measured distance is smaller than a predefined value. Therefore, it is possible for a user to identify the location of desired data while quickly scrolling through a considerable amount of data on a screen.

Owner:SAMSUNG ELECTRONICS CO LTD

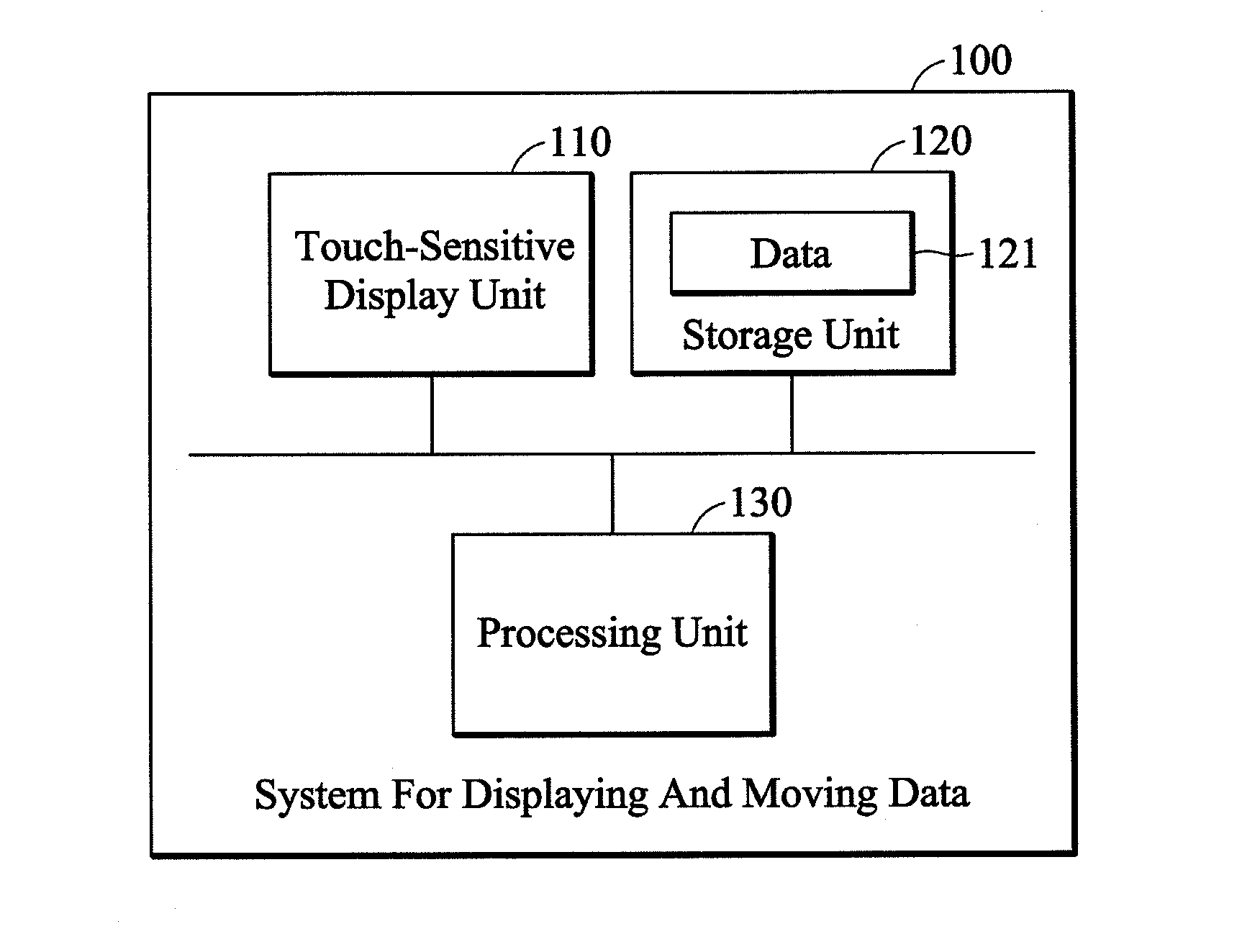

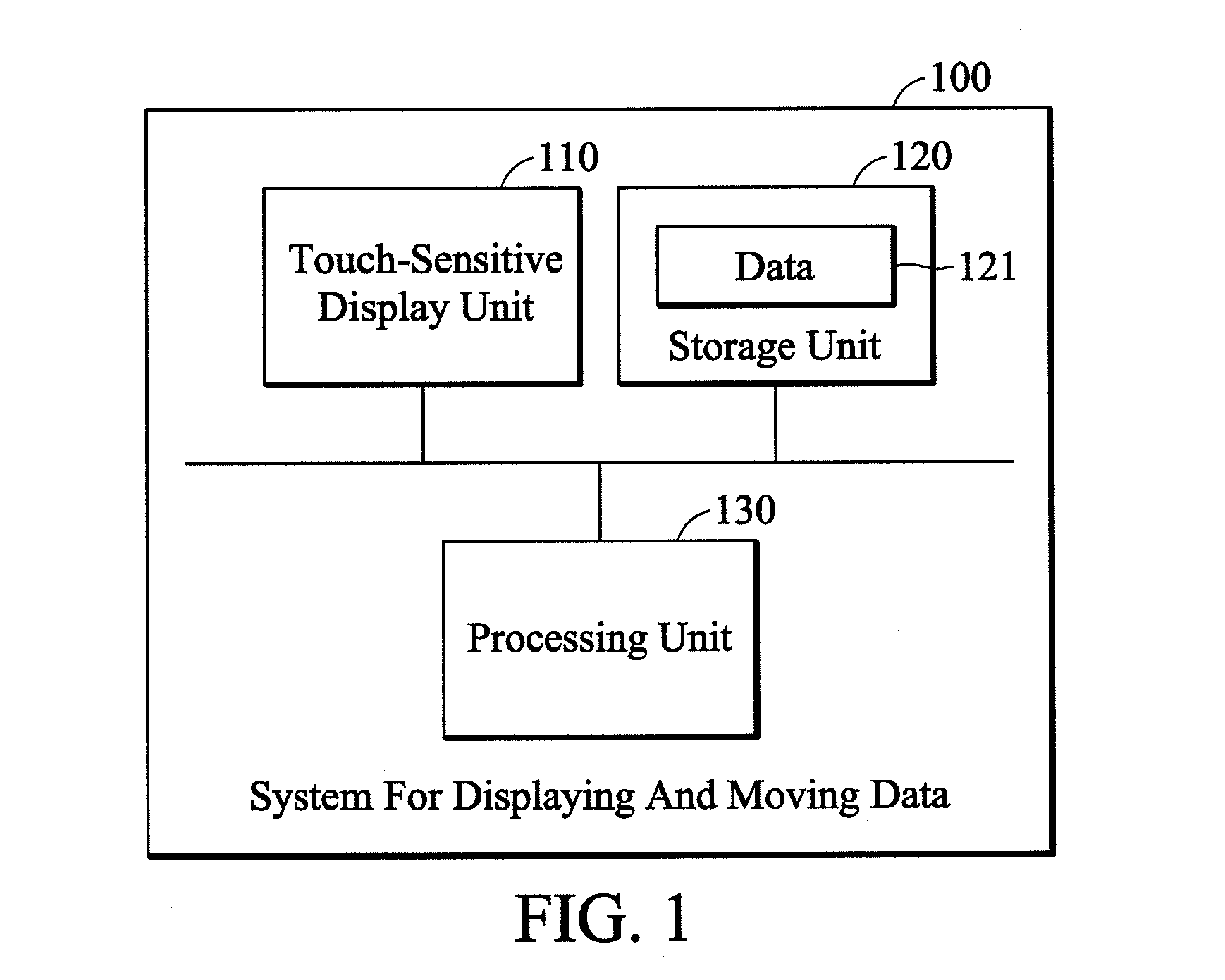

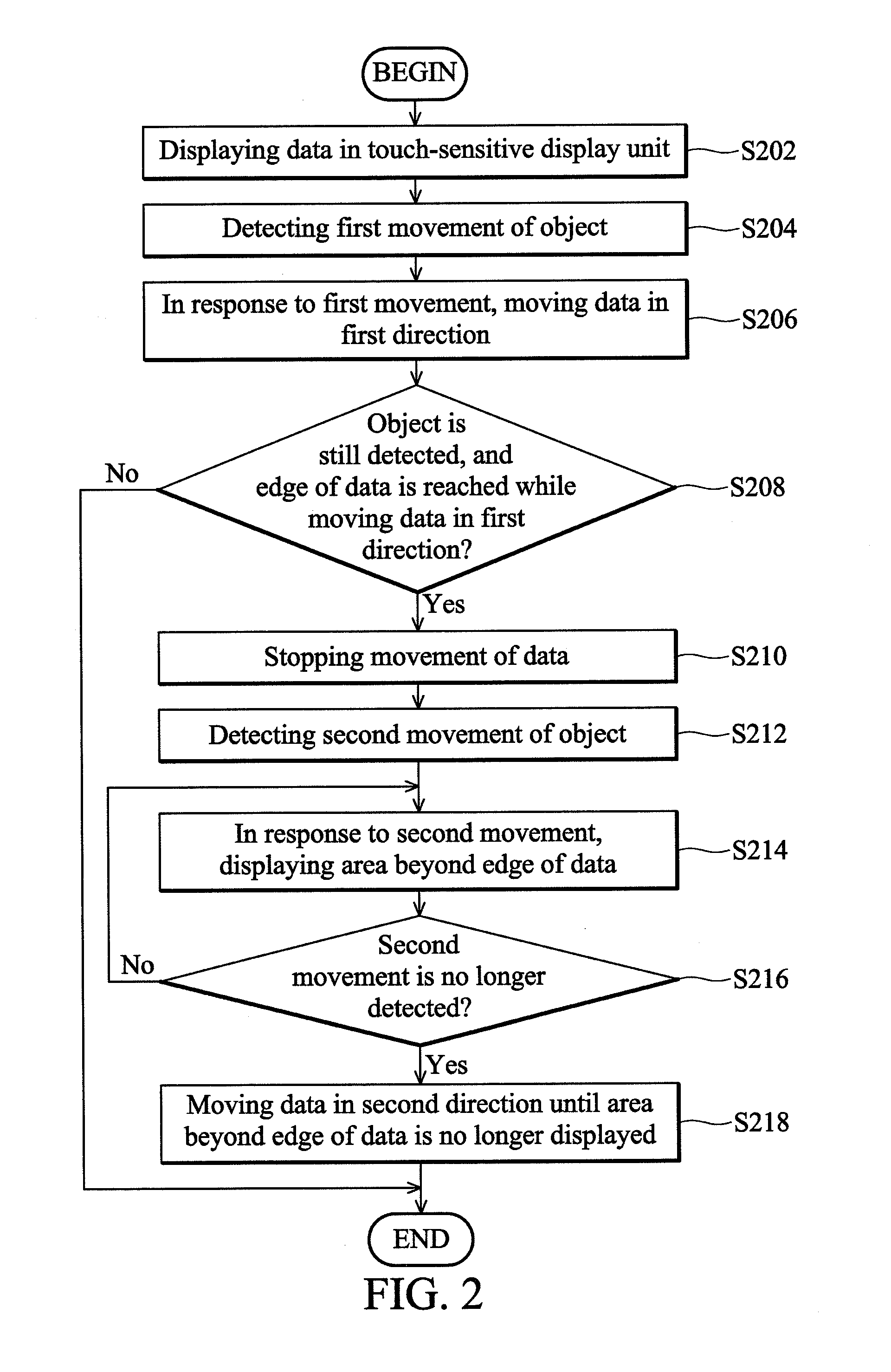

Methods for displaying and moving data and systems using the same

InactiveUS20110001709A1Reduce scrolling speedInput/output processes for data processingHuman–computer interactionData display

Owner:HTC CORP

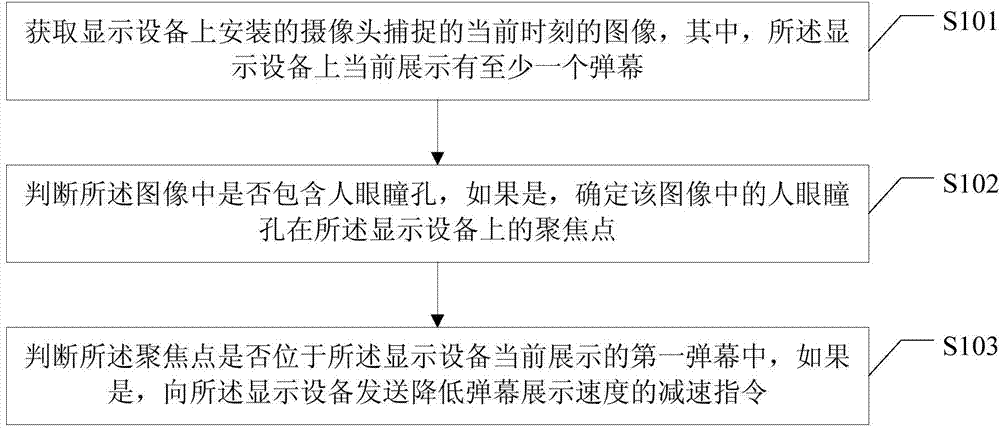

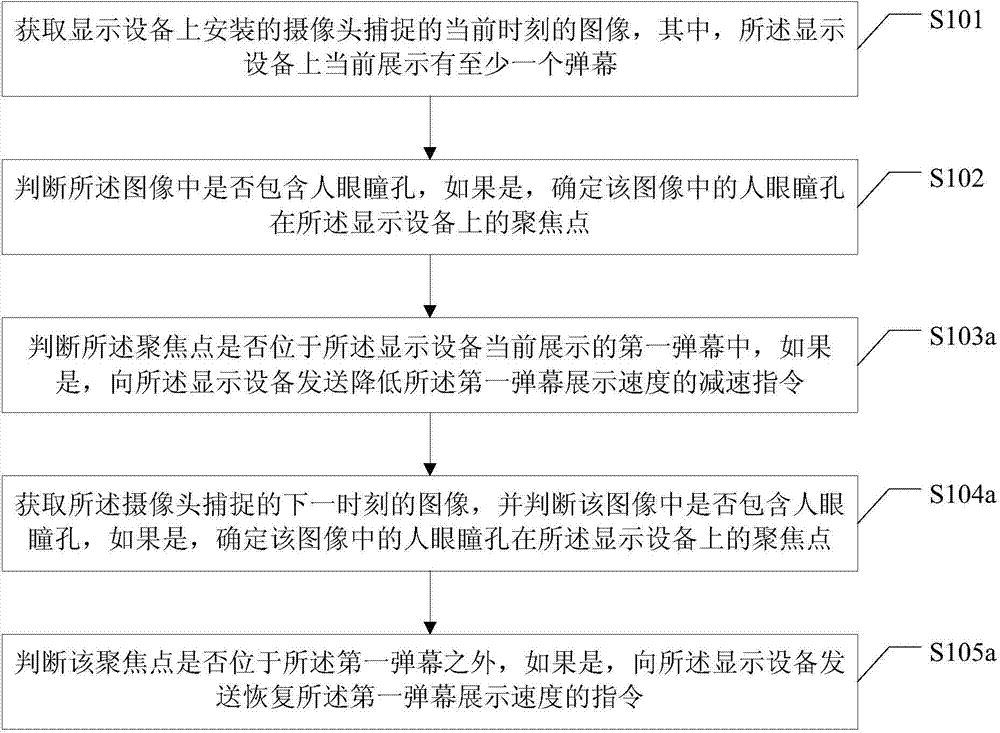

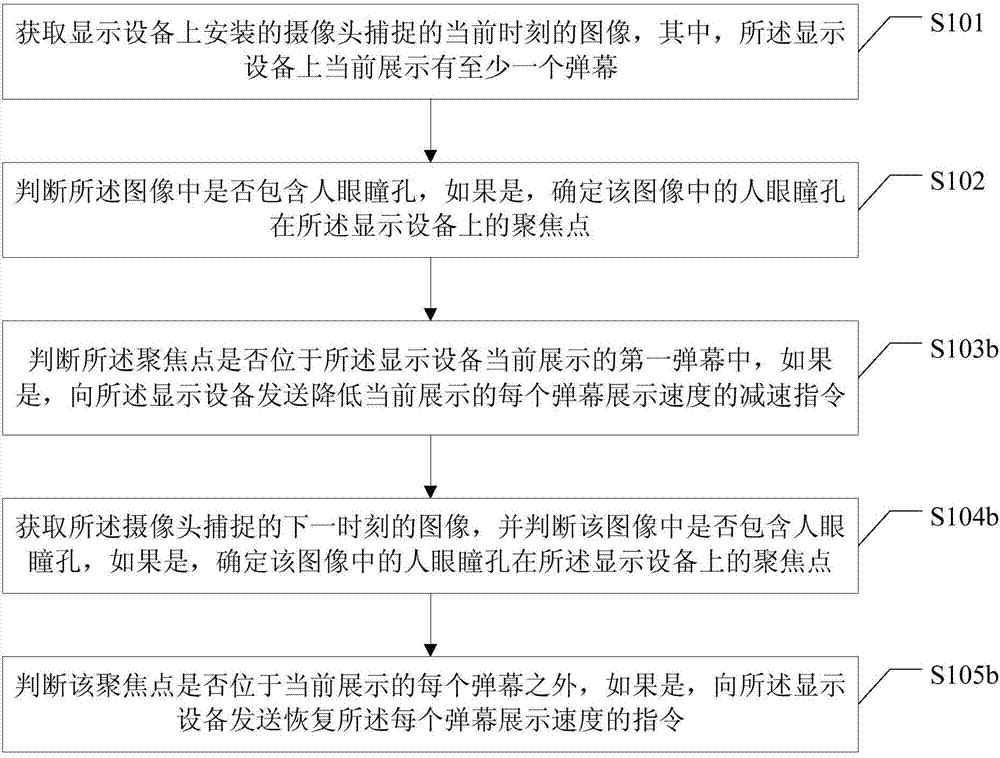

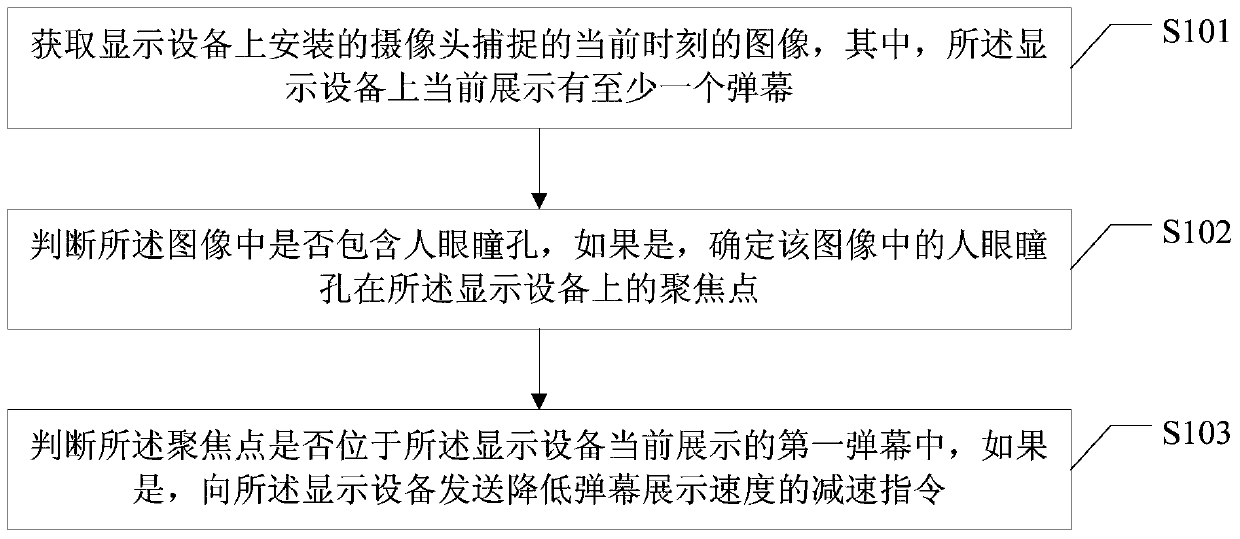

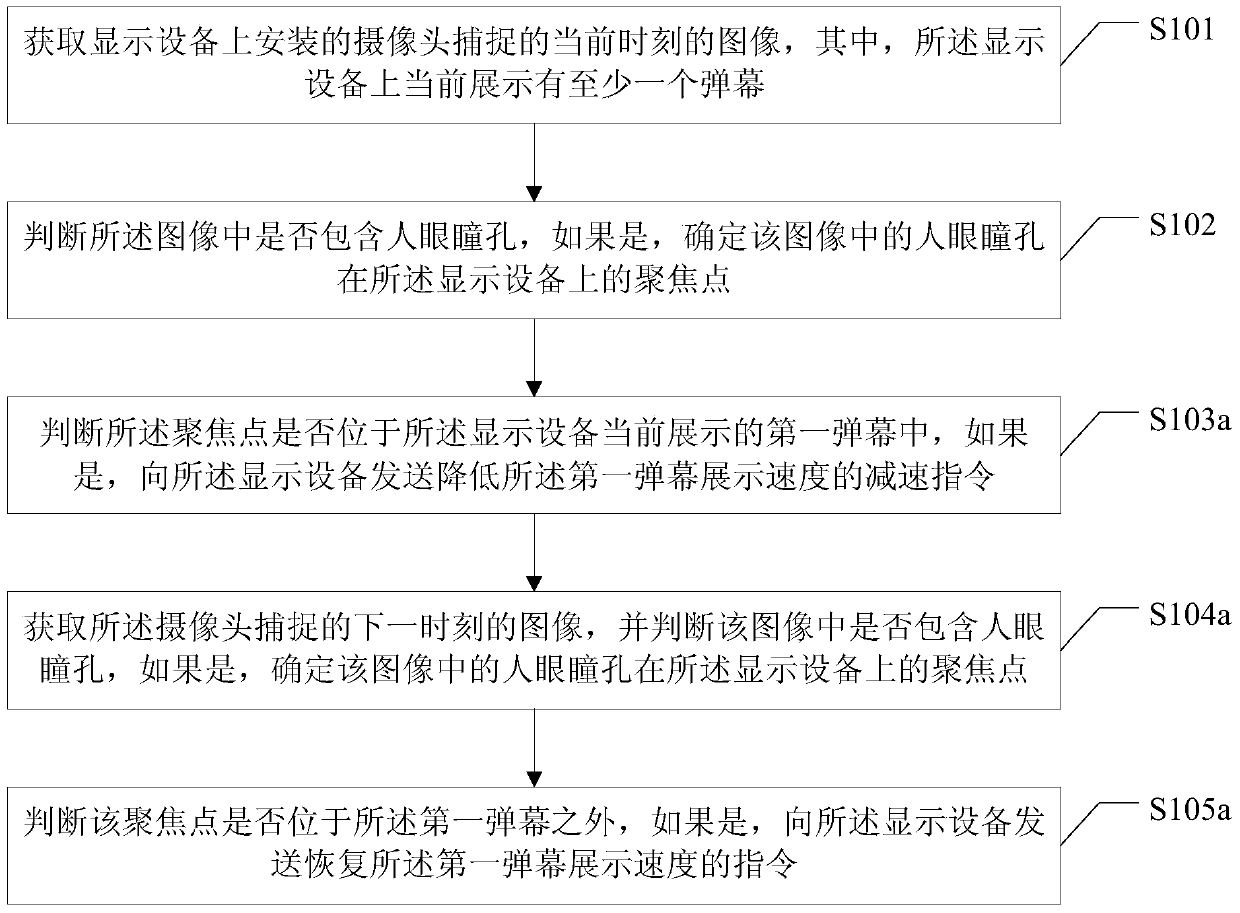

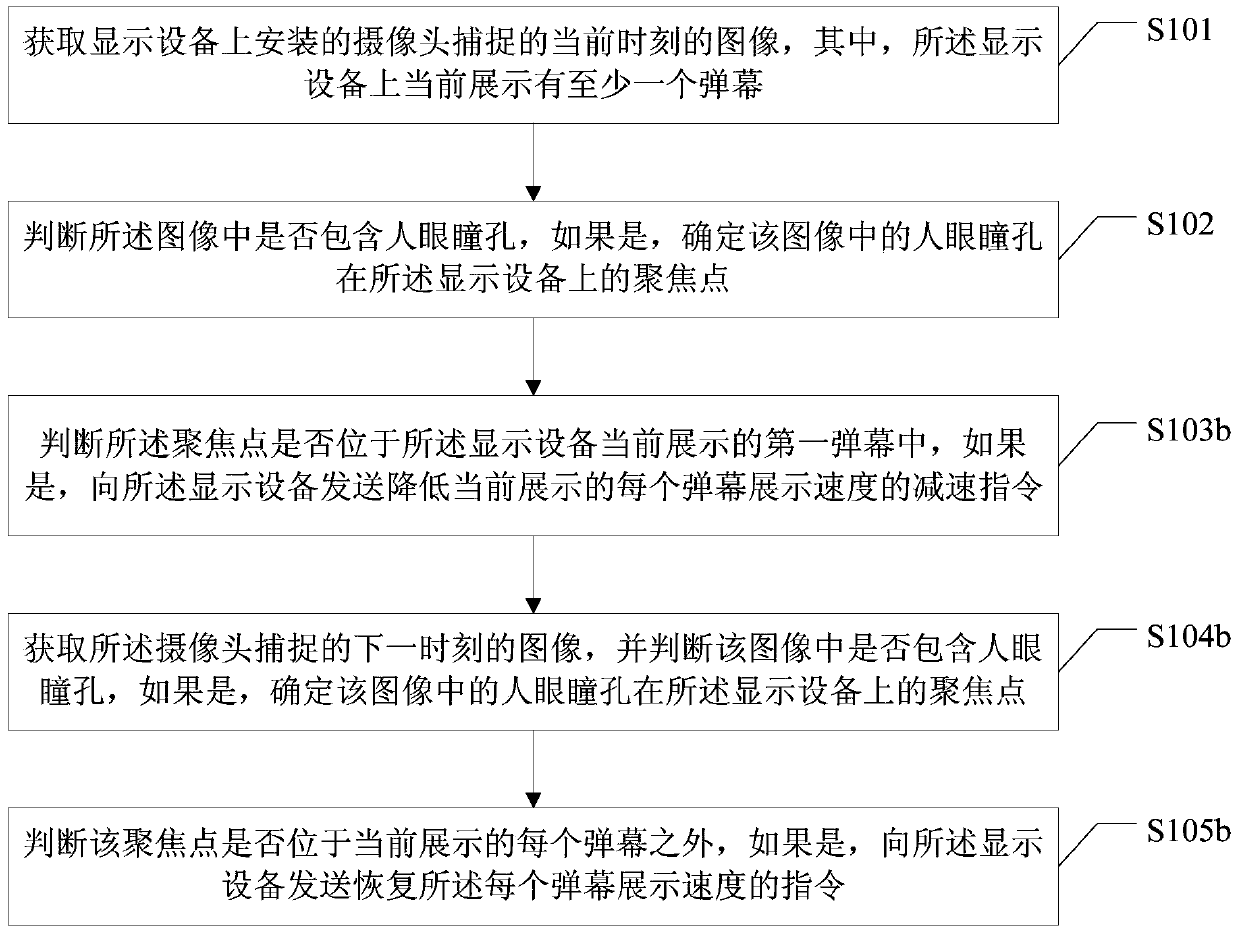

Method and device for displaying pop screen

ActiveCN104777912ASlow down the display speedReduce scrolling speedInput/output for user-computer interactionGraph readingVisual FocusingPupil

