Patents

Literature

76results about How to "To achieve the crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

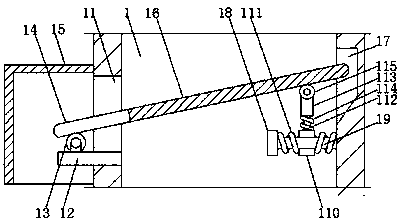

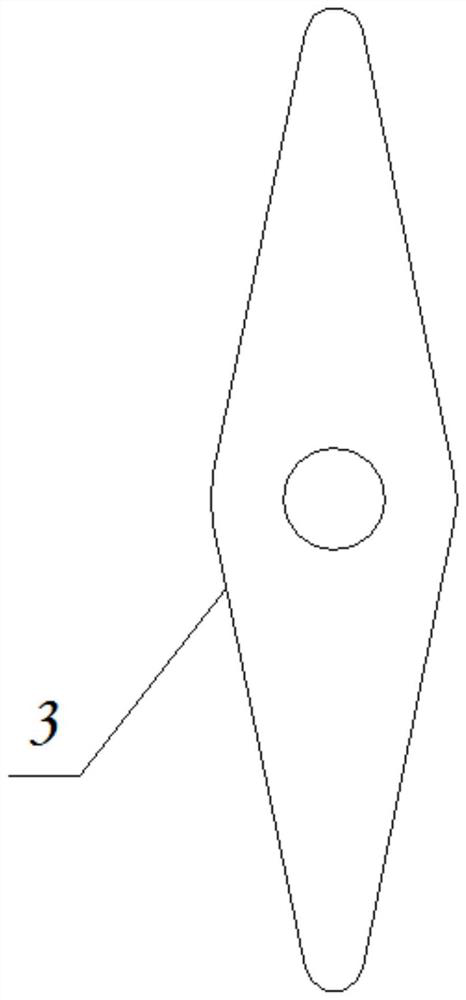

Pulverizing soil dispersal ditching device matched with rotary cultivator

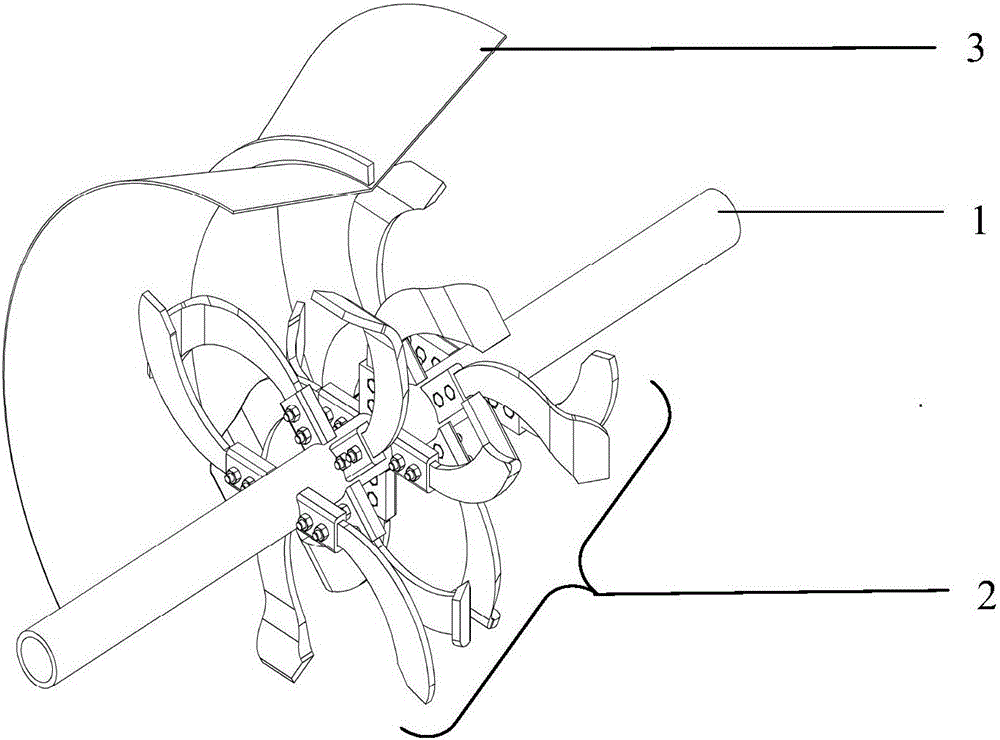

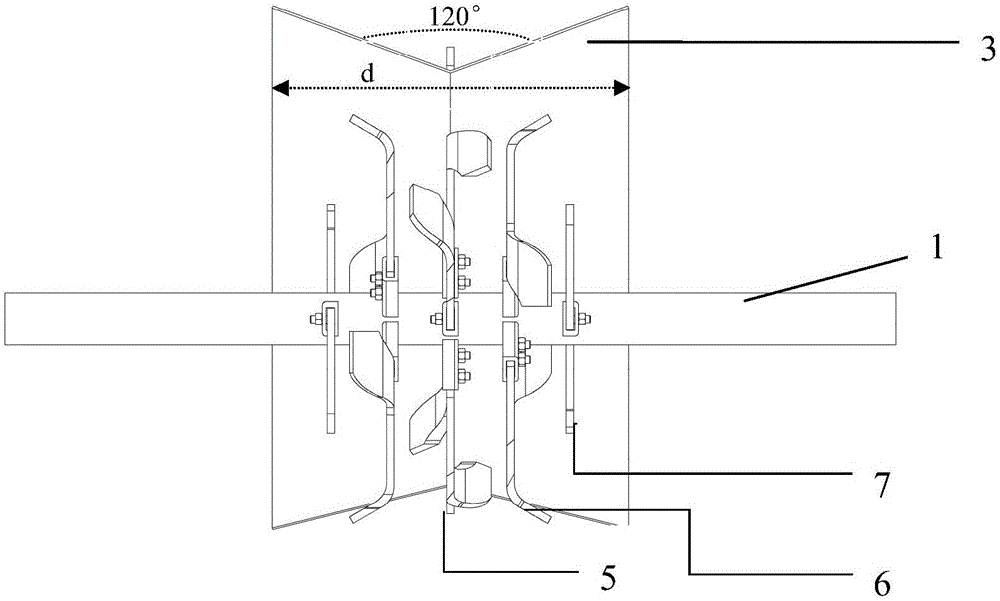

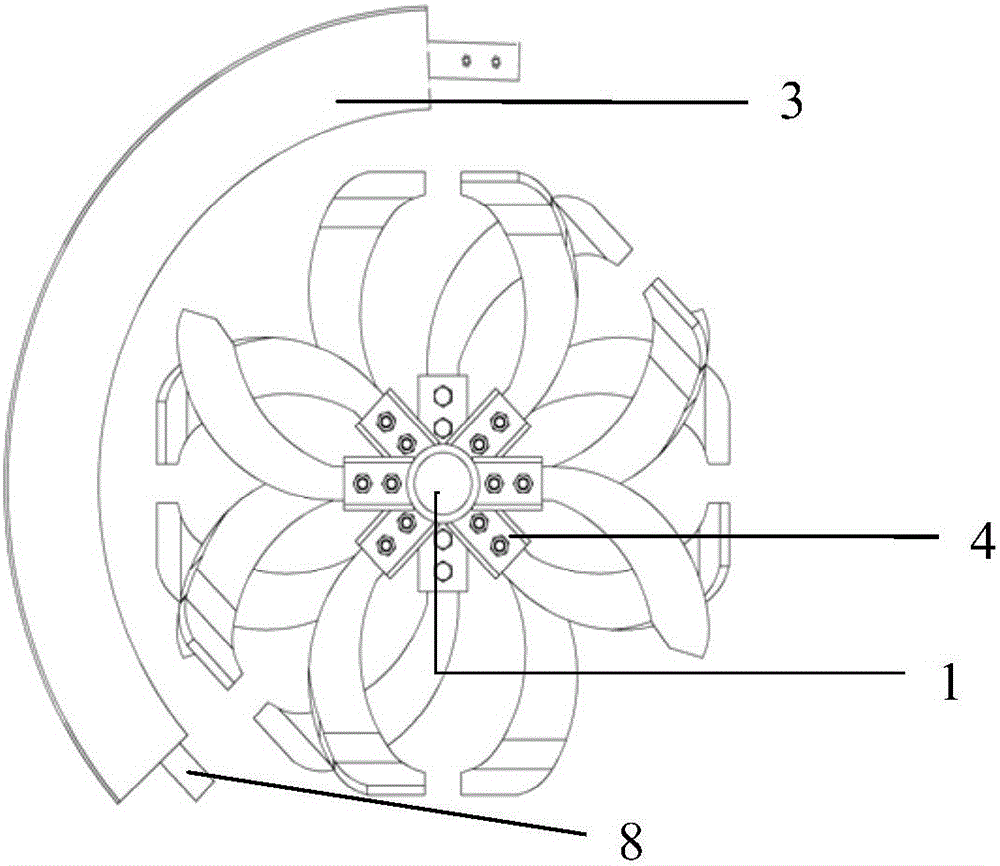

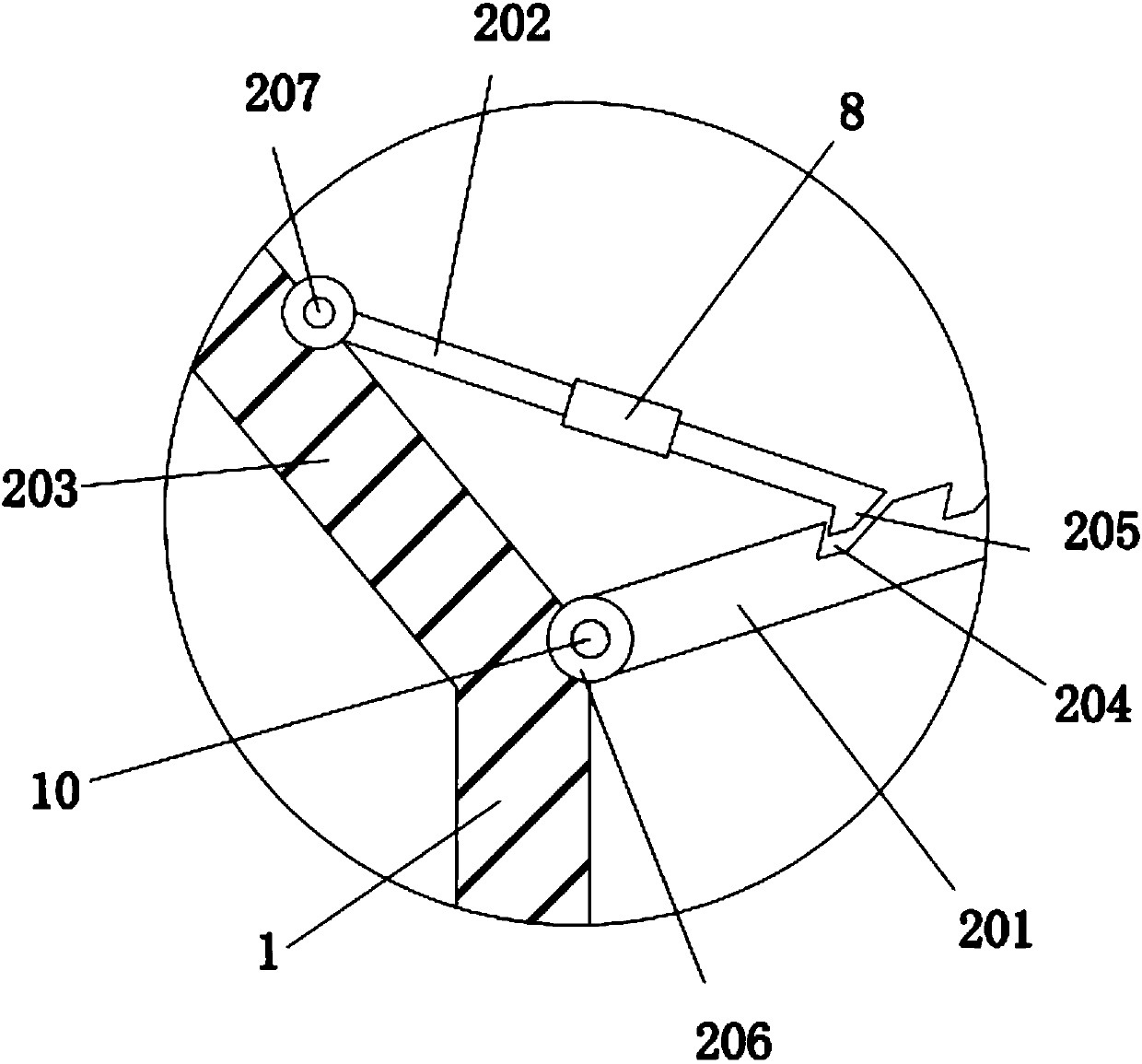

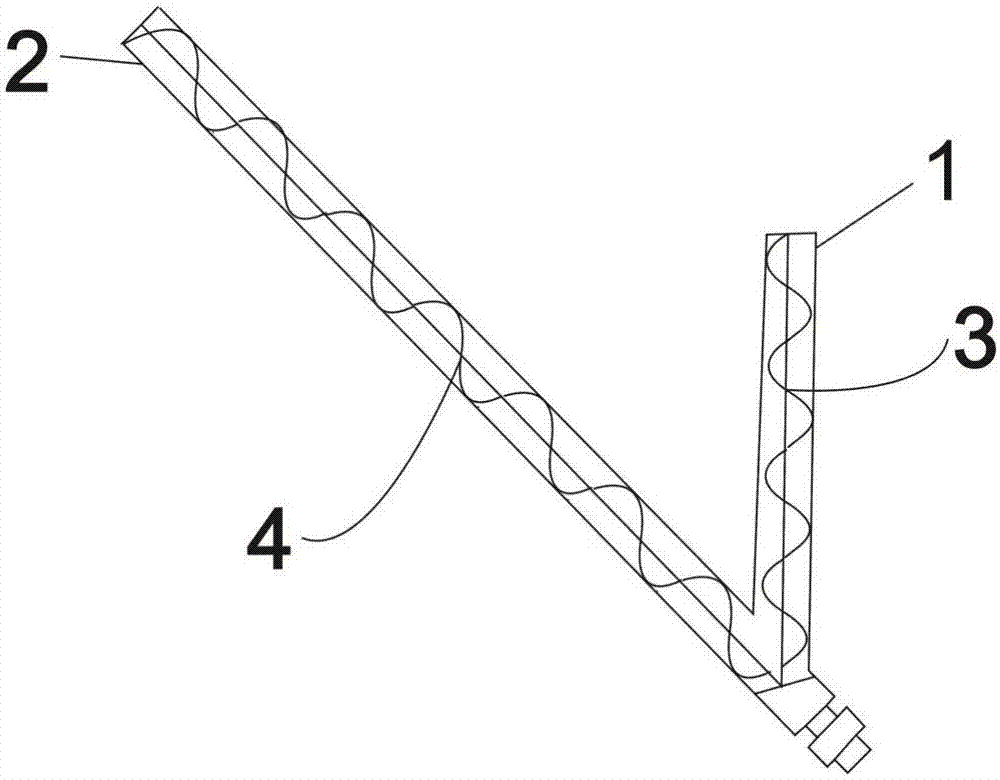

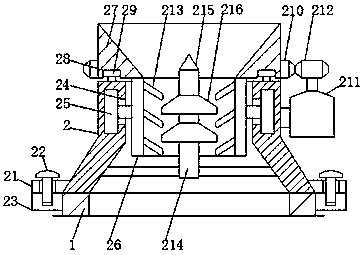

A pulverizing soil dispersal ditching device matched with a rotary cultivator comprises a cutter shaft which is connected with a conveyer driven shaft of the rotary cultivator, a rotary tillage cutter head which is arranged on the cutter shaft and a soil separating board which is fixed on the rotary cultivator, and is characterized in that the rotary tillage cutter head comprises a first bent cutter head, a second bent cutter head and a straight cutter head; the first bent cutter head is arranged in the middle of the cutter head, the straight cutter head is symmetrically arranged on the cutter head with the first bent cutter head as the center, the second bent cutter head is arranged on the cutter head between the straight cutter head and the first bent cutter head, wherein the first bent cutter head, the second bent cutter head and the straight cutter head have the same diameter; a plurality of first right angled bent cutters provided with straight cutting edges are symmetrically arranged on the first bent cutter head with the axis of the cutter shaft as the center. By means of novel arrangement of the rotary tillage cutters, the ditching mode is changed, the soil pulverizing rate and the ditching rate are improved, and the ditching width can reach 20 cm-30 cm; the pulverizing soil dispersal ditching device is simple in structure, convenient to use in various rotary cultivators, low in cost, convenient to assemble and unassembled, and higher in ditching quality and efficiency.

