Auxiliary device with buffer shunt-winding function for textile spool paper slitting machine of paper angle bead production line

An auxiliary device and paper corner protection technology, applied in metal processing and other directions, can solve the problems of many occupants, industrial accidents, paper strip damage, etc., and achieve the effects of high safety, avoiding damage and slowing down the rolling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

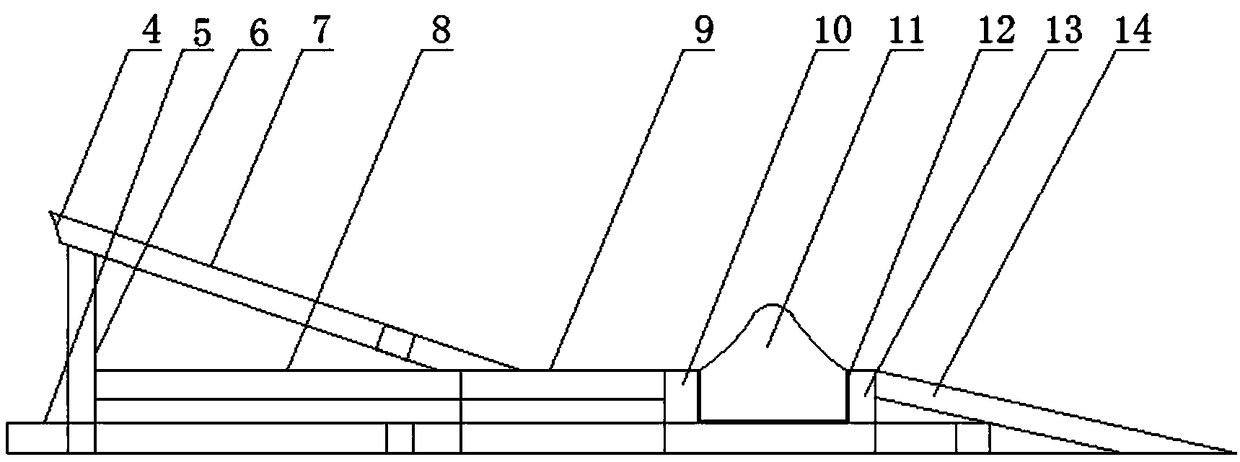

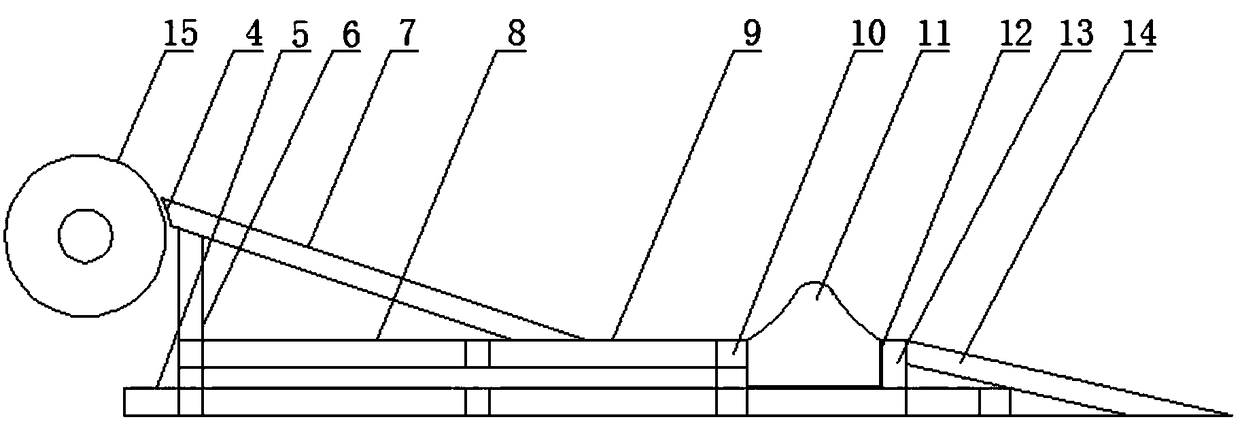

[0022] An auxiliary device for bobbin paper slitting machine of a paper corner protection production line with the function of buffering and splitting. Curved projections 11 are formed on it. The buffer ramp frame can gradually decelerate the bobbin paper strip rolls, and the deceleration baffle plate can automatically separate multiple paper strip rolls that are connected together while slowing down the rolling speed of the bobbin paper strip rolls. The arc-shaped protrusions can not only form a certain impact force on the rolling paper strip roll, but also ensure that the paper strip roll can pass smoothly and relatively stably without causing damage to the paper strip roll.