The embodiment of the invention discloses a method and a device for displaying a pop screen. The method for displaying the pop screen comprises the following steps: obtaining an image at the current moment captured by a camera mounted on the display equipment, judging whether the image contains a human eye pupil or not, if so, determining the focus point of the human eye pupil in the image on the display equipment; judging whether the focus point is positioned in a first pop screen displayed at the current moment on the display equipment or not, if so, sending a speed-reduction instruction for reducing the displaying speed of the pop screen to the display equipment, wherein at least one pop screen is displayed on the display equipment at the current moment. By obtaining a human face image of an observing user of the pop screens, and by performing the vision focusing calculation on the human face image, the focusing point of the user, who is in front of the screen displaying the pop screens, on the screen is determined; the browse intention of the user is further determined; when the focusing point of the user is positioned in the pop screen, the rolling speed of the pop screen is automatically reduced for the user; the purpose of matching the rolling speed of the pop screen with the browse intention of the user is realized.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

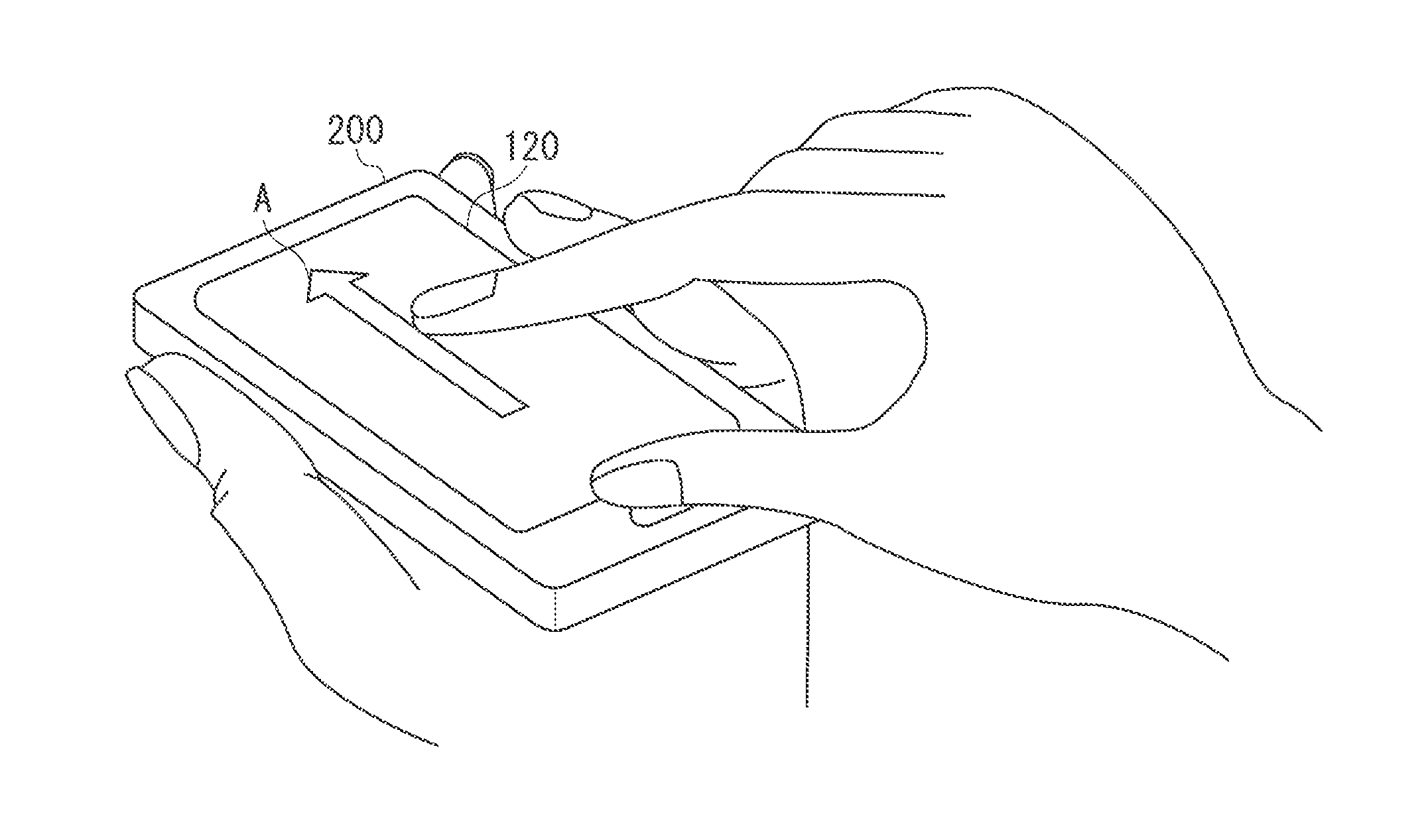

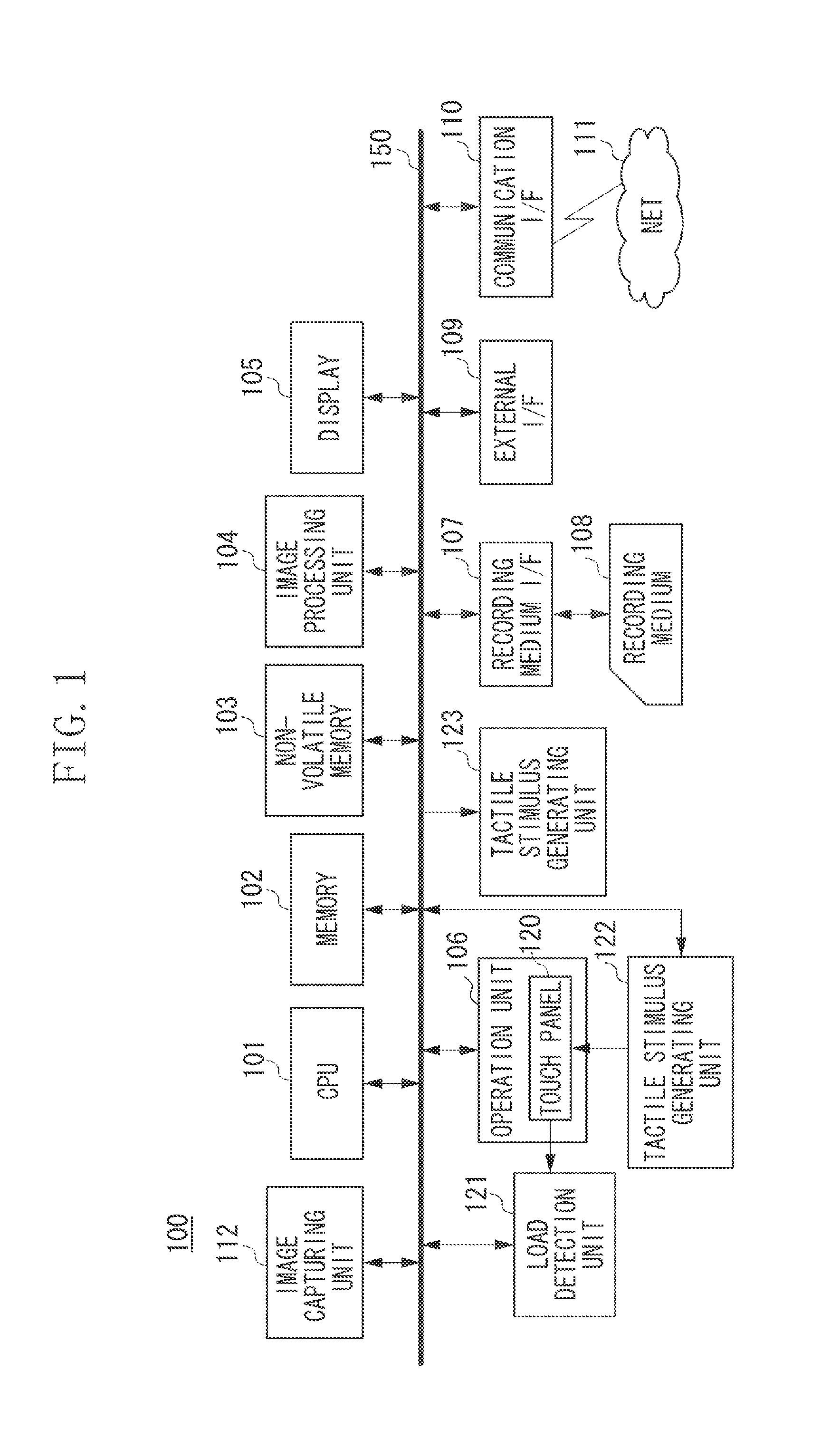

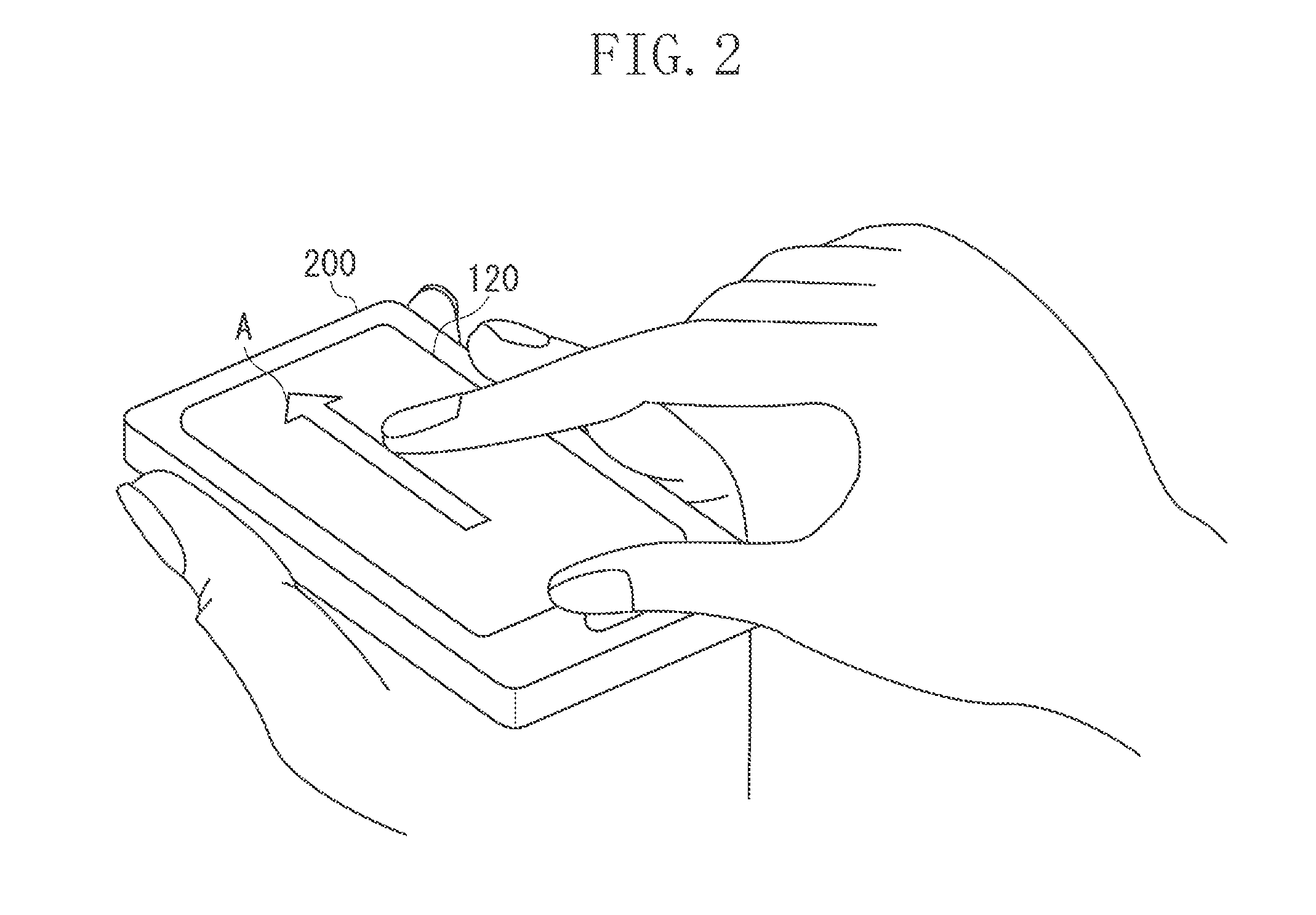

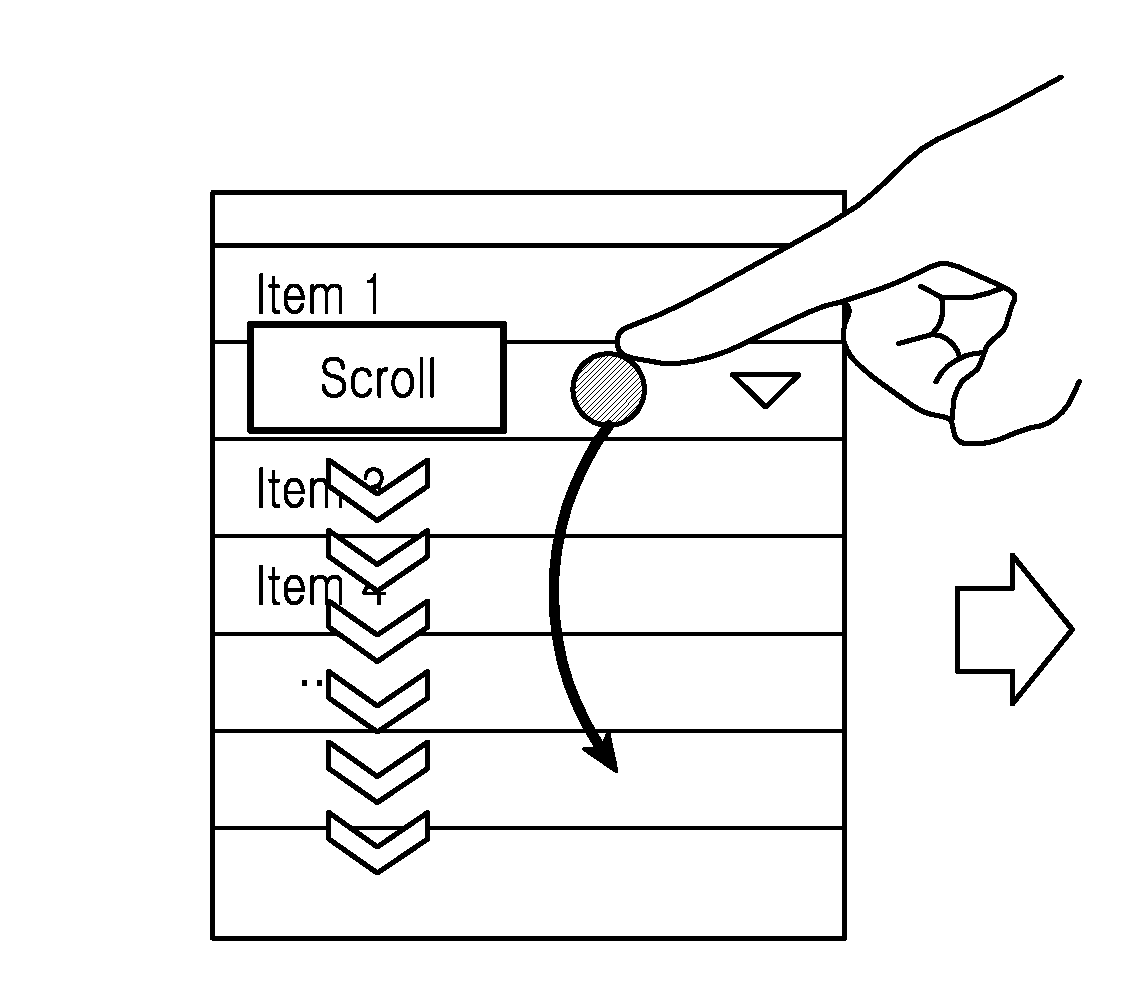

Tactile stimulus control apparatus, tactile stimulus control method, and storage medium

ActiveUS20150277564A1Reduce scrolling speedInput/output for user-computer interactionGraph readingTouch PerceptionVibrotactile stimulation

To provide the user with the relationship between the scrolling speed in scroll-displaying and an operation performed on an input surface, a tactile stimulus control apparatus includes an intensity determination unit and a tactile stimulus control unit. In a case where an operation performed by a manipulator on the input surface provided corresponding to a display unit is detected while an image is scroll-displayed by the display unit, the intensity determination unit determines the intensity of a tactile stimulus to be provided to the manipulator based on the scrolling speed at the timing of detection of the operation. The tactile stimulus control unit controls a tactile stimulus generating unit, which is configured to generate the tactile stimulus to be provided to the manipulator, to generate the tactile stimulus with the intensity determined by the intensity determination unit.

Owner:CANON KK

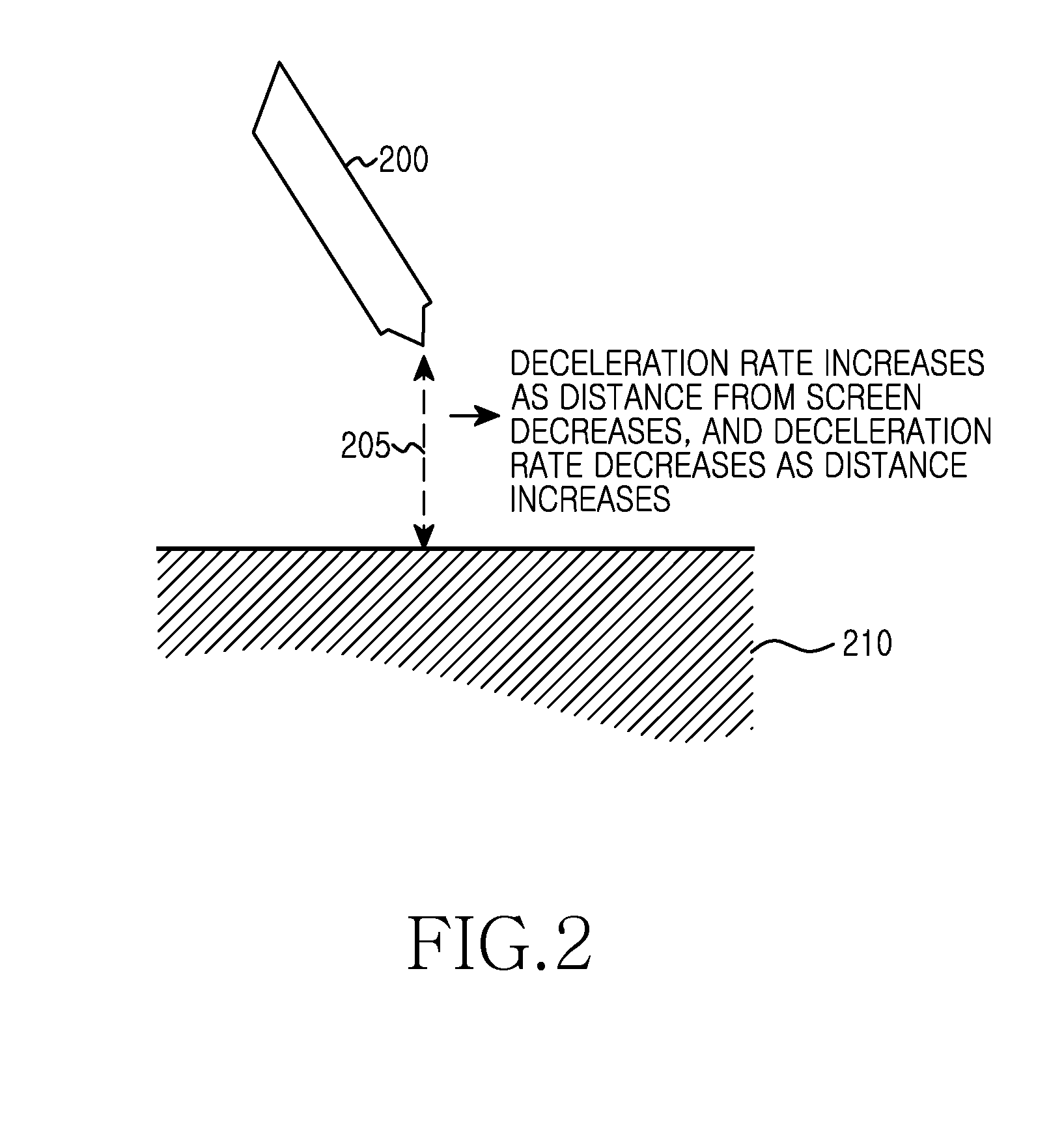

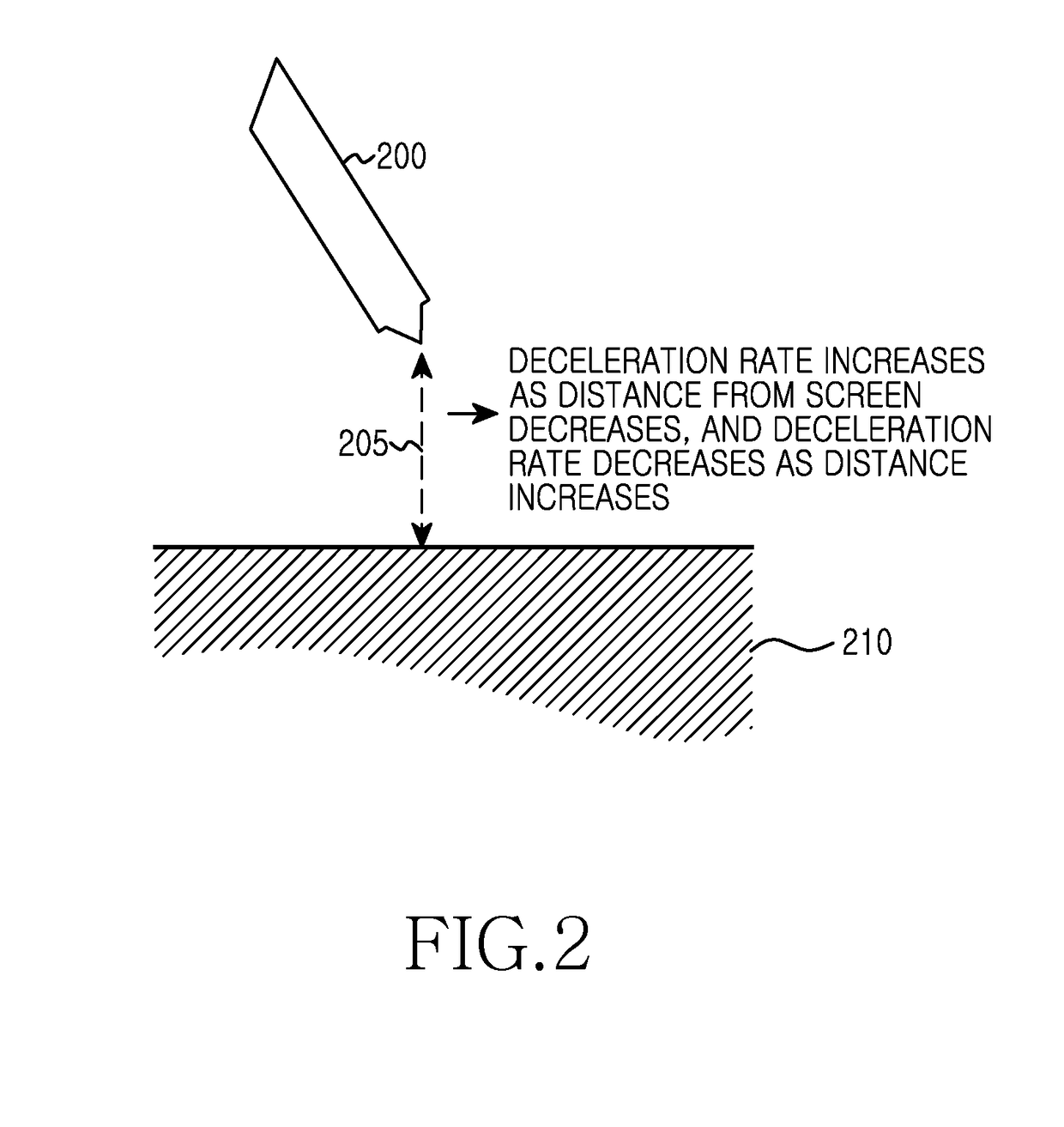

Method and apparatus for controlling user interface by using objects at a distance from a device without touching

InactiveUS20140258932A1Easily and accurately selectReducing initial scroll speedInput/output for user-computer interactionComputer graphics (images)Control electronics

Disclosed herein are a method and apparatus for controlling a user interface in an electronic device. Content details are displayed and scrolled at an initial scroll speed. An object is detected within a predetermined distance from an electronic device without touching the object. The initial scroll speed is reduced in accordance with the distance of the object.