Owner:HUNAN SOIL & FERTILIZER INST +1

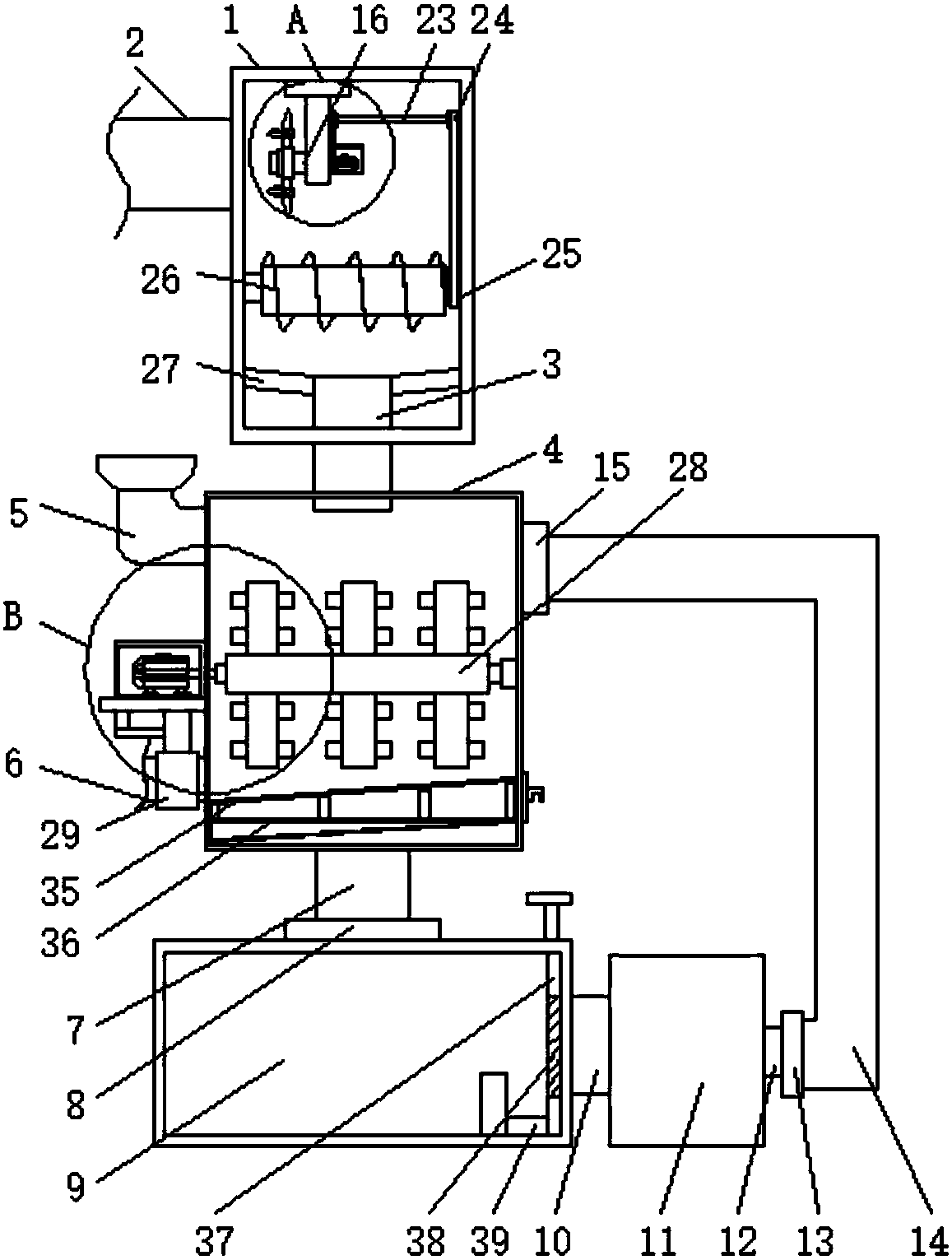

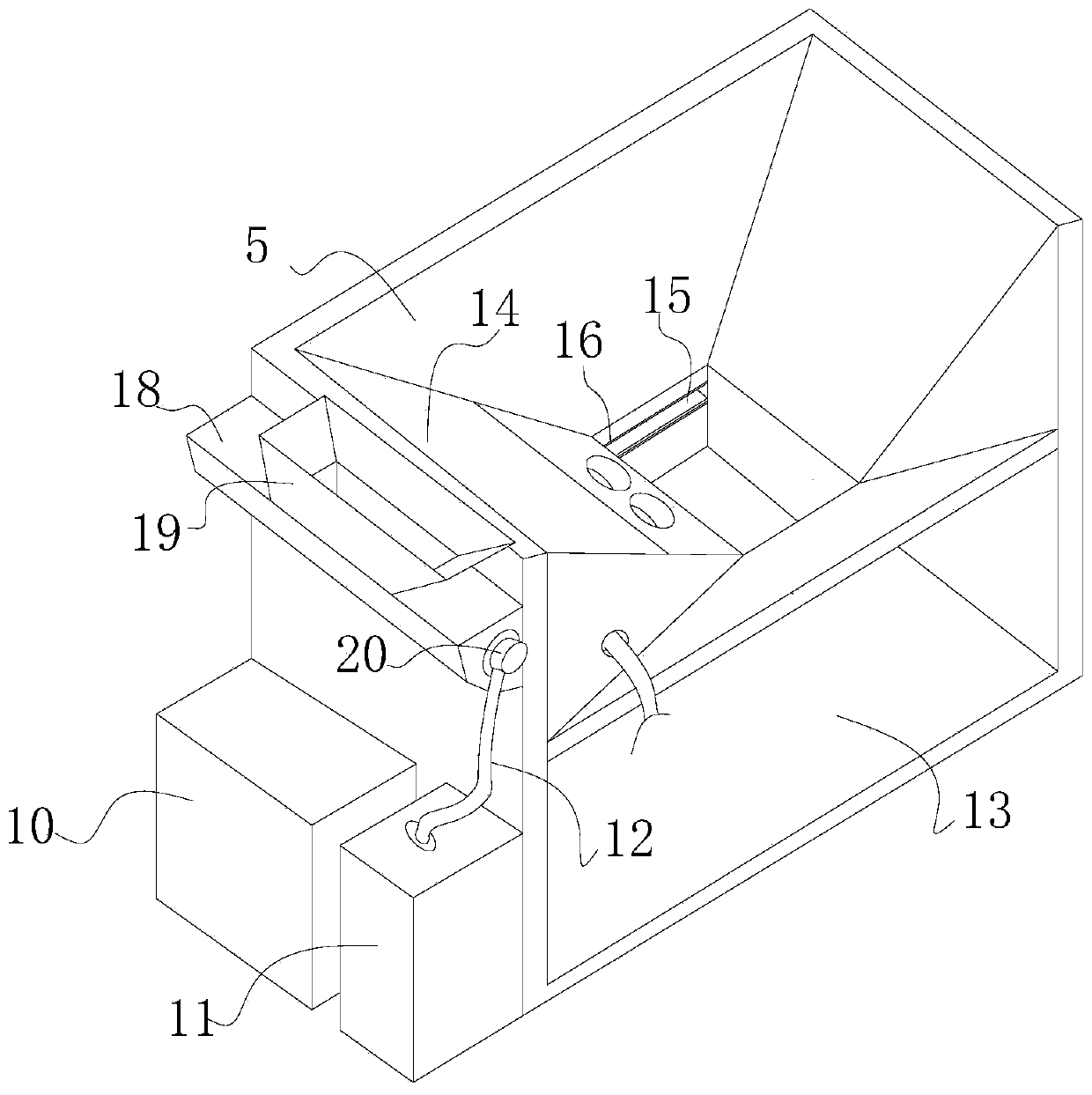

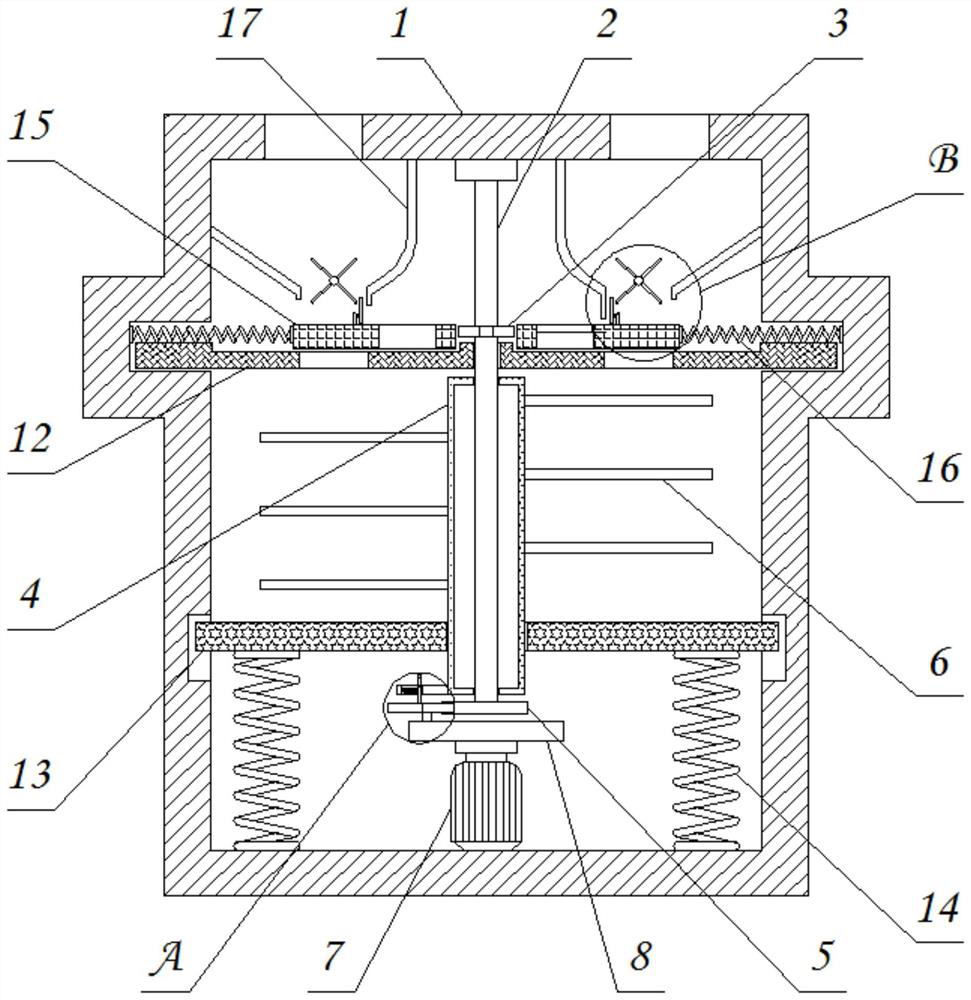

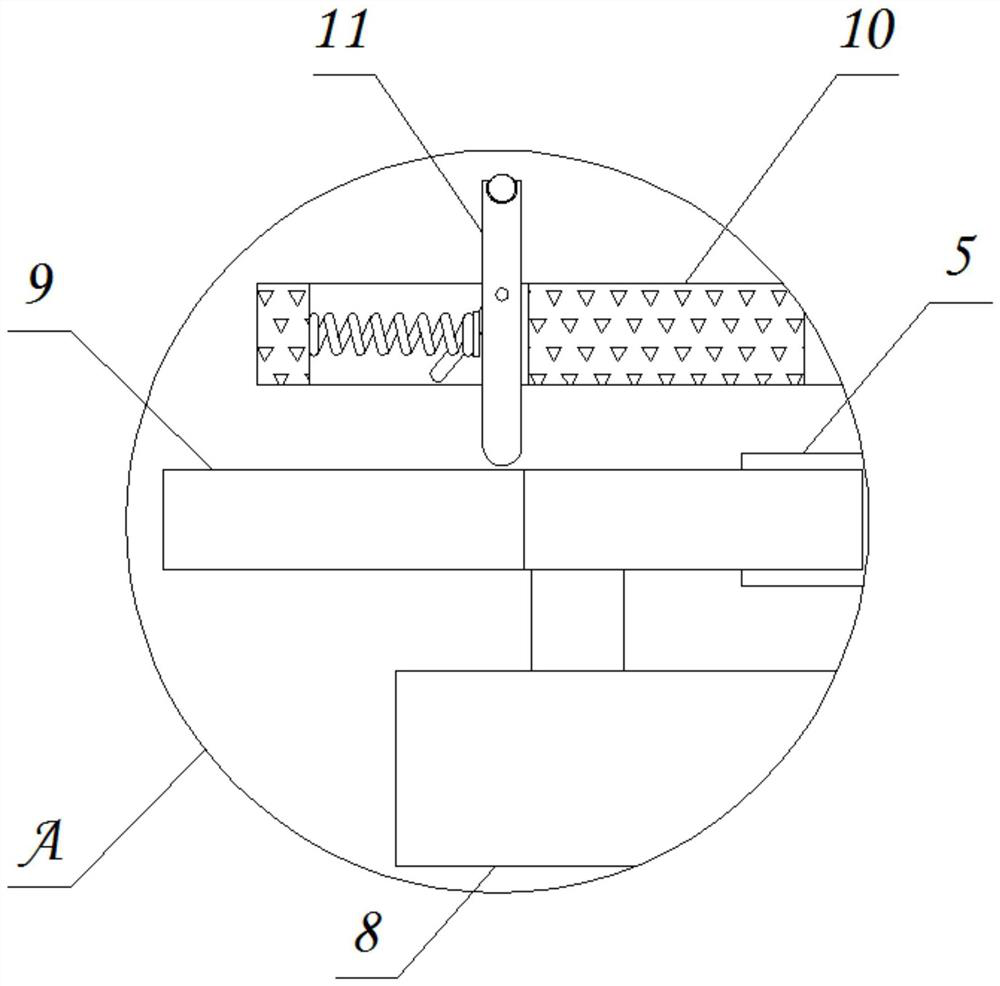

Bi-smashing equipment for animal husbandry feed production

InactiveCN107983442ASimple structureReasonable designFeeding-stuffDirt cleaningDrive motorEngineering

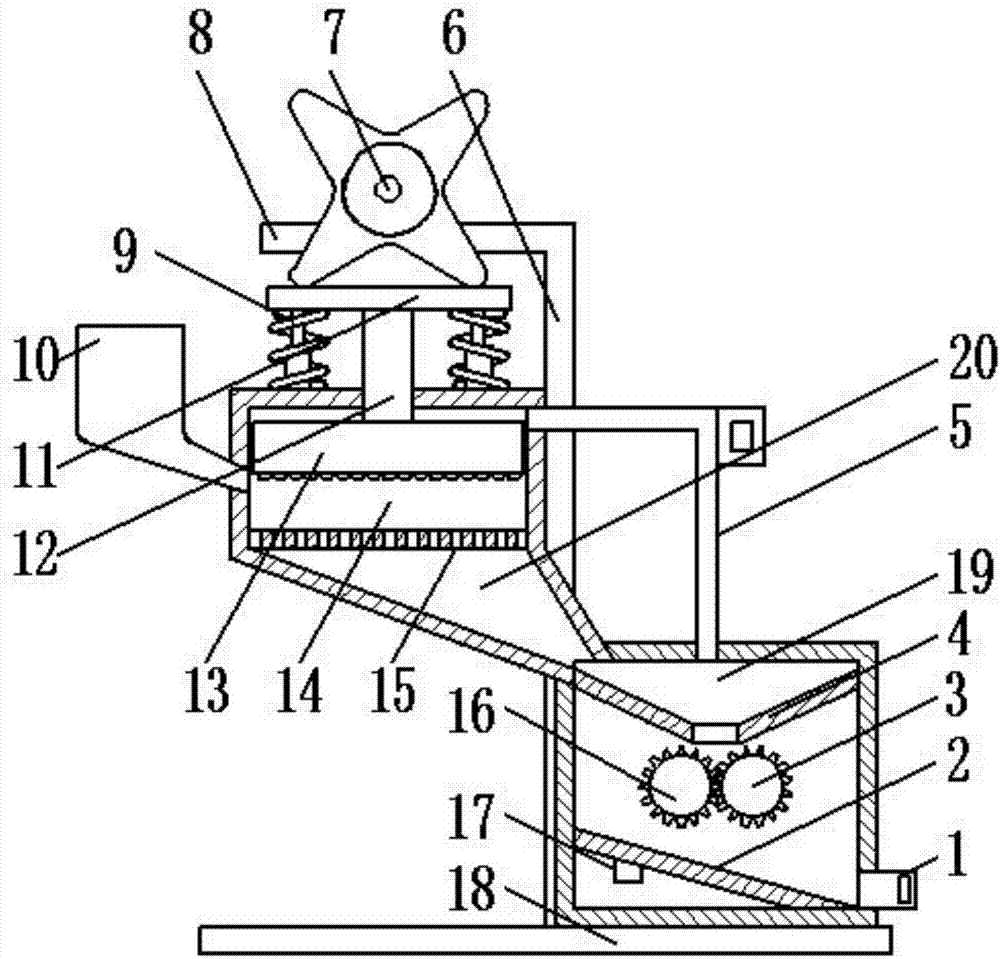

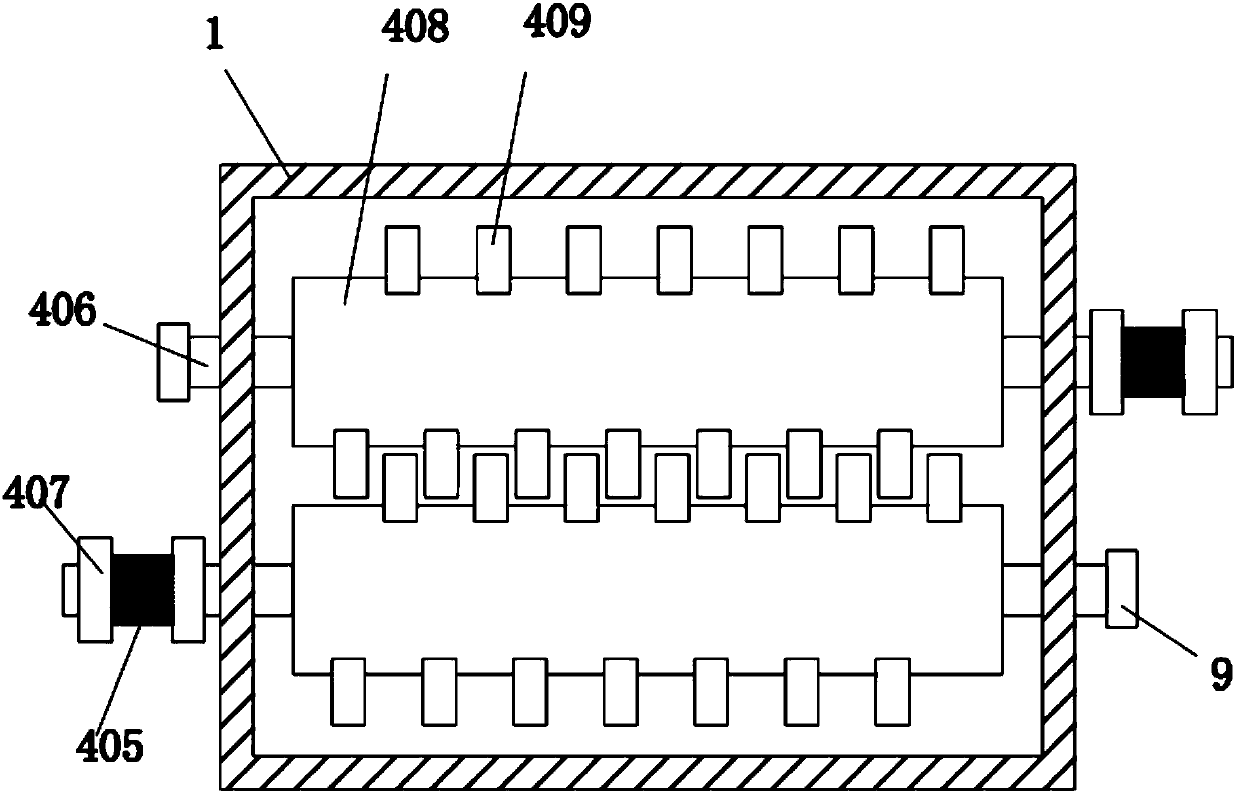

The invention provides bi-smashing equipment for animal husbandry feed production and belongs to the technical field of animal husbandry production. The bi-smashing equipment for the animal husbandryfeed production is simple in structure, reasonable in design and convenient to use. By means of the arrangement of a smashing block, reset devices and a drive device, under the action of the drive device, a drive motor drives a rotating wheel to rotate so as to drive the smashing block to downwards move to carry out smashing treatment on materials; under the action of the reset devices, the smashing block is driven to upwards move to reset; and the drive motor drives the smashing block to downwards move again, movement is carried out repeatedly in this way, the effect of smashing the materialsis achieved, after smashing is completed, the materials are input to a smashing chamber through a flow equalizing plate, the materials are downwards input through a guide plate, under the action of afirst smashing roller and a second smashing roller, smashing treatment is carried out on the materials again, after smashing is completed, the materials are input to the position of a discharge pipethrough an oblique plate, and a vibration motor is used for driving the oblique plate to carry out vibration, so that the materials can be discharged completely from the discharge pipe.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Plastic recycling crusher

InactiveCN105965727AAchieve the opposite effectSimple structurePlastic recyclingCocoaDrive motorEngineering

The invention discloses a plastic recycling crusher, and relates to the technical field of plastic machines. The plastic recycling crusher comprises a rack, a feeding hopper arranged at the upper portion of the rack, a lower crushing wheel arranged on the rack, and an upper crushing wheel arranged above the lower crushing wheel. The center of the upper crushing wheel is fixedly connected with a rotating shaft, and the rotating shaft is rotationally connected with the lower crushing wheel and the rack. The lower crushing wheel is fixedly or rotationally connected with the rack. The lower surface of the upper crushing wheel and the upper surface of the lower crushing wheel are grinding faces matched with each other. The feeding hopper is located above the upper crushing wheel. The upper crushing wheel is internally further provided with a plurality of feeding ports communicating with the feeding hopper and the grinding faces. Material collecting grooves are formed in the periphery of the lower crushing wheel. The rack is further provided with a drive motor and a gear case. The drive motor is connected with the rotating shaft through the gear case. According to the plastic recycling crusher, the characteristic of tenacity of plastic particles is avoided, the plastic particles are crushed through friction force, and the crushing effect and efficiency are improved.

