Manufacturing process of a rolling ball type shock absorber

A manufacturing process and shock absorber technology, applied in the field of manufacturing process of ball-type shock isolation shock absorbers, can solve the problems of increasing the difficulty of installation, unsatisfactory shock absorption effect, affecting the effect of shock absorption, etc., so as to reduce the installation Difficulty, improve shock absorption, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

[0026] Example. A manufacturing process of a rolling ball type shock absorber, comprising the following steps:

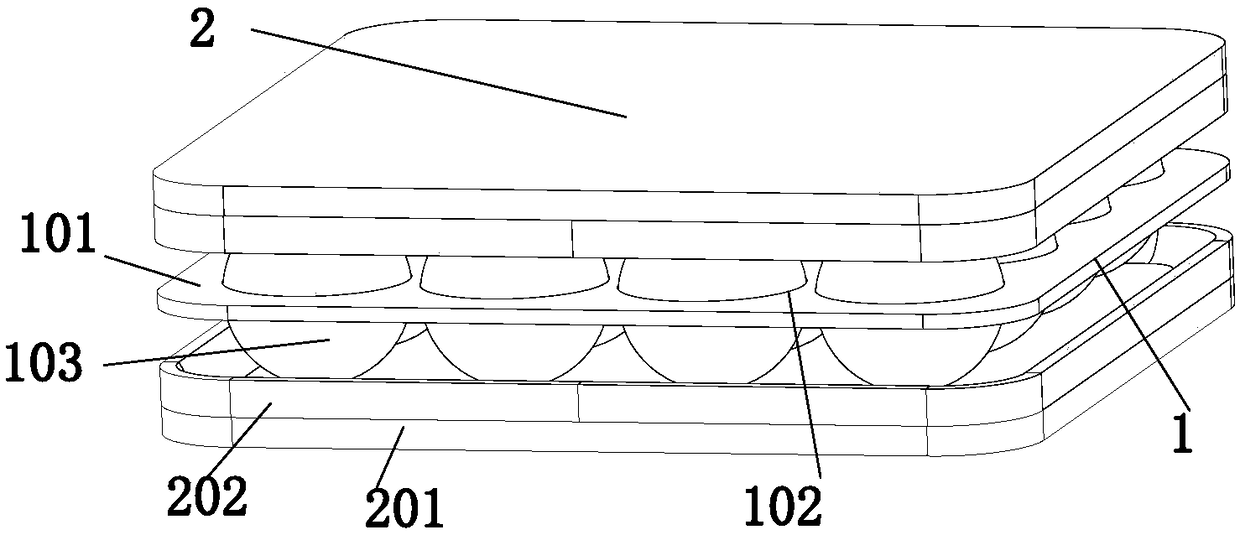

[0027] A. Make the shock absorber at the upper and lower ends; weld the ball friction plate and retaining ring to obtain the shock absorber;

[0028] B. Assembling; first place multiple rolling balls above the lower end of the shock-absorbing seat, then install the upper half of the rolling ball on the cage, and finally install the upper end of the rolling ball on the upper end of the shock-absorbing seat to obtain shock absorption Finished appliance;

[0029] The shock-absorbing seat is a rectangular structure with a length and a width greater than 1000 mm.

[0030] The manufacturing process of the described rolling ball friction plate includes the following steps,

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com