Owner:SAMSUNG ELECTRONICS CO LTD

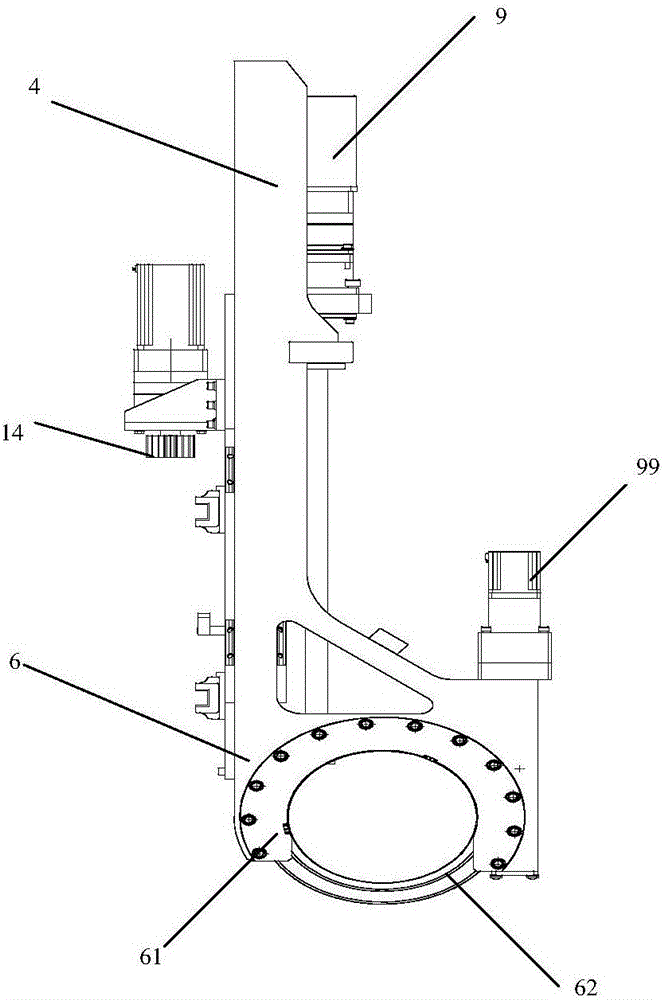

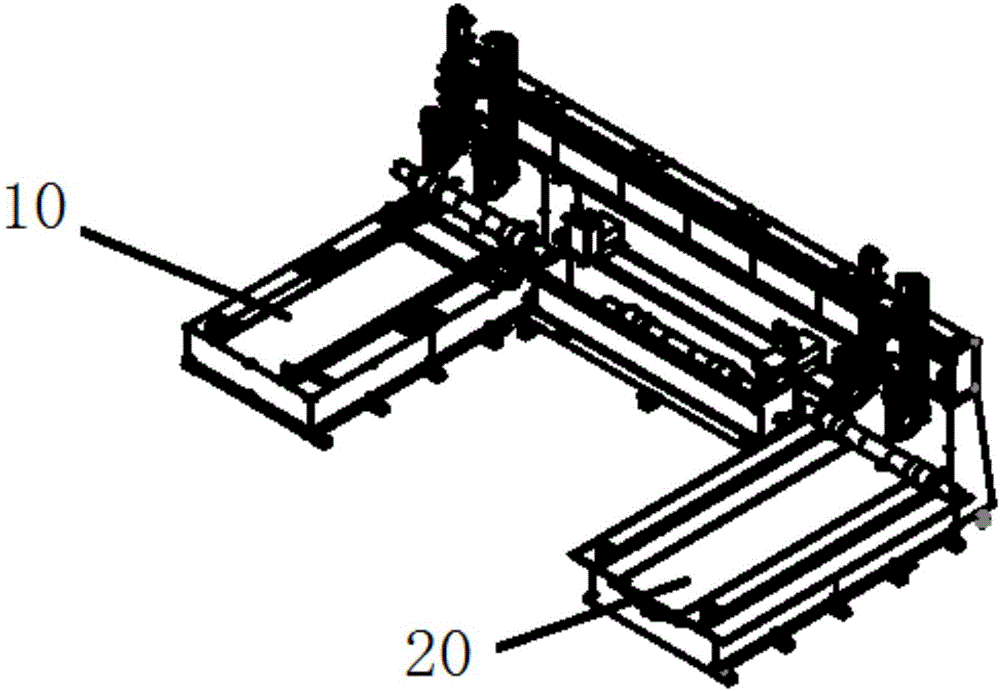

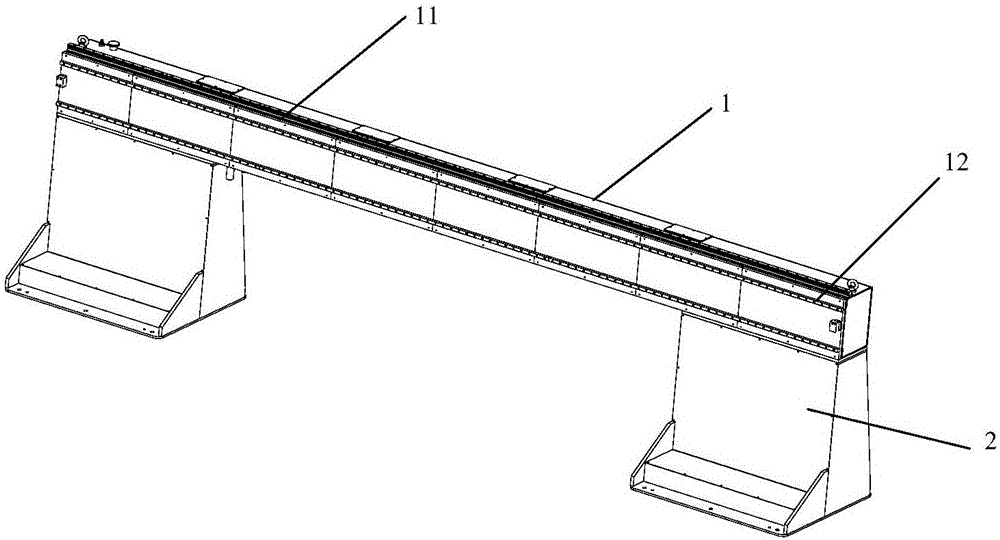

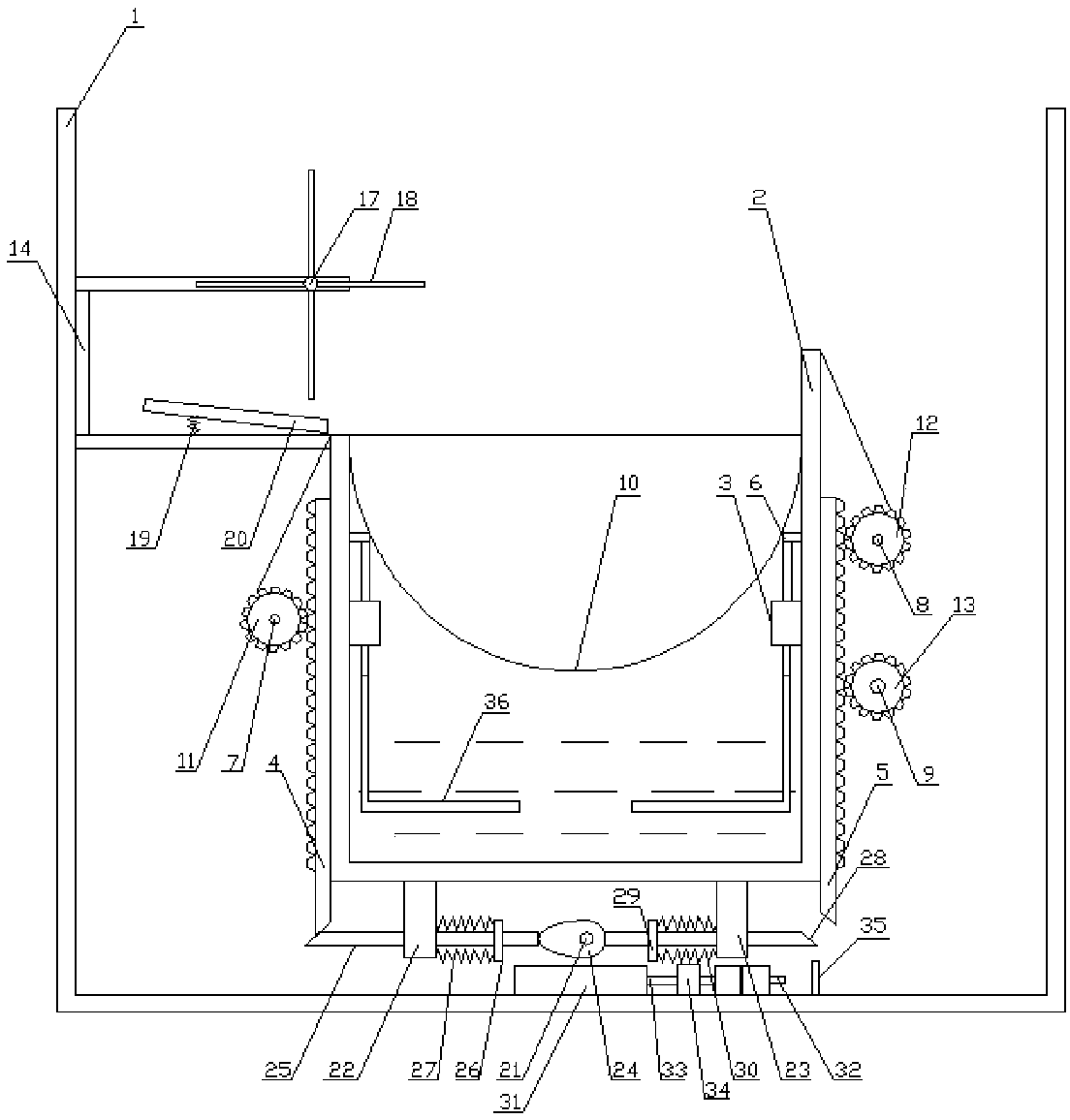

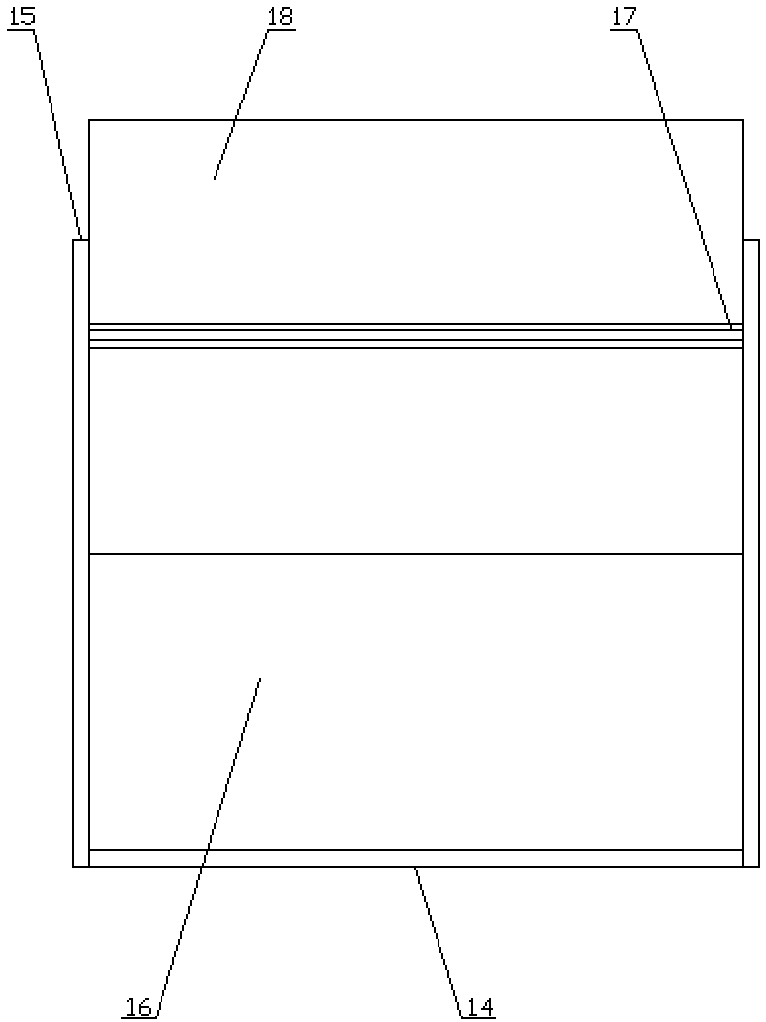

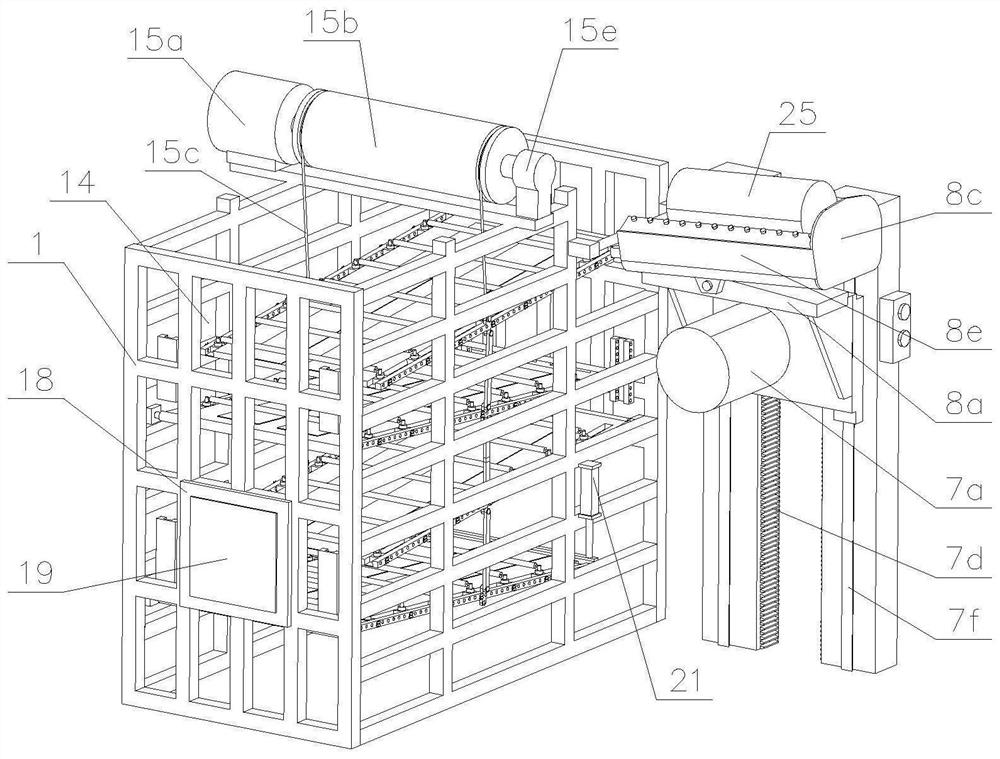

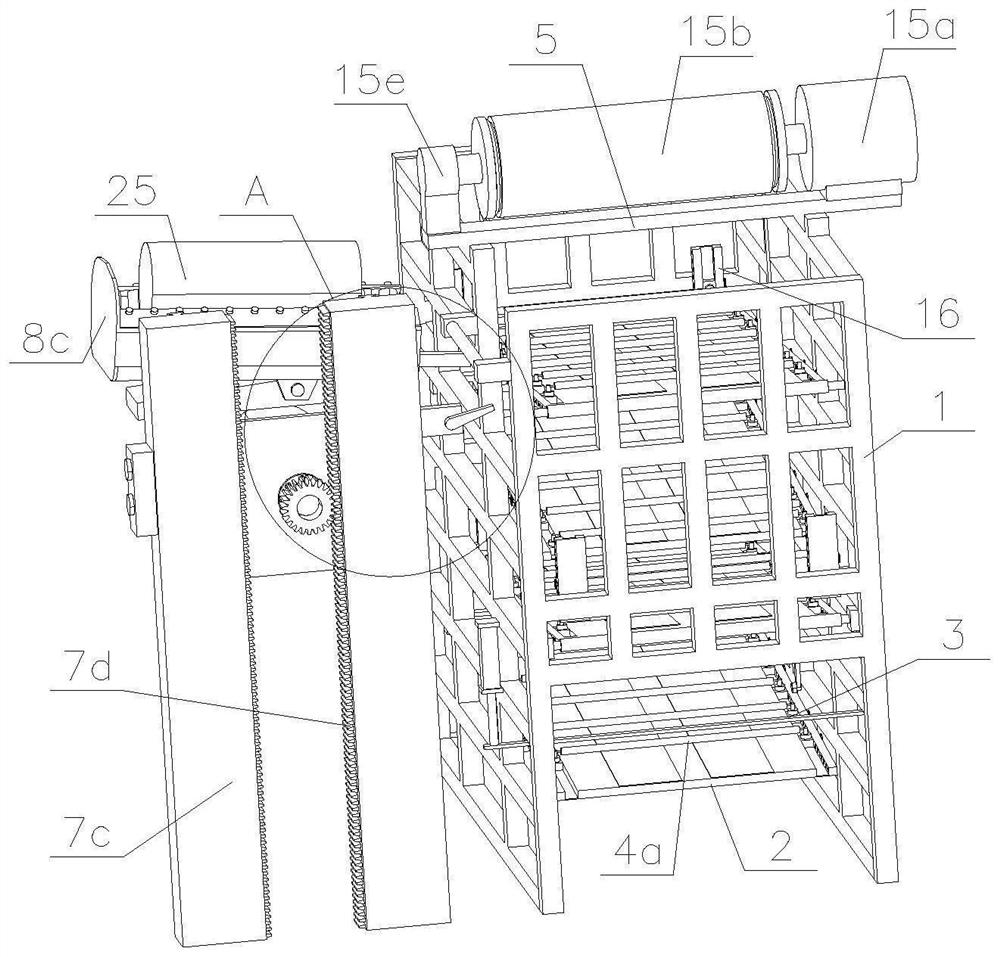

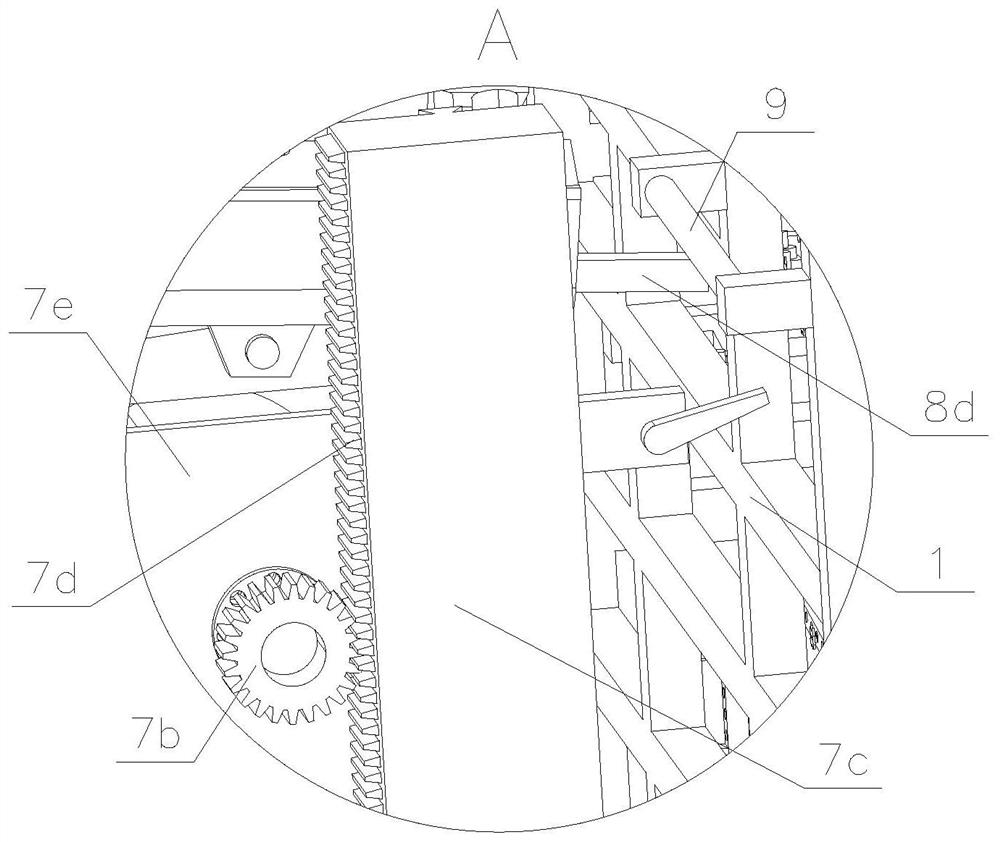

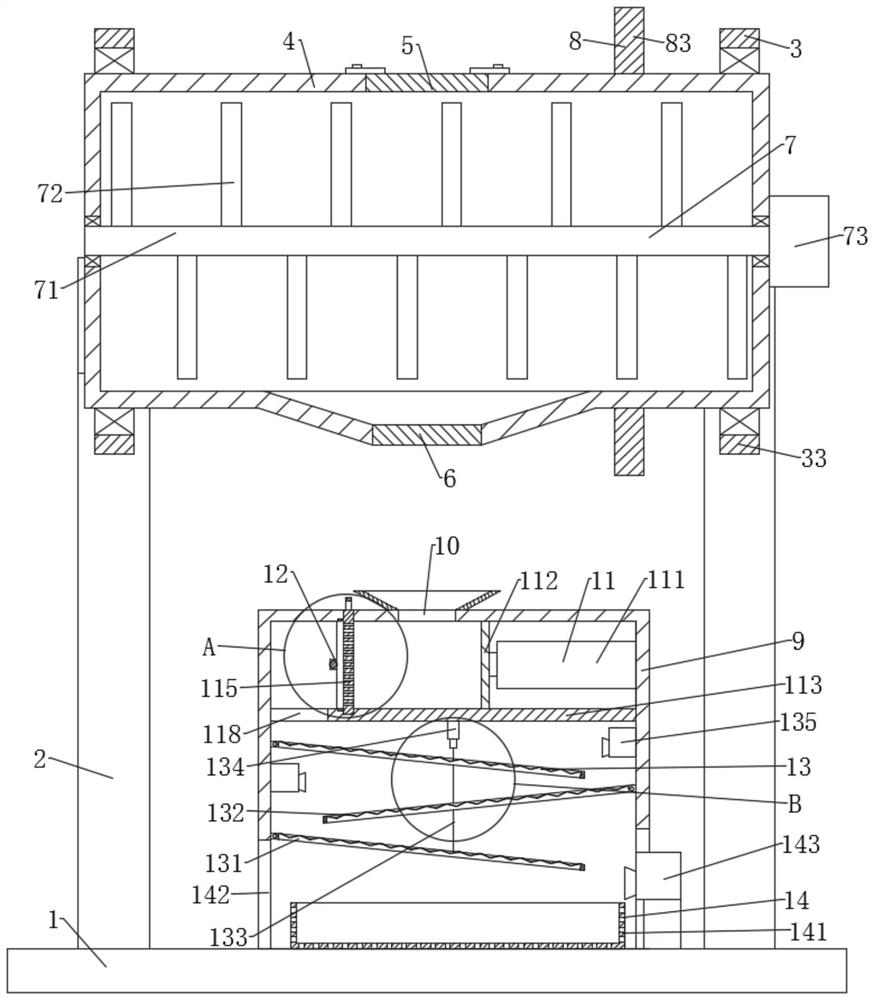

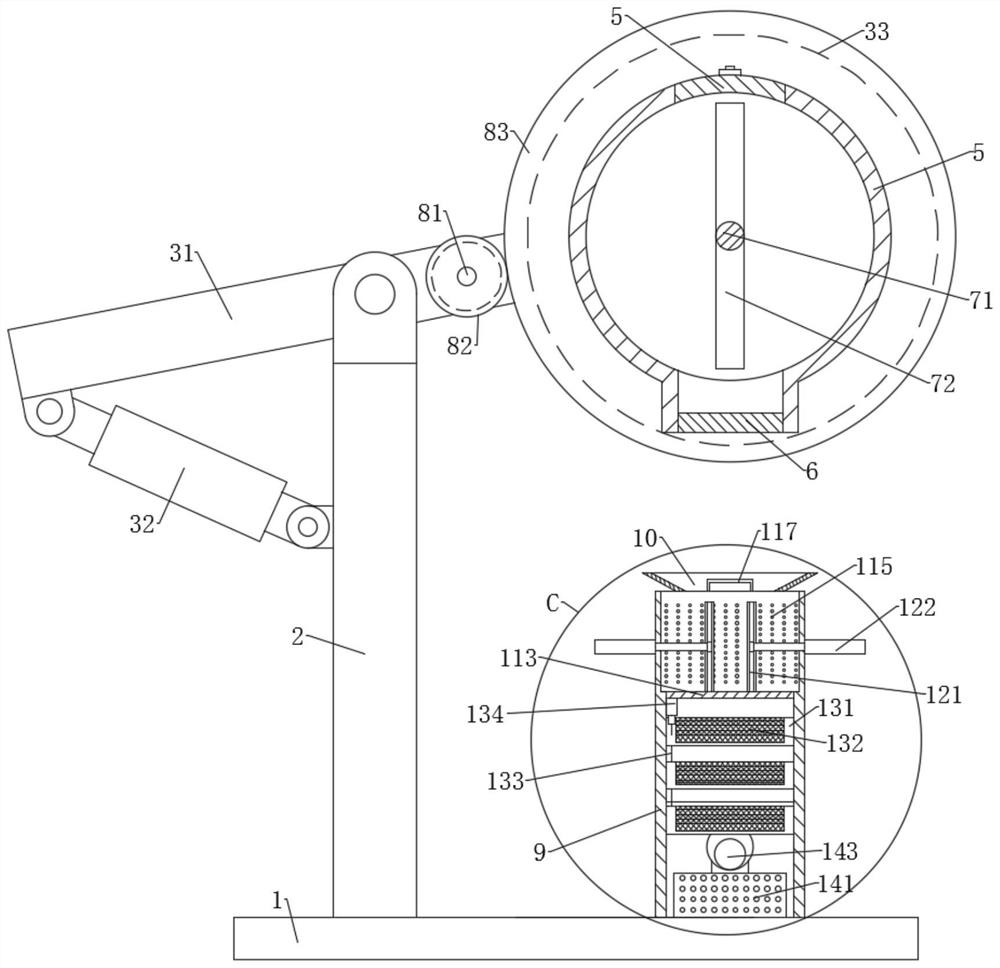

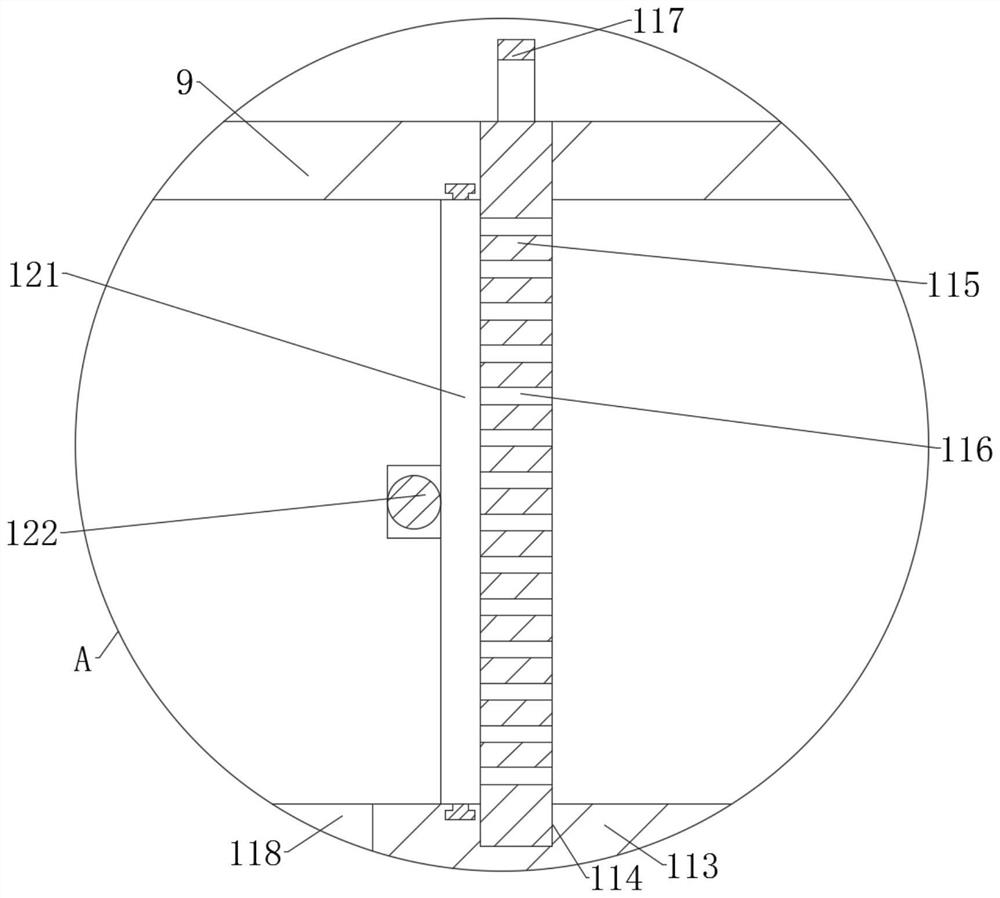

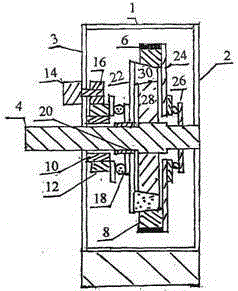

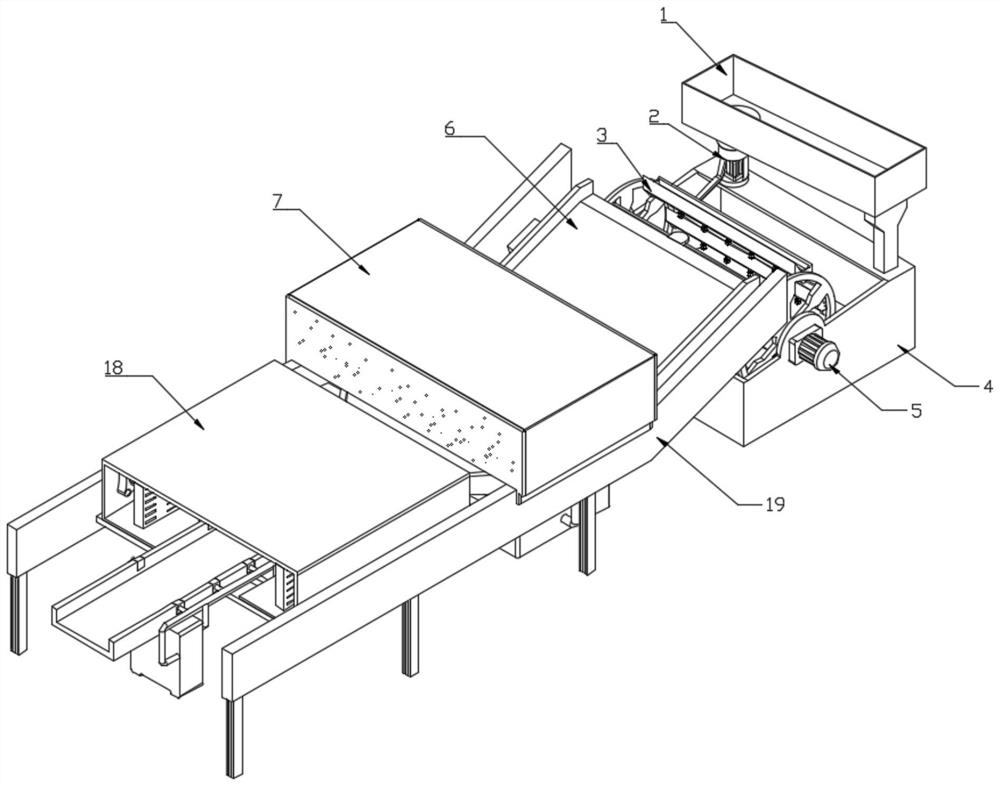

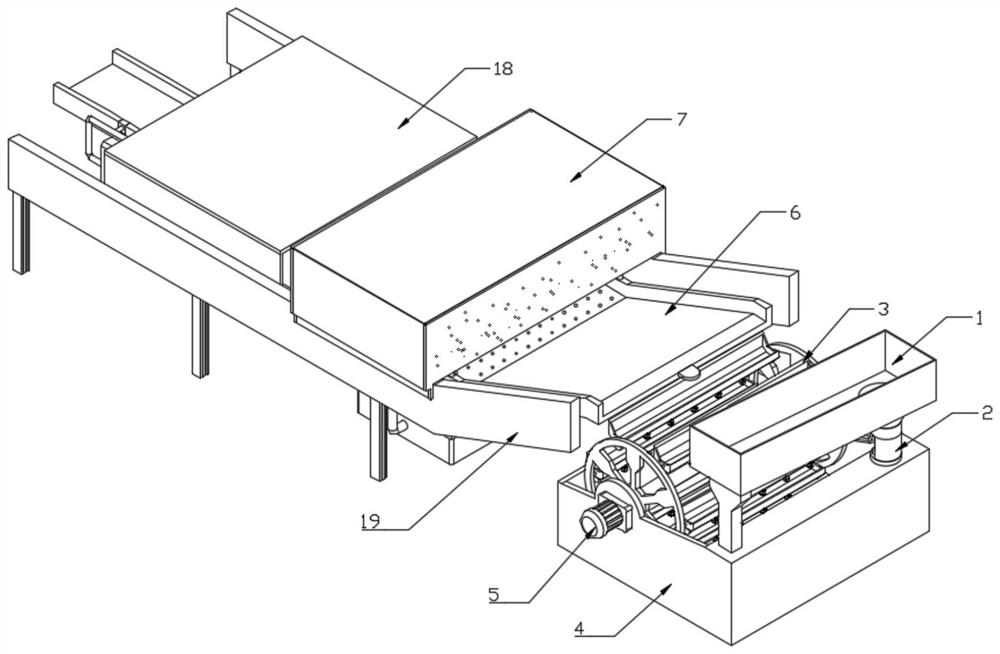

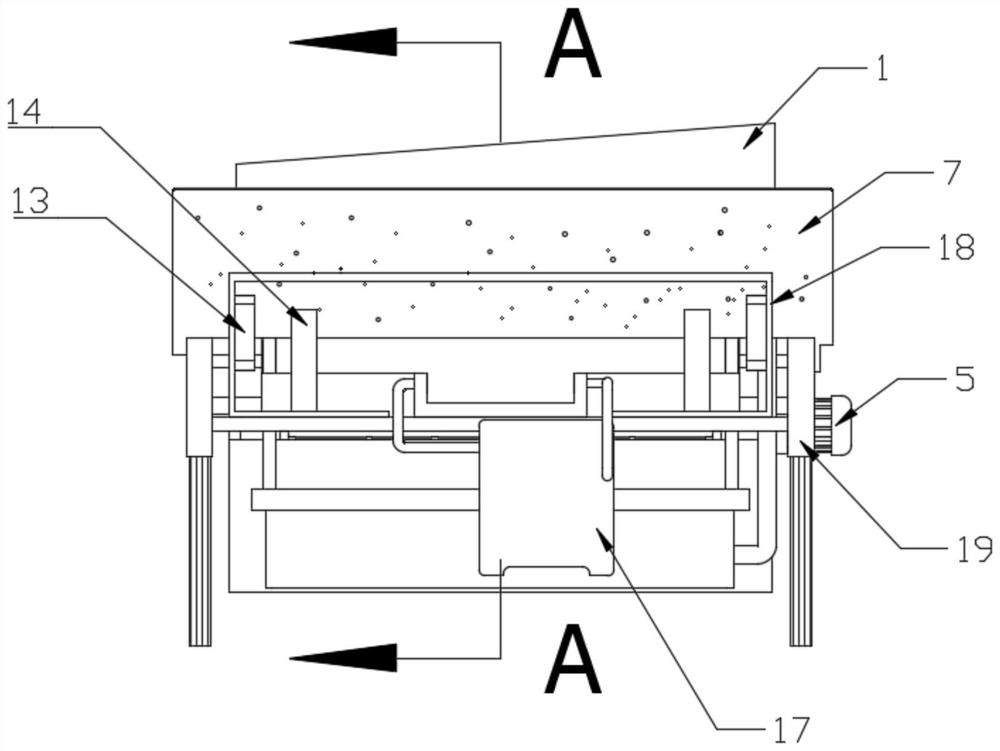

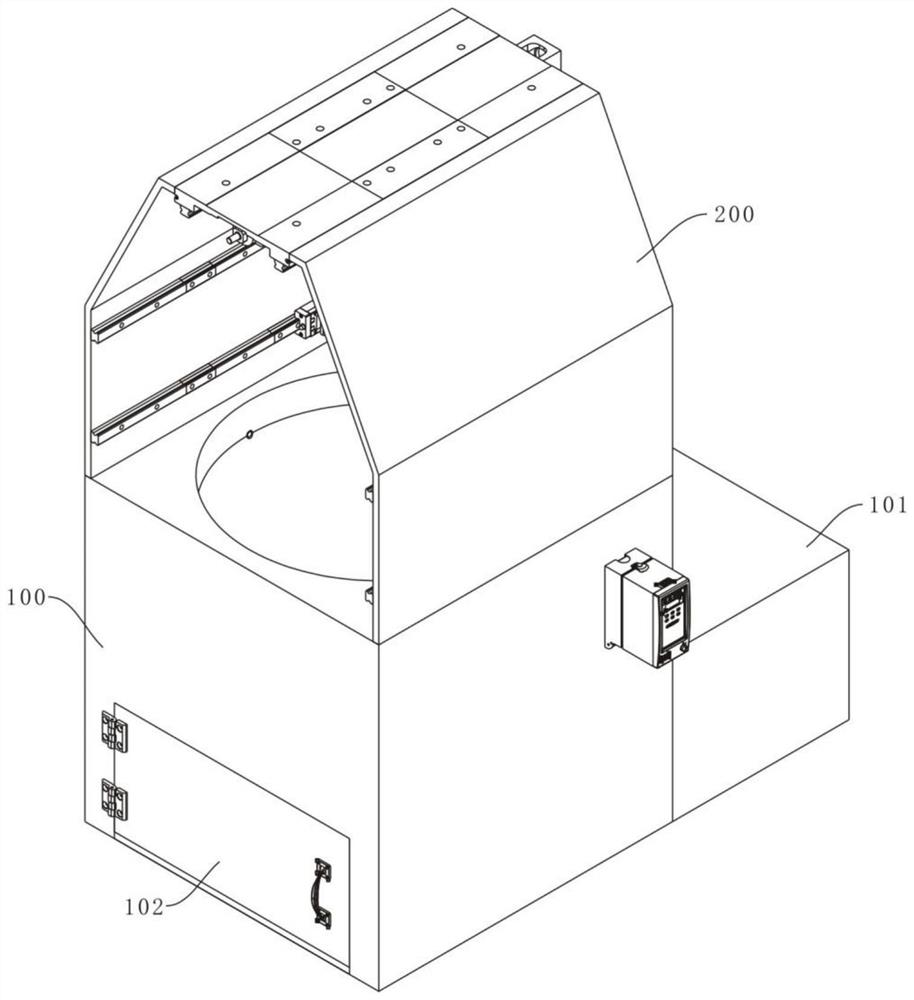

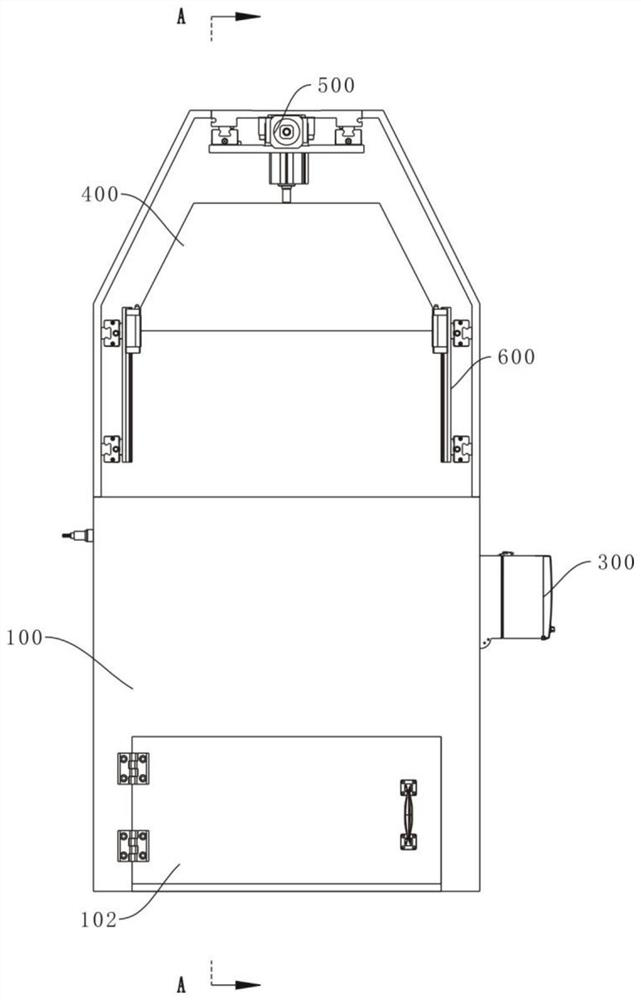

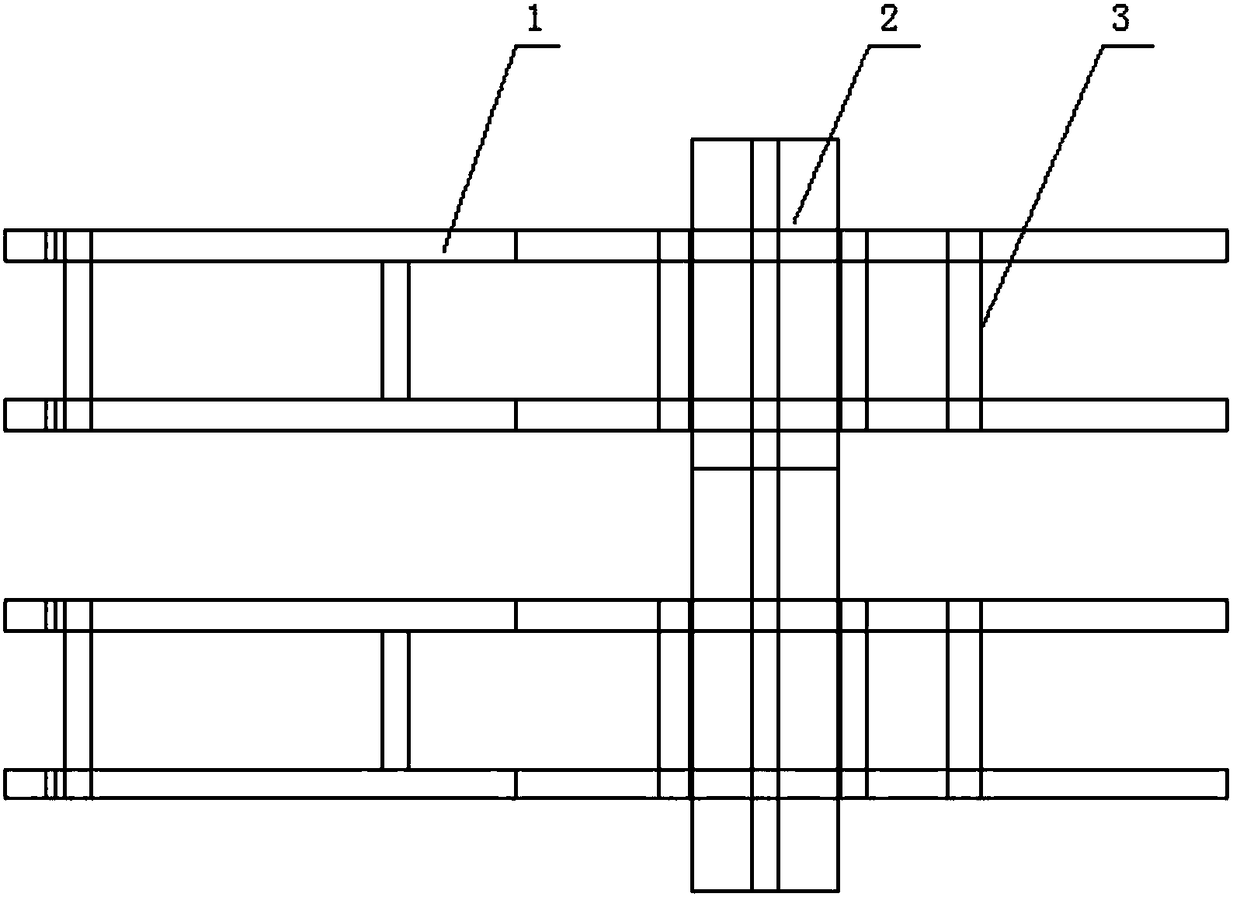

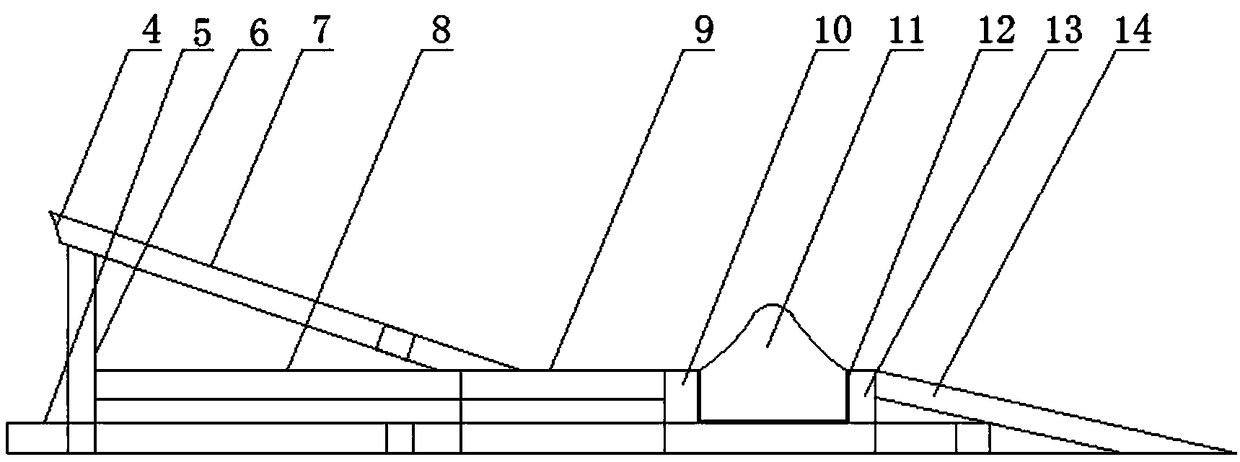

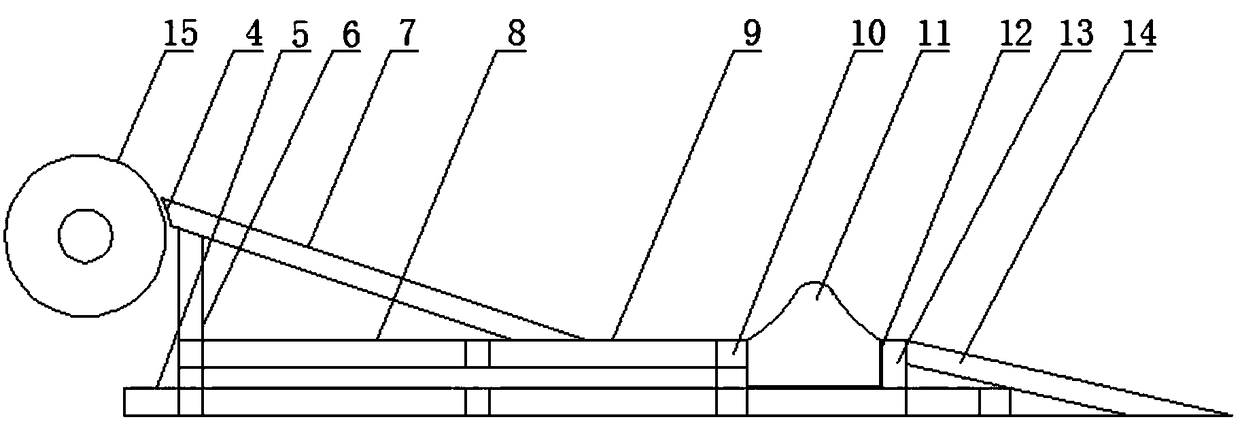

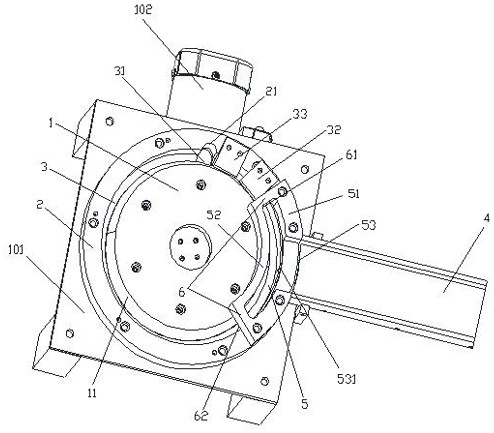

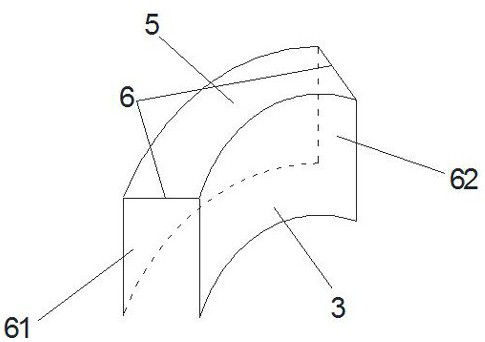

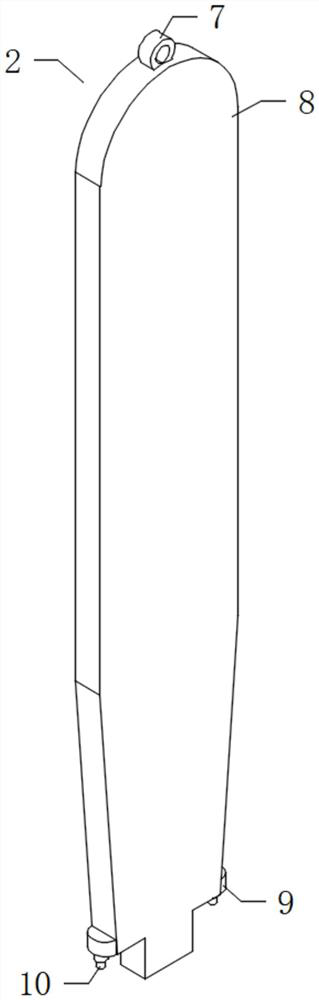

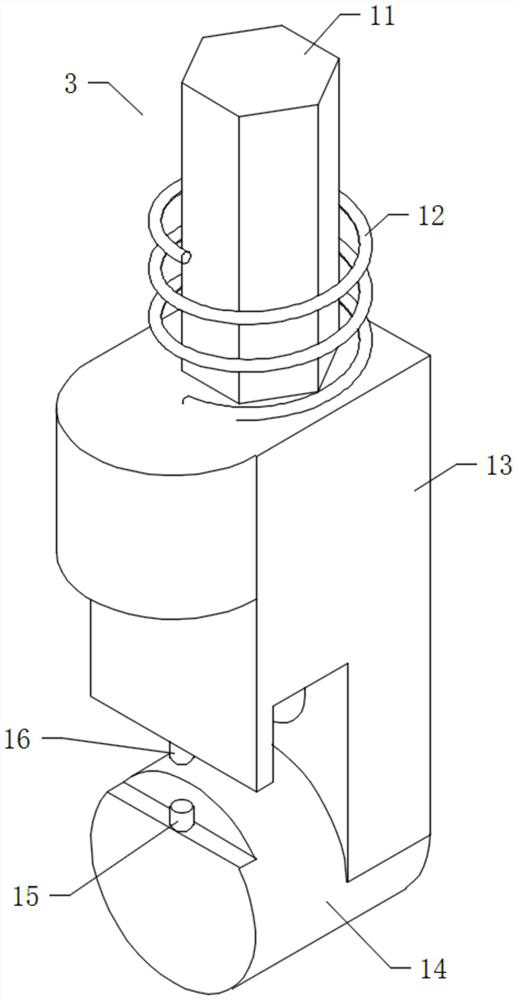

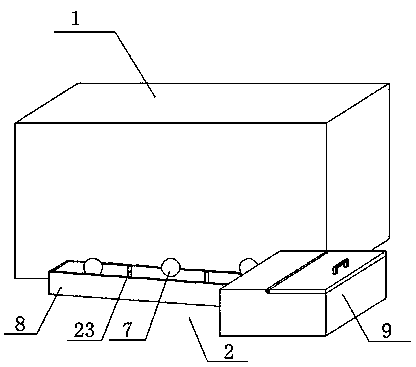

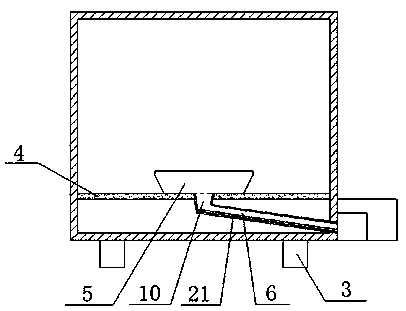

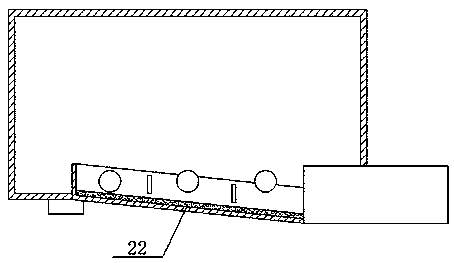

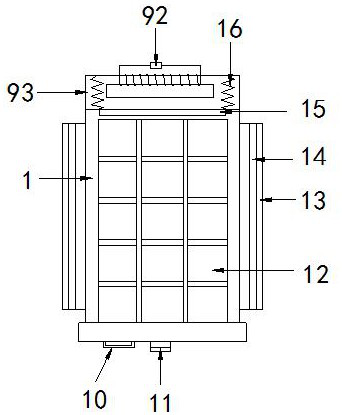

Feeding and discharging equipment for water-immersed ultrasonic flaw detection equipment for direct-axis component

ActiveCN106395235AReduce scrolling speedAvoid bruisesAnalysing solids using sonic/ultrasonic/infrasonic wavesConveyorsManipulatorUltrasound