Owner:重庆敏驰塑胶有限公司

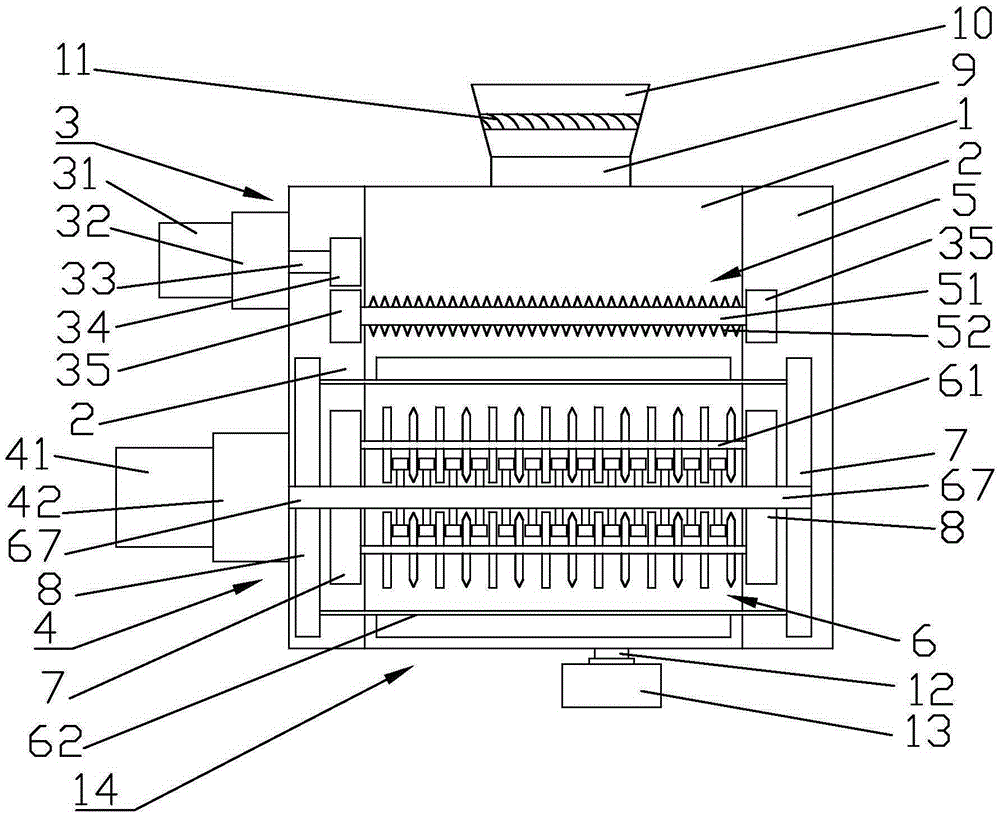

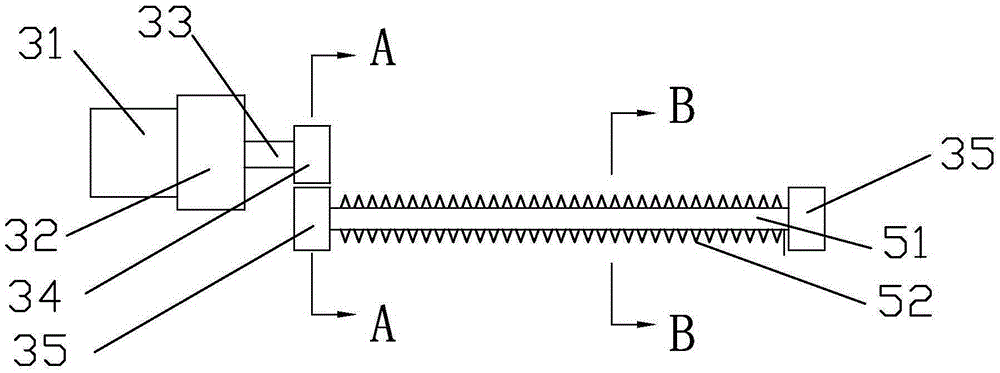

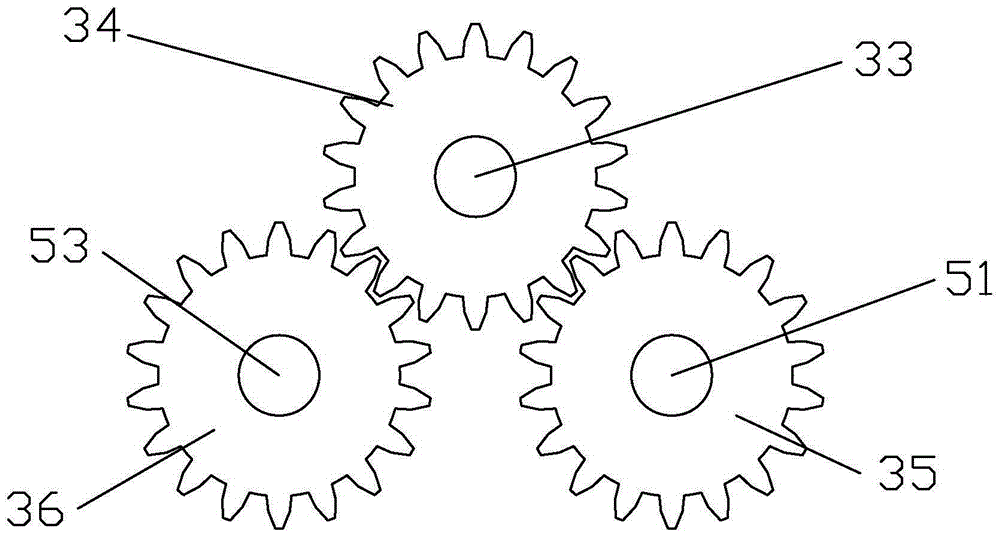

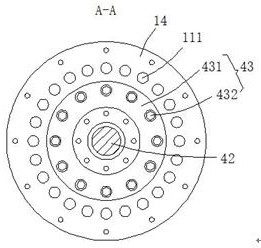

Pulverizer applied to recycling of waste glass

InactiveCN105413798ASolve the crushing problemSimple structureGrain treatmentsGlass fragmentGlass recycling

The invention discloses a pulverizer applied to recycling of waste glass. The pulverizer comprises a pulverizing cavity. The pulverizing cavity comprises a transmission room and a pulverizing room. A transmission device is arranged in the transmission room. A pulverizing device is arranged in the pulverizing room. The transmission device comprises a first transmission device body and a second transmission device body. The pulverizing device comprises a first pulverizing device body and a second pulverizing device body. The first pulverizing device body comprises a pulverizing roller which is connected with the first transmission device body. The pulverizing roller comprises a first pulverizing roller body and a second pulverizing roller body. The second pulverizing device body comprises a center pulverizing main shaft which is connected with the second transmission device body. According to the pulverizer, the two levels of pulverizing device bodies are adopted, the first pulverizing device body, the first pulverizing roller and the second pulverizing roller are used for conducting primary pulverizing on waste glass, and then the second pulverizing device body is used. Small glass fragments can be pulverized further, and in addition, the glass fragments is evenly pulverized further to become aggregate capable of being used for concrete.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Household domestic waste treatment robot

InactiveCN107824303ADispose of garbage quicklyDisposal garbage clean and hygienic collectionGrain treatmentsDomestic wasteWaste disposal

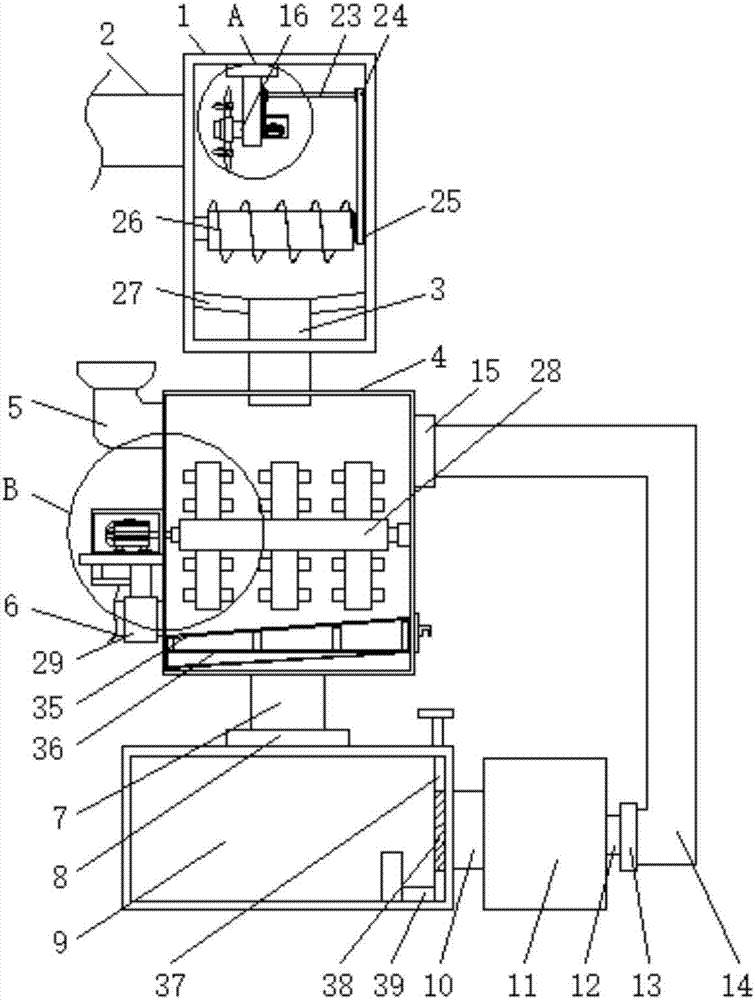

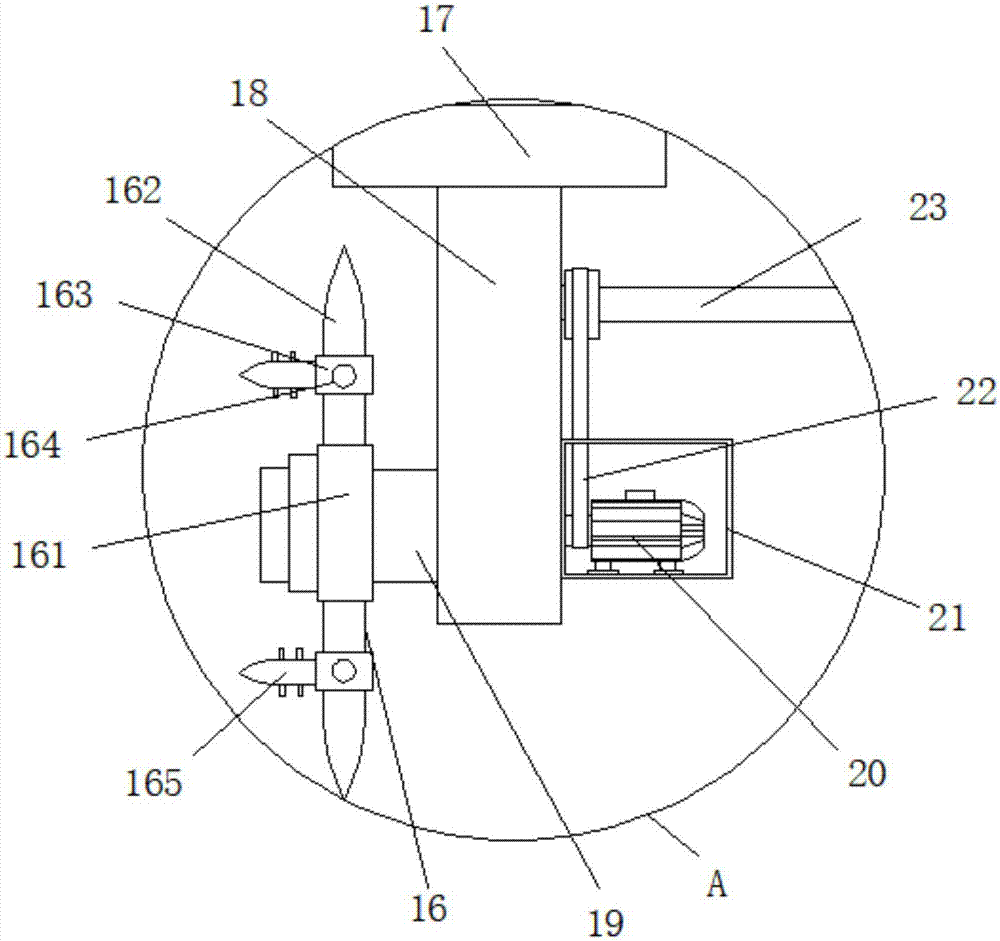

The invention discloses a domestic garbage processing robot, which comprises a box body, a volume control device is provided on the top of the box body, and the volume control device includes a hopper, and clamp rods are provided on the left and right sides of the hopper. The clamping rod is connected with the hopper through the second connecting shaft, the bottom end of the right side of the clamping rod is provided with a clamping head, the lower part of the clamping head is provided with a baffle plate, and the top of the baffle plate is provided with a bayonet opening. The baffle is connected with the hopper through the first connecting shaft, and the left and right sides of the box are provided with a crushing device, the crushing device includes a motor, the bottom of the motor is provided with a base, and the right side of the motor A first pulley is arranged on the side, and the first pulley is connected with the motor through a bearing, and a rotating shaft is arranged above the first pulley. The domestic domestic waste treatment device achieves the effect of crushing the waste, has the advantages of performing secondary screening on the degree of waste crushing, and has the advantages of quicker disposal of waste and clean and hygienic collection.

Owner:湖州创一装饰设计工程有限公司

Paper production method capable of recycling water

InactiveCN107513876ASave waterEasy to crushPulp beating/refining methodsRaw material divisionWater storageFiber

The invention discloses a paper production method capable of water recycling. The paper production equipment capable of water recycling includes a crushing box, the crushing box is fixedly connected with a stirring box through a material guide pipe fixedly connected at the bottom, and the bottom of the side of the stirring box is fixedly connected There is a discharge pipe, and the mixing tank is fixedly connected to the water storage tank through the catheter tube fixedly connected at the bottom. One end of the tube is fixedly connected to the top of the stirring tank. The invention crushes the trees through the crushing box, stirs the crushed trees through the stirring box to separate the plant fibers, collects the used water in the stirring box through the water storage tank, and then imports the water collected in the water storage tank into the stirring box through the water suction pump , to achieve the advantages of recycling water resources to stir the crushed trees, and has the advantage of saving water resources.

Owner:傅恺

Novel garbage pulverizer

The invention discloses a novel garbage pulverizer. The novel garbage pulverizer comprises a shell, the inside of the shell is provided with a first cavity, a second cavity and a power cabin respectively, the second cavity is located right below the first cavity, and the power cabin is located on the right side of the second cavity, the inner bottom wall of the first cavity is equipped with a material port, the inner side wall of the first cavity is fixedly connected to first teeth and is equipped with a through-hole, the first cavity is internally equipped with an extrusion block, the left side of the extrusion block is fixedly connected to second teeth, the right side of the extrusion block is fixedly connected to support rod, one end of the support rod far from the extrusion block runsthrough the through-hole and extends to the inside of the power bin, the inner top wall of the power bin is fixedly connected to a first bearing, the inner side wall of the power bin is fixedly connected to a first motor, and the output end of the first motor is fixedly connected to a curved bar. The novel garbage pulverizer can improve the overall paper shredding effect and meet the needs of users, has high practical value, and is beneficial to popularization.

