Liquid curtain type premixer for toughened modified plastic production

A premix and toughening technology, applied in the field of modified plastic production related equipment, can solve the problems of reducing production efficiency, poor plastic fluidity, increasing the difficulty of preparation, etc., to improve production efficiency and quality, and reduce the difficulty of mixing and time, the effect of production quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

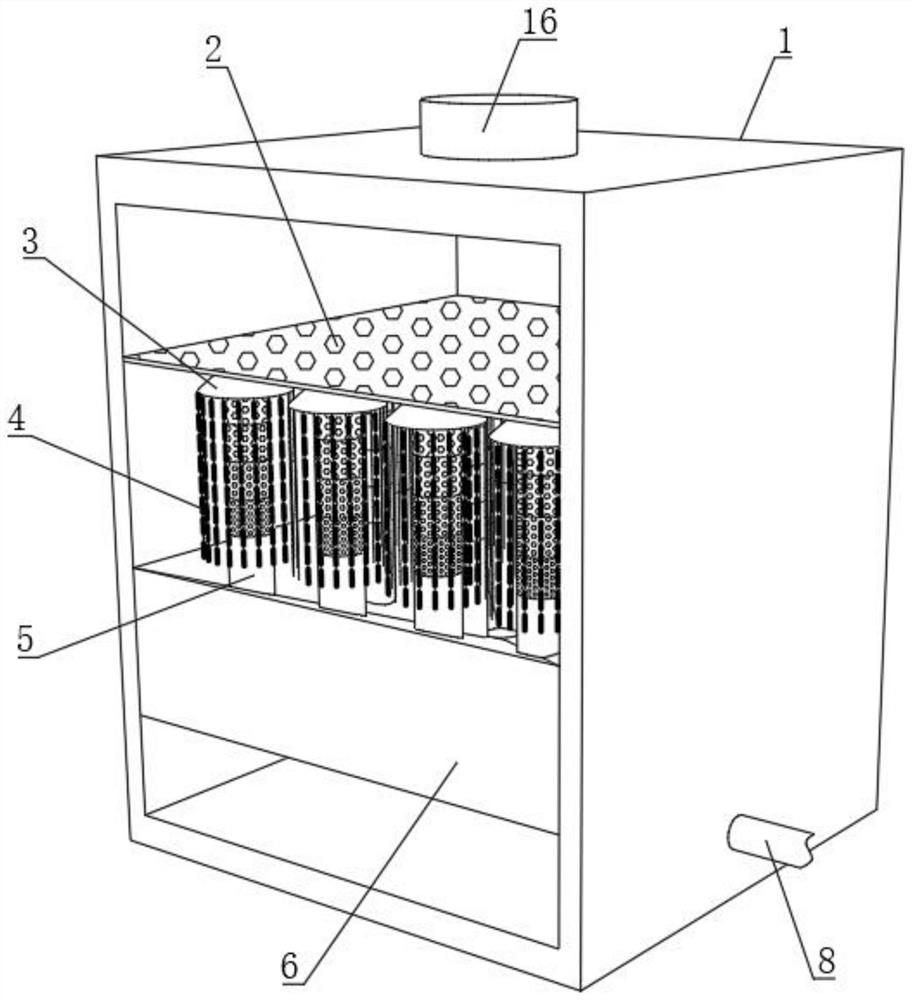

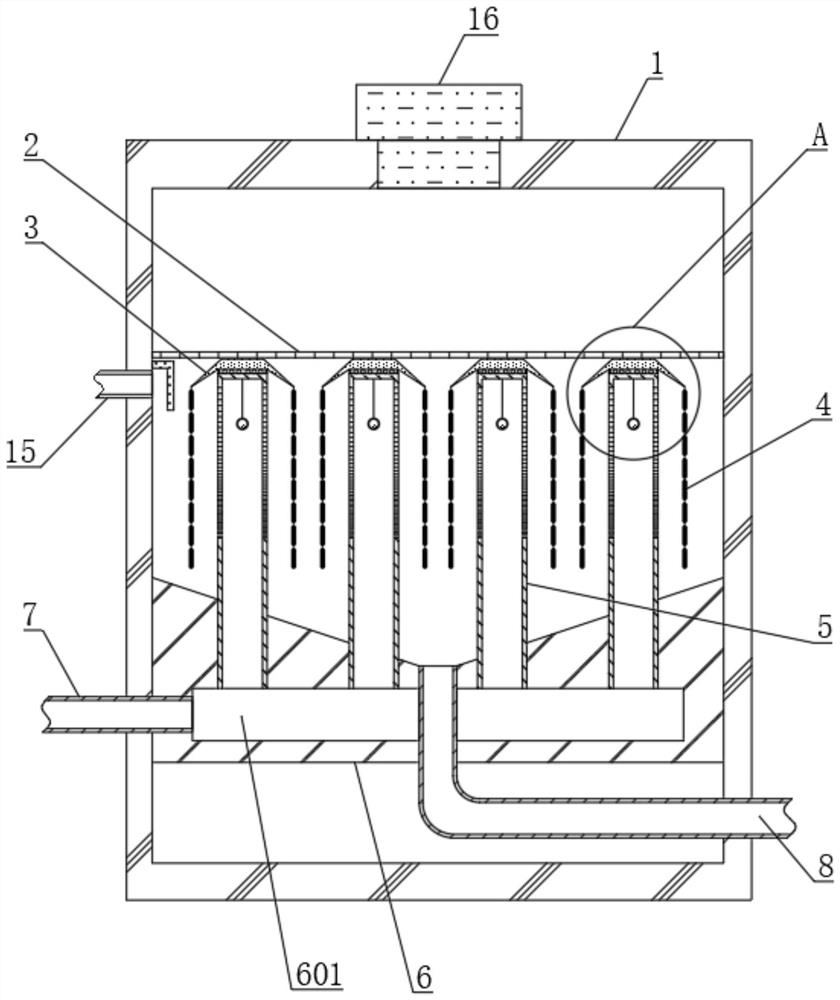

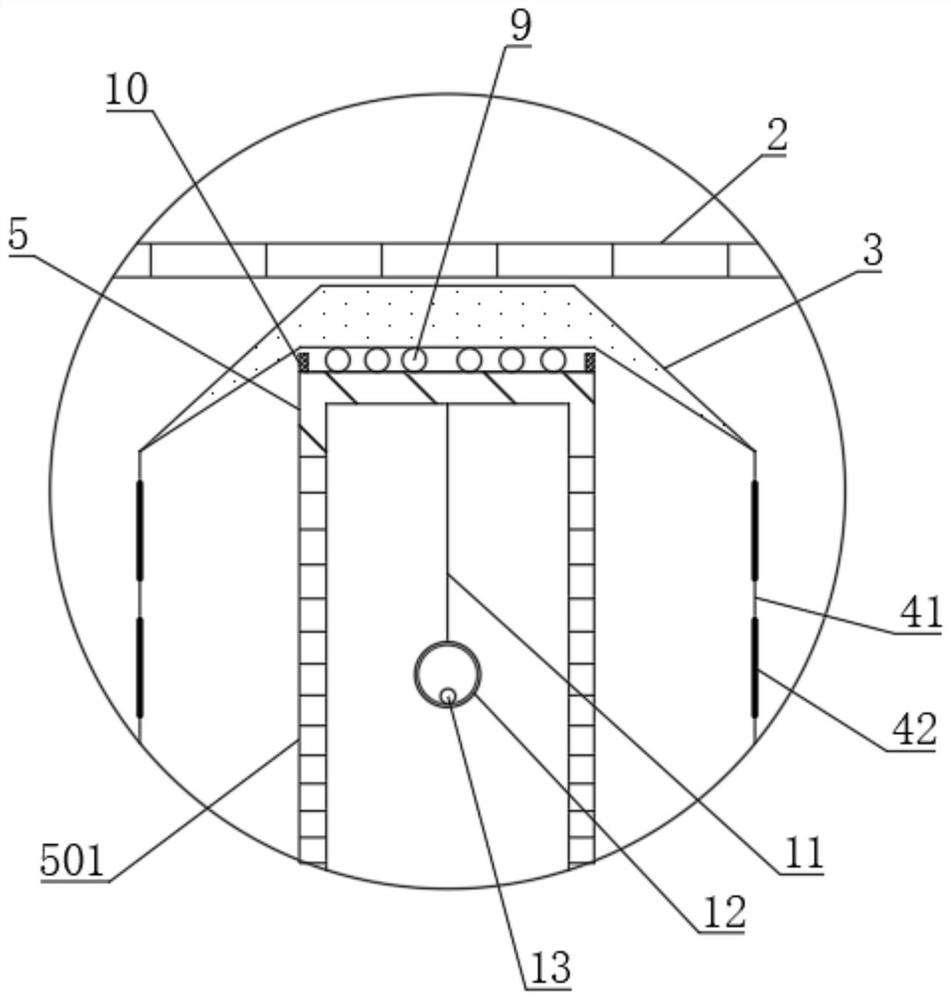

[0041] see figure 1 , figure 2 and image 3 , a liquid curtain premixer for the production of toughened modified plastics, comprising a premixing box 1, the inner wall of the premixing box 1 is fixedly connected with a filter plate 2 and a collection table 6, and the filter plate 2 is located in the collection table On the upper side of the material table 6, between the filter plate 2 and the material collection table 6, there are a plurality of uniformly distributed liquid curtain powder suction covers. The liquid curtain powder suction cover includes a trapezoidal cover 3 and a powder powder cylinder 5. 5, the lower end of the trapezoidal cover 3 is fixedly connected with a plurality of evenly distributed bamboo liquid guide chains 4, and the plurality of bamboo liquid guide chains 4 are evenly distributed on the outer side of the loose powder tube 5, and the loose powder tube 5 is provided with multiple A uniformly distributed powder outlet 501, the inside of the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com