The invention provides feeding and discharging equipment for water-immersed ultrasonic flaw detection equipment for a direct-axis component. The feeding and discharging equipment for the water-immersed ultrasonic flaw detection equipment for the direct-axis component comprises a feeding device, a moving device and a discharging device. In the embodiment, the direct-axis component is born through the feeding device; the direct-axis component is grabbed and fed into the flaw detection equipment through a manipulator of the moving device; after the direct-axis component is detected, the direct-axis component is fed into the discharging device through the moving device. The feeding and discharging equipment for the water-immersed ultrasonic flaw detection equipment for the direct-axis component has the beneficial effects that the direct-axis component can be fed into a flaw detection machine and discharged from the flaw detection machine, so that the using frequency of an overhead travelling crane is reduced, and the labour efficiency is improved.

Owner:ZHUZHOU TIANLI FORGING IND

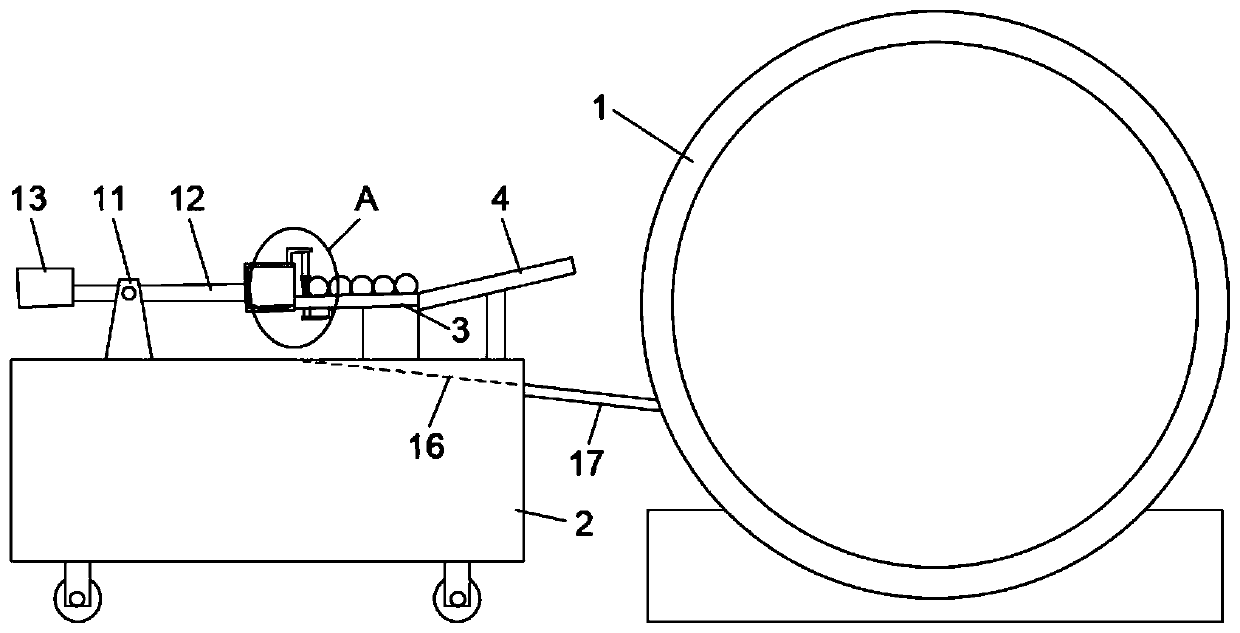

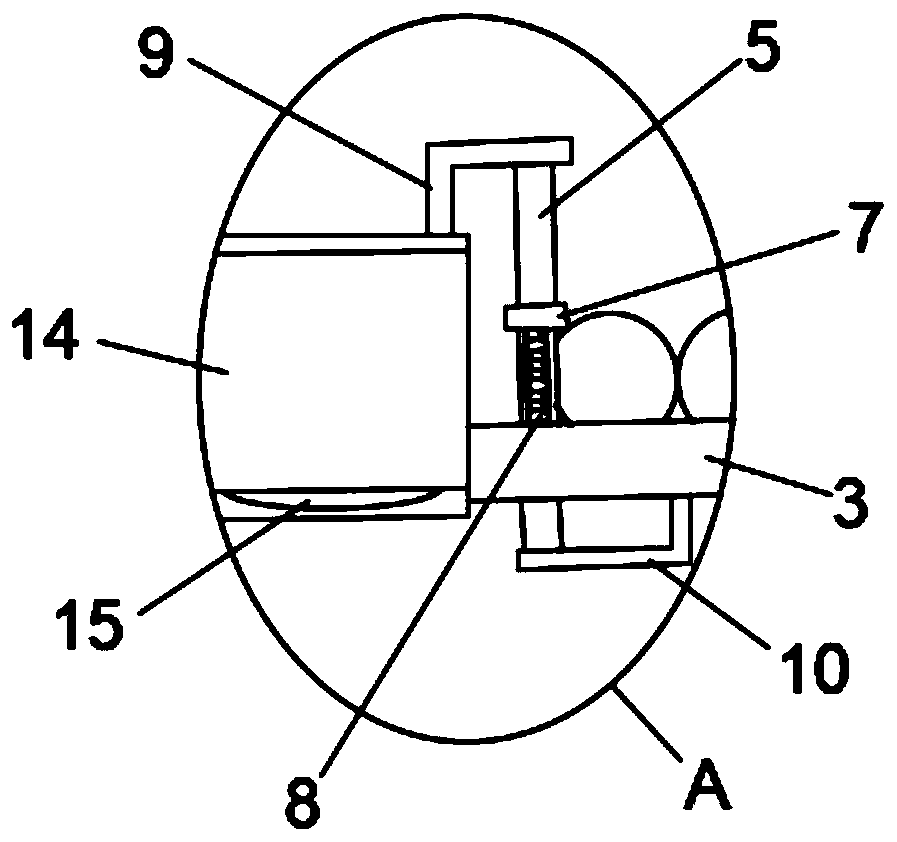

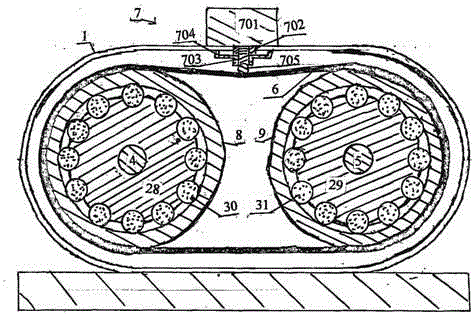

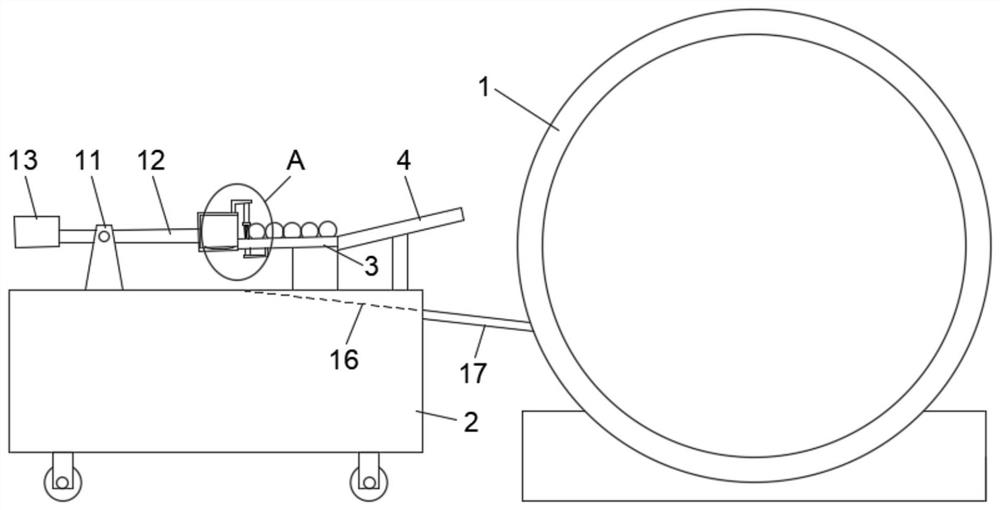

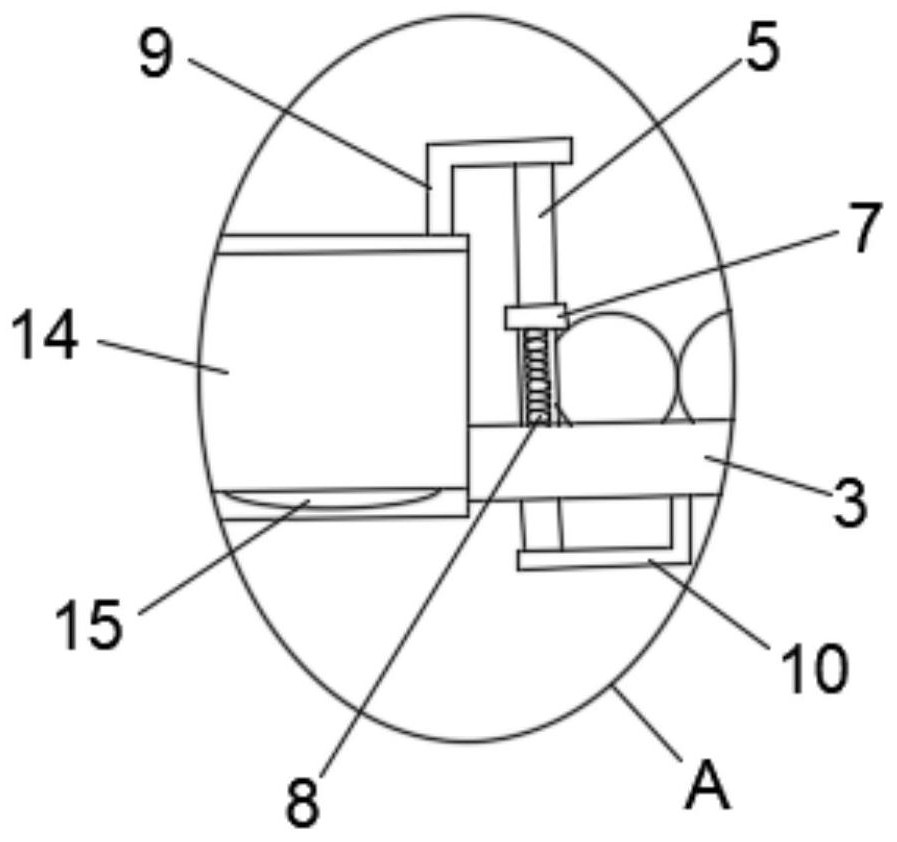

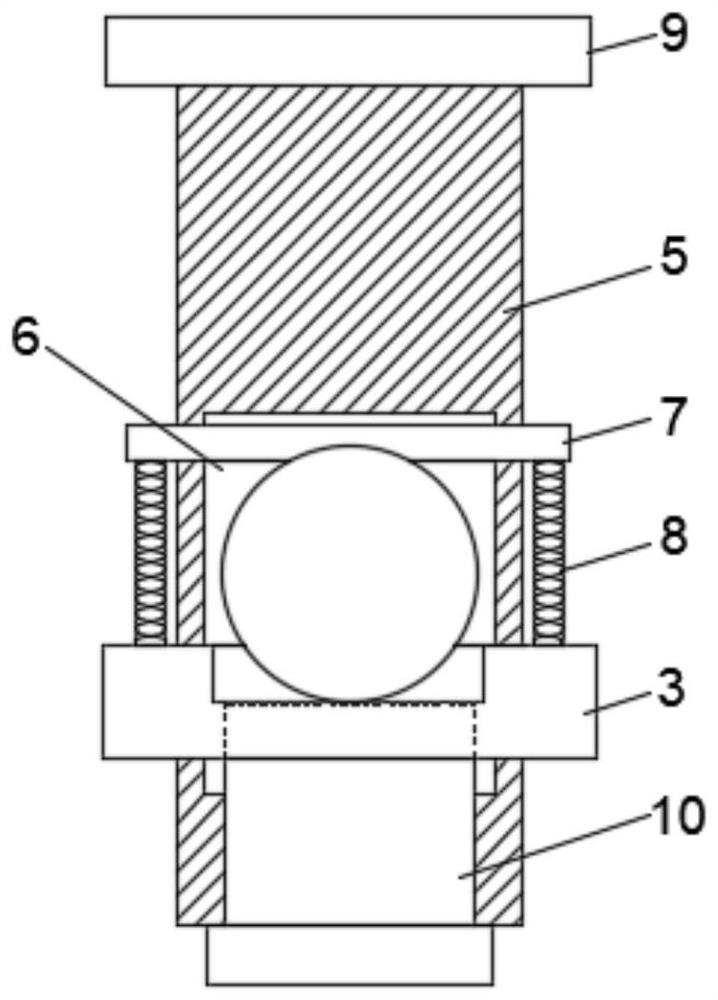

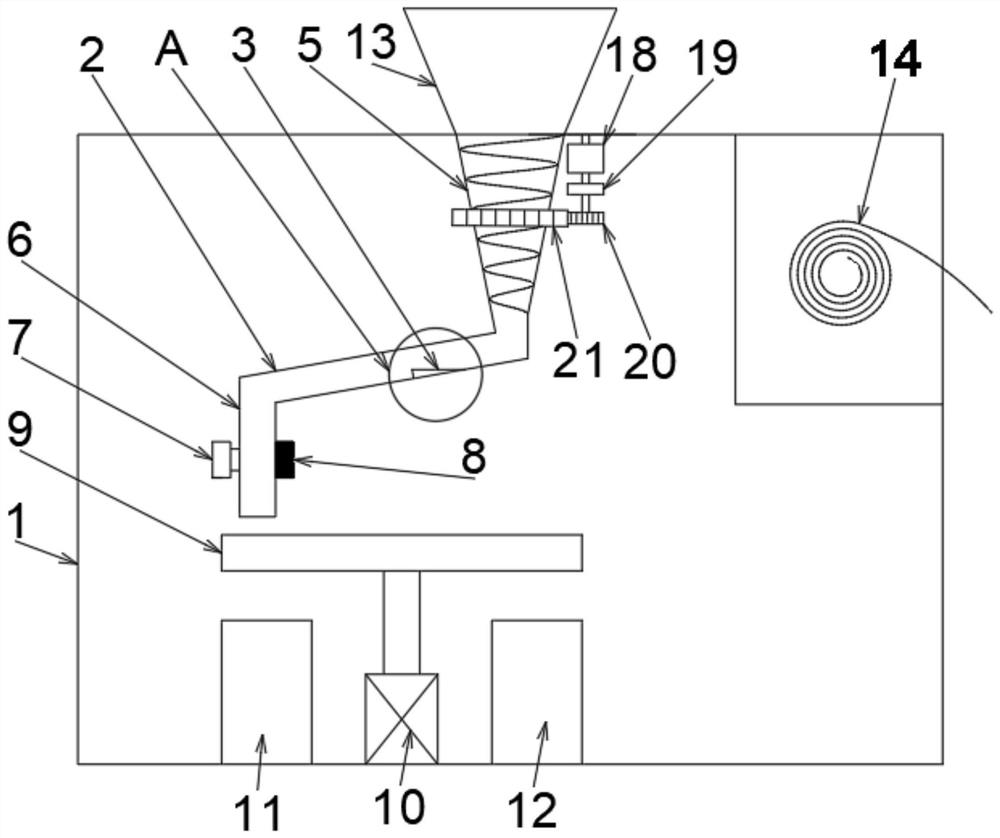

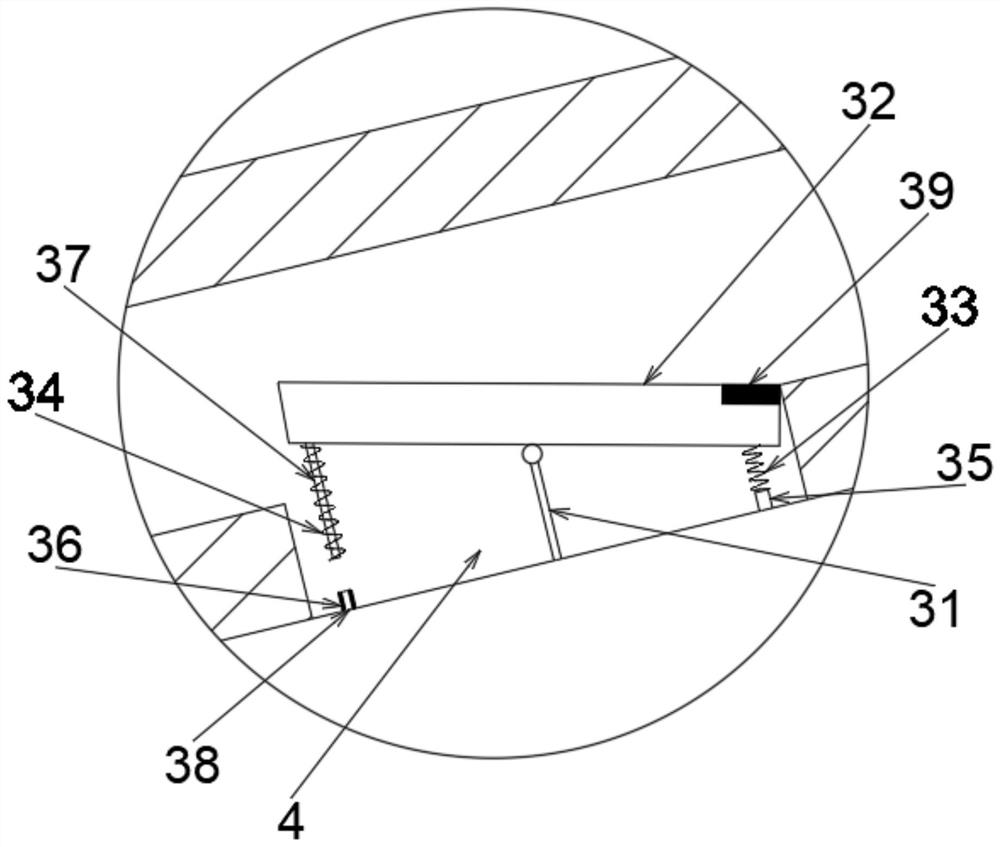

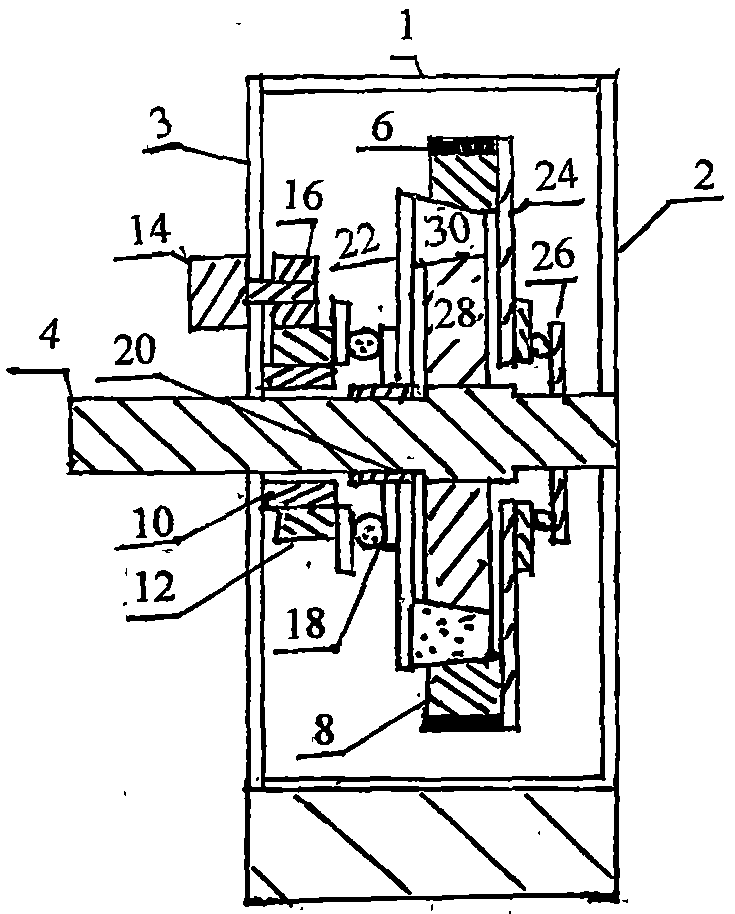

Automatic ball loading device of ball mill

InactiveCN110237907ASave time and effortImprove work efficiencyGrain treatmentsSlide plateEngineering

The invention discloses an automatic ball loading device of a ball mill. The ball mill is included, and a table body is arranged on one side of a bin door of the ball mill; an obliquely arranged track is fixedly supported to the upper end of the table body; the higher end of the track is fixedly provide with a ball containing disk; the side edge of the ball containing disk is provided with a ball outflow port used in cooperation with the track; a sliding plate is arranged at the end, away from the ball containing disk, of the track in a penetrating manner; the middle of the sliding plate is provided with a rectangular hole; the middle portion of the sliding plate is further fixedly sleeved with a stopping rod; the bottom faces of the two ends of the stopping rod and the upper surface of the track are fixedly connected a spring; the upper end of the sliding plate is further fixedly connected with an L-shaped ejecting block; the lower end of the sliding plate is further fixedly connected with an L-shaped partition plate; and the end, away from the sliding plate, of the L-shaped partition plate and the bottom of the track are also in penetrating sliding connection. Due to the automatic ball loading device of the ball mill, grinding balls can be automatically loaded into the bin door of the ball mill one by one, the time and energy of manual ball loading are saved, and the work efficiency is higher; and damage to the interior of a tank body of the ball mill when the grinding balls are loaded in can be lowered.