Owner:江苏万通塑业有限公司

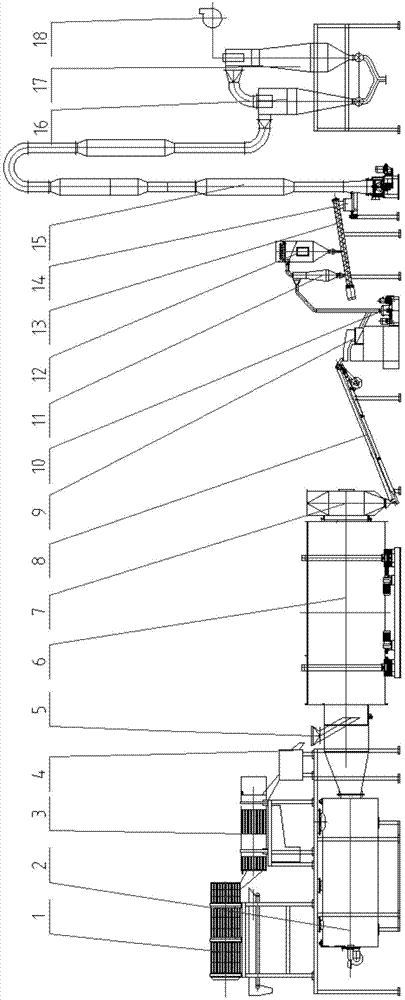

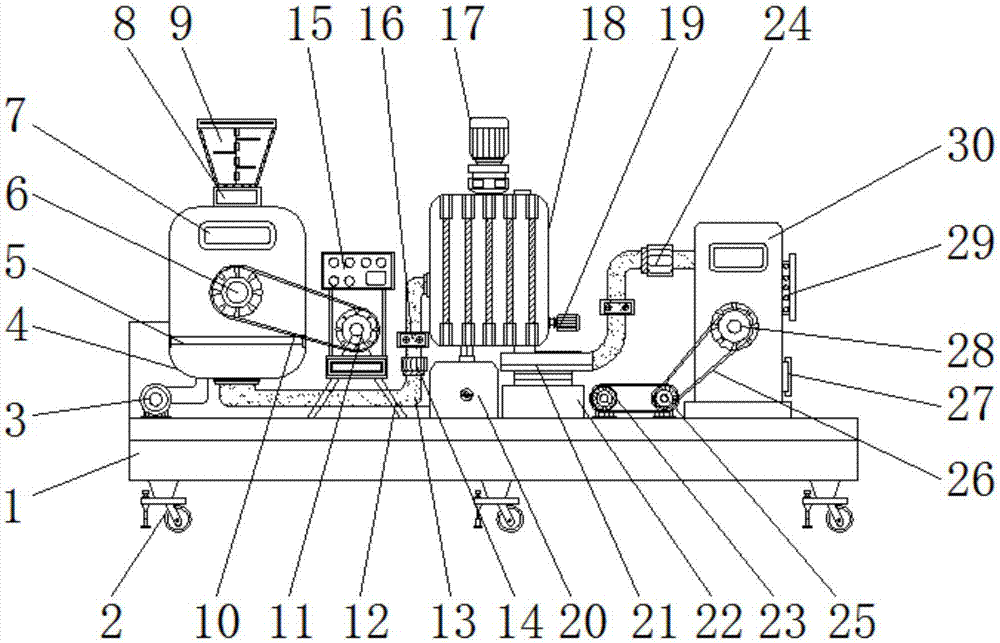

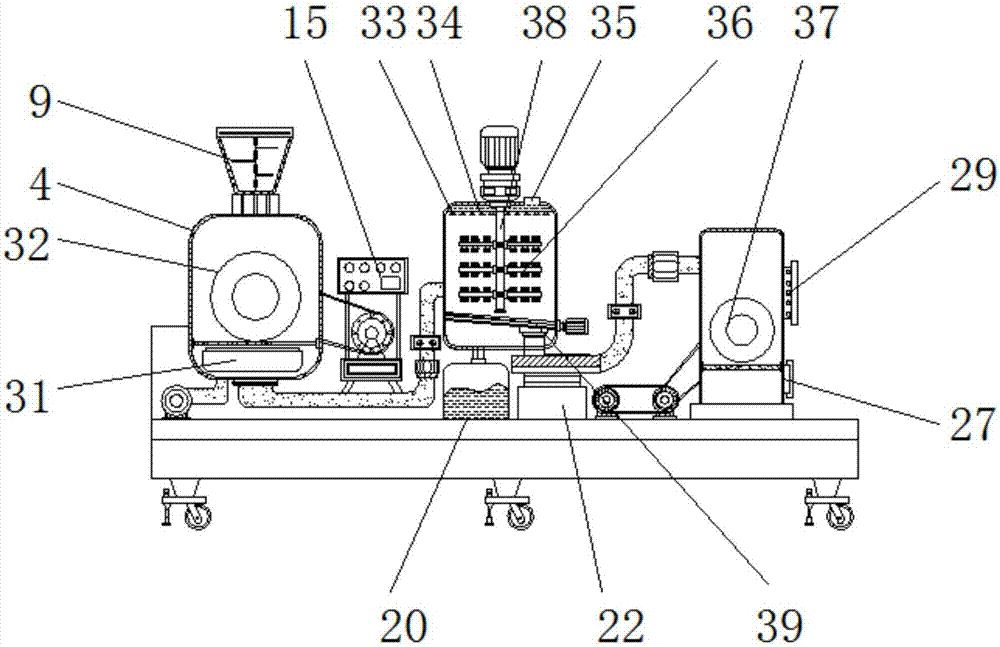

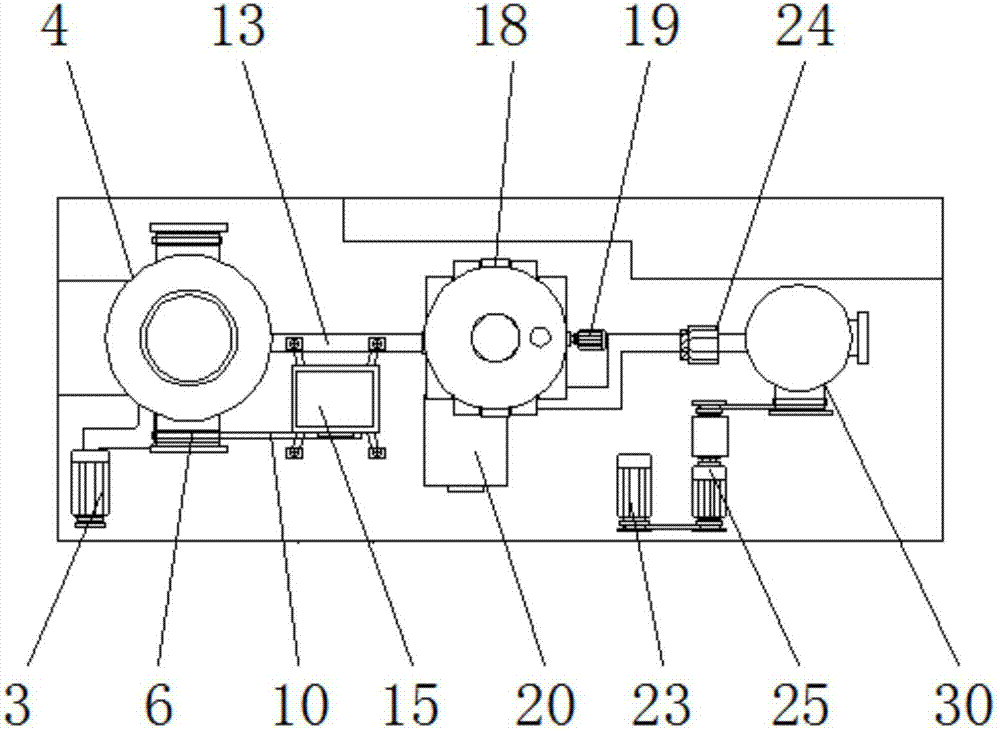

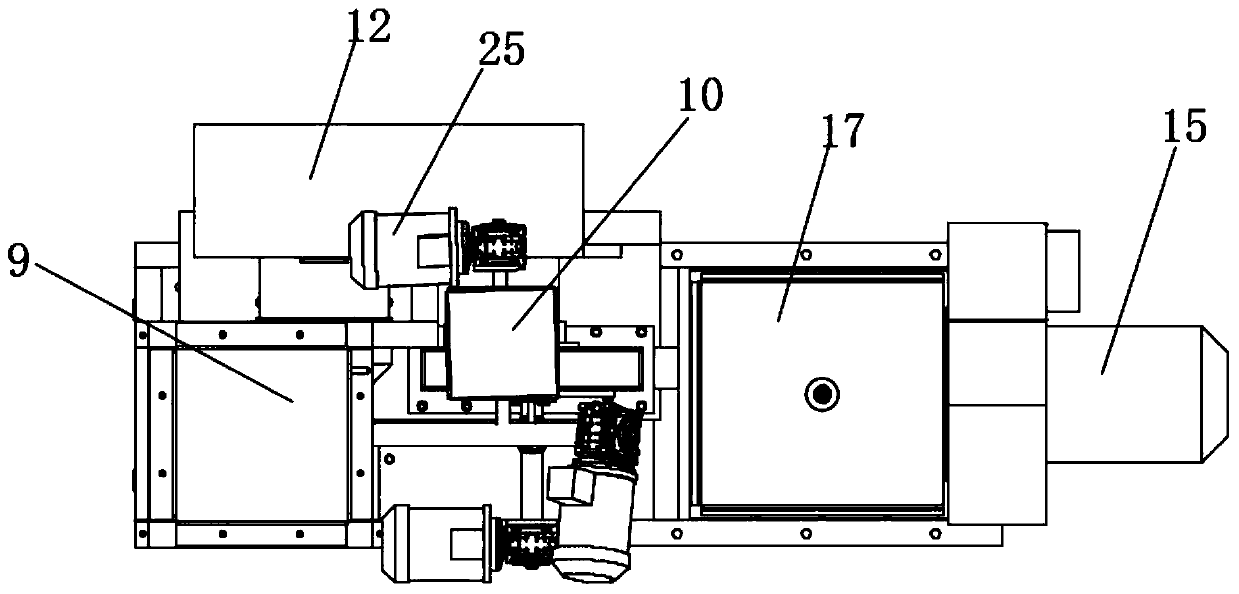

Cassava starch production equipment and method using three-pass drum and air flow combined drying

ActiveCN104848663AIncrease granularityReduce manual laborDrying machines with non-progressive movementsFood preparationElectricityAgricultural engineering

The invention discloses cassava starch production equipment and method using three-pass drum and air flow combined drying. The cassava starch production equipment comprises a peeling and dicing system. The inlet end of the peeling and dicing system is a cassava inlet. The outlet end of the peeling and dicing system is connected with the inlet end of a three-pass drum drying system. The outlet end of the three-pass drum drying system is connected with the inlet end of a pulverizing system. The outlet end of the pulverizing system is connected with the inlet end of an air flow drying system. The outlet end of the air flow drying system is a cassava starch outlet. The method includes: peeling cassava through a dry method and a wet method, and dicing the cassava; drying cassava dices; pulverizing the dried cassava dices to obtain cassava starch; drying the cassava starch, and packaging. By the cassava starch production equipment and method, a large amount manual operation is omitted, the cassava is completely pulverized, the refining degree of the cassava starch is increased greatly, and energy such as water and electricity is saved.

