A rolling ball type shock absorber

A technology of shock absorber and rolling ball type, which is applied in the manufacturing process field of rolling ball type shock absorber, can solve the problems of affecting the shock absorption effect and unsatisfactory shock absorption effect, so as to improve the shock absorption effect and improve the welding performance. The effect of quality and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

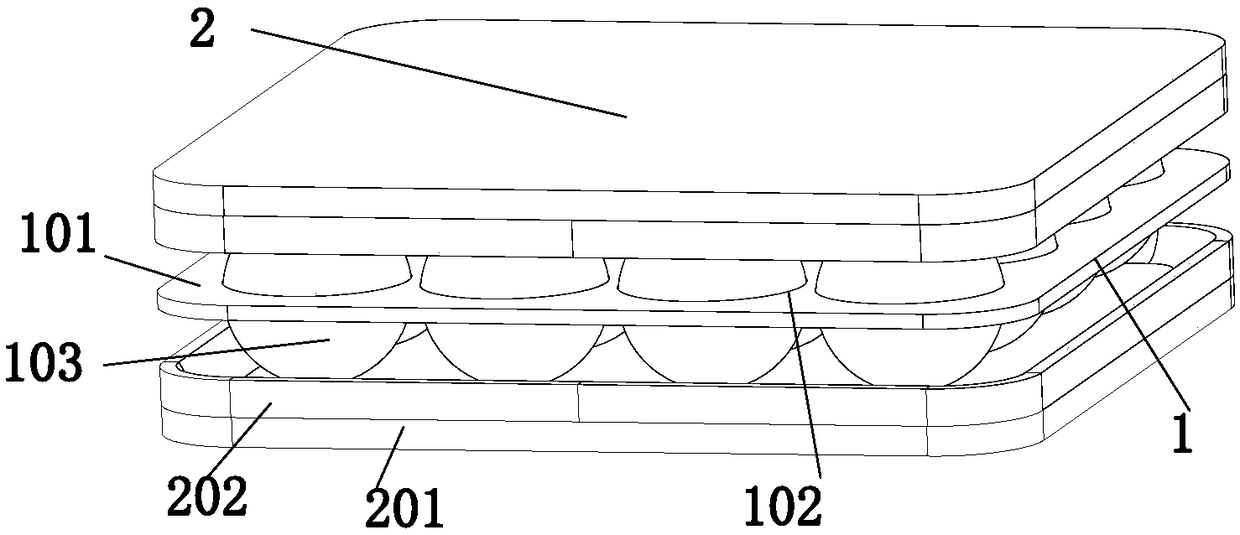

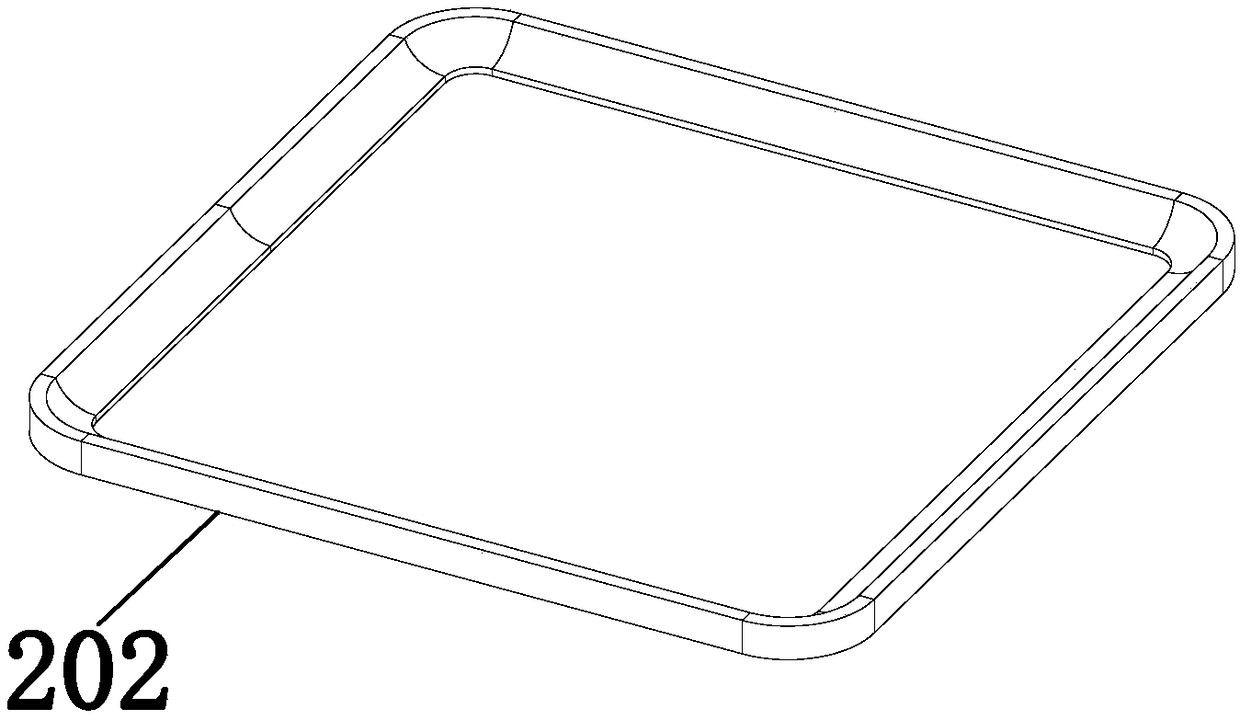

[0025] Example. A rolling ball type shock absorber, constituted as Figure 1 to Figure 8 As shown, a rolling mechanism 1 is included, and the upper and lower ends of the rolling mechanism 1 are respectively provided with shock absorbers 2; the rolling mechanism 1 includes a cage 101, and the cage 101 is provided with a plurality of through holes 102, each through hole 102 is provided with rolling balls 103, and the upper and lower ends of the rolling balls 103 are respectively in contact with the shock absorbing seat 2; the shock absorbing seat 2 includes a rolling ball friction plate 201, and a retaining ring 202 is arranged on the rolling ball friction plate 201.

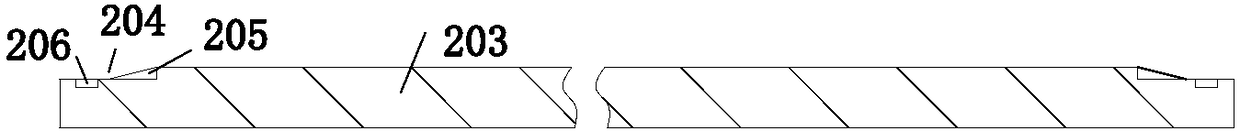

[0026] The ball friction plate 201 includes a base plate 203, on which there is an annular installation groove 204, the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com