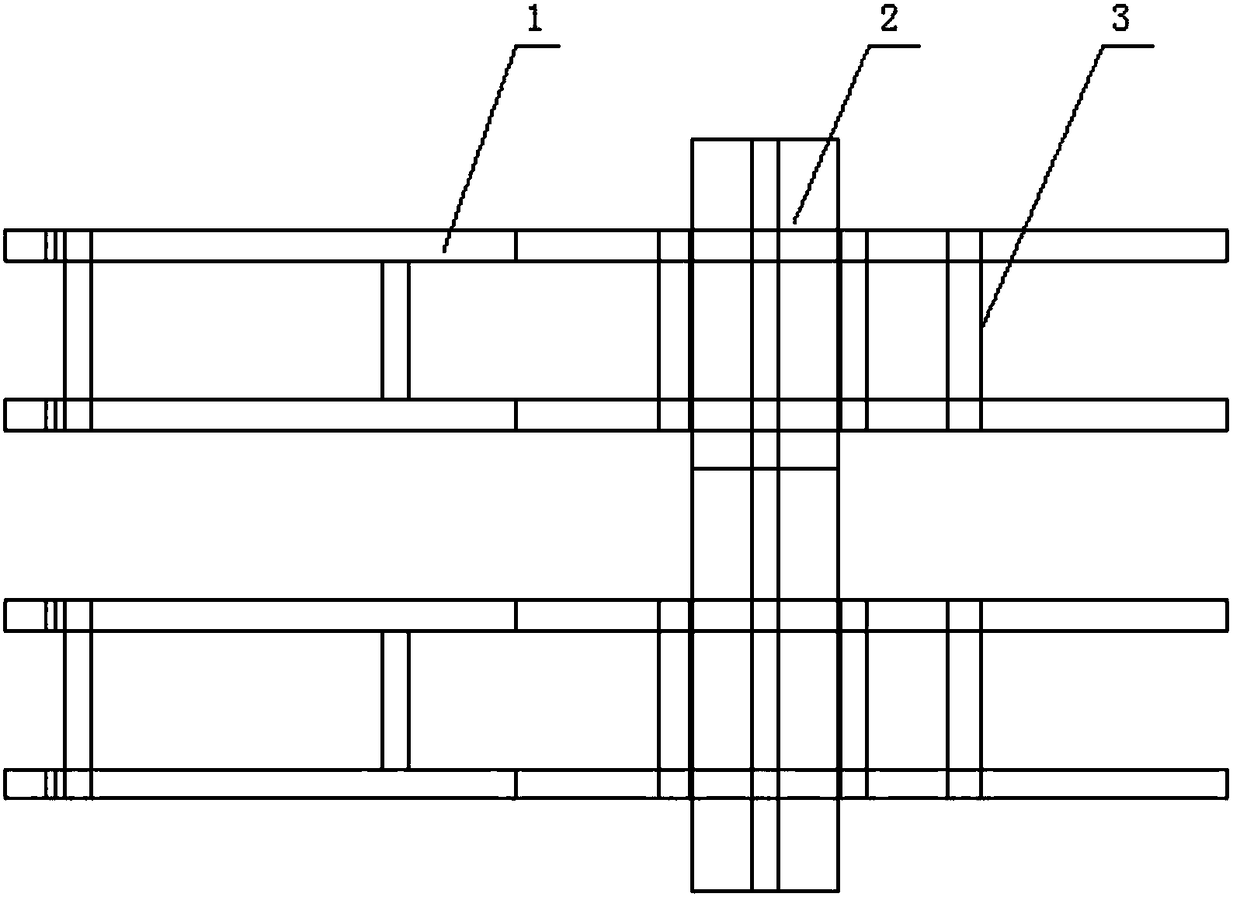

[0023] There are two buffer ramp frames, both of which are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com