Owner:SHAANXI UNIV OF SCI & TECH

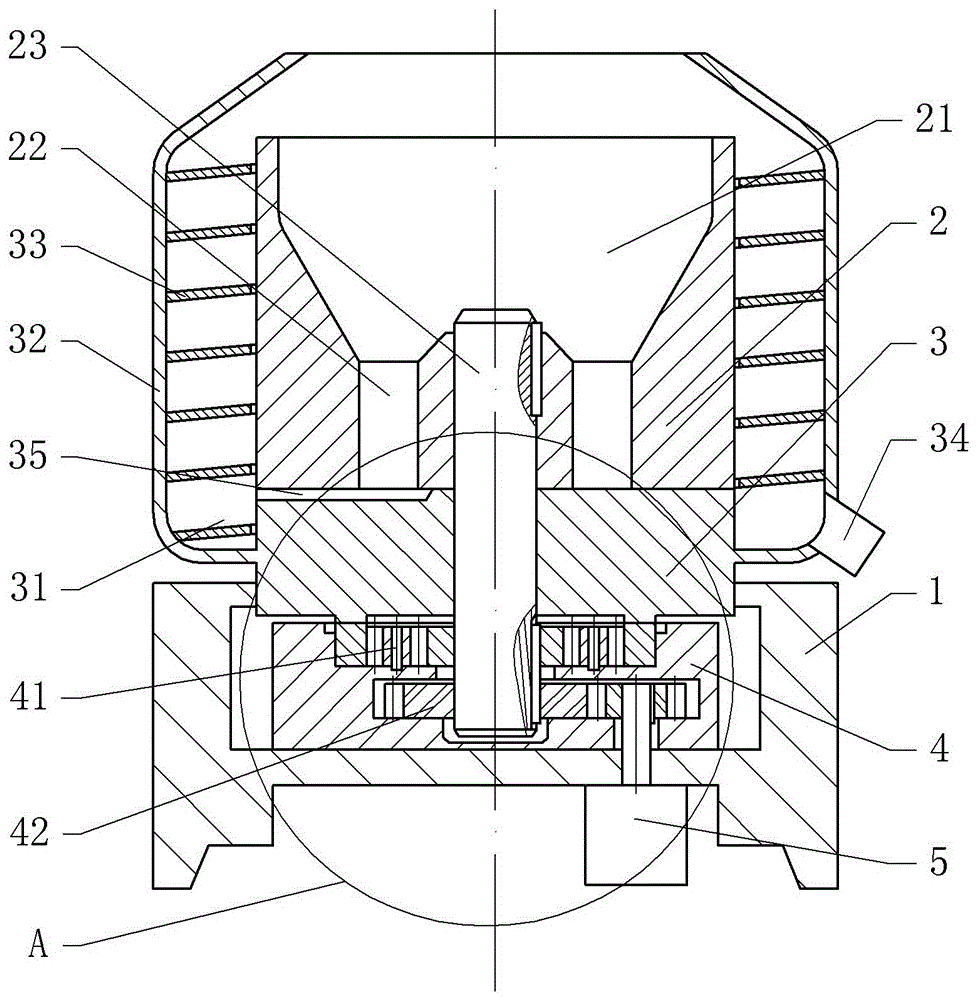

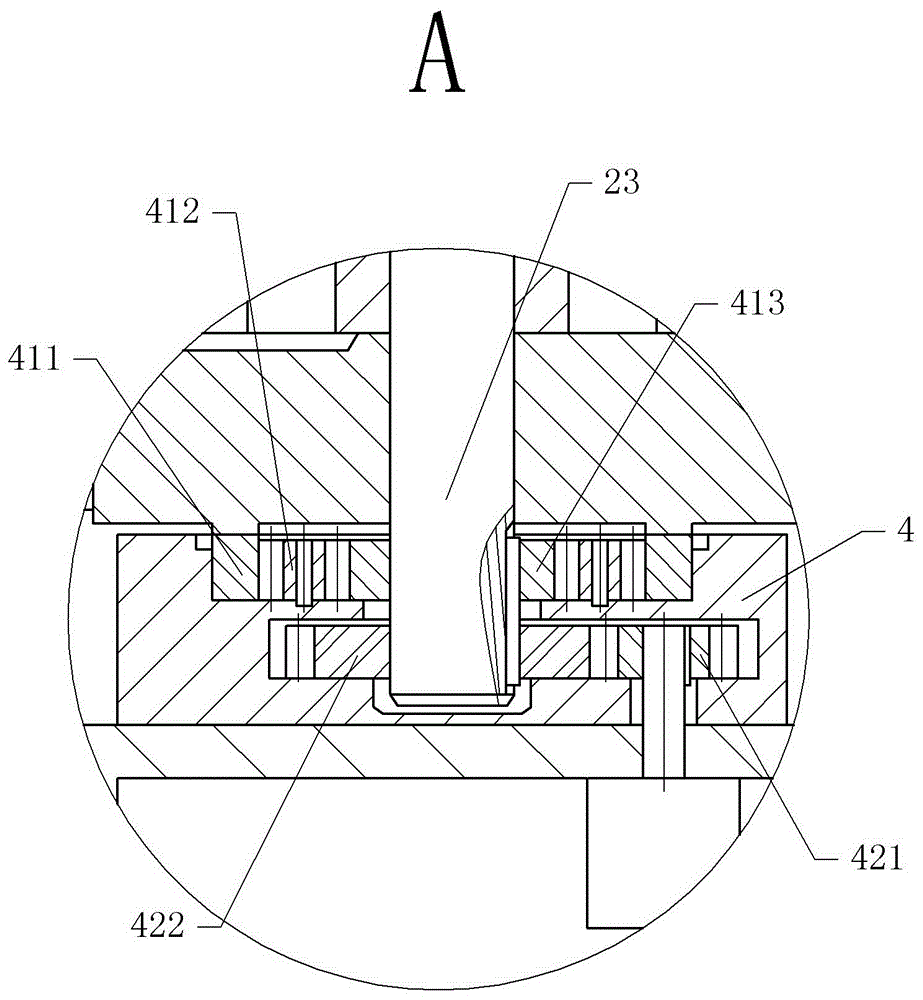

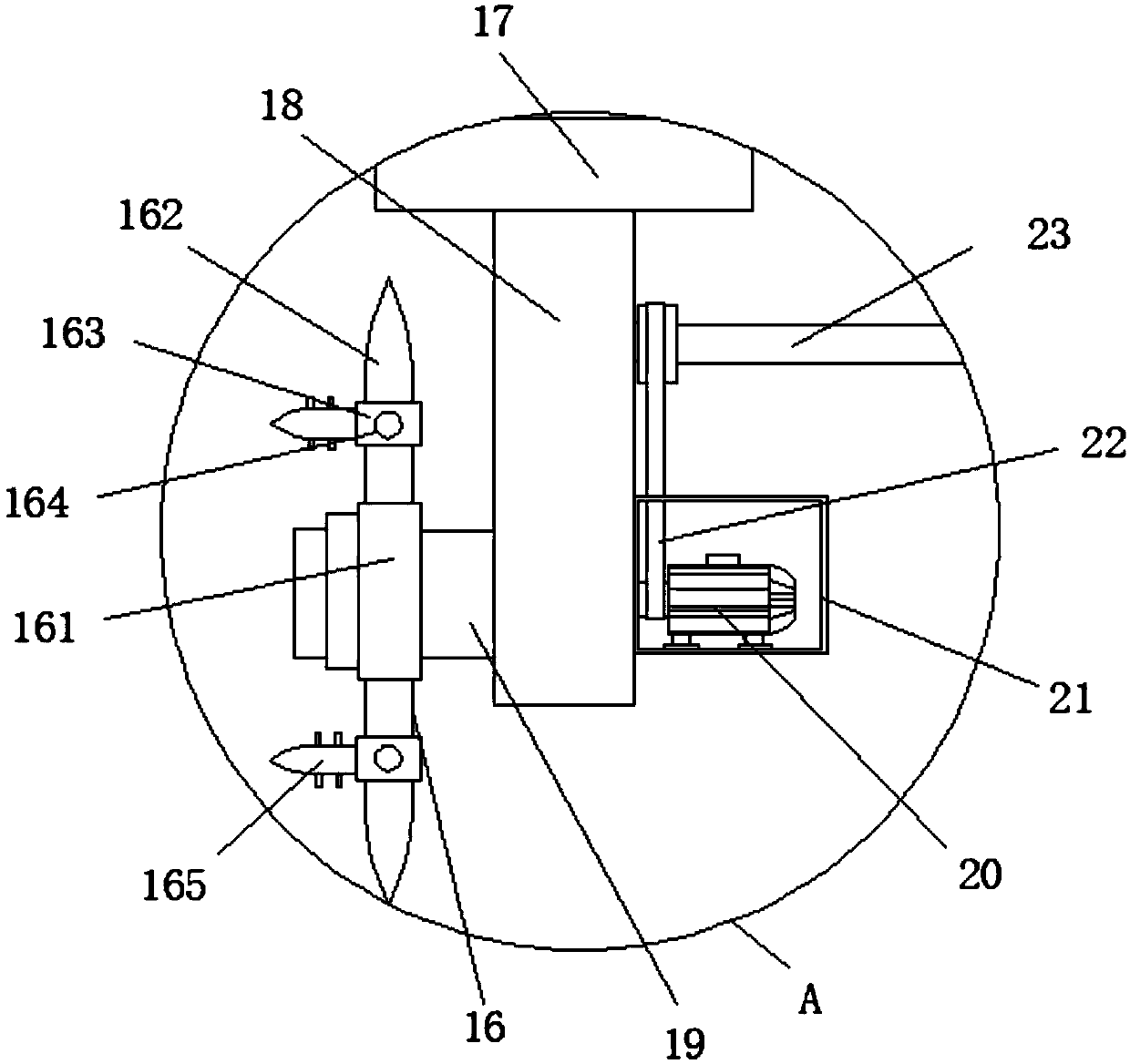

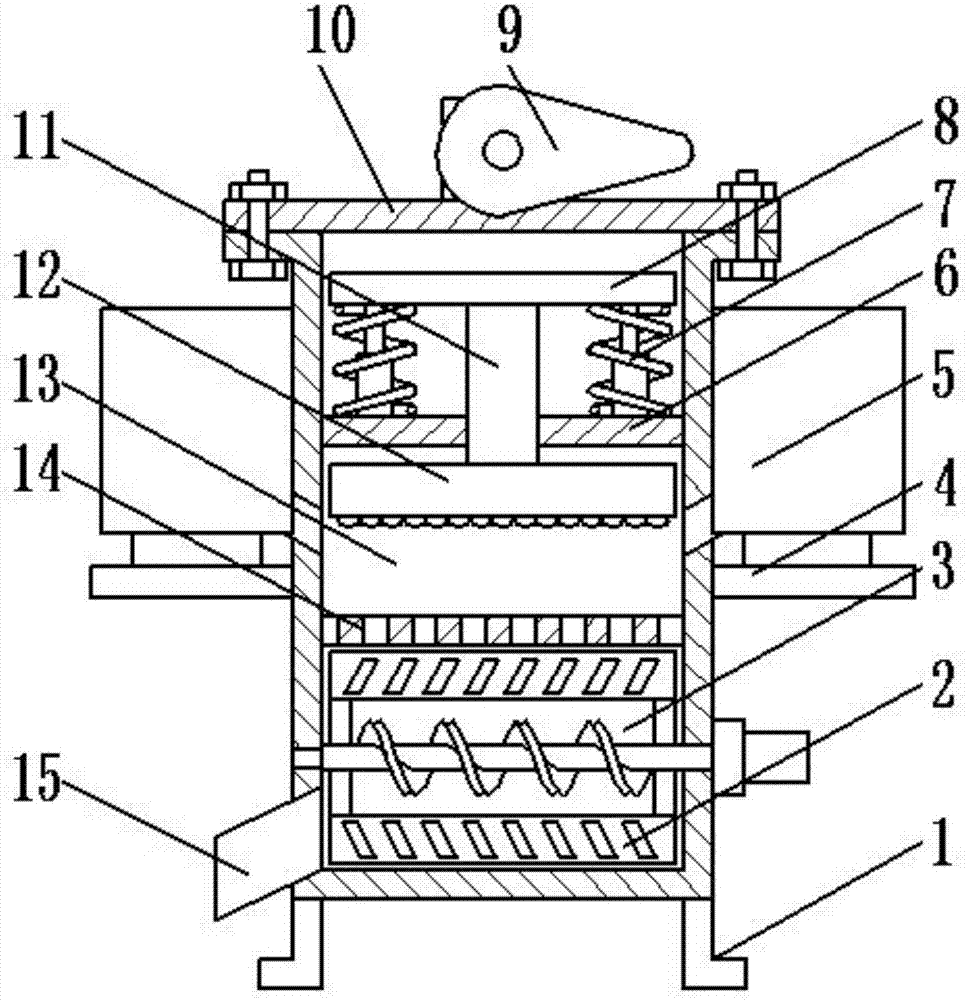

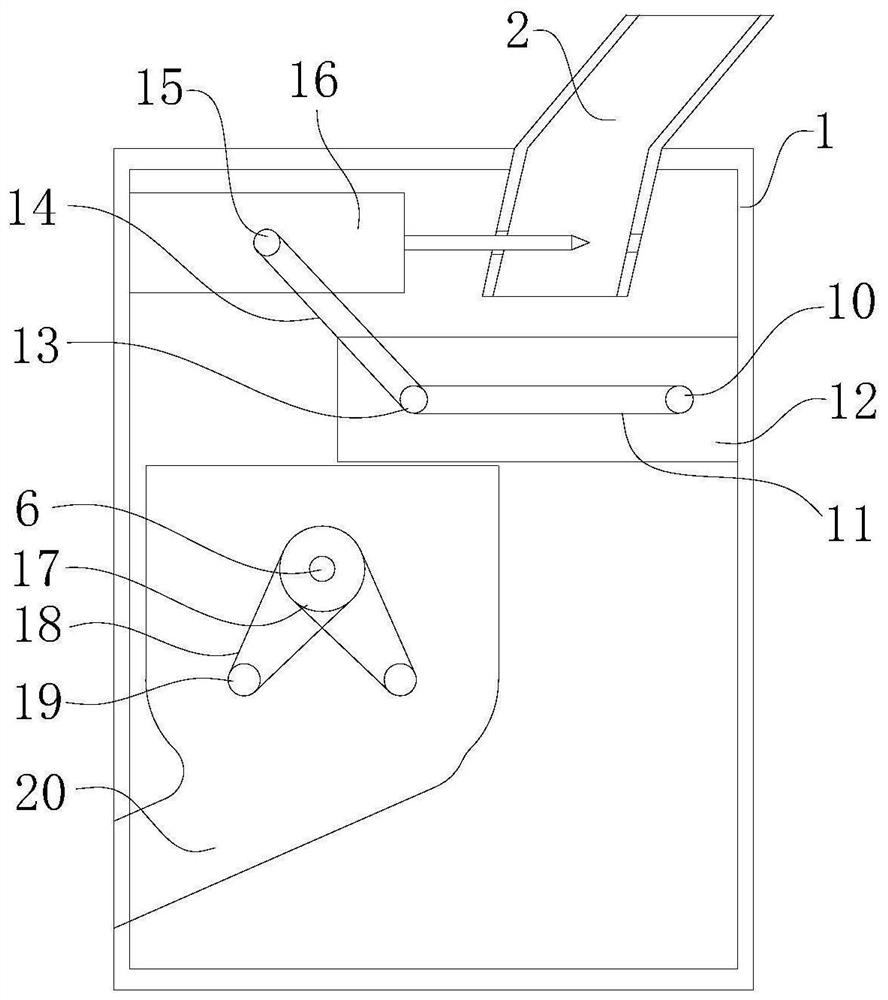

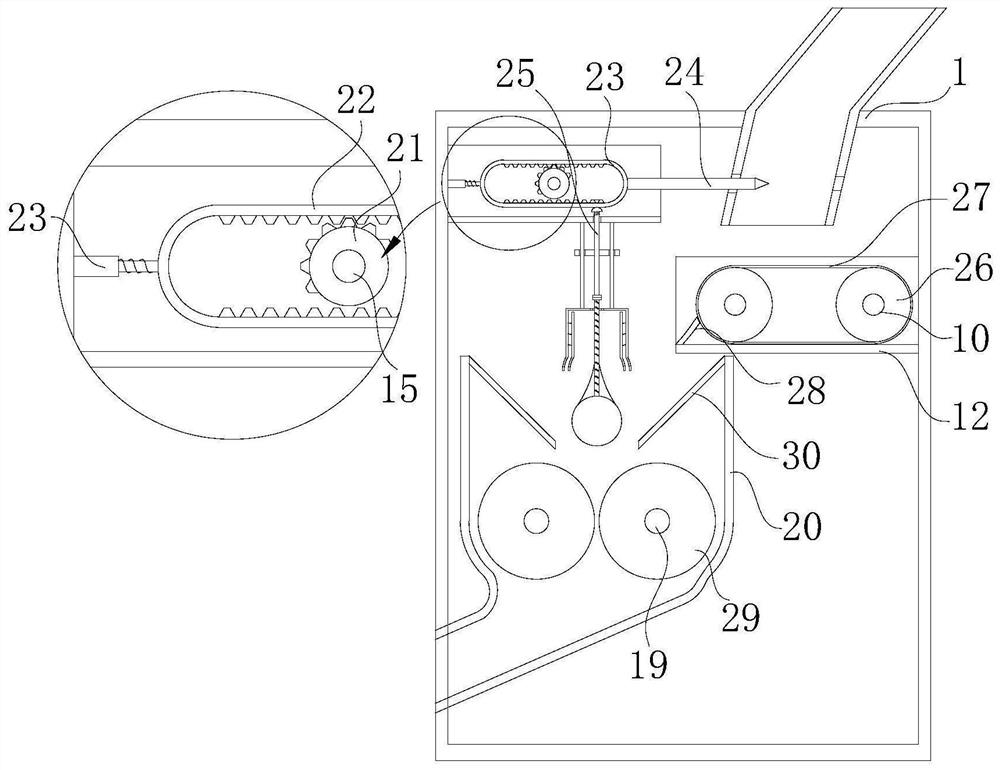

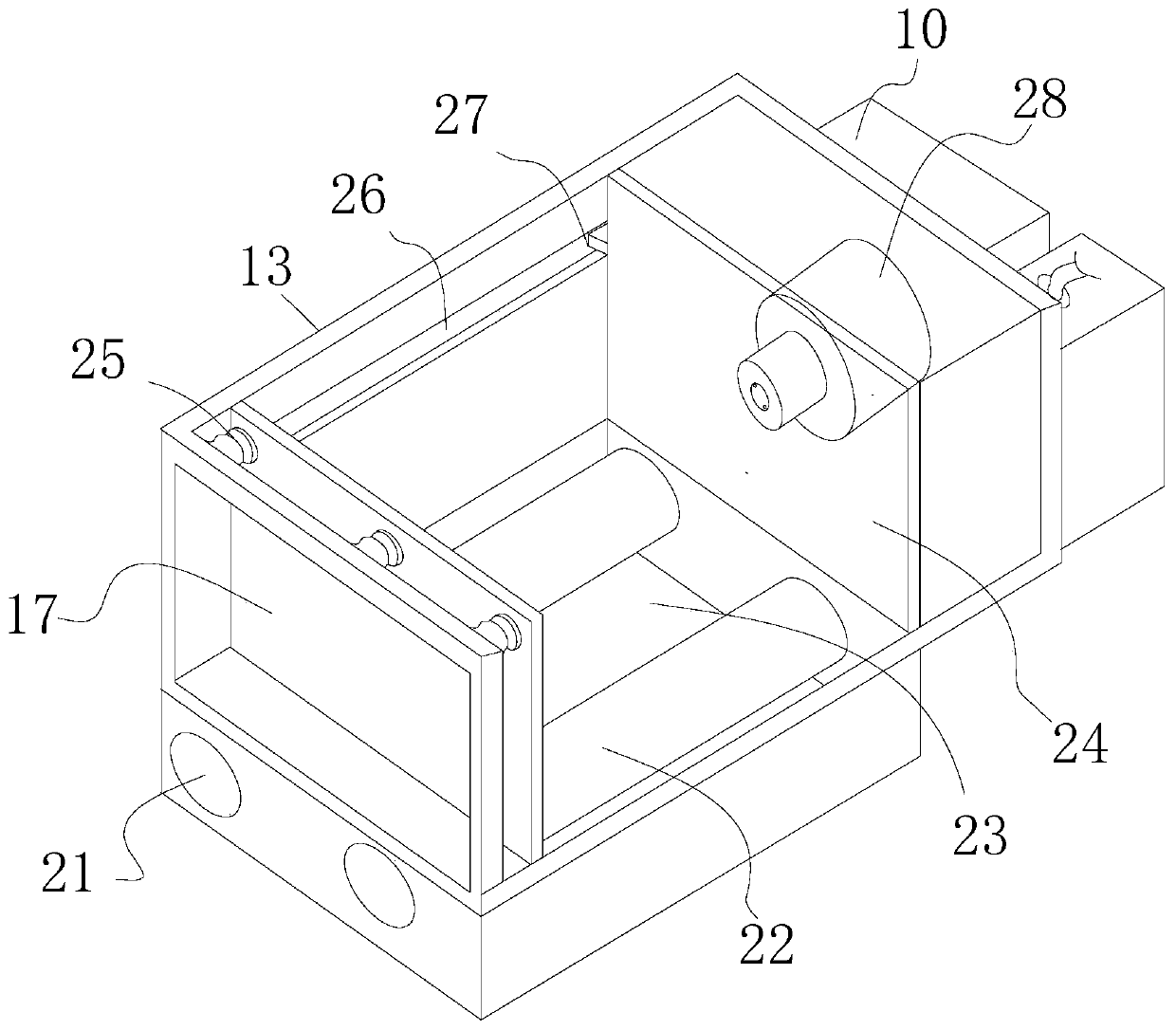

Efficient western medicine crushing and recovering equipment

InactiveCN108187875ATo achieve the crushing effectSimple structureGrain treatmentsWestern medicineEngineering

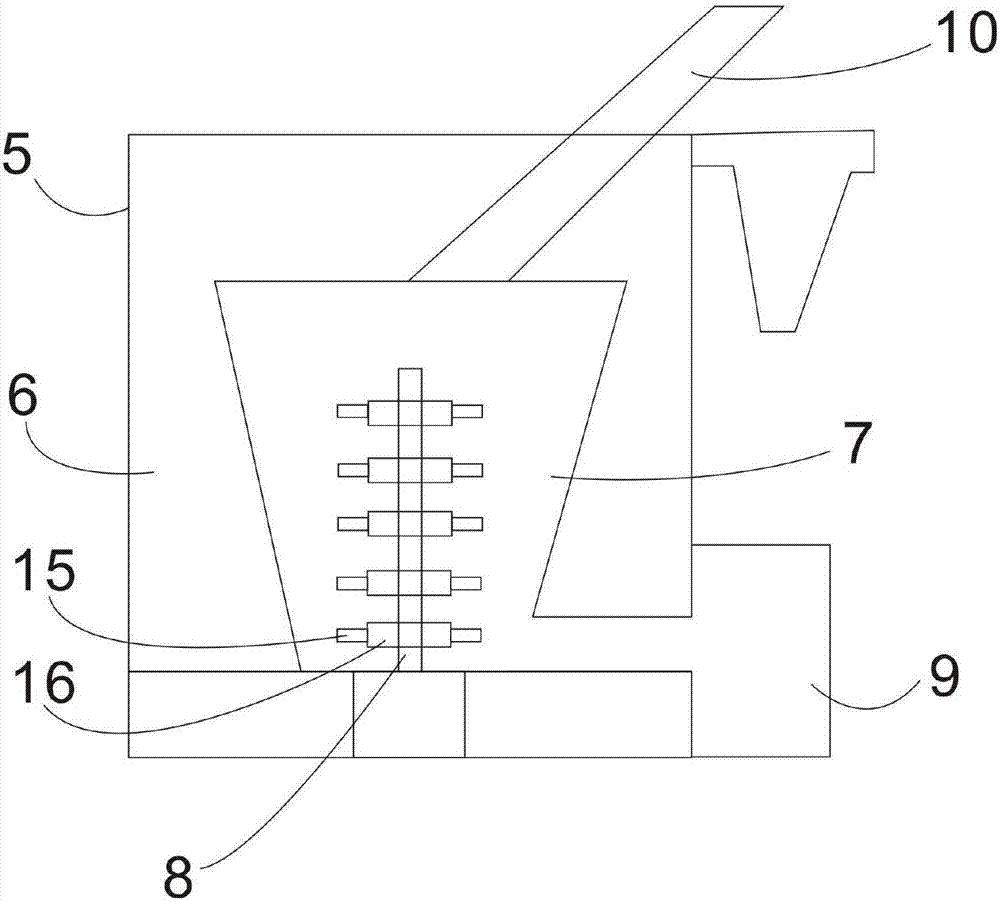

The invention provides efficient western medicine crushing and recovering equipment and belongs to the technical field of western medicine disposal. The efficient western medicine crushing and recovering equipment comprises a supporting leg, wherein a bottom plate is arranged on the top of the supporting leg; and a crushing cavity is formed in the top of the bottom plate. The equipment is simple in structure, reasonable in design and convenient to use. By arranging a feeding box, materials can be centralized and are initially crushed under the action of a crushing motor which drives a crushingshaft and crushing blades, so that follow-up crushing and grinding of the materials are facilitated, and the grinding efficiency and quality are improved; by arranging a transmission device, a resetdevice and a crushing block, a connecting shaft can be driven to rotate through a motor on the transmission device, so that a rotating wheel moves to drive a baffle plate to move downward, and the crushing block following the baffle plate moves downward to achieve an effect of crushing the materials; under the action of the reset device, the crushing block is reset, so that the effect of crushingthe materials is achieved so repeatedly. Therefore, the crushing quality of the materials is improved greatly.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