Owner:FUJIAN DATANG INT NINGDE POWER GENERATION

Cleaning device for shaft type accessories for refrigerators

ActiveCN108114943AReduce scrolling speedIssues Affecting Post-AssemblyCleaning using liquidsEngineeringUltimate tensile strength

The invention discloses a cleaning device for shaft type accessories for refrigerators, and particularly relates to the technical field of cleaning equipment. The cleaning device for the shaft type accessories for the refrigerators comprises a framework. A cleaning tank is fixed into the framework, two slide grooves are formed in the inner walls of the left side and the right side of the cleaningtank, two inflators are arranged on the inner walls of the left side and the right side of the cleaning tank, a first rack and a second rack are slidably connected with the cleaning tank, push rods are connected onto the first rack and the second rack, a first rotary shaft, a second rotary shaft and a first motor are fixed onto the framework, a cleaning net is arranged between the first rotary shaft and the second rotary shaft in a connected manner, a first gear is rotationally connected onto the first rotary shaft, a second gear is rotationally connected onto the second rotary shaft, a thirdgear is rotationally connected onto an output shaft of the first motor, a push mechanism is connected with the lower side of the cleaning tank, a linkage mechanism is arranged on the push mechanism, and a drying chamber is connected onto the cleaning tank. According to the technical scheme, the cleaning device has the advantages that the problem of high labor intensity in shaft type accessory cleaning procedures in the prior art can be solved by the aid of the cleaning device, and the cleaning device can be used for cleaning work on the shaft type accessories.

Owner:枞阳县黎阳中小企业服务中心

Roller surface treatment device for steel rolling mill

InactiveCN110773481AIncrease frictionEasy to cleanRolling equipment maintainenceCleaning using toolsStructural engineeringRolling mill

The invention discloses a roller surface treatment device for a steel rolling mill. The roller surface treatment device comprises a bottom plate; a rectangular groove is formed in the middle of the outer wall of the top of the bottom plate; the inner walls of the two sides of the rectangular groove are quarter arcs; first springs are arranged on the two sides of the outer wall of the top of the bottom plate correspondingly; a placement plate is disposed on the outer walls of the tops of the two first springs; a fixing strip is disposed on the outer wall of one side of the placement plate; a strip-shaped groove is formed in one side of the outer wall of the top of the bottom plate; a sliding block is slideably connected with the inner wall of the bottom of the strip-shaped groove; a positioning hole is formed in the outer wall of one side of the sliding block; and supporting plates are disposed in the middle of the outer wall of the top of the sliding block and on one side of the outerwall of the top of the bottom plate correspondingly. By means of the roller surface treatment device for the steel rolling mill, supporting blocks can be prevented from colliding with the rectangulargroove and being damaged, the situation that the device cannot work due to insufficient motive power can be prevented, the environment-friendliness of the device can be improved, and the situation that a roller falls off from a fixing sleeve and is damaged due to insecure fixing can be prevented.

Owner:湖北贵昌机械设备科技有限公司

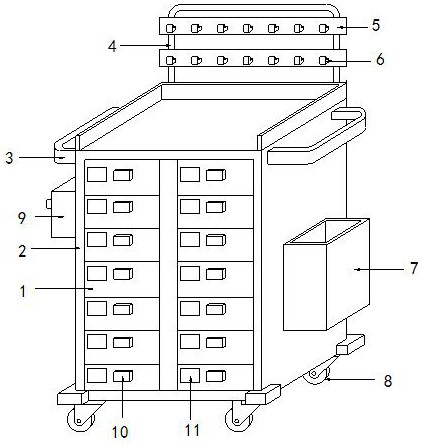

Automatic feeding and storing device

PendingCN113859849AReduce scrolling speedAvoid deformation damageStorage devicesEngineeringStress sensors

The invention discloses an automatic feeding and storing device which comprises a storing frame. A plurality of obliquely downward storing plates are distributed on the storing frame in the height direction of the storing frame; the adjacent storing plates enclose to form a zigzag storing passage; an intercepting part is movably arranged at the output end of the storing passage; speed reducing parts are arranged in the storing passage at intervals in the storing direction of the storing passage; the speed reducing parts are connected with a pressure sensor; the speed reducing parts comprise straight-through speed reducing parts arranged on the storing plate and corner speed reducing parts arranged on the storing frame; the interval between every two adjacent straight-through speed reduction parts is equal to the diameter of a material; and a feeding mechanism is arranged in a mode of directly facing the input end of the storing passage. According to the automatic feeding and storing device, the speed reducing parts are used for buffering and reducing the rolling speed of the material, so that collision is relieved, noise is reduced, the material is prevented from being deformed and damaged, the interval and the positions of the speed reducing parts are limited, the material is guaranteed to be abutted against the speed reducing parts during storage, then a pressure sensor detects pressure signals, and a current material storage amount of the device is determined according to the signal quantity.

Owner:江阴金属材料创新研究院有限公司

Aquatic product breeding feed manufacturing device and method

PendingCN114098117AImprove mix qualityRaw materials are mixed evenlyFeeding-stuffTransportation and packagingProcess engineeringInternal cavity

According to the aquatic product breeding feed manufacturing device and method, various raw materials are stirred through a stirring assembly, meanwhile, a stirring barrel is driven to swing up and down through a swinging assembly, the stirring barrel is driven to rotate through a driving assembly, the various raw materials in an inner cavity of the stirring barrel are fully mixed, and the mixing effect is good; the feed is extruded into long strips through the extrusion assembly, and the long-strip feed is sheared into granules through the shearing assembly; pellet feed is fully dried through the drying assembly, the drying effect is good, the pellet feed is dried, cooled and collected through the collecting assembly, feed spoilage caused by accumulation of hot feed is prevented, an insertion plate is convenient to disassemble, assemble and replace, and the device is suitable for manufacturing feed with different diameters.

Owner:含山县创兴水产品养殖专业合作社

CVT stepless speed changer

The invention discloses a CVT stepless speed changer. A clamping speed reduction motor rotates to drive a clamping nut to rotate, so that a clamping screw and a roller are driven to move upwards or downwards to adjust the tightness degree and the slipping degree of a metal belt, and the rotating speed ratio of a driving rotating shaft to a driven rotating shaft is adjusted. If the needed rotating speed is not reached through a roller type clamping device, the rotating speed will be adjusted through two AT stepless speed changers. The adjusting process of the AT stepless speed changer on the driving rotating shaft includes the steps that an input speed reduction motor rotates and drives an input gear nut to rotate on an input annular screw through an input driving gear, and the input gear nut drives an input spline to move through an input rear thrust bearing, so that an input thrust disc on the input spline moves to adjust pressure exerted on input conical rollers, the rolling speed of the input conical rollers is adjusted, and then the rotating speed difference between a driving grooved wheel and a driving belt wheel is adjusted. The adjusting process of the AT stepless speed changer on the driven rotating shaft is the same as that of the AT stepless speed changer on the driving rotating shaft.

Owner:张英华

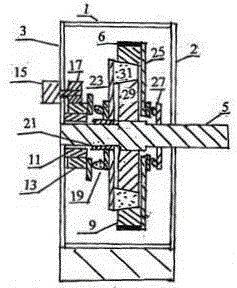

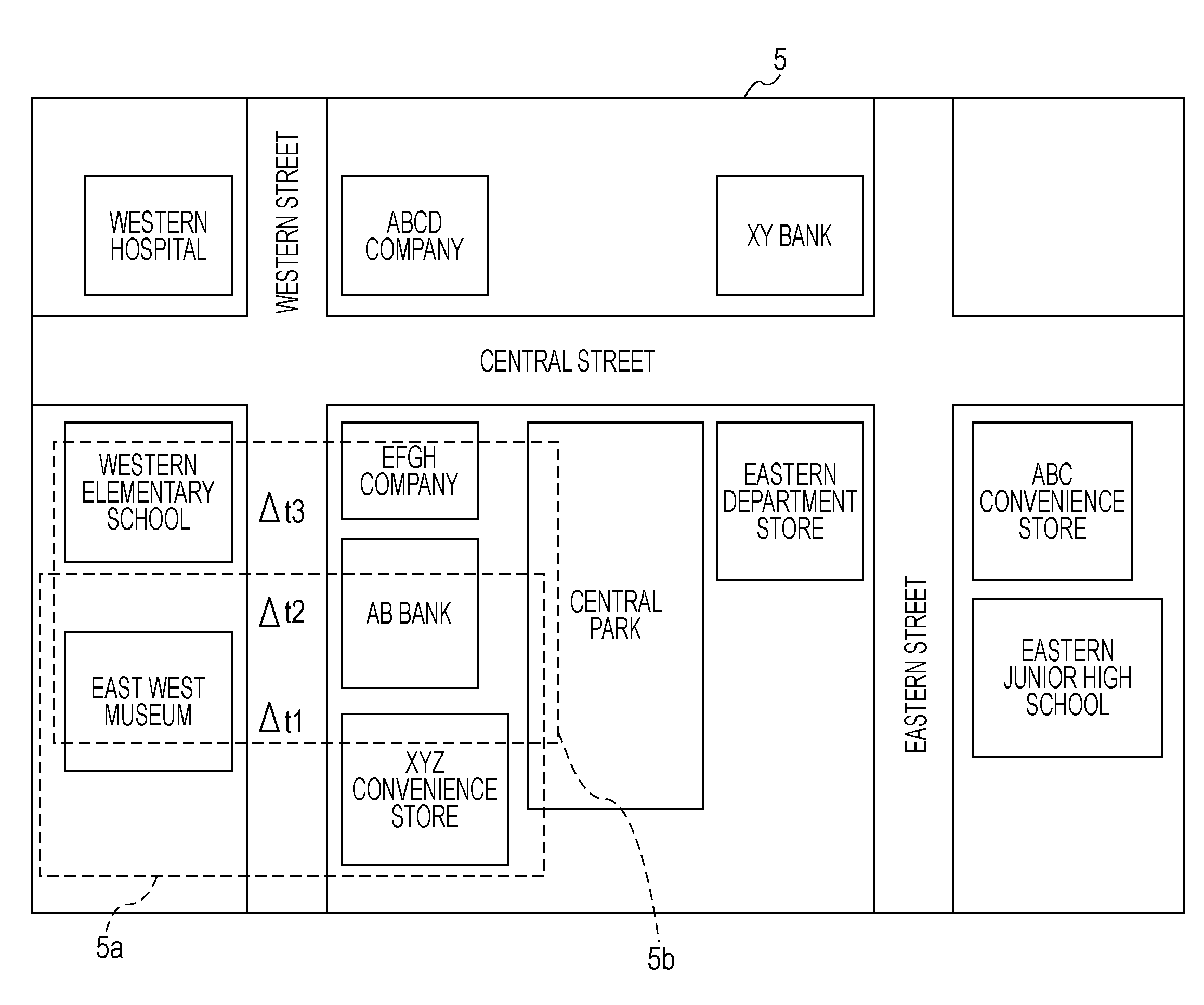

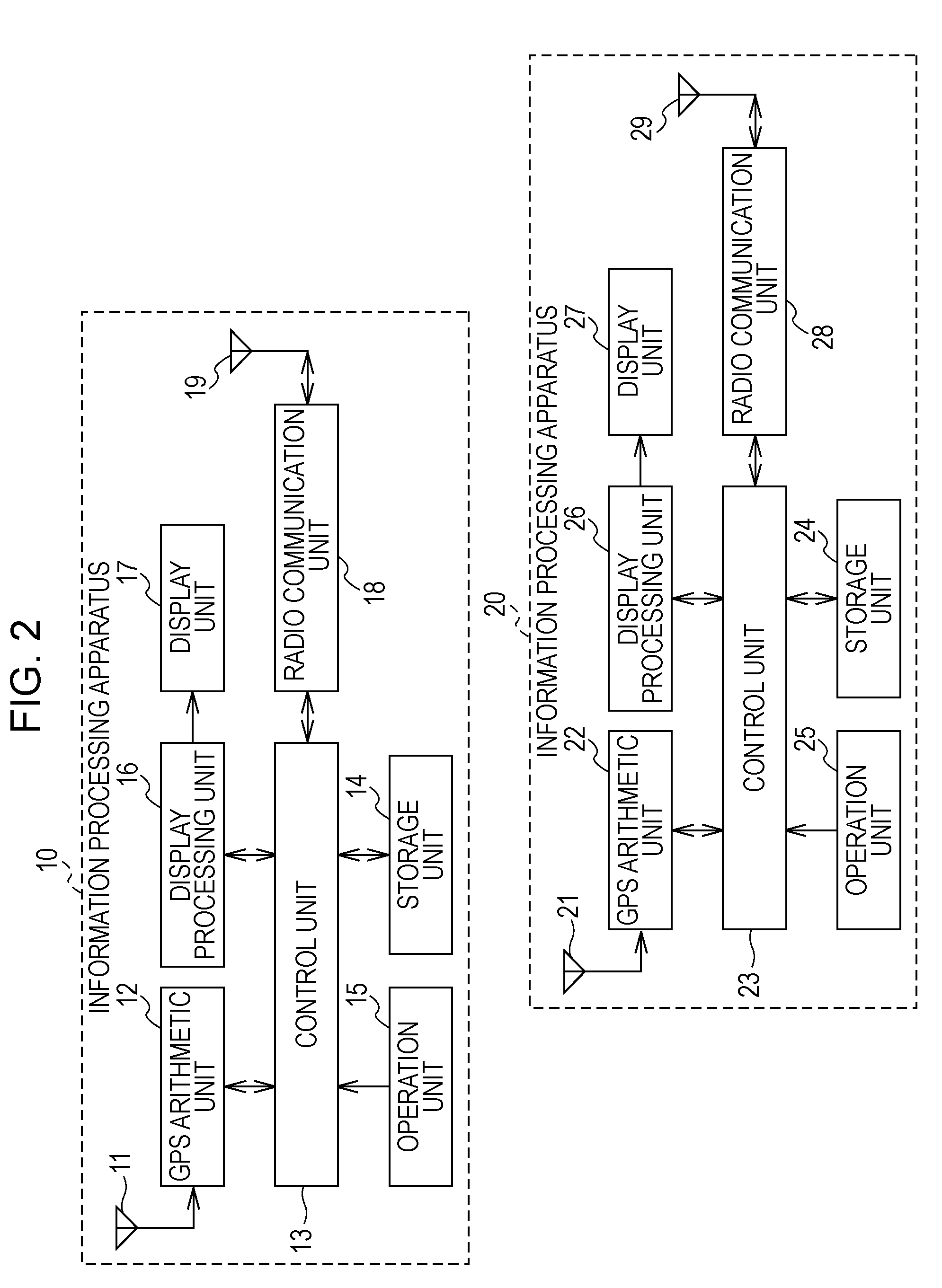

Information display method, information processing apparatus, and information display program

ActiveUS8321127B2Reduce scrolling speedReliable readInstruments for road network navigationRoad vehicles traffic controlInformation processingScrolling

Disclosed is an information display method whereby an information processing apparatus displays a map on a display screen such that a cursor is displayed at a position measured as the current position of a position indication object on the map. The method includes the steps of, when the moving speed of the position indication object is equal to or less than a threshold speed, scrolling the map on the display screen in accordance with the movement of the position indication object in a first display mode, and when the moving speed of the position indication object is greater than the threshold speed, fixing the map on the display screen in a second display mode or reducing the speed of scrolling the map on the display screen so that the scrolling speed is less than that in the first display mode.

Owner:SONY CORP

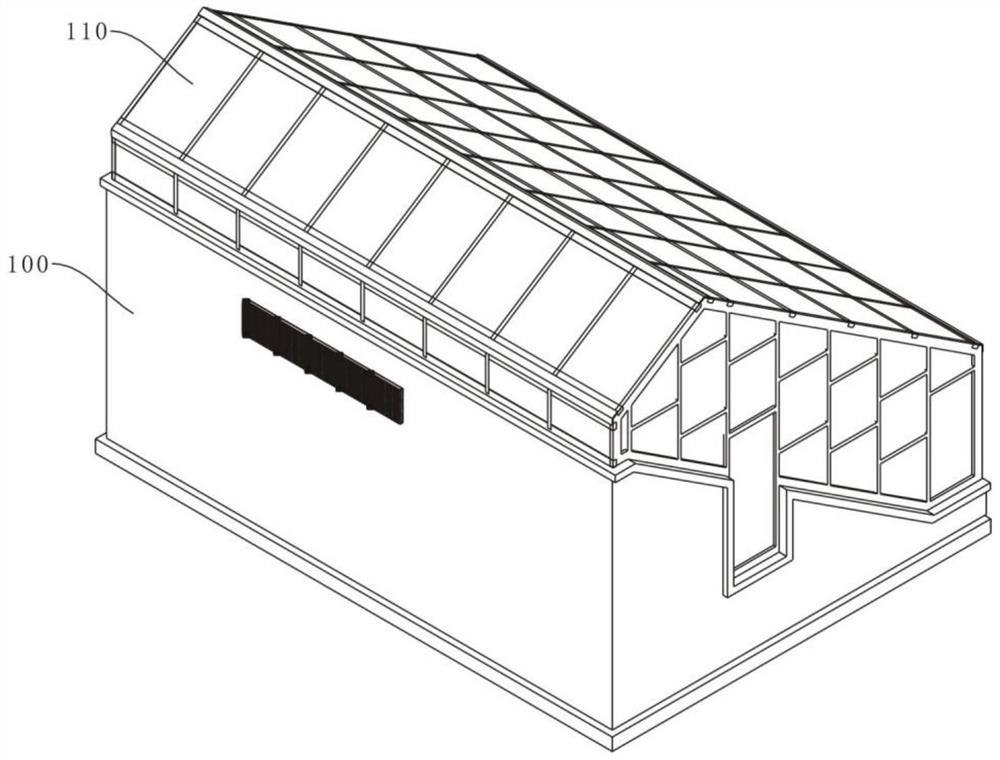

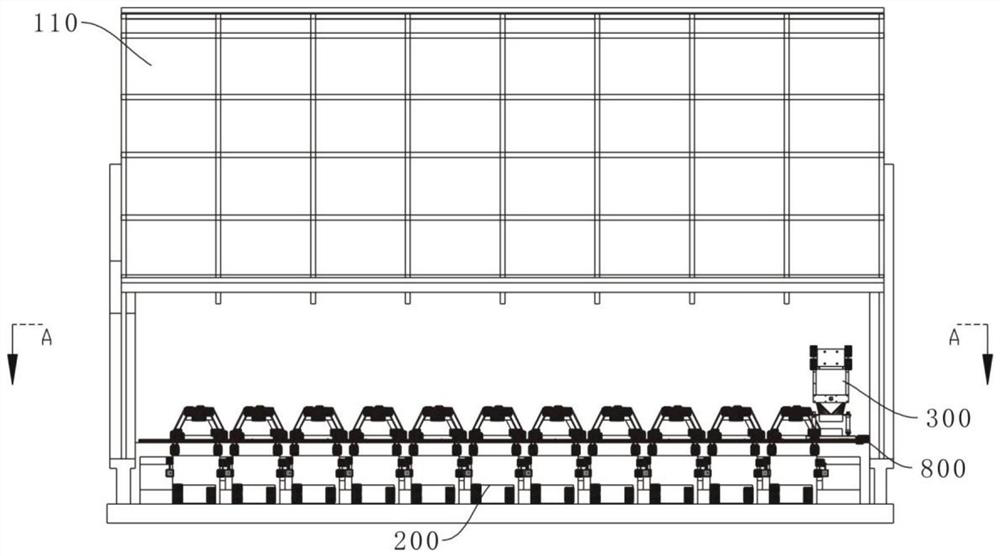

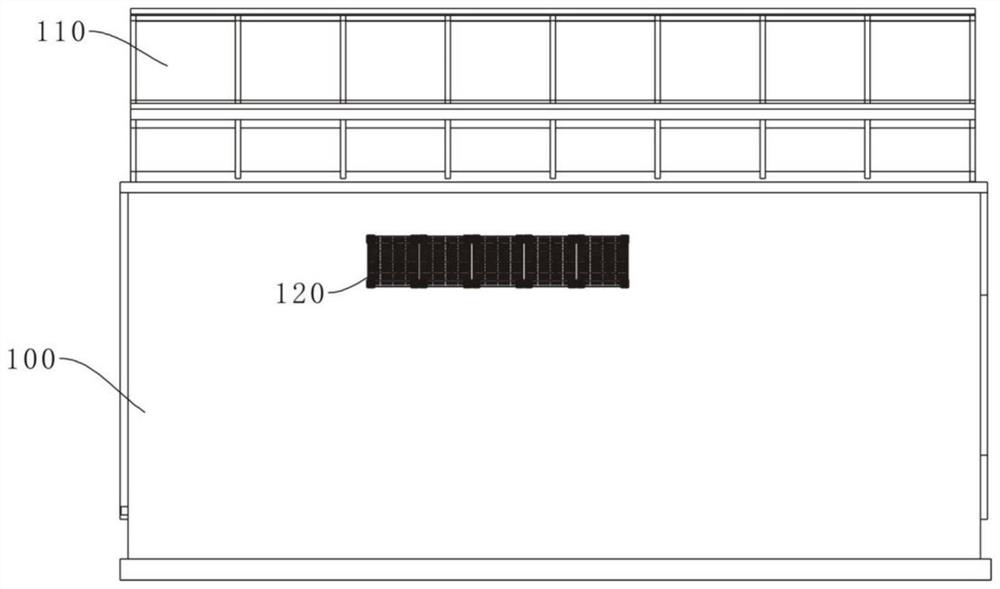

Environment-friendly free-range chicken coop

ActiveCN111838009AAvoid infectionAvoid wastingMeasurement devicesLivestock managementBreeding chickenWater source

The invention discloses an environment-friendly free-range chicken coop. The environment-friendly free-range chicken coop comprises a shed body, wherein a layer of solar panels are laid on the top ofthe shed body to supply power for equipment in the shed body; a ventilator is arranged on the side wall of the shed body so as to realize air circulation in the shed body; a chicken coop body is arranged in the shed body; a feed trough is arranged in the shed body; a frame body is arranged in the shed body; a feed trough is arranged in the frame body; a feeding device is arranged above the frame body and is slidably connected with the frame body; a driving mechanism B is arranged on the frame body and drives the feeding device to move in the direction of the feed trough when a feed is fed intothe feed trough; a water supply pipeline is installed on the frame body; the water supply pipeline is arranged above the feed trough and communicates with an external water source; and a plurality ofball valve drinkers are evenly installed at the lower end of the water supply pipeline and communicate with the water supply pipeline. According to the invention, solar energy is fully used to allowair in the chicken coop to flow, feeding of the feed and drinking water is automatic, and free-range chickens having laid eggs can be expelled.

