Plastic recycling crusher

A technology of plastic recycling and shredder, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of low crushing efficiency and poor crushing effect, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

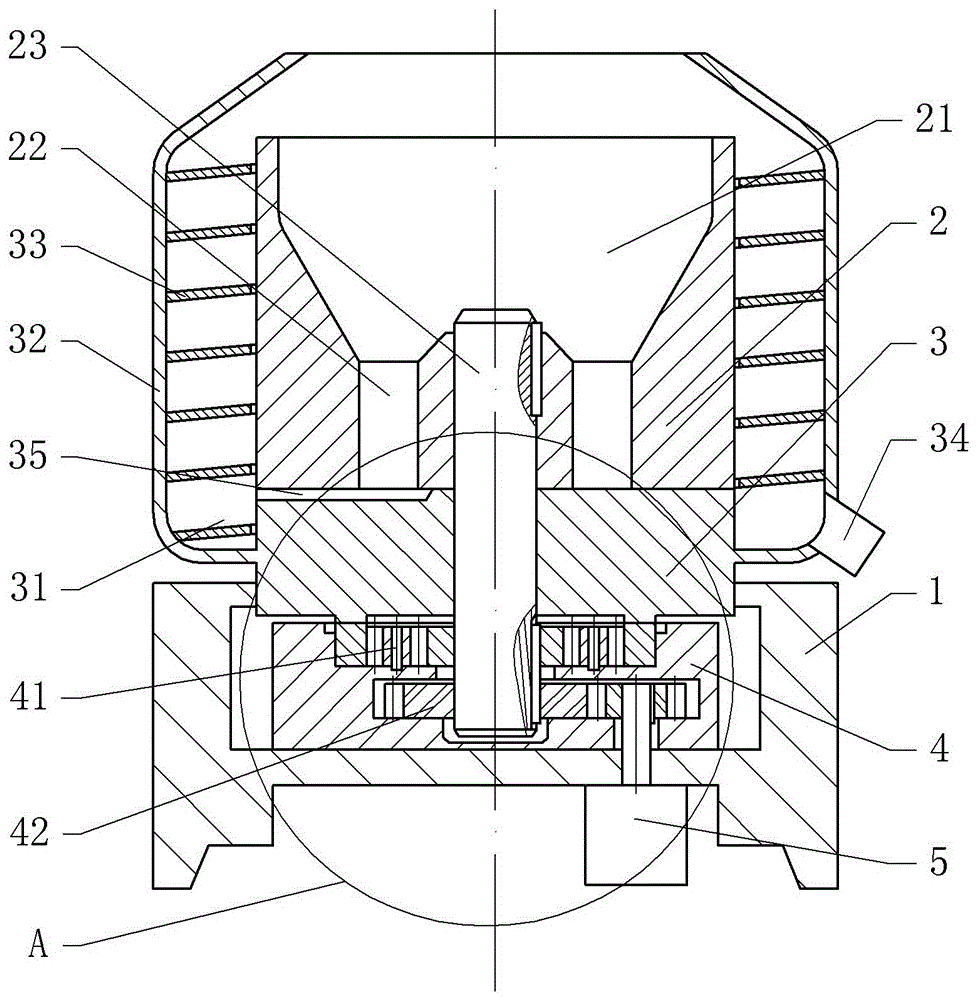

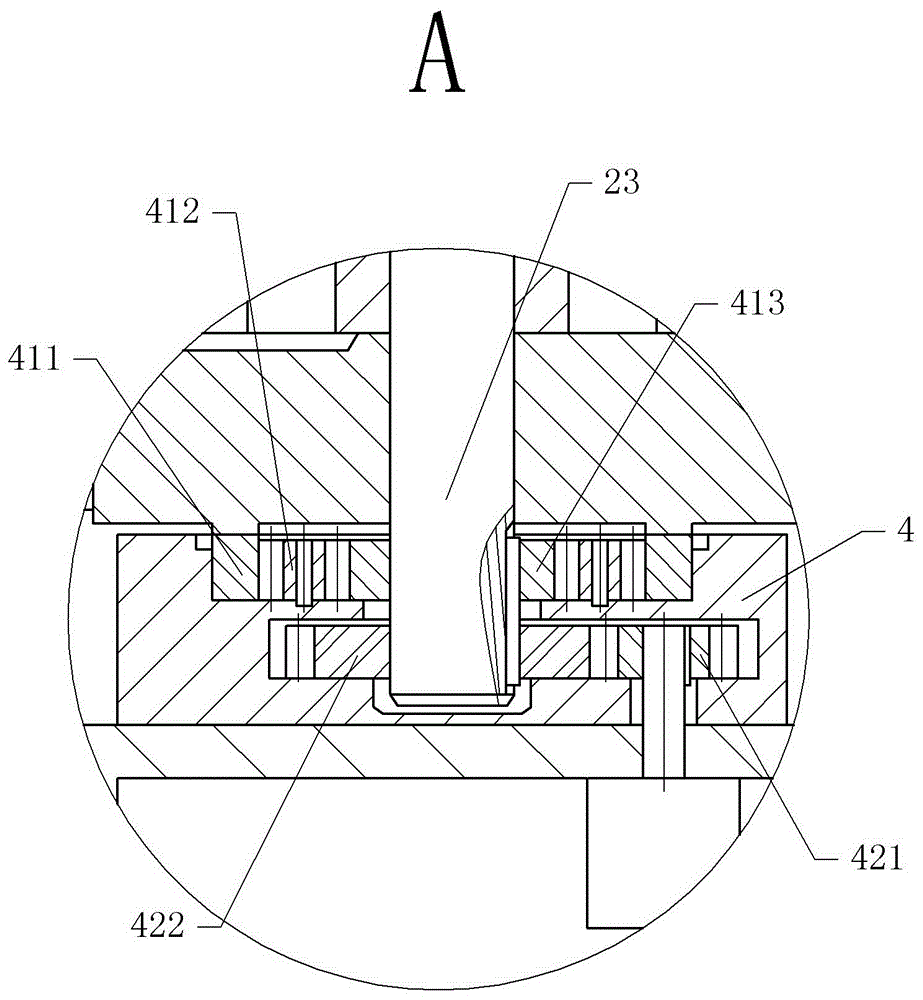

[0019] The reference signs in the accompanying drawings of the description include: frame 1, upper crushing wheel 2, lower crushing wheel 3, gear box 4, feeding hopper 21, feeding port 22, rotating shaft 23, receiving trough 31, feeding cylinder 32, Spiral blade 33, discharge valve 34, bar groove 35, reverse gear set 41, reduction gear set 42, ring gear 411, planetary gear 412, sun gear 413, driving gear 421, driven gear 422.

[0020] Example basic figure 1 Shown:

[0021] The plastic recycling pulverizer comprises a frame 1, a lower crushing wheel 3 arranged on the frame 1, and an upper crushing wheel 2 arranged above the lower crushing wheel 3. The center key of the upper crushing wheel 2 is connected with a rotating shaft 23, and the rotating shaft 23 is connected to the The lower grinding wheel 3 and the frame 1 are connected in rotation; the lower grinding wheel 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com