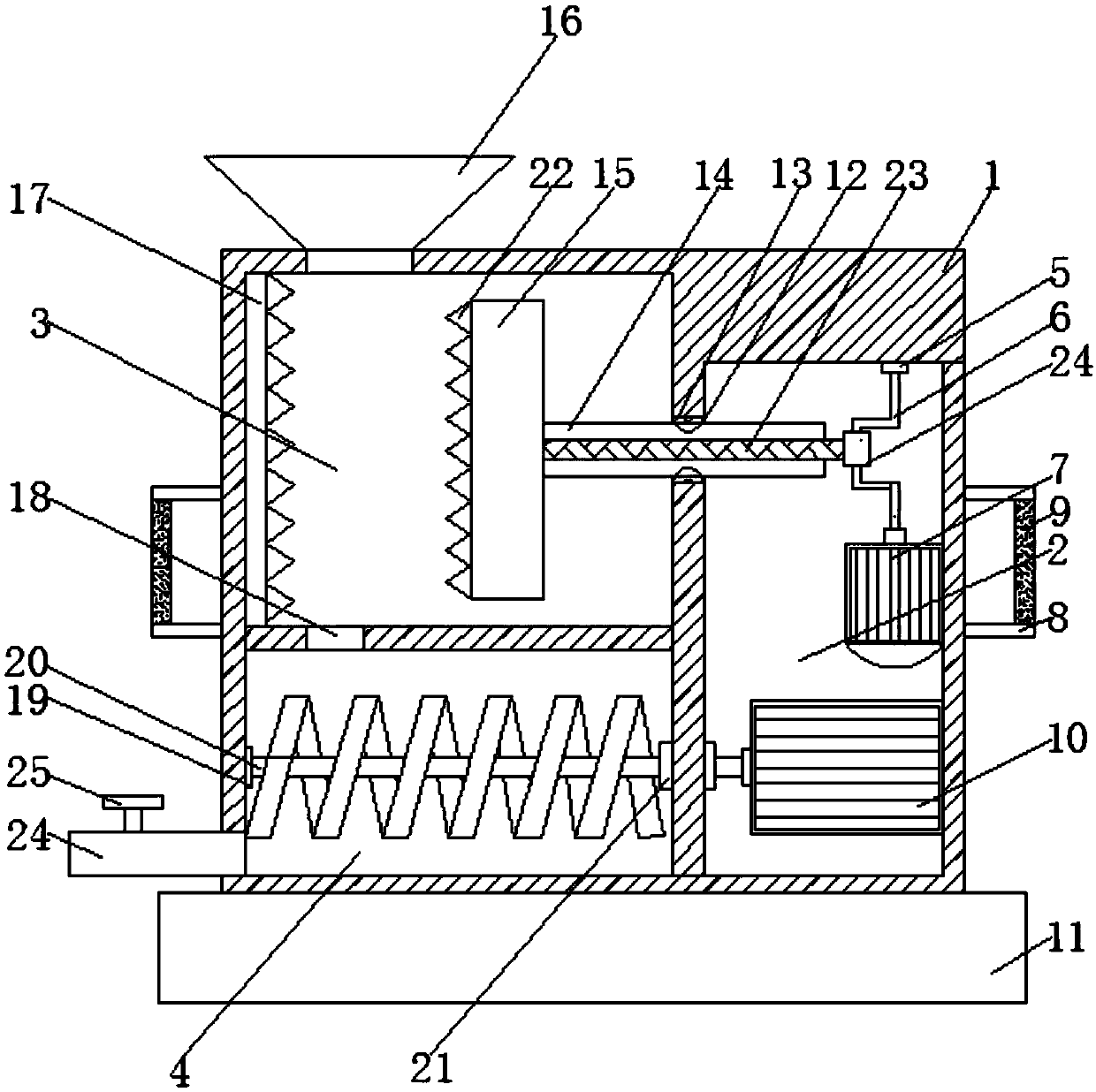

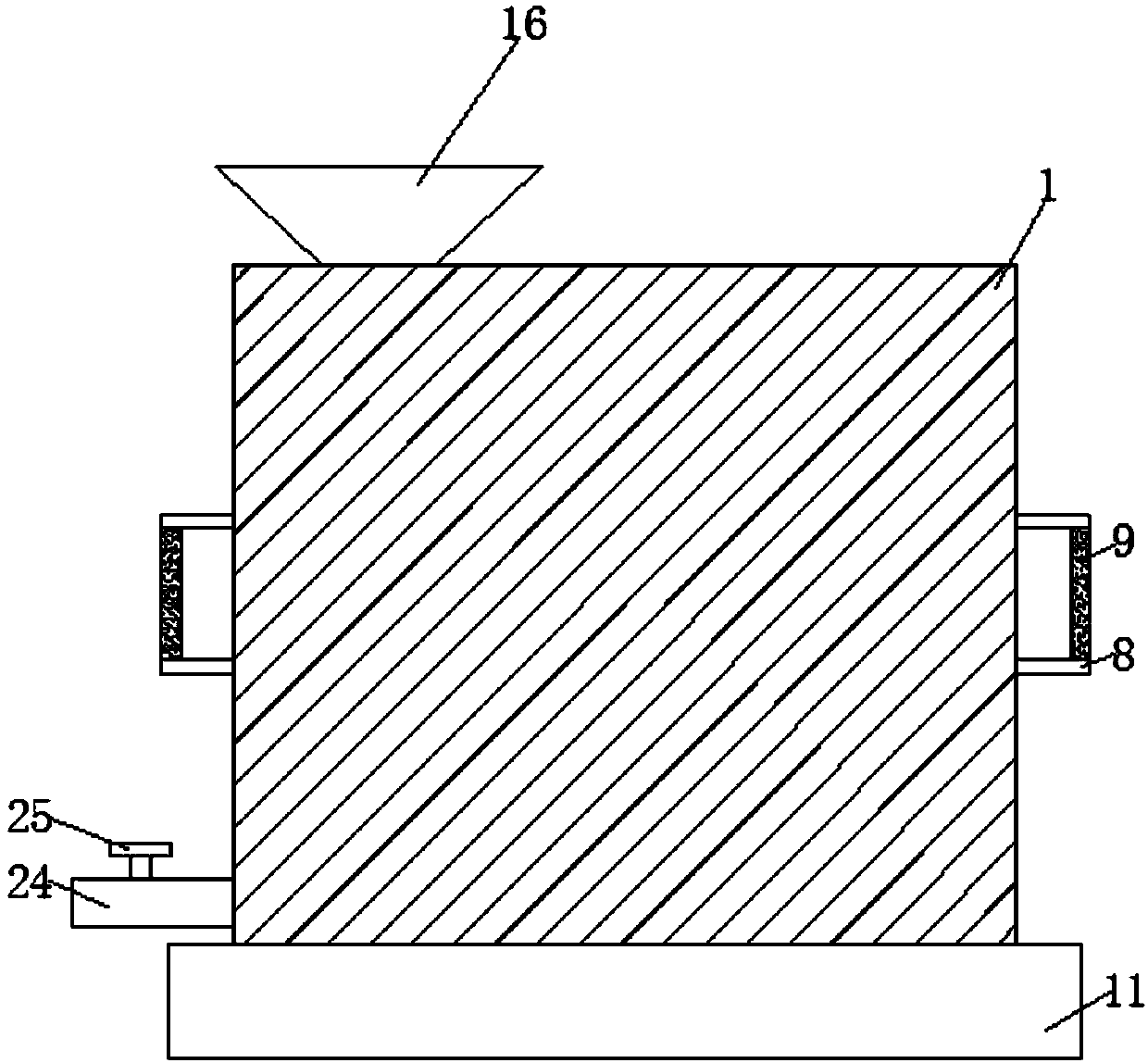

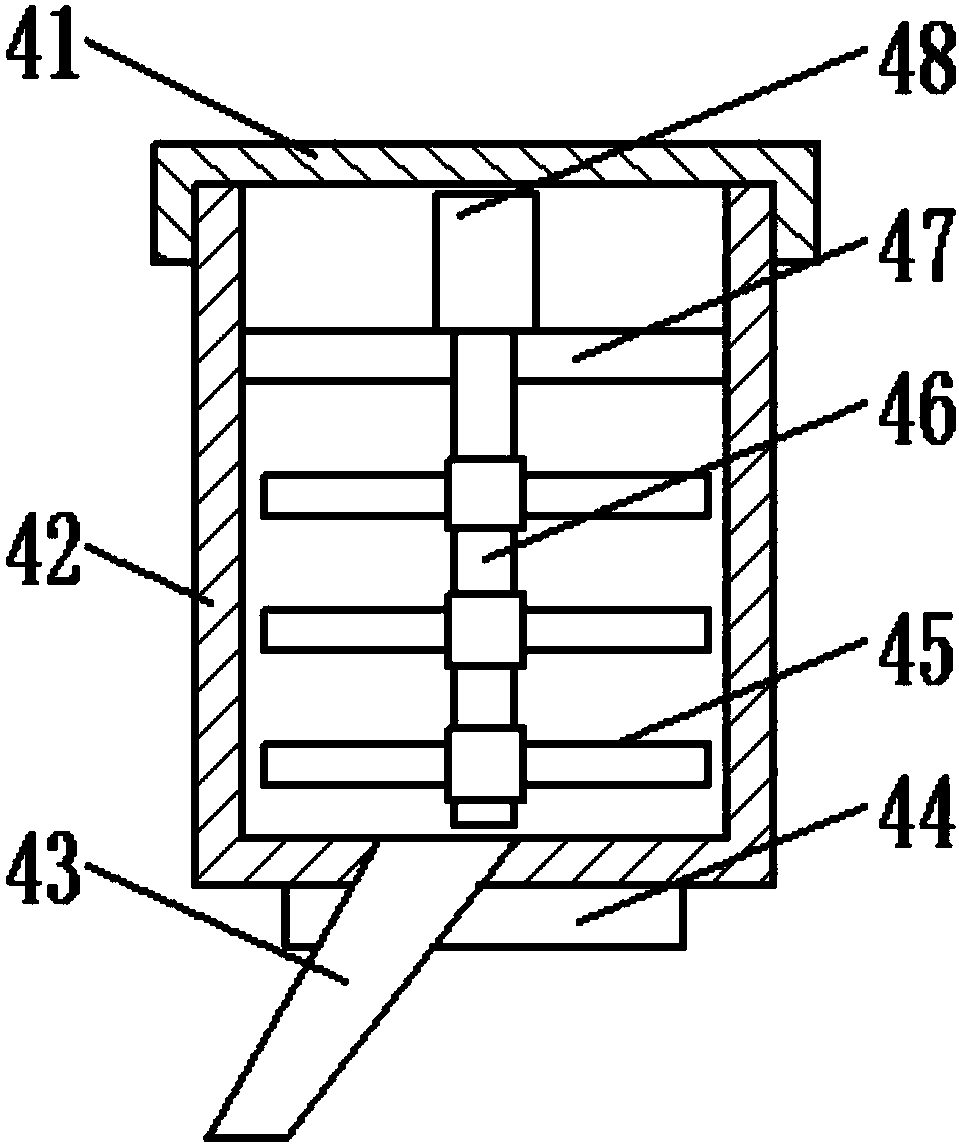

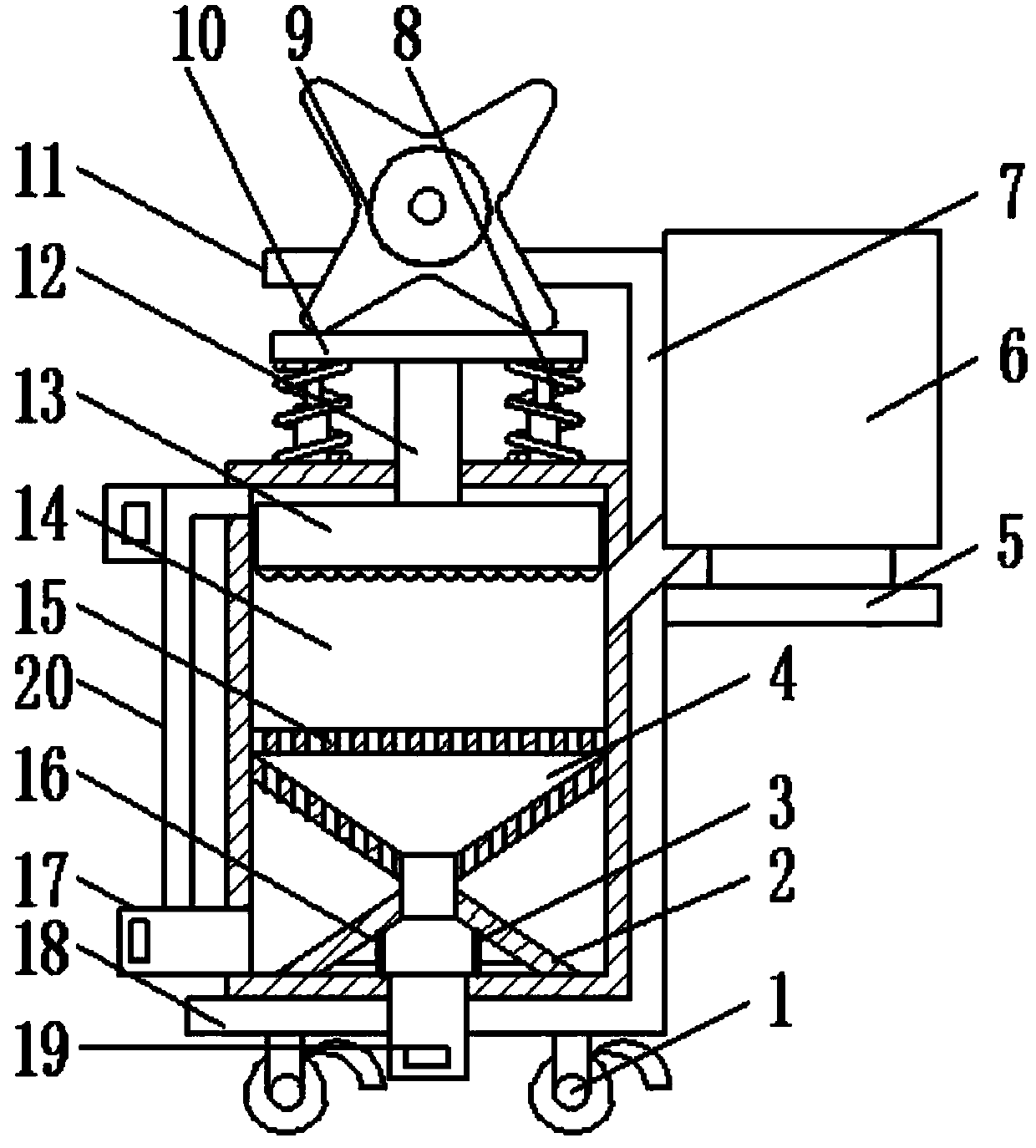

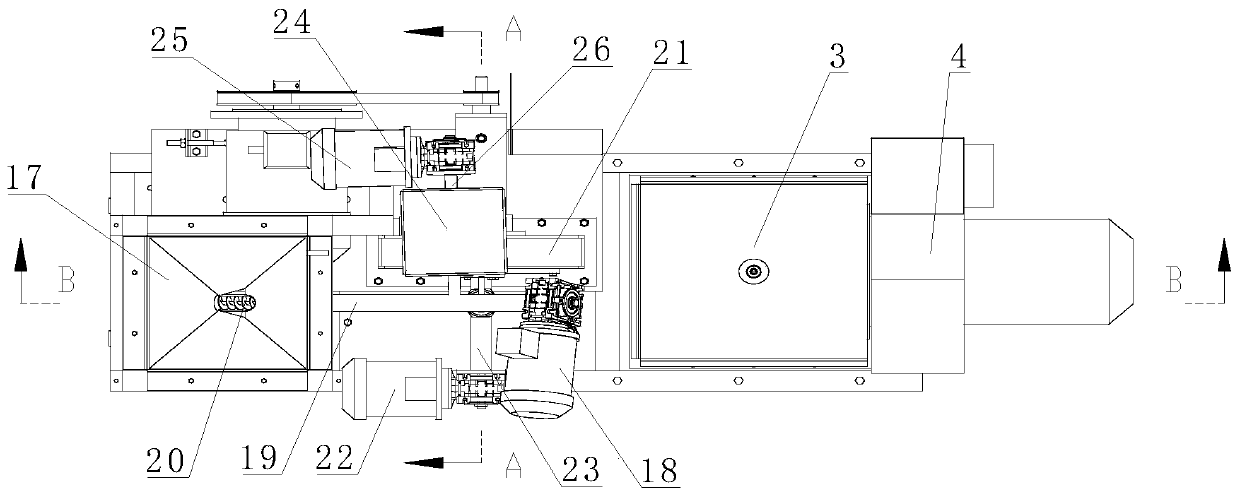

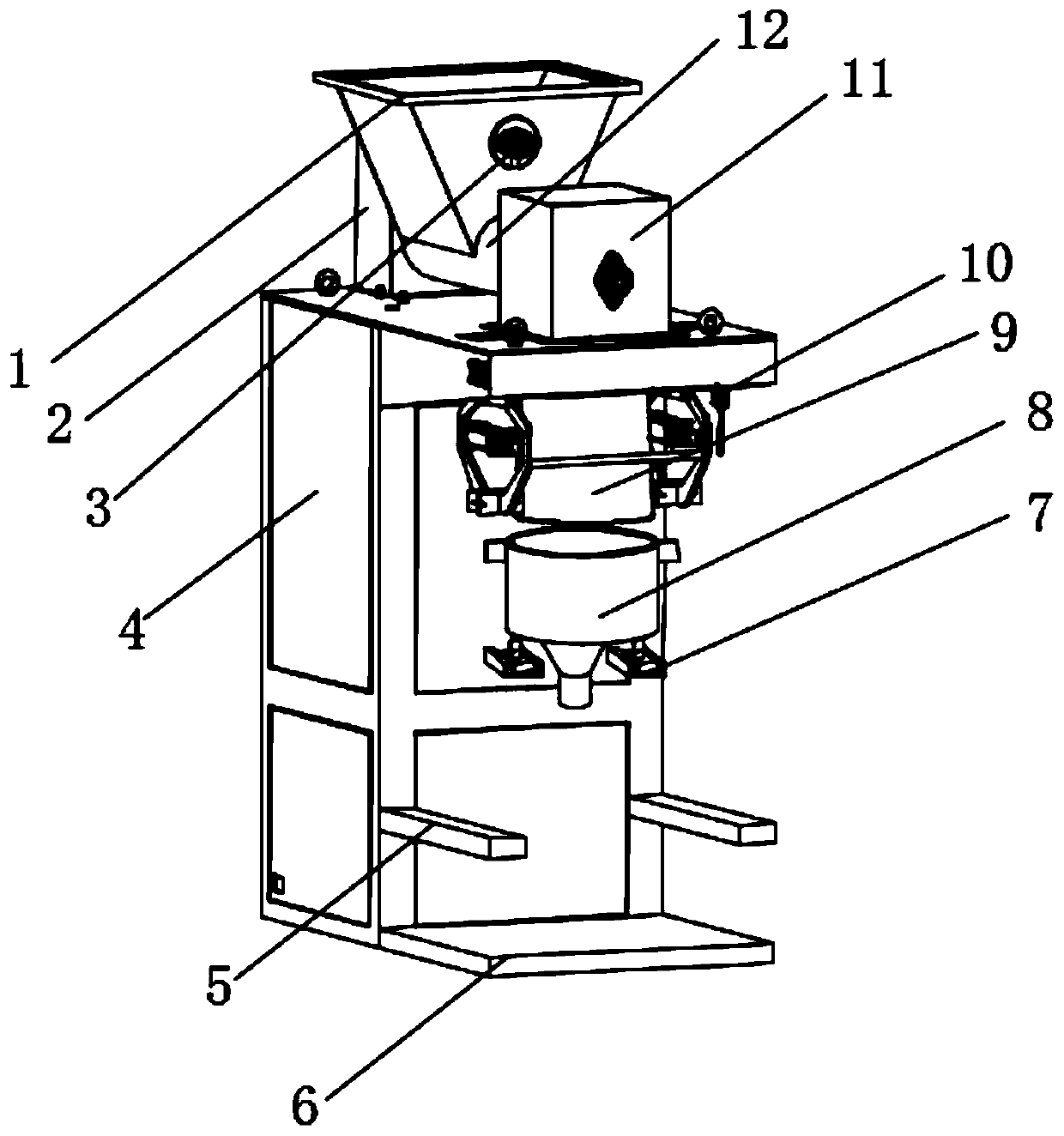

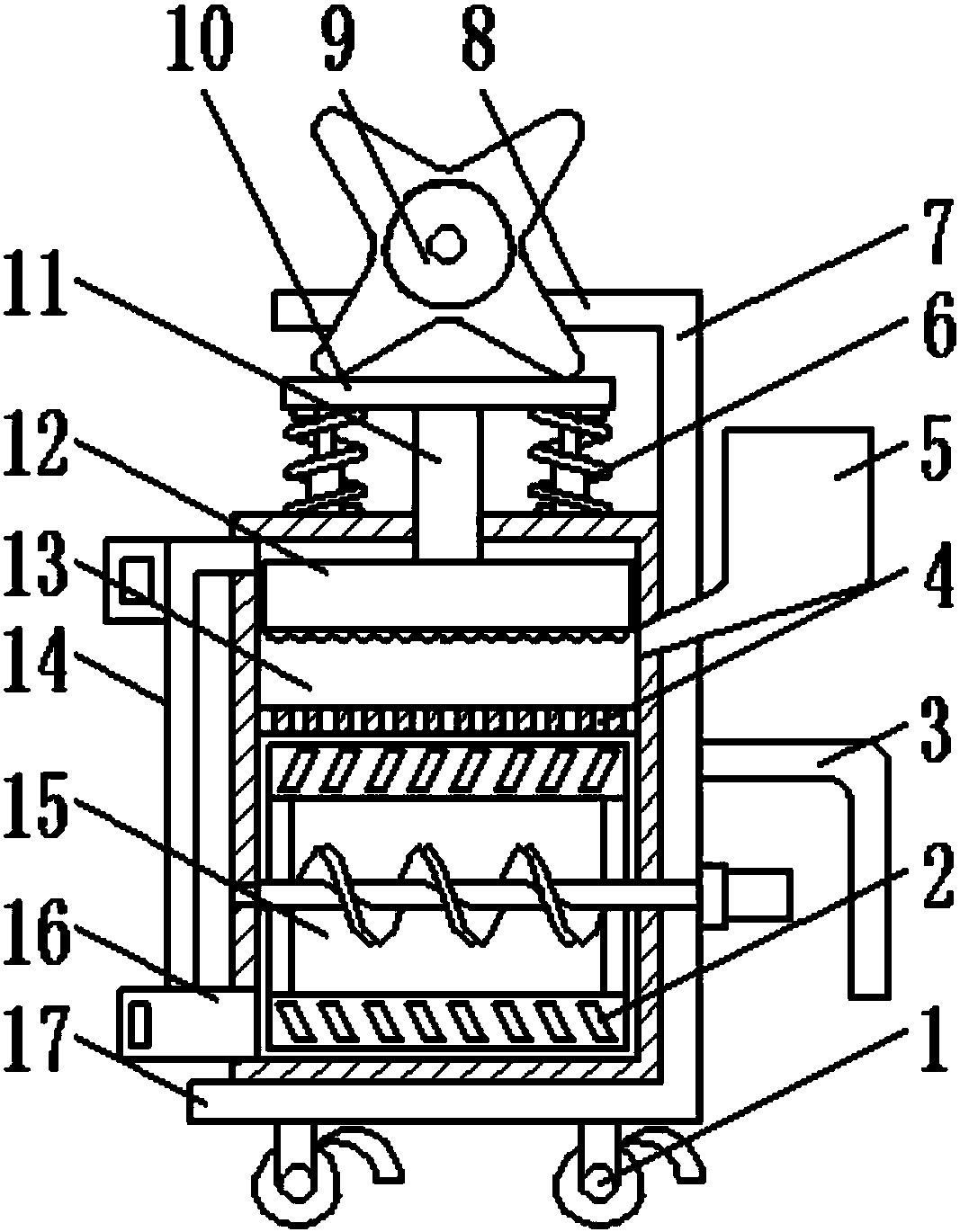

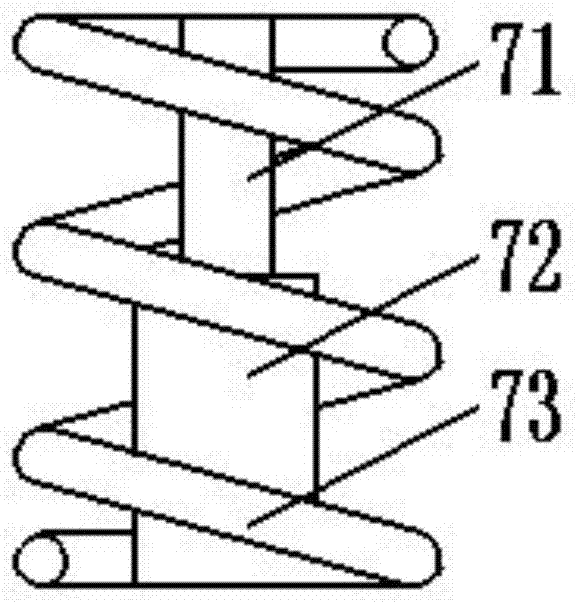

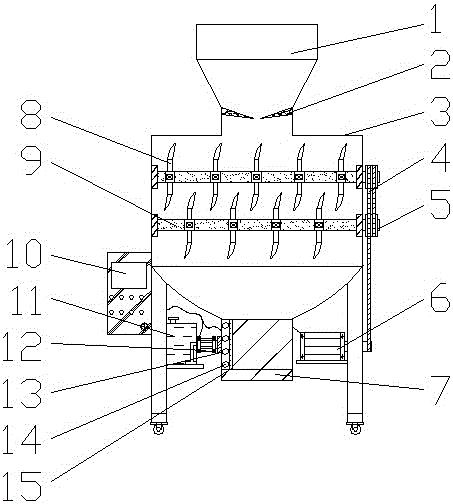

Smashing, grinding and screening device for traditional Chinese medicinal materials

InactiveCN108043540ATo achieve the crushing effectTo achieve the effect of crushing againCleaning using gasesGrain treatmentsFilter funnelTraditional Chinese medicine

The invention provides a smashing, grinding and screening device for traditional Chinese medicinal materials and belongs to the technical field of traditional Chinese medicinal material production. The smashing, grinding and screening device for the traditional Chinese medicinal materials comprises universal wheels; the tops of the universal wheels are welded to the bottom of a bottom plate; the top of the bottom plate is provided with a filtering chamber and a supporting vertical rod; a filtering funnel, a motor cavity and a vibrating motor are arranged inside the filtering chamber; the filtering funnel is arranged at the bottom of a flow equalizing plate and is in an X shape; and the left end of the upper portion of the filtering funnel is welded to the left inner wall of a smashing chamber, and the right end of the upper portion of the filtering funnel is welded to the right inner wall of the smashing chamber. The smashing, grinding and screening device for the traditional Chinese medicinal materials is simple in structure, reasonable in design and convenient to use; by arranging the universal wheels, the device can be moved and installed conveniently; by arranging a feeding device, the materials can be collected, and a smashing shaft and smashing paddles are driven to move under the action of a smashing motor so that the materials can be subjected to primary smashing; and by arranging a dust sucking pipe, dust generated in the smashing chamber can be sucked out, and is discharged out of a first discharging pipe together with the qualified smashed materials.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Paper manufacturing robot with water recycled

InactiveCN107604721ASave waterEasy to crushPulp beating/refining methodsRaw material divisionWater useFiber

The invention discloses a paper manufacturing robot with water recycled. The paper manufacturing equipment with the water recycled comprises a smashing box, a stirring box is fixedly connected with the smashing box through a material guiding pipe fixedly connected to the bottom of the smashing box, a material outlet pipe is fixedly connected to the bottom of the side surface of the stirring box, the stirring box is fixedly connected with a water storage tank through a liquid guiding pipe fixedly connected to the bottom of the stirring box, a water sucking pump is fixedly connected to the sidesurface of the water storage tank through a water sucking pipe, a drainage pipe is fixedly connected to one end of the water sucking pump through a water outlet pipe, and one end of the drainage pipeis fixedly connected to the top of the stirring box. According to the paper manufacturing robot with the water recycled, trees are smashed by the smashing box, the smashed trees are stirred by the stirring box to extract plant fibers, water used in the stirring box is collected by the water storage tank, then water collected in the water storage tank is guided into the stirring box through the water sucking pump, so that the purpose that water resources are recycled to stir the smashed trees is achieved, and the paper manufacturing robot has the advantage of water resource conservation.

Owner:傅恺

Dust removal device for traditional Chinese medicine pretreatment equipment

InactiveCN107596839AAchieve the effect of rotationTo achieve the crushing effectCombination devicesDirt cleaningSprayerChinese herbology

Owner:徐俊浩

Meal replacement powder with function of improving human metabolism and preparation method thereof

InactiveCN110946282AEnhance metabolic functionPromote absorptionGrain treatmentsFood scienceBiotechnologyMeal replacement

The invention discloses meal replacement powder with function of improving metabolism of a human body and a preparation method thereof. The meal replacement powder is prepared from the following component raw materials in parts by weight: 50-80 parts of coix seeds, 45-74 parts of small red beans, 4-9 parts of oat kernels, 3-6 parts of white granulated sugar, 10-20 parts of instant oatmeal, 3-7 parts of whole milk powder, 5-10 parts of black sesame seeds, 2-5 parts of Chinese yams, 5-10 parts of sugared blueberry powder, 4-8 parts of sugared cranberry powder, 5-12 parts of inulin, 8-15 parts ofporia cocos and 9-14 parts of wolfberries, and 2-6 parts of almond kernels. The meal replacement powder has the function of improving human metabolism, the raw material crushing effect of the meal replacement powder is good, the activity of effective components in the raw materials is improved, and the eating effect of the meal replacement powder is improved.