Owner:湖南恒欣农业股份有限公司

System and method for prolonging storage life of litchis through heat treatment

PendingCN114431289AAvoid damageBright colorFood thermal treatmentFruits/vegetable preservation by heatingThermodynamicsWater storage tank

The invention relates to a system and method for prolonging the storage period of litchis through heat treatment and relates to the technical field of litchis treatment.The sodium nitroprusside solution is stored in a water storage tank, when a litchis discharging frame carrying the litchis comes out of a soaking box and rotates to the position below a stopping block, the litchis discharging frame makes contact with the stopping block, and under the stopping of the stopping block, the litchis are discharged out of the soaking box; the litchi discharging frame starts to turn over, at the moment, the litchis are completely poured onto the conveying frame, the litchis roll towards the left side along the conveying frame, when the litchis pass through the spraying pipe, the water pump sprays the sodium nitroprusside solution through the spraying pipe, and compared with common litchis, the litchis sprayed with the sodium nitroprusside solution are bright in color, the aging phenomenon is delayed, and the preservation time is prolonged; when passing through the heater, the fan blows hot air generated by the heater to the litchis to heat the litchis, and at the moment, the set temperature of the heater is 150 DEG C; the heated litchis are red in color and luster and glittering and translucent in pulp, the shells and the pulp are completely separated during shelling, and the adhesion phenomenon is avoided.

Owner:广西东鸣现代农业发展有限公司

Hen house used for field scattered-feeding hen coop

ActiveCN111838010AAvoid damageImprove comfortFood processingNon-rotating vibration suppressionBreeding chickenEngineering

Owner:彭阳县益斌园农畜综合开发有限责任公司

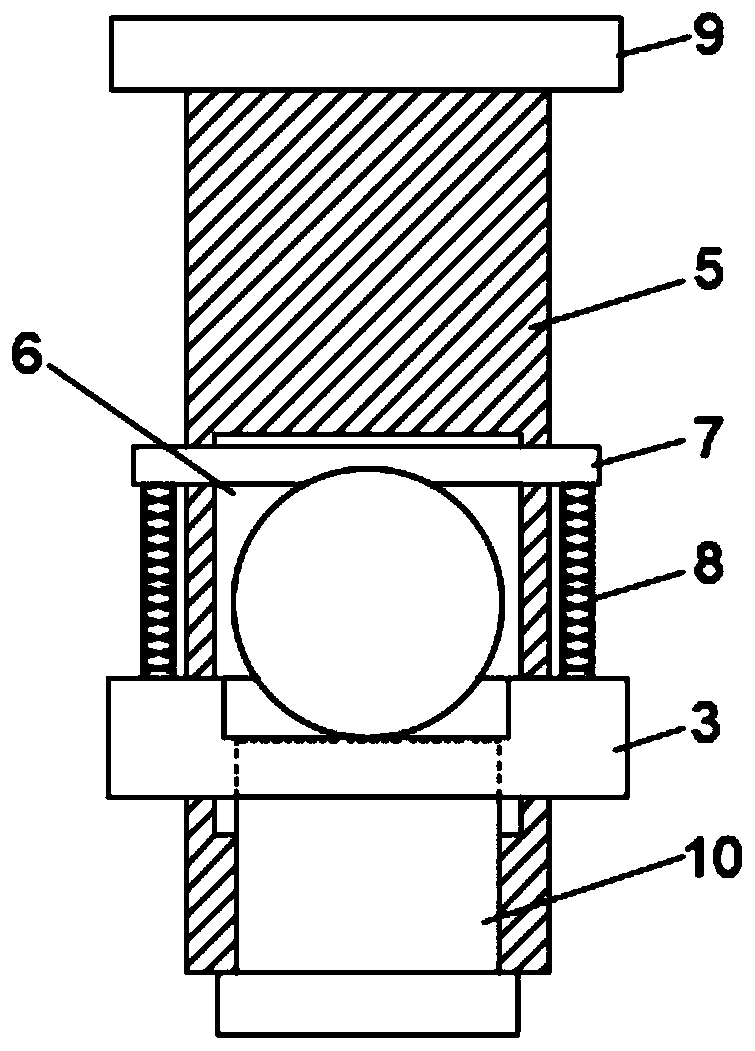

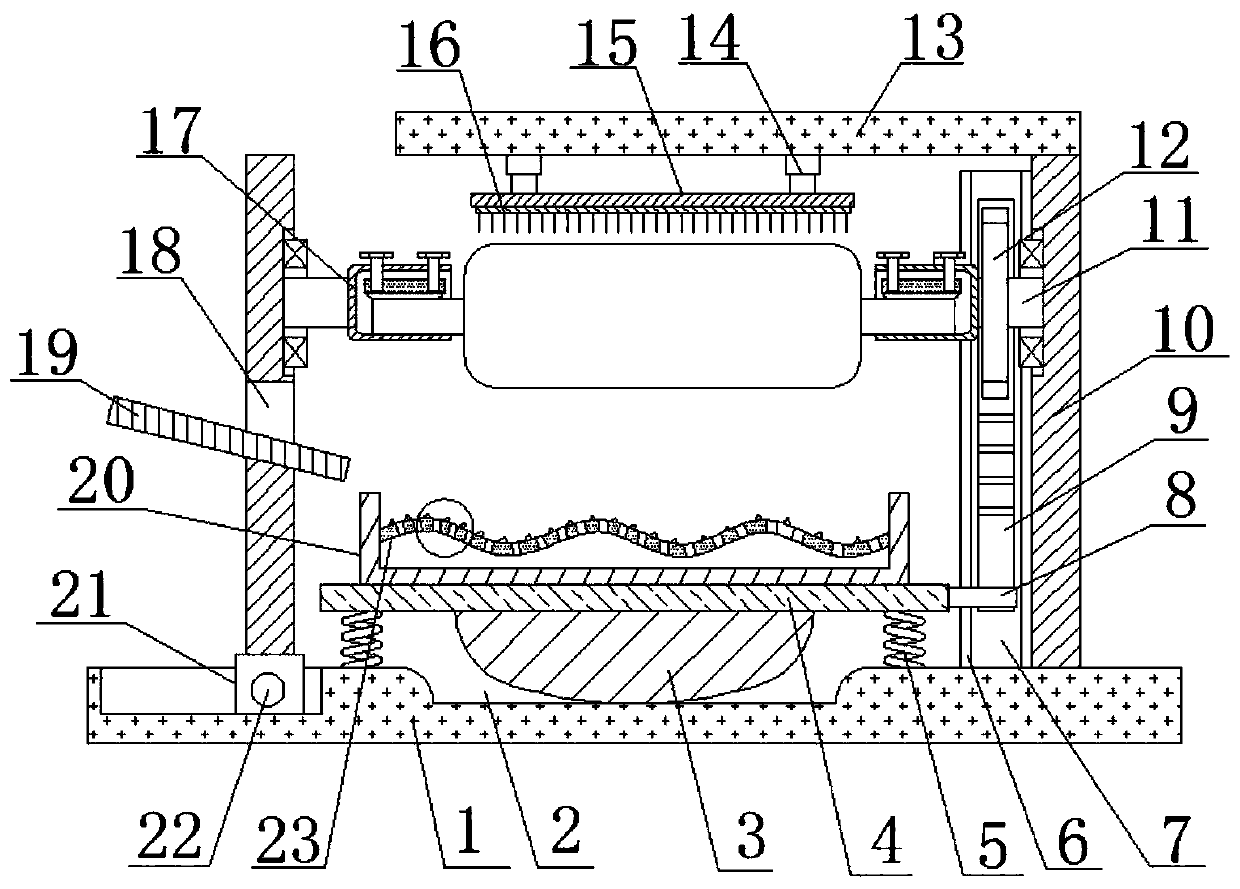

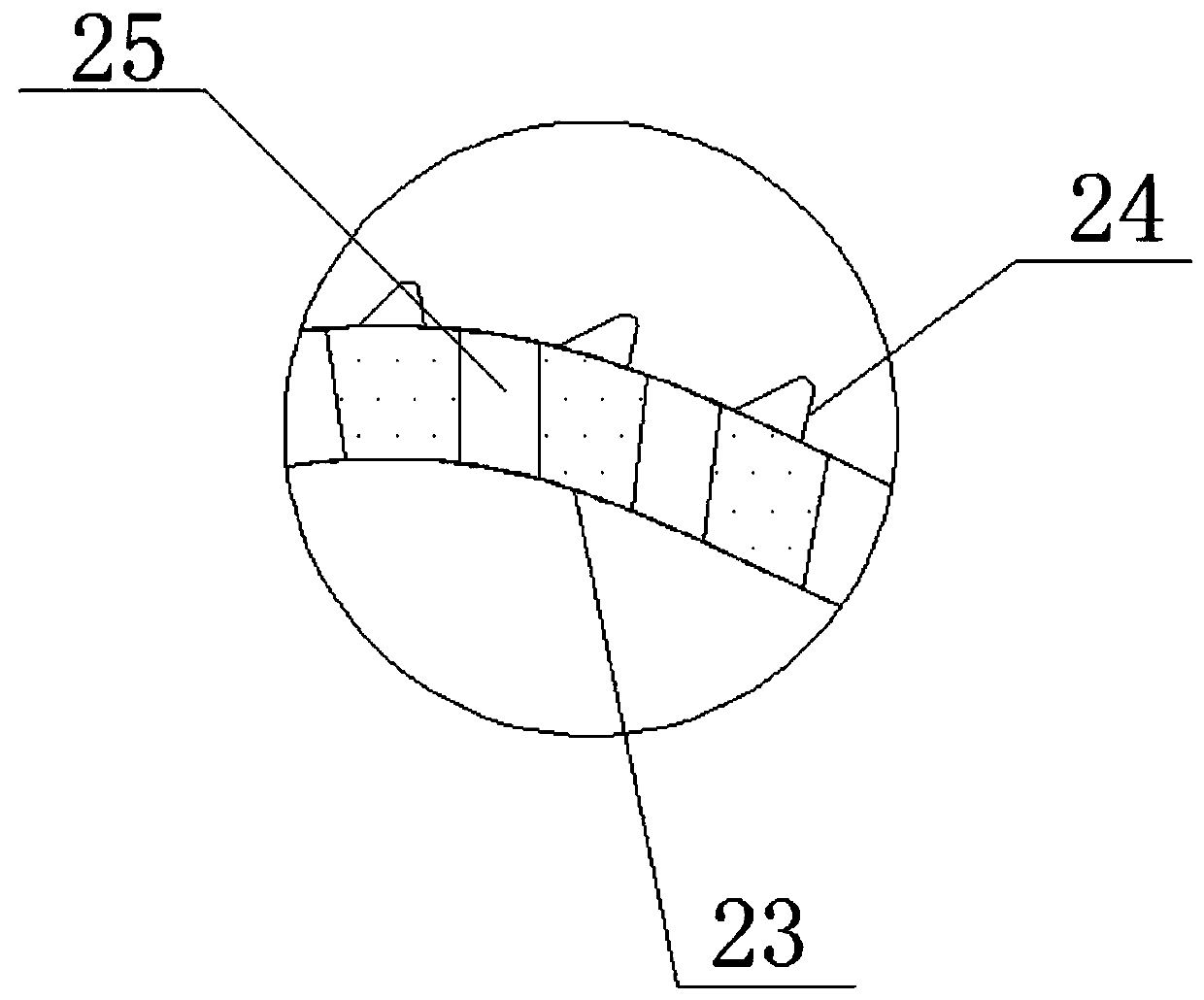

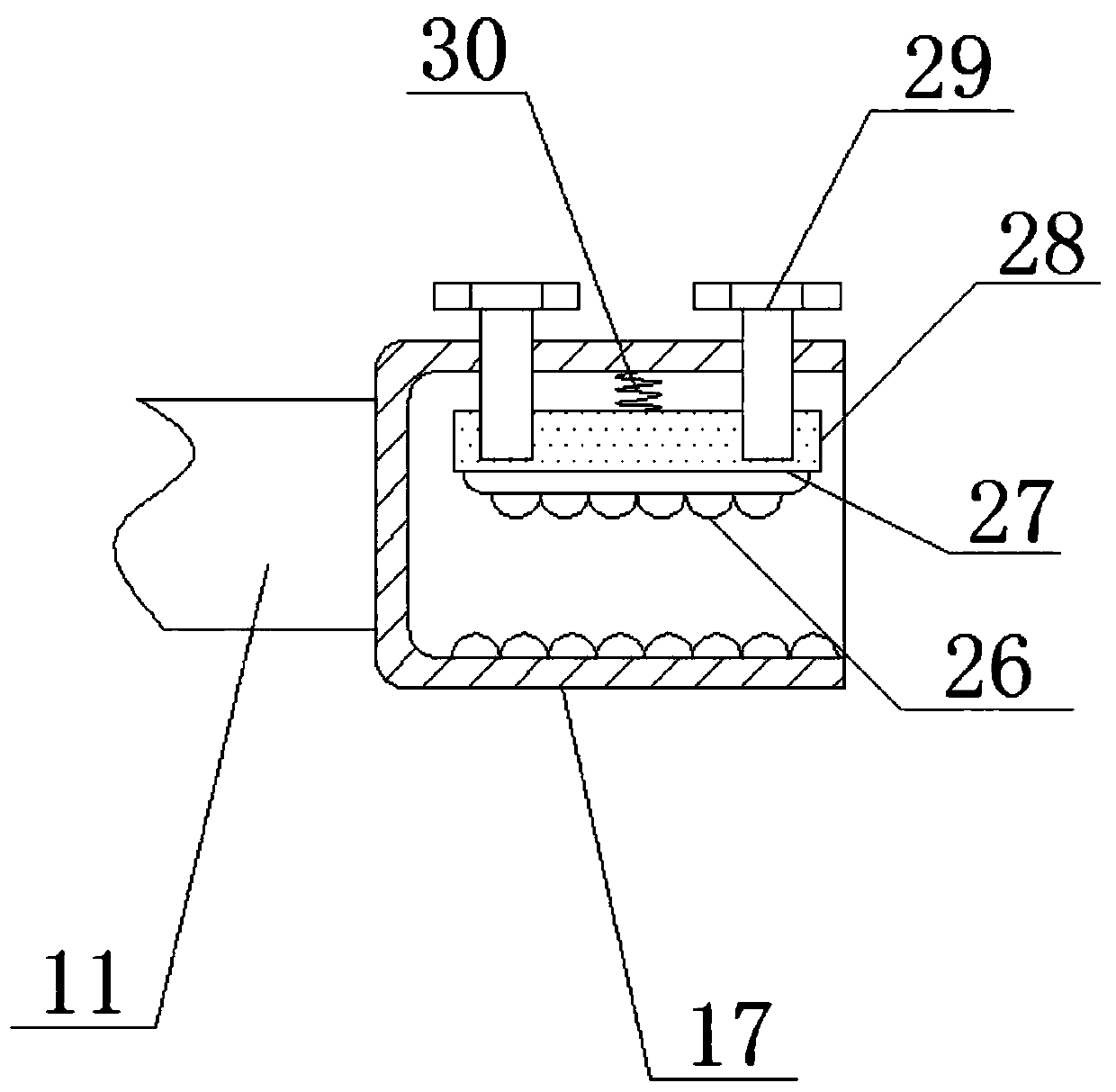

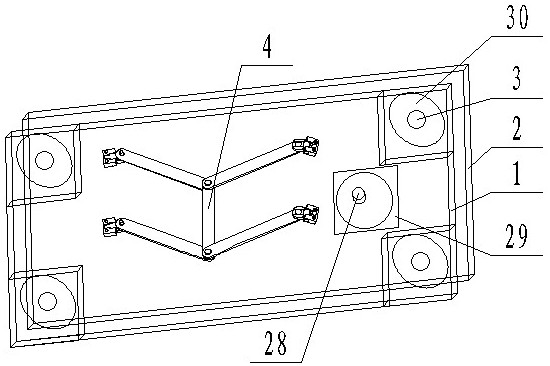

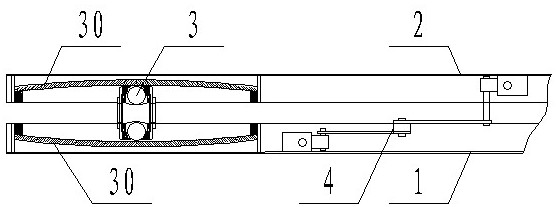

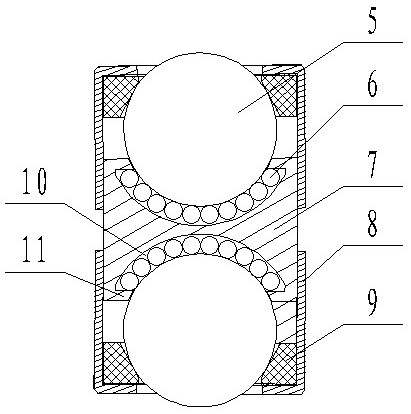

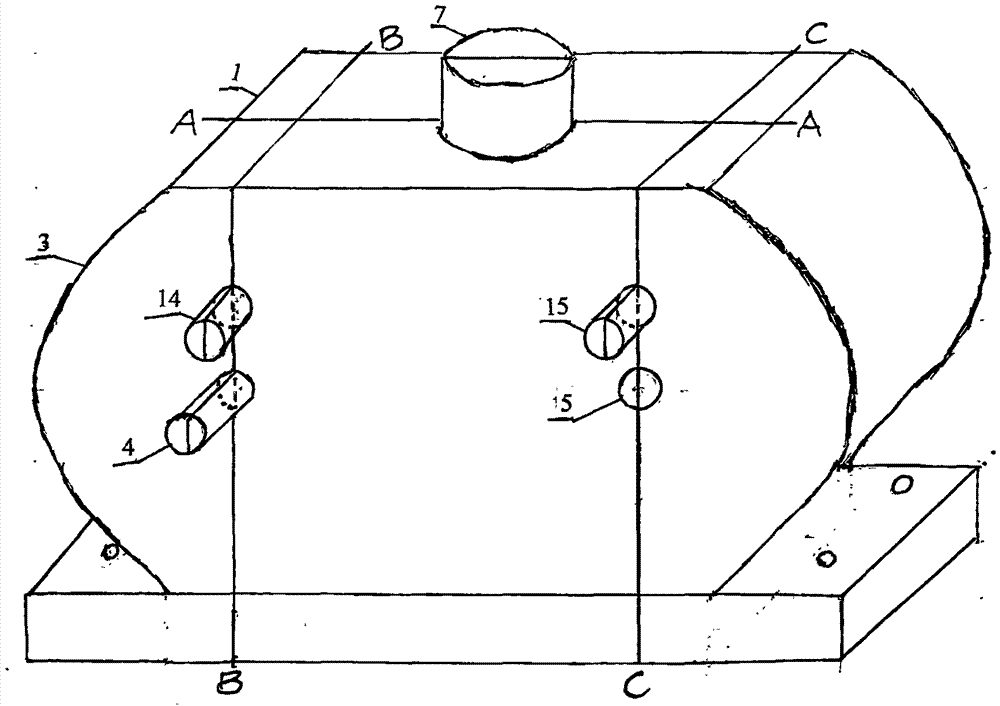

Damping ball type anti-torsion seismic isolation table

PendingCN111664213AReduce scrolling speedReduce displacementSpringsNon-rotating vibration suppressionClassical mechanicsEngineering

The invention discloses a damping ball type anti-torsion seismic insulation table. The damping ball type anti-torsion seismic insulation table comprises a base, an upper panel, damping adjusting universal ball devices and a connecting rod mechanism, wherein the damping adjusting universal ball devices are arranged on the base and used for supporting the upper panel; the damping adjusting universalball devices are arranged between the base and the upper panel, and the base and the upper panel are connected through the connecting rod mechanism; a connecting rod device of the connecting rod mechanism does plane translational motion, and the connecting rod device does not rotate; and the damping adjusting universal ball devices are connected through connecting devices I, so that the relativepositions of the damping adjusting universal ball devices are not changed. According to the damping ball type anti-torsion seismic insulation table, the structure is reasonable, using is convenient, and object displacement can be effectively avoided under the action of seismic waves.

Owner:张玉峰

An automatic ball loading device for a ball mill

InactiveCN110237907BSave time and effortImprove work efficiencyGrain treatmentsSlide plateControl theory

The invention discloses an automatic ball loading device of a ball mill. The ball mill is included, and a table body is arranged on one side of a bin door of the ball mill; an obliquely arranged track is fixedly supported to the upper end of the table body; the higher end of the track is fixedly provide with a ball containing disk; the side edge of the ball containing disk is provided with a ball outflow port used in cooperation with the track; a sliding plate is arranged at the end, away from the ball containing disk, of the track in a penetrating manner; the middle of the sliding plate is provided with a rectangular hole; the middle portion of the sliding plate is further fixedly sleeved with a stopping rod; the bottom faces of the two ends of the stopping rod and the upper surface of the track are fixedly connected a spring; the upper end of the sliding plate is further fixedly connected with an L-shaped ejecting block; the lower end of the sliding plate is further fixedly connected with an L-shaped partition plate; and the end, away from the sliding plate, of the L-shaped partition plate and the bottom of the track are also in penetrating sliding connection. Due to the automatic ball loading device of the ball mill, grinding balls can be automatically loaded into the bin door of the ball mill one by one, the time and energy of manual ball loading are saved, and the work efficiency is higher; and damage to the interior of a tank body of the ball mill when the grinding balls are loaded in can be lowered.

Owner:FUJIAN DATANG INT NINGDE POWER GENERATION

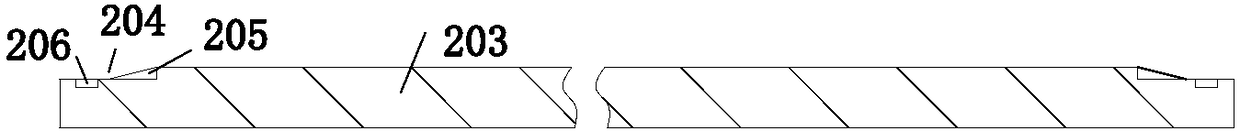

Auxiliary device with buffer shunt-winding function for textile spool paper slitting machine of paper angle bead production line

InactiveCN108189122AImprove bearing capacityReduce scrolling speedMetal working apparatusProduction lineEngineering

The invention belongs to the technical field of packaged product processing, and particularly relates to an auxiliary device with a buffer shunt-winding function for a textile spool paper slitting machine of a paper angle bead production line. The auxiliary device consists of two buffer ramp racks and a reduction baffle plate, wherein the reduction baffle plate is blocked on the buffer ramp racks;each buffer ramp rack consists of a bracket and a first inclined beam and a second inclined beam which are symmetrically arranged on the bracket, wherein the bracket consists of a first bottom beam,a second bottom beam, a vertical beam, a first small vertical beam, a second small vertical beam and a plurality of beams which are symmetrically arranged, the vertical beam, the first small verticalbeam and the second small vertical beam are vertically and fixedly arranged on the bottom beams, the second bottom beam is fixedly arranged on the vertical beam and the first small vertical beam, andthe beams are transversely connected onto the first bottom beam and the second bottom beam. The auxiliary device has the advantages of being scientific and reasonable in structural design, being firmand strong, being great in bearing capacity, being capable of gradually slowing down rolling speed of a paper slip roll and capable of automatically separating, saving time and labor, being high in safety, being convenient to assemble, and the like, and has relatively high innovation.

