Automatic feeding and storing device

An automatic material feeding and material storage technology, applied in the field of material storage, can solve the problems of increased collision strength, material wear, noise, etc., to reduce the rolling speed of materials, prevent material deformation and damage, and facilitate the storage state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the invention.

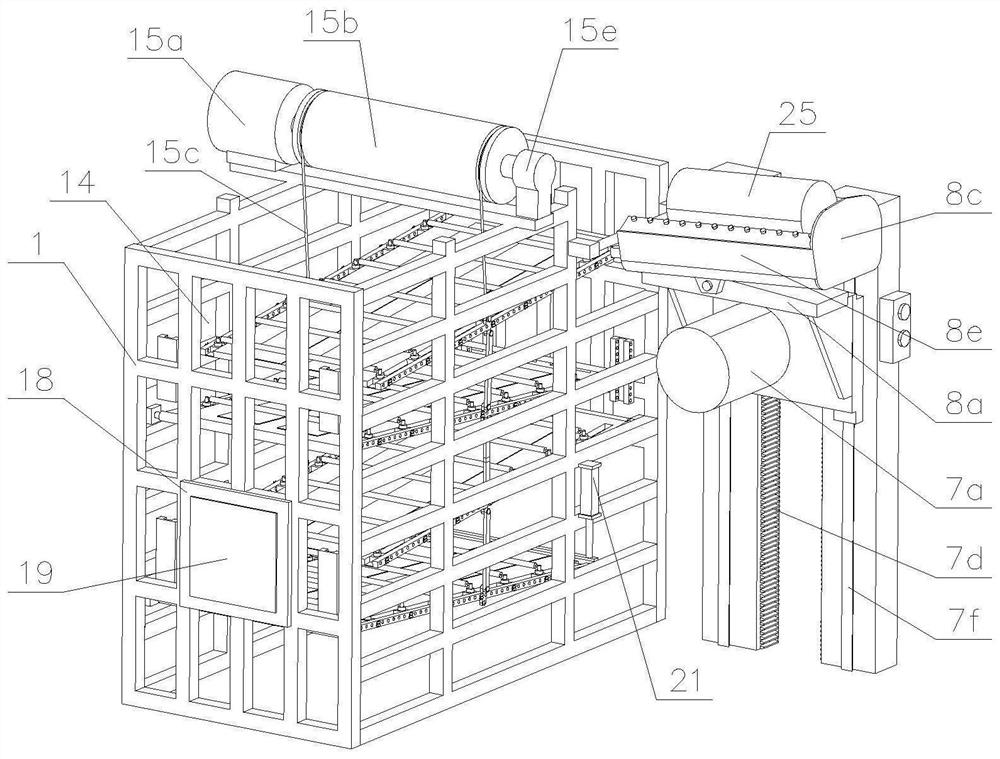

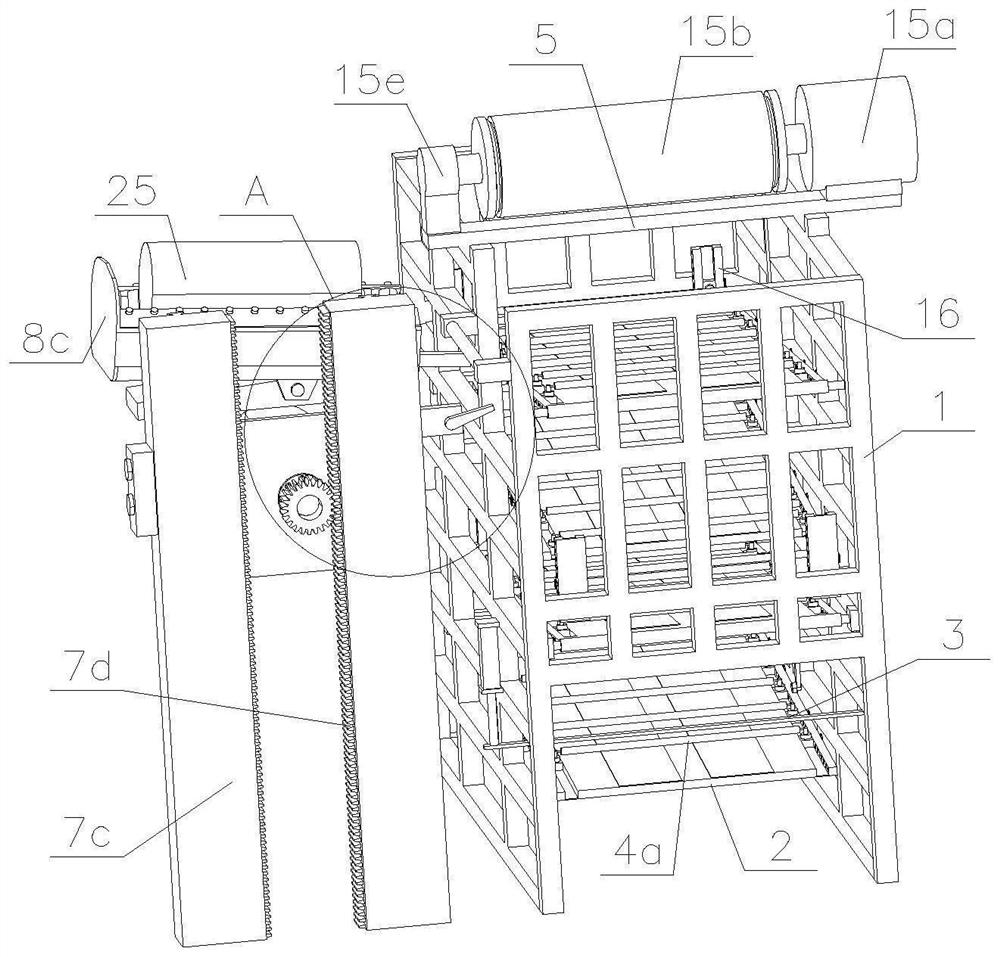

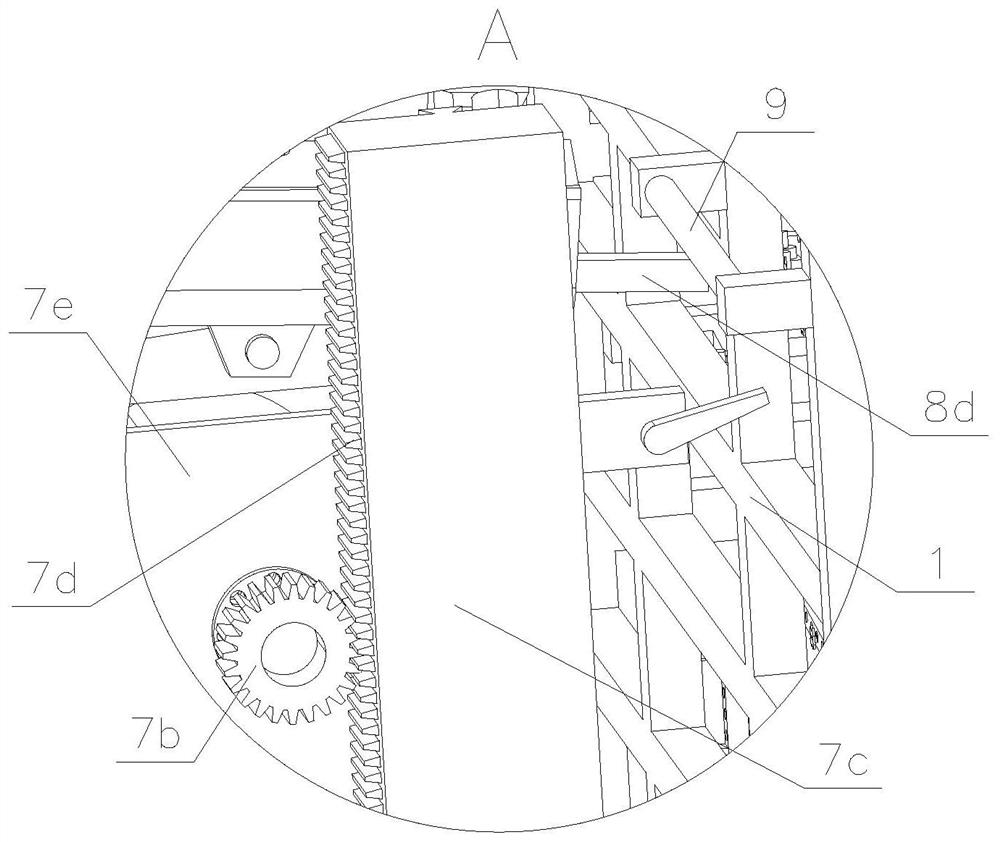

[0031] like Figure 1 - Figure 12 , The automatic feeding material storage apparatus of the invention, the main material for the single fixed cylindrical specification model 25, comprising a storage rack, a storage rack comprising four vertically disposed and sequentially connected end to end bracket, four brackets are formed stocker enclosed space, wherein the bottom of the storage rack 1 is provided with a discharge opening at one end, wherein the top side is provided with a feed inlet; provided four longitudinal direction with an inclined direction in which material storage space height down plate stocker 2, the stocker 2 is a rectangular plate, two inclined directions stocker plate 2 adjacent the contrary, the stocker plate 2 four enclosed channels formed tortuous stocker, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com