Owner:ANHUI QIUGUO FOOD

Plastic processing pulverizing device with cleaning function

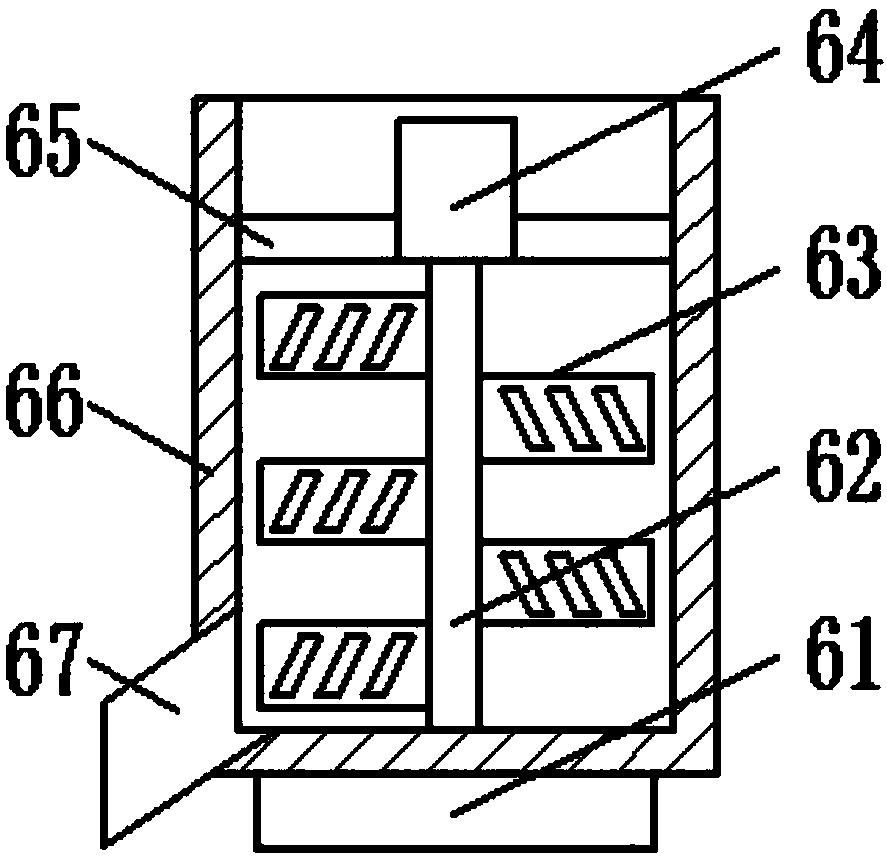

InactiveCN107186925AWide range of usesKeep healthyPlastic recyclingCleaning using liquidsEngineeringMechanical engineering

The invention relates to a plastic processing pulverizing device with a cleaning function. The plastic processing pulverizing device comprises a base, a first pulverizing barrel, a power box, a washing barrel, a third motor, a discharging port, a sliding cover, a first pulverizer, a water spraying port, brushes, a second pulverizer and a vibration plate. Sliding wheels are arranged at the bottom end of the base. The top end of the first pulverizing barrel is connected with a feeding port through a connector. The power box is located above the first motor. The washing barrel is connected with the first pulverizing barrel through a material passing pipe. A waste water box is arranged at the bottom end of the washing barrel. A heating device is arranged below a heating platform. The third motor is arranged on the upper surface of the base. The first pulverizer is arranged in the first pulverizing barrel. The brushes are arranged on the outer side of a rotation shaft. The vibration plate is arranged below the interior of the washing barrel. The plastic processing pulverizing device with the cleaning function is little in noise pollution, the application range of pulverized plastic is wide, the service life of the machine is prolonged, and the pulverizing effect is good.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

High temperature-resistant porous ceramic material and preparation method thereof

InactiveCN110204355AHigh strengthLow thermal conductivityFeeding arrangmentsAuxillary shaping apparatusMolding machineWhiskers

The invention discloses a high temperature-resistant porous ceramic material and a preparation method thereof. The porous ceramic material is prepared from, by weight, 25-40 parts of silicon carbide,4-6 parts of silicon carbide whiskers, 10-15 parts of a sintering aid, 1-5 parts of a binder, 1-5 parts of n-octanol, 1-5 parts of a pore-forming agent and 0.5-1 part of a grinding aid. The preparation method of the high temperature-resistant porous ceramic material comprises the following steps: weighing the above raw materials, placing a mold on a tray, fixing the mold by a manipulator, uniformly mixing the silicon carbide, the silicon carbide whiskers, the sintering aid, n-octanol and the pore-forming agent, and adding the obtained mixture into the inner cylinder of a molding machine. The ceramic material prepared in the invention has the advantages of improved gas permeability, expansion of the practical application range, improvement of the strength of porous ceramic, ensuring of theapplication in the actual process, low thermal conduction coefficient (less than 0.35 W / m.k), and good high temperature resistance.

Owner:彭雅妮

Method for producing nonfat dried insect pupa protein powder at low temperature

ActiveCN107469939AMix thoroughlyComplete extraction and separationFatty-oils/fats productionGrain treatmentsInsect pupaEconomic benefits

The invention discloses a method for producing nonfat dried insect pupa protein powder at a low temperature. The method comprises the following steps that (1) fresh and alive insect pupas are thoroughly cleaned and then dried, then the dried insect pupas are subjected to coarse crushing, the dried insect pupas subjected to coarse crushing are fed into a rotary delivery extractor and subjected to continuous counter-current extraction at the temperature of 10-15 DEG C with liquefied butane as solvent, and afterwards filter residues obtained through extraction of the rotary delivery extractor are nonfat dried insect pupas; and (2) the nonfat dried insect pupas which are dried are delivered into a special pulverizer to be pulverized into the nonfat dried insect pupa protein powder. By means of the method, the residue amount of raw oil is small, the smashing fineness meets the requirement of food-grade protein powder raw materials and medical protein powder raw materials, the quality guarantee period is long, and the economic benefits are high.

Owner:青岛新农康源生物工程有限公司

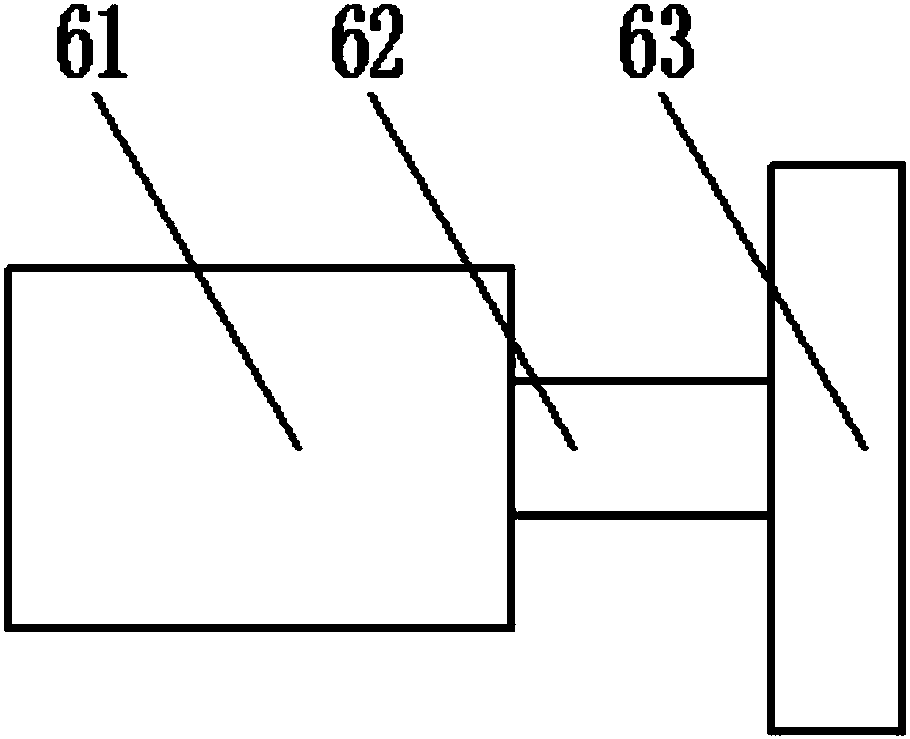

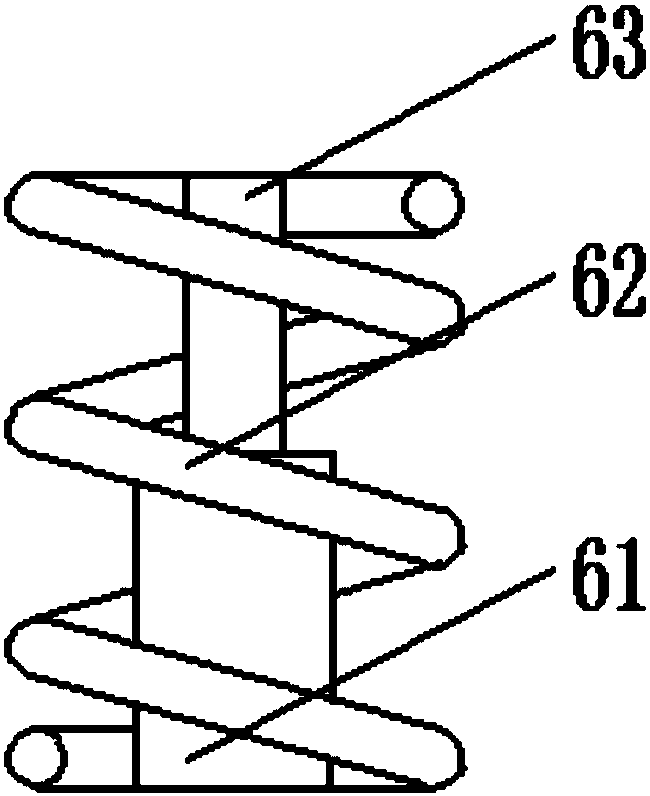

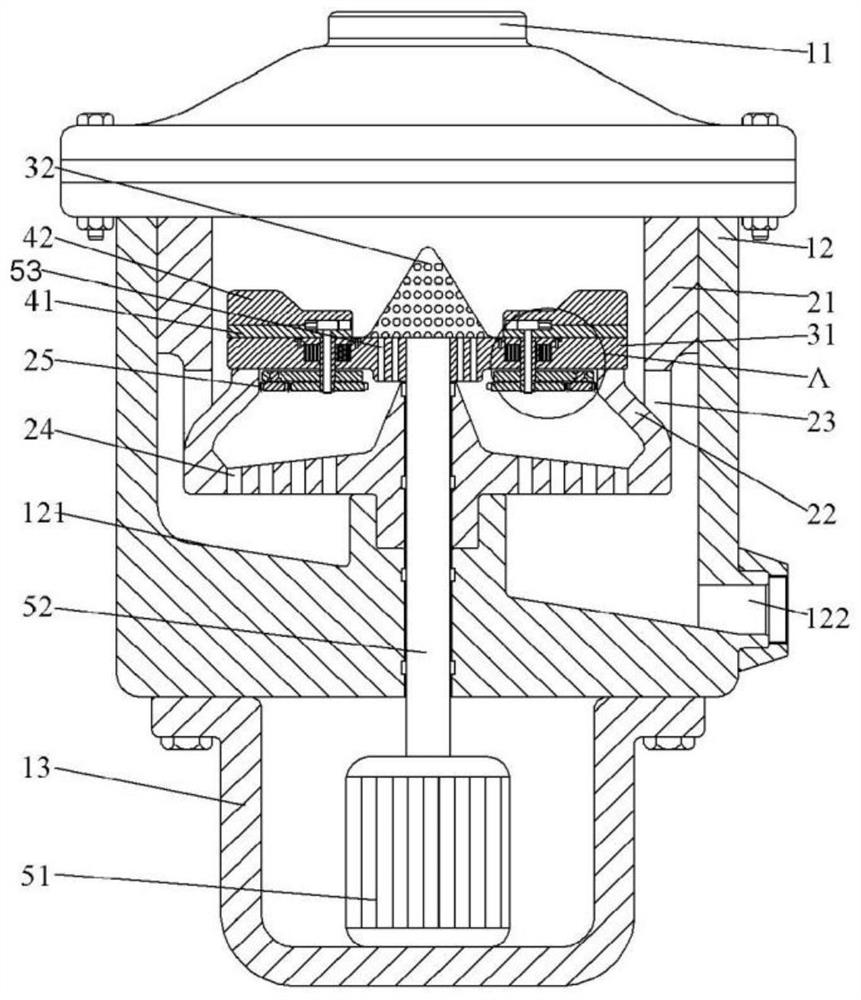

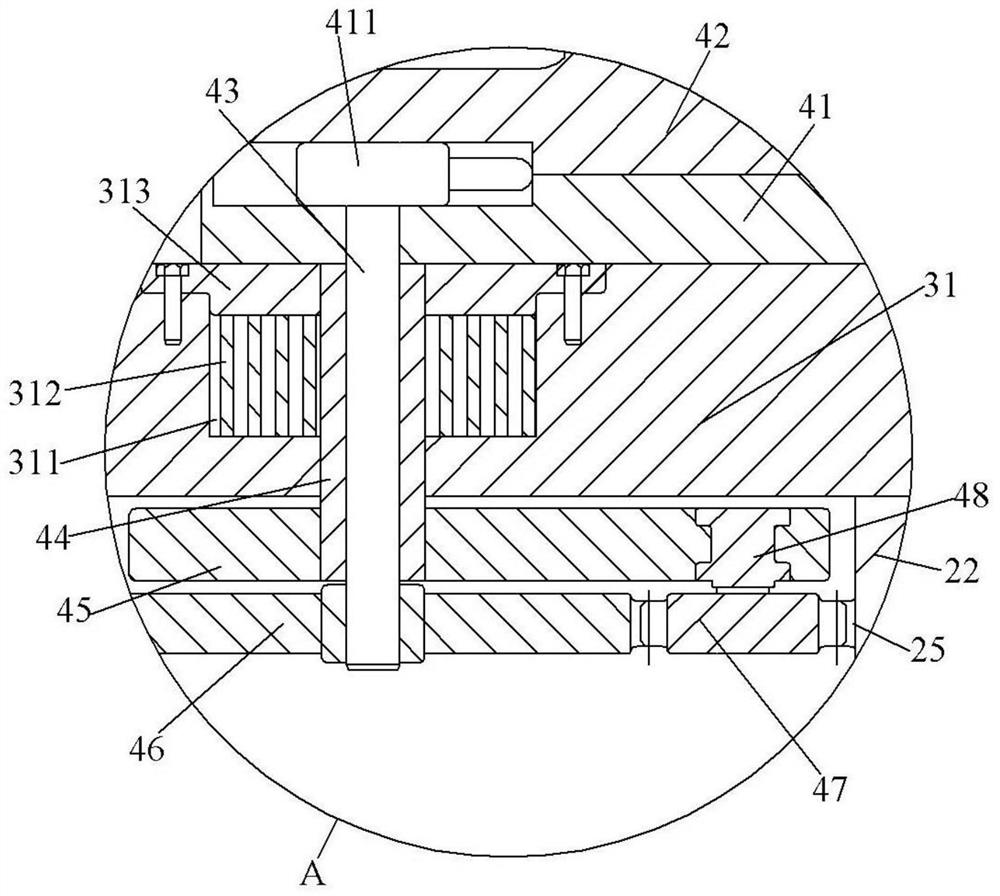

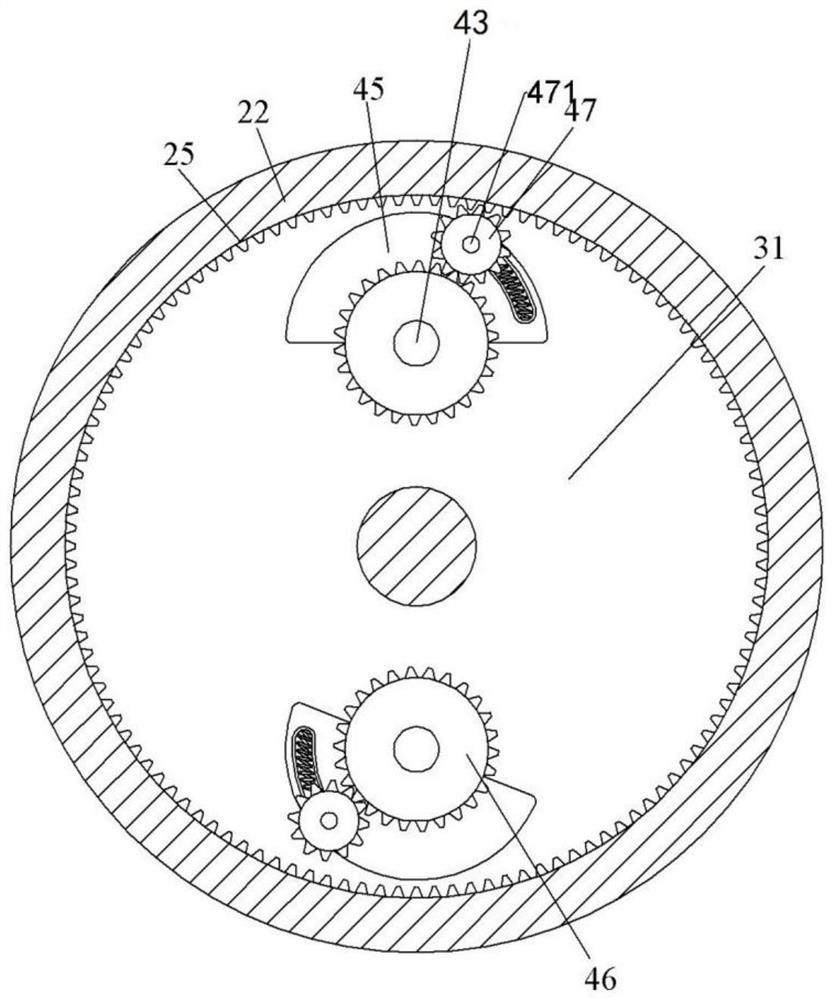

Medicine roller based on deformation of elastic element so as to change pressure

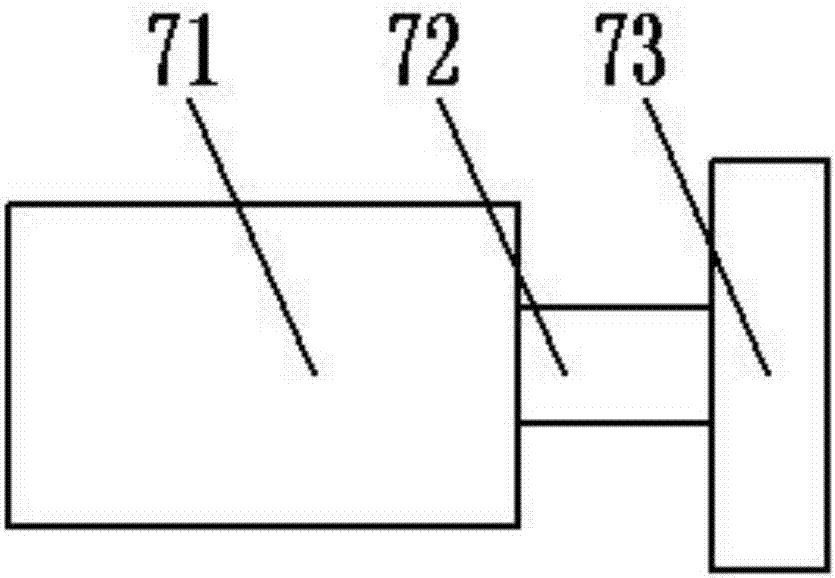

InactiveCN108714458AChange the elasticityTo achieve the crushing effectGrain treatmentsElectric machineryEngineering