Owner:天津市顺通达包装制品有限公司

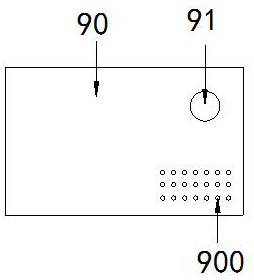

A barrage display method, device and system

ActiveCN104777912BSlow down the display speedReduce scrolling speedInput/output for user-computer interactionGraph readingVisual FocusingDisplay device

The embodiment of the invention discloses a barrage display method, device and system. A barrage display method, comprising: acquiring an image captured by a camera installed on a display device at the current moment, judging whether the image contains human eye pupils, and if so, determining that the human eye pupils in the image are on the display device the focus point on the screen; determine whether the focus point is located in the first barrage currently displayed by the display device, and if so, send a deceleration command to the display device to reduce the display speed of the barrage, wherein, on the display device The current display has at least one barrage. The present invention determines the focus point of the user on the screen in front of the screen playing the bullet chat by acquiring the face image of the user watching the bullet chat, and performs visual focus calculation on the face image, and then determines the user's browsing intention. When the user's When the focus point is inside the bullet chatting, the scrolling speed of the bullet chatting is automatically reduced for the user, which realizes the matching of the scrolling speed of the bullet chatting with the user's browsing intention.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

Intelligent drug dispensing device

ActiveCN110510189BReduce error rateReduce work intensityPackaging automatic controlMagnet coilEngineering

The invention discloses an intelligent drug dispensing device, which comprises a body and a control device. A buffer slideway is arranged in the body, a groove is opened on the buffer slideway, a buffer structure is arranged in the groove, and the buffer structure includes a The fixed rod at the fixed rod, the baffle connected to the fixed rod in rotation, the first electromagnetic coil is provided on the bottom surface of the front end of the baffle, the second electromagnetic coil is provided on the rear bottom surface of the baffle, and the bottom of the groove is provided with the first electromagnetic coil. A first electromagnet and a second electromagnet that cooperate with the electromagnetic coil and the second electromagnetic coil, wherein a conductive rod is arranged at the center of the second electromagnetic coil, and a conductive block that is matched with the conductive rod is arranged inside the second electromagnet. The present invention realizes intelligent drug distribution, does not need manual counting of drugs, saves labor and reduces time.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

Steel ball counting ball supplementing mechanism

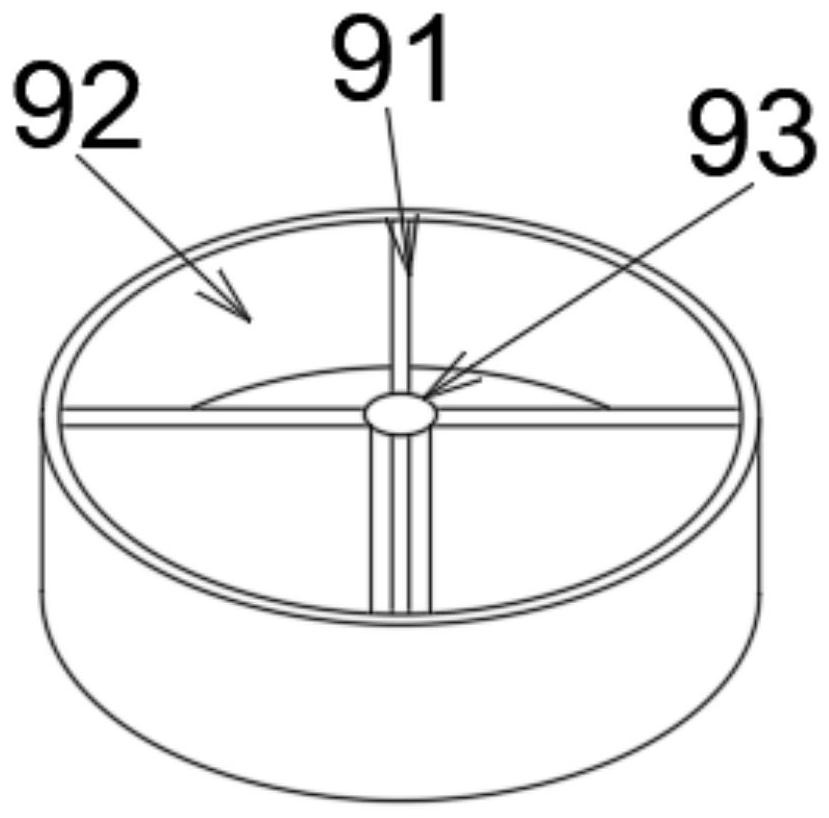

PendingCN112124706AScroll fastReduce scrolling speedPackaging automatic controlFrequency changerCircular disc

The invention discloses a steel ball counting ball supplementing mechanism. The steel ball counting ball supplementing mechanism provided structurally comprises a base. An inner disc and an outer circular ring are arranged on the surface of the base. The inner disc and the outer circular ring are coaxially arranged, and an annular groove is formed between the inner disc and the outer circular ring. The inner disc is rotatably arranged on the base. A driving piece for driving the inner disc to rotate is arranged on the base. A falling hole communicating with the outside is formed in the bottomof the annular groove. A steel ball feeding groove is formed in the base, and the feeding groove communicates with the interior of the annular groove and is formed far away from the falling hole. A counting sensor is arranged on the falling hole. A frequency converter is connected to the driving piece. The counting sensor is electrically connected with the frequency converter. According to the steel ball counting ball supplementing mechanism, the steel ball supplementing efficiency is guaranteed, and the accuracy of the number of supplemented steel balls is improved and ensured.

Owner:南通辰同智能科技有限公司

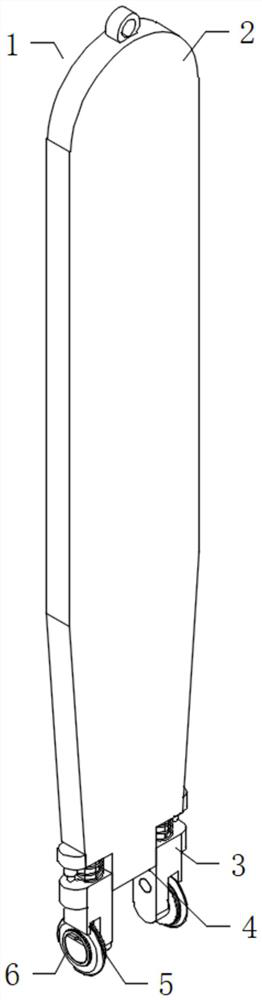

Intelligent device for English teaching

InactiveCN113554020AIncrease rotational resistanceReduce scrolling speedNatural language translationCharacter and pattern recognitionMachineScroll wheel

An intelligent device for English teaching disclosed by the present invention comprises an English translation pen, the English translation pen comprises a machine body and an electric switch, and the English translation pen further comprises a pair of trigger main bodies, a pair of deceleration main bodies and a pair of rollers. The upper end of the trigger main body is installed at the lower end of the machine body in a sliding and inserted mode, the electric switch and the trigger main body are fixedly installed together, the machine body, the electric switch, the speed reduction main body and the machine body are electrically connected in series, the rolling wheels are rotatably installed at the lower end of the trigger main body, and the machine body comprises the trigger switch and further comprises a shell frame and a fixing block. A pair of trigger switches are arranged, the fixing blocks are symmetrically and fixedly connected to the lower end of the shell frame, the trigger switches are fixedly connected to the lower ends of the fixing blocks, and the machine body further comprises hanging rings. The invention relates to the technical field of translation pen equipment for English teaching, and better meets the use requirements.

Owner:ZHANG ZHOU HALTH VOCATIONAL COLLEGE

Method and apparatus for controlling user interface by using objects at a distance from a device without touching

InactiveUS9671949B2Easily and accurately selectReduce scrolling speedInput/output for user-computer interactionComputer graphics (images)Control electronics

Disclosed herein are a method and apparatus for controlling a user interface in an electronic device. Content details are displayed and scrolled at an initial scroll speed. An object is detected within a predetermined distance from an electronic device without touching the object. The initial scroll speed is reduced in accordance with the distance of the object.

Owner:SAMSUNG ELECTRONICS CO LTD

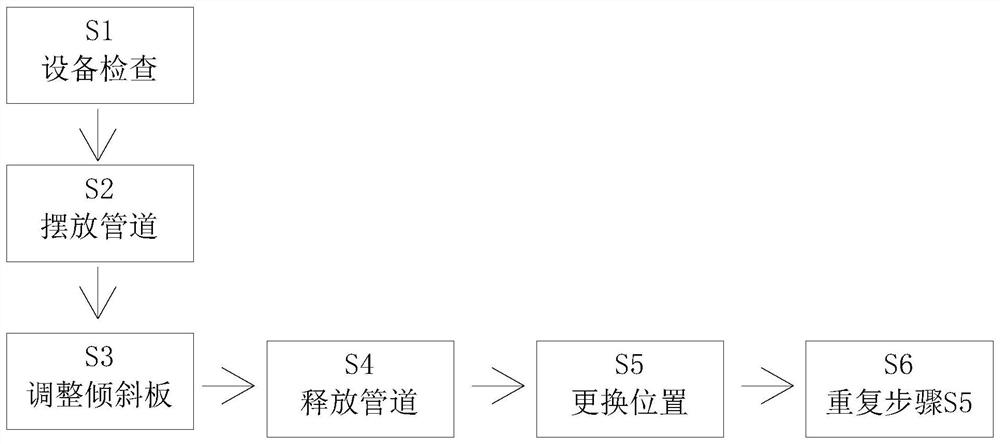

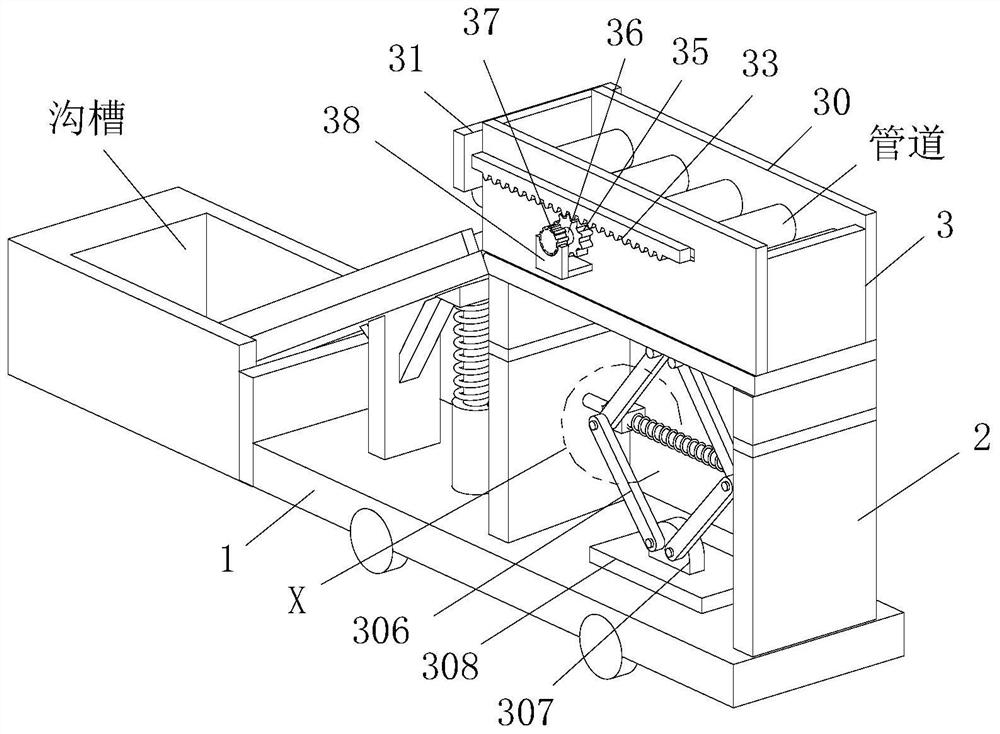

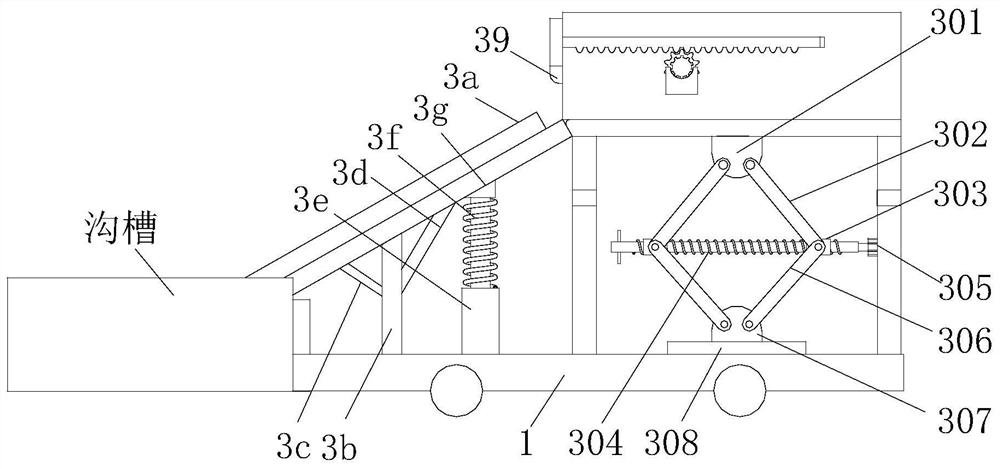

Construction process for blow-off pipeline for sewage treatment

InactiveCN112361078AReduce shockReduce scrolling speedPipe laying and repairGear wheelArchitectural engineering

The invention provides a construction process for a blow-off pipeline for sewage treatment. The construction process for the blow-off pipeline for sewage treatment adopts the following equipment for auxiliary construction: the equipment includes a movable base, telescopic plates and a feeding device; the lower end of the movable base is connected with the existing ground; the telescopic plates aremounted on the upper end surface of the movable base; the telescopic plates are of structures which are arranged in a bilateral symmetry manner; and the upper end of each telescopic plate is providedwith a conveying device. By means of mutual cooperation of a No.1 motor, a rotating shaft, a gear, a rack, a T-shaped plate and a partition plate, pipelines on the lowermost layer of a storage box can be driven to roll leftwards to an inclined plate one by one and then roll into a groove along the inclined plate; afterwards, the function that the equipment releases the pipelines one by one can beachieved through mutual cooperation of a baffle and the T-shaped plate so as to guarantee that the construction process of the blow-off pipeline for sewage treatment is smoothly conducted, and thus the construction efficiency of the blow-off pipeline for sewage treatment can be improved.

Owner:杭州中易杭建筑工程有限公司

Poultry breeding egg collection device

The invention discloses a poultry breeding egg collection device, which comprises a cage and a collection mechanism. The bottom end of the cage is provided with a base. The bottom of the interior of the cage is provided with a breeding plate. The top end of the breeding plate is provided with a plurality of nest basins. The collection mechanism is arranged on one side of the cage and extends intothe cage. The collection mechanism is composed of a guide groove, an egg outlet, a collection groove, and a collection box. The guide groove and the nest basins are connected through an egg outlet that penetrates the breeding plate. The guide groove and the collection groove are connected through the egg outlet. One end of the collection groove is connected to the collection box. The collection box is composed of a collection box shell, a servo motor, an egg push plate, and a microwave inductor. By setting the collection mechanism, the eggs can be conveniently collected and effectively protected, the damage rate of eggs is reduced during the collection process, the egg collection efficiency is improved, and the production efficiency is improved.

Owner:HEFEI HAOWANG AQUACULTURE TECH CO LTD

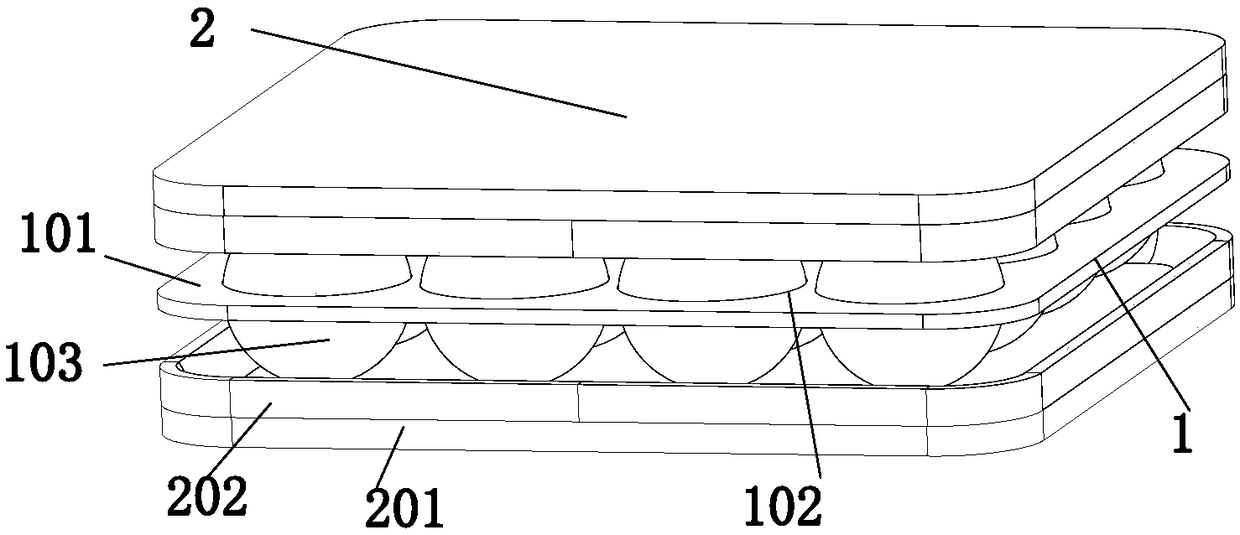

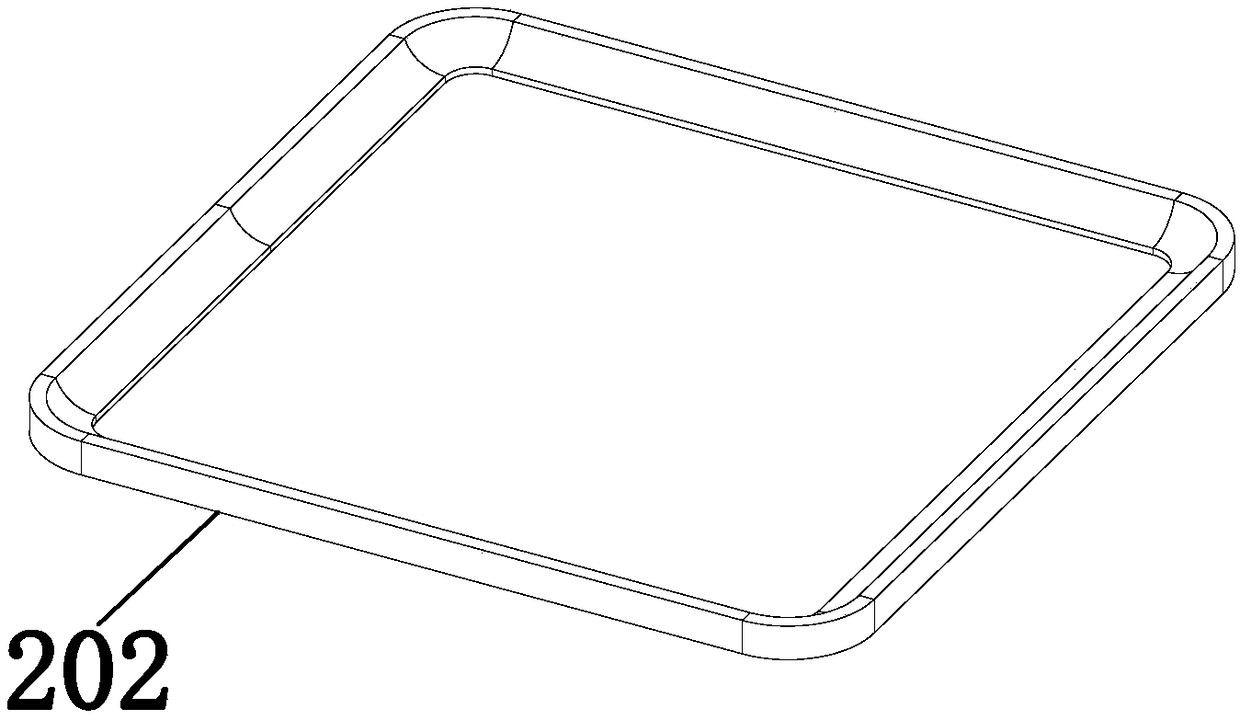

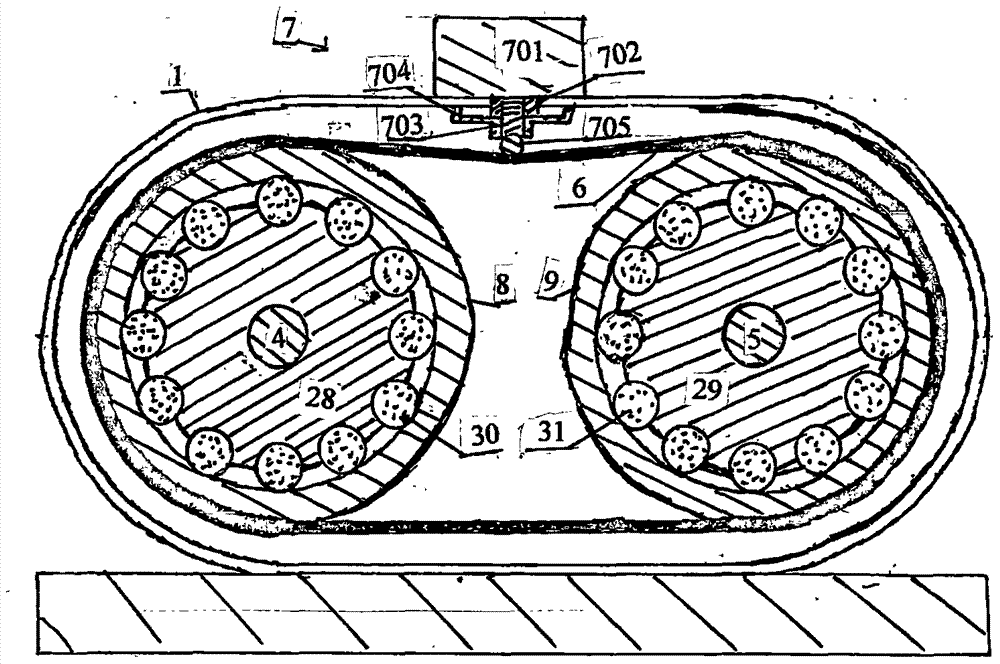

A rolling ball type shock absorber

ActiveCN107606046BGuaranteed Rolling RequirementsNot easy to get outNon-rotating vibration suppressionBall typeEngineering

The invention discloses a roll ball type shock insulation damper. The roll ball type shock insulation damper comprises a rolling mechanism (1). The upper end and the lower end of the rolling mechanism(1) are provided with damping seats (2) correspondingly. The rolling mechanism (1) comprises a retainer (101). The retainer (101) is provided with a plurality of through holes (102). Each through hole (102) is internally provided with a roll ball (103). The upper ends and the lower ends of the roll balls (103) make contact with the damping seats (2) correspondingly. Each damping seat (2) comprises a roll ball friction plate (201). Each roll ball friction plate (201) is provided with a check ring (202). The roll ball type shock insulation damper has the characteristics of being convenient to install and capable of improving the damping effect.

Owner:HANGZHOU DETI CIVIL AIR DEFENSE EQUIP CO LTD

Dispensing nursing trolley with refined classified storage function

ActiveCN113057834AReduce scrolling speedAvoid confusionWaste collection and transferNursing accommodationHandrailSpeech control

The medicine dispensing nursing trolley structurally comprises a drawer, a trolley body, a handrail, a U-shaped rod, a supporting plate, a hook, a garbage can, universal wheels and a voice control structure, wherein the drawer is installed on the trolley body; the top of the back face of the trolley body is connected with the U-shaped rod; the supporting plate is connected to the U-shaped rod; the hook is arranged on the supporting plate; and the garbage can is connected to the right side of the trolley body; universal wheels are installed at the bottom of the trolley body; a voice control structure is arranged on the left side of the trolley body and comprises a host, a switch button, an independent switch and an electromagnet, and the host is connected to the right side of the trolley body. The beneficial effects of the present invention are that the time for searching for medicines can be saved through the voice control structure, so that fast searching for medicines can be realized, and the designed roller structures are matched with the elastic devices, so that sliding of the drawer can be slowed down, and disorder of medicines in the drawer caused by too fast movement is prevented.

Owner:THE AFFILIATED HOSPITAL OF SOUTHWEST MEDICAL UNIV

cvt stepless speed changer

The invention discloses a CVT stepless speed changer. A clamping speed reduction motor rotates to drive a clamping nut to rotate, so that a clamping screw and a roller are driven to move upwards or downwards to adjust the tightness degree and the slipping degree of a metal belt, and the rotating speed ratio of a driving rotating shaft to a driven rotating shaft is adjusted. If the needed rotating speed is not reached through a roller type clamping device, the rotating speed will be adjusted through two AT stepless speed changers. The adjusting process of the AT stepless speed changer on the driving rotating shaft includes the steps that an input speed reduction motor rotates and drives an input gear nut to rotate on an input annular screw through an input driving gear, and the input gear nut drives an input spline to move through an input rear thrust bearing, so that an input thrust disc on the input spline moves to adjust pressure exerted on input conical rollers, the rolling speed of the input conical rollers is adjusted, and then the rotating speed difference between a driving grooved wheel and a driving belt wheel is adjusted. The adjusting process of the AT stepless speed changer on the driven rotating shaft is the same as that of the AT stepless speed changer on the driving rotating shaft.

Owner:张英华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com