An automatic ball loading device for a ball mill

A ball mill, automatic technology, applied in the direction of grain processing, etc., can solve the problems of low work efficiency, high grinding ball quality, high labor intensity, etc., achieve high work efficiency, reduce damage, save time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

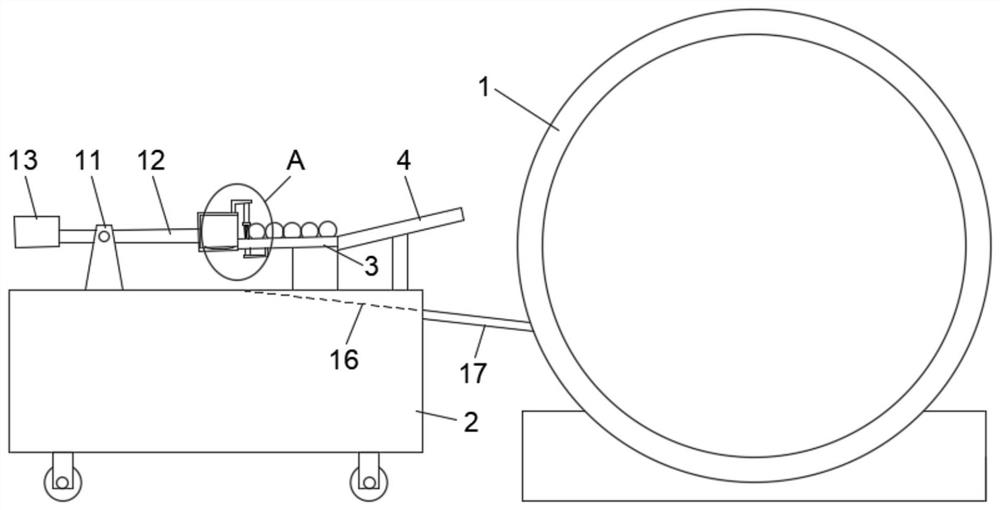

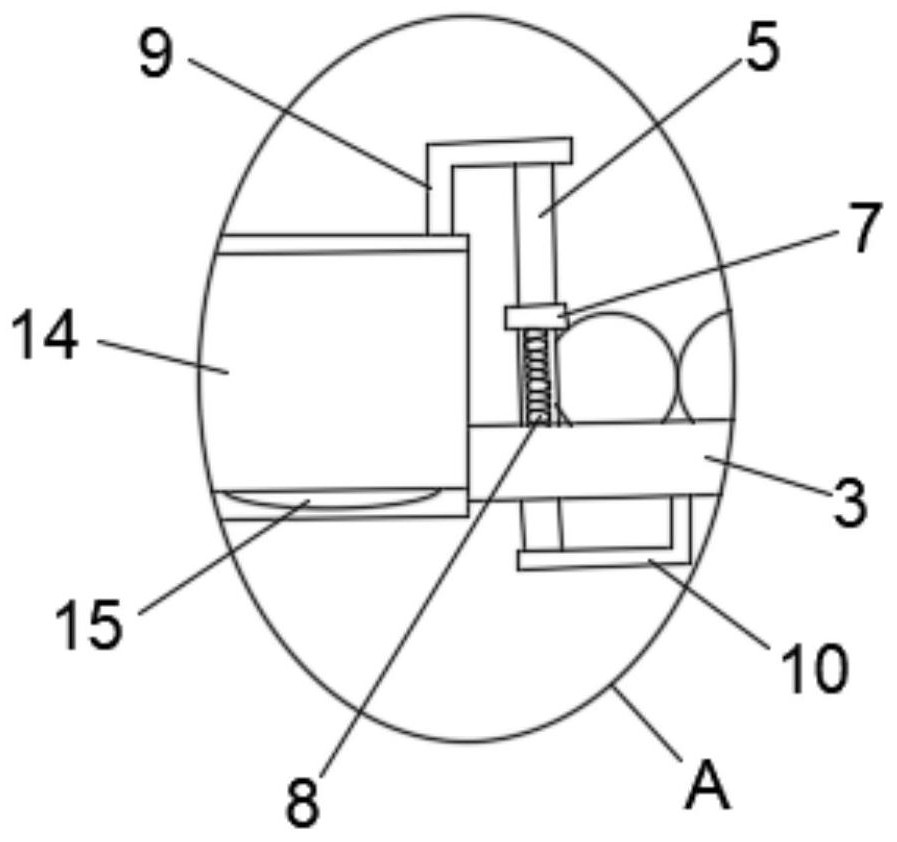

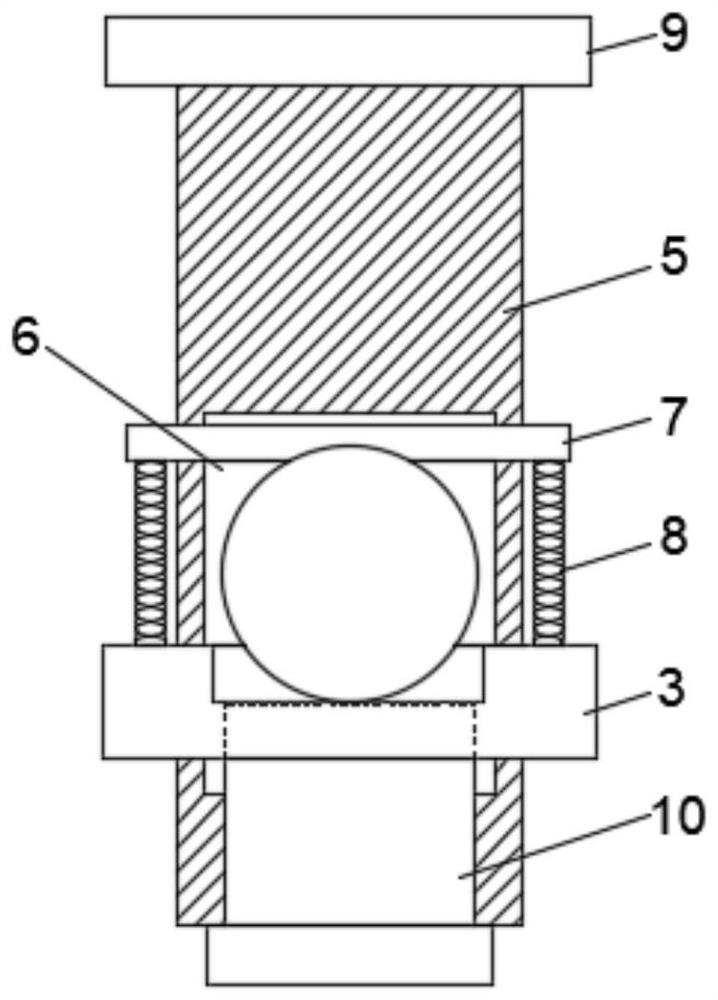

[0016] Refer Figure 1-3 An automatic ball mill apparatus 1 comprises a mill, a ball mill 1 is provided with two side doors have an upper end fixed to the support rails an inclined table 2, table 3, the higher end of the fixed rail 3 is provided with a teeing disk 4, the discharge side of the ball disks 4 with rail 3 defines a ball used in the mouth, the position corresponding to the track ball outlet 3 and the width equal to the width of the track 3, track ball plate 3 remote from the discharge end of the slide plate 4 is provided with a through 5, the intermediate slide plate 5 defines a rectangular aperture 6, the middle slide plate 5 has also a lever 7 is fixed sleeved ends and the bottom surface of the lever 7 are fixed to the surface of the upper rail 3 is connected to a spring 8, the spring 8 are made of stainless steel a return spring, resetting effect precise, greater resistance to corrosion and rust, longer life; the upper end of the slide plate 5 is further secured to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com