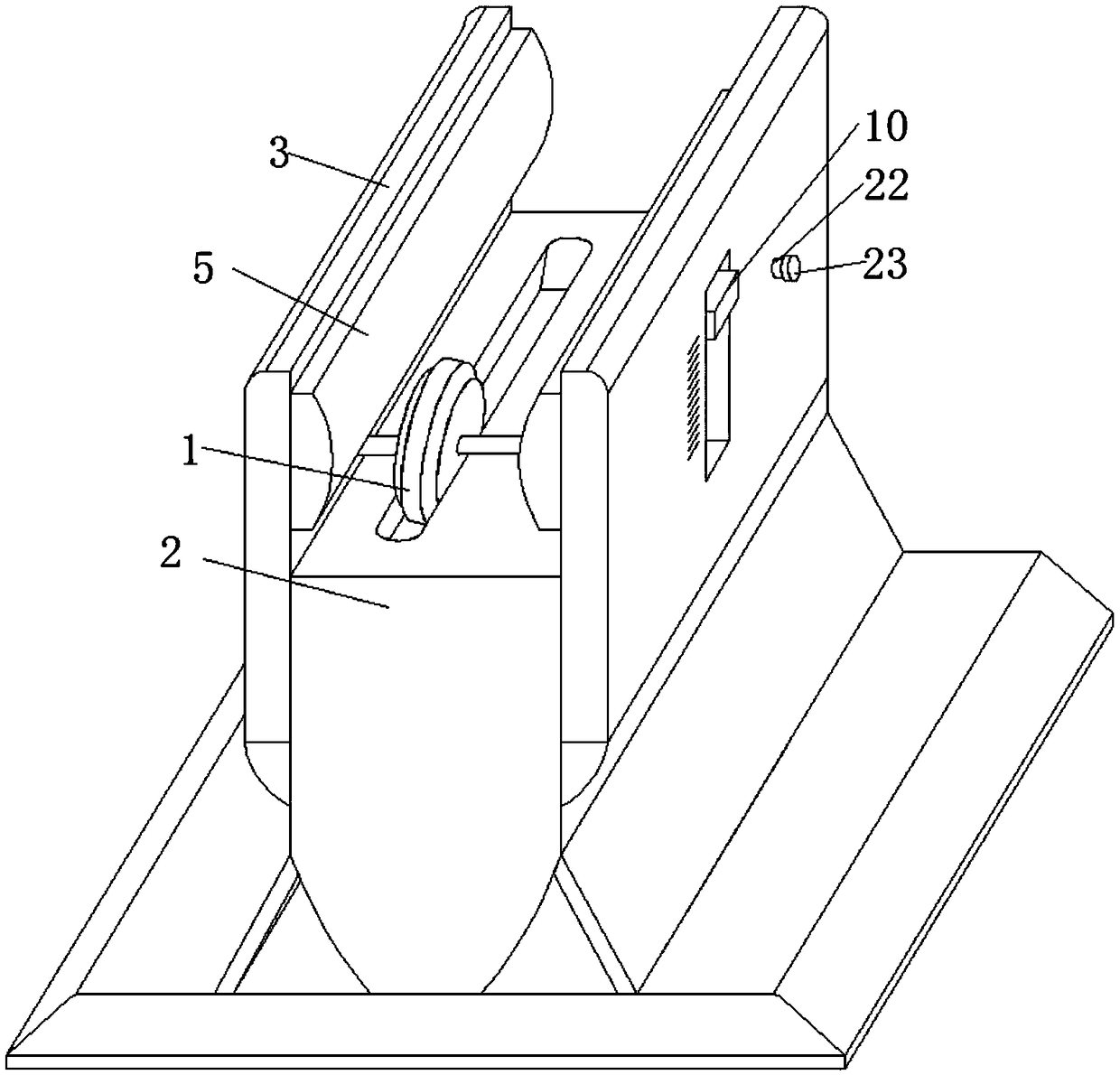

The invention provides a medicine roller based on deformation of an elastic element so as to change pressure, and relates to the field of traditional Chinese medicines. The medicine roller based on the deformation of the elastic element so as to change the pressure comprises a grinding wheel and a grinding disc, wherein the two sides of the grinding disc are provided with convex carrying plates; and the opposite surfaces of the two carrying plates are provided with a pressure adjustable linear drive, wherein the linear drive can drive the grinding wheel to work; the pressure adjustable lineardrive is composed of a linear motor, a lifting body capable of moving longitudinally, a first elastic element, a limiting body and an adjusting mechanism, wherein the adjusting mechanism is used for adjusting the height of the limiting body; and the adjusting mechanism is composed of a rack and a one-way limiting wheel. Compared with the prior art, through the arrangement of the carrying plates tocoordinate with the pressure adjustable linear drive, the linear motor in the adjustable linear driving mechanism is used for driving the grinding wheel to move so as to roll the traditional Chinesemedicines, and the pressure of the grinding wheel is adjusted through the adjusting mechanism, so that different degrees of rolling of different medicines can be achieved.

Owner:曹江

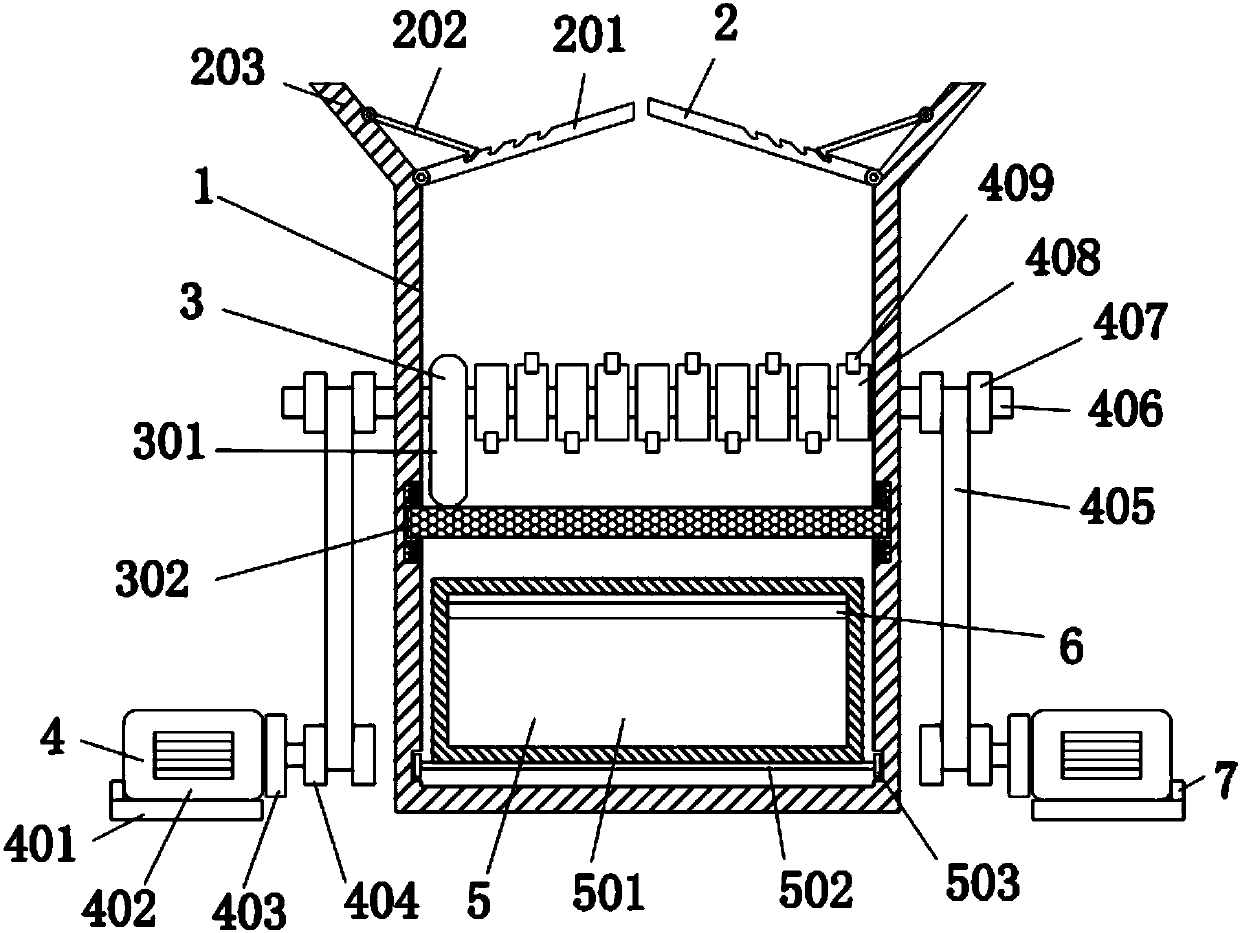

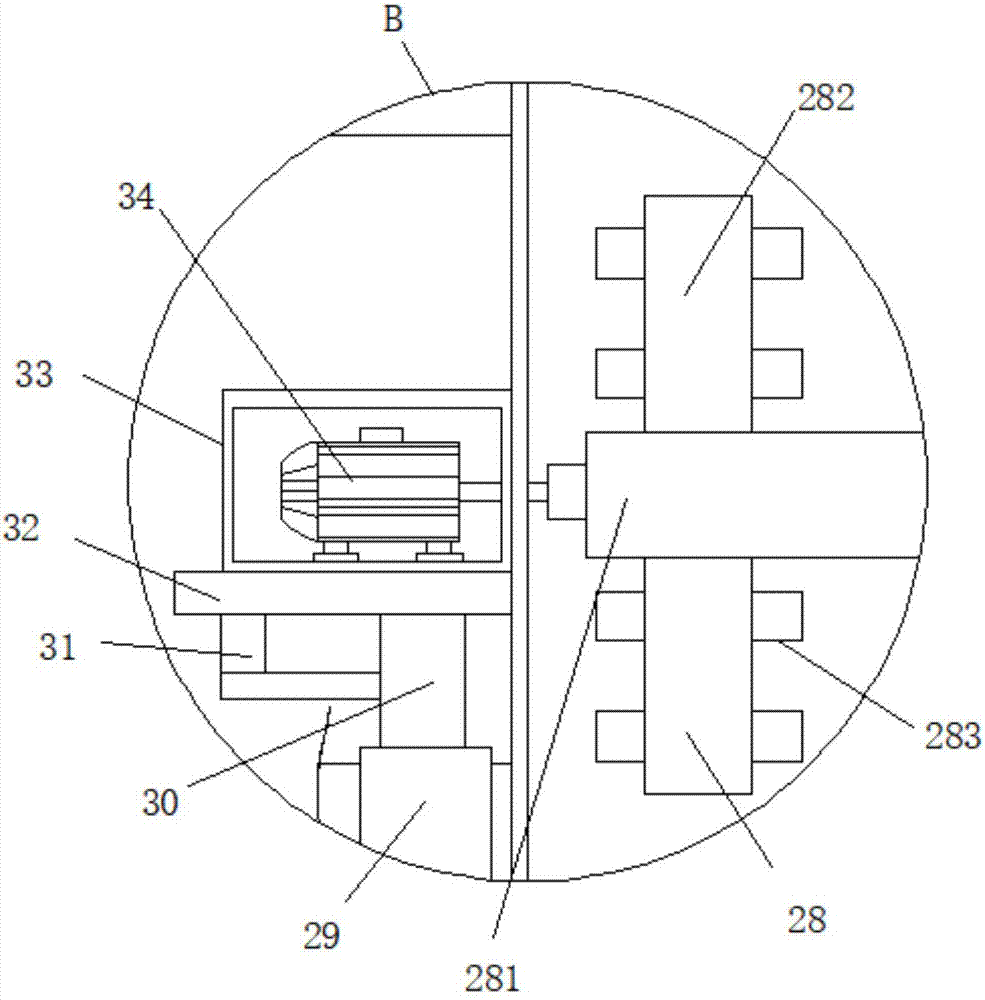

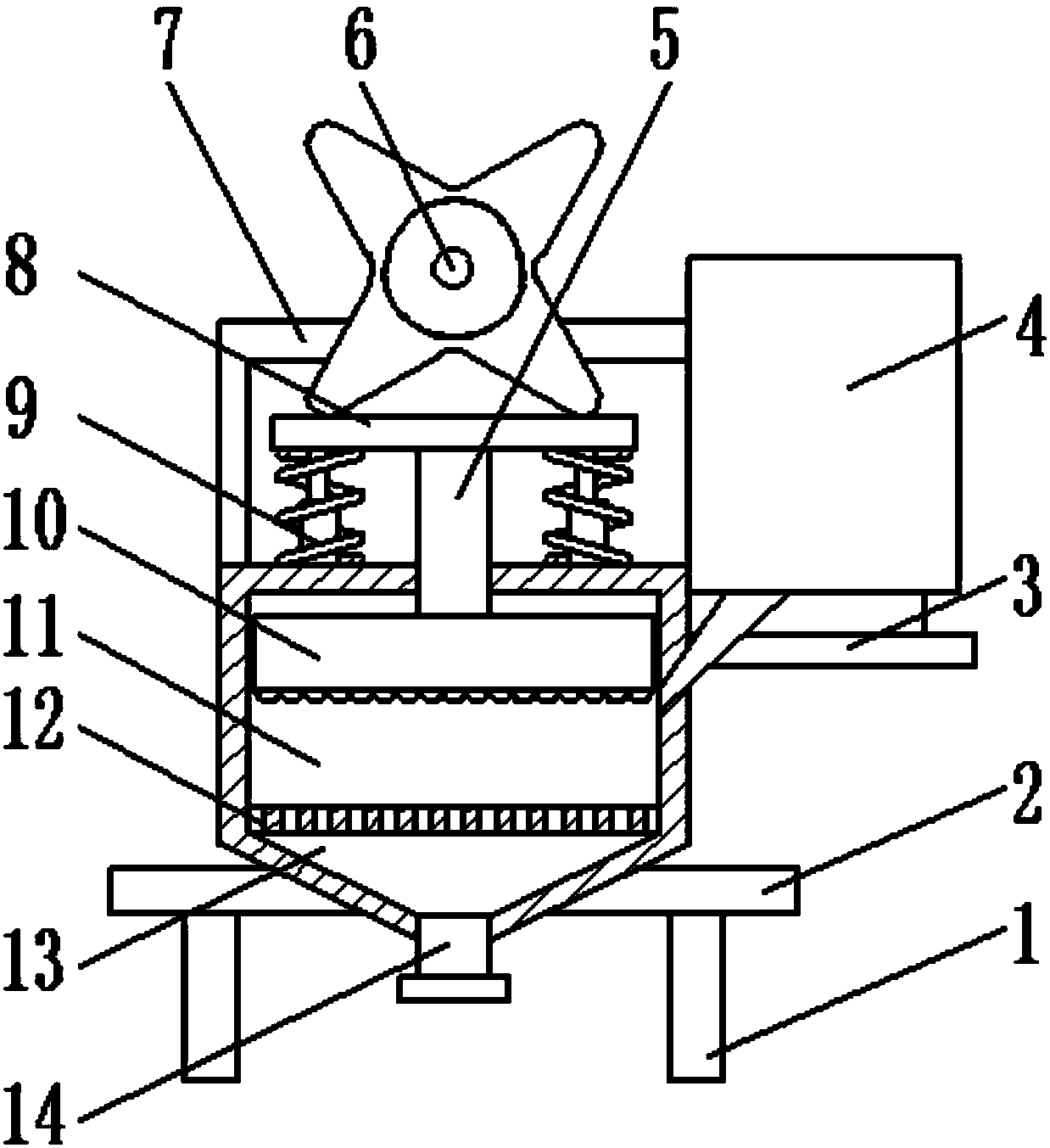

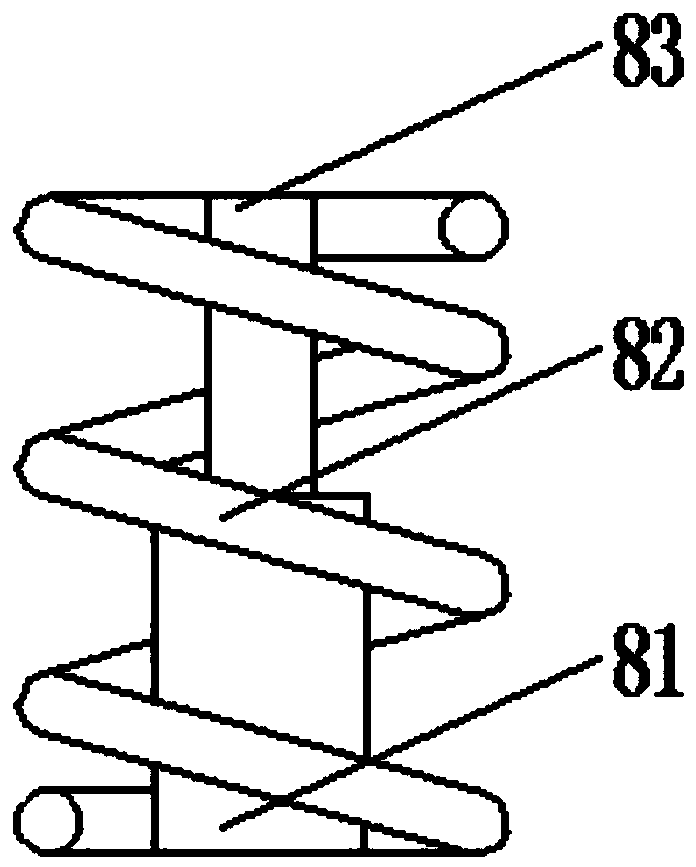

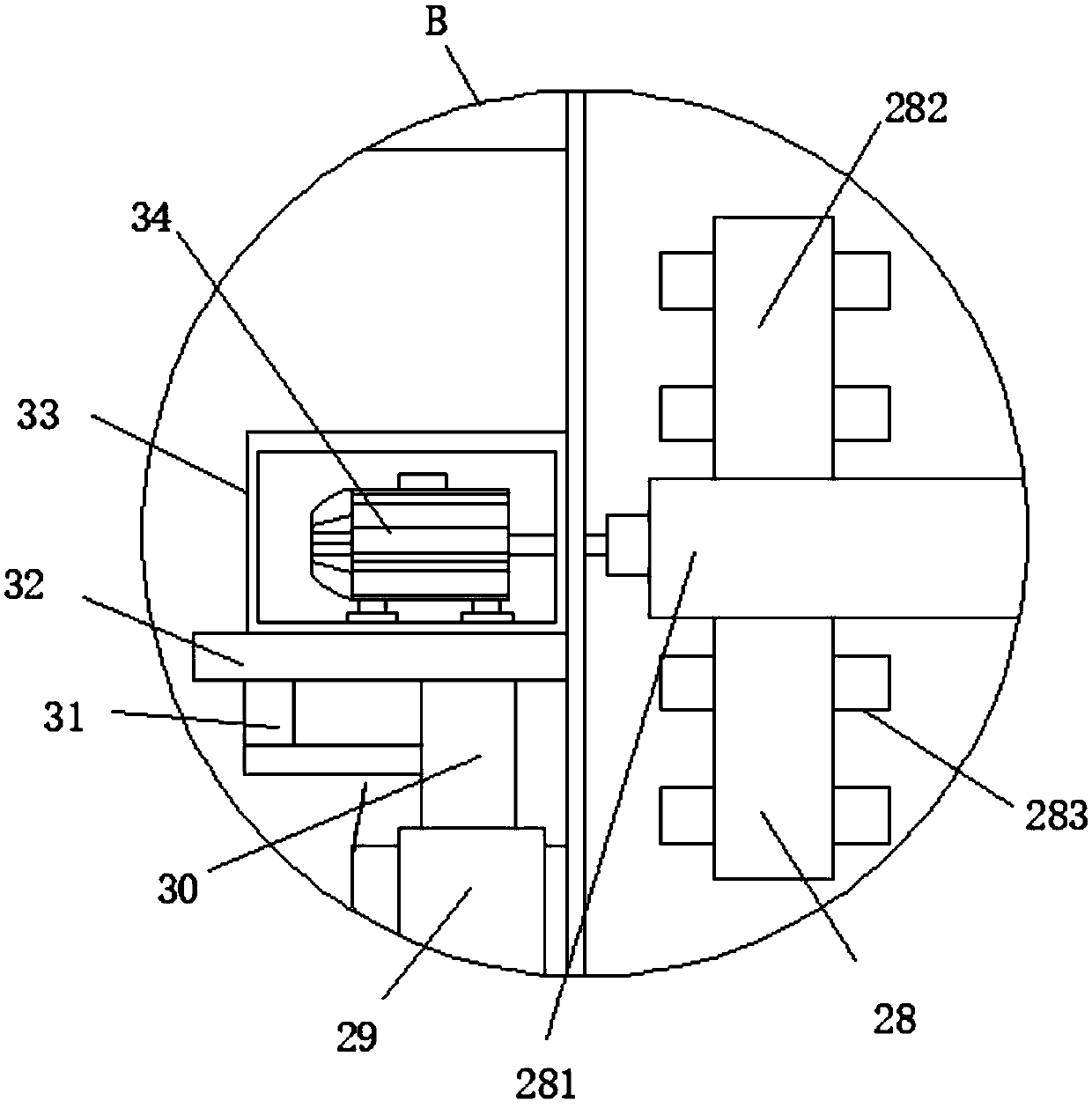

