CVT stepless speed changer

A variable speed machine, stepless technology, applied in the direction of mechanical equipment, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

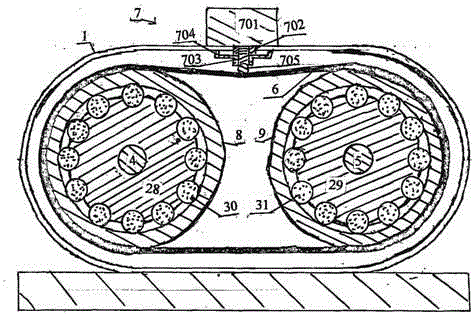

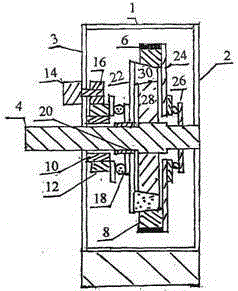

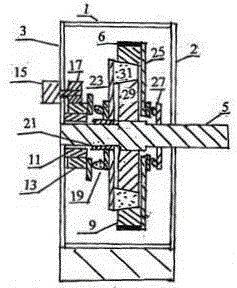

[0011] figure 1 , figure 2 , image 3 with Figure 4 As shown, the CVT continuously variable transmission of the present invention is mainly composed of a casing 1, a front end cover 2, a rear end cover 3, a driving shaft 4, a driven shaft 5, a driving pulley 8, a driven pulley 9, a metal belt 6 and a roller Type clamp 7 components. The metal 6 belt is wound on the driving pulley 8 and the driven pulley 9, the driven rotating shaft 5 stretches out from the front end cover 2, and the driving rotating shaft 4 enters from the rear end cover 3. The input ring screw 10 is sleeved on the rear section of the driving shaft 4 in the housing 1 , and the rear end of the input ring screw 10 is fixed on the inner side of the rear end cover 3 . The input gear nut 12 has an inner thread and an outer tooth, and the input gear nut 12 is matched with the input ring screw 10 , and the input ring screw 10 is screwed into the input gear nut 12 . The front end of the input gear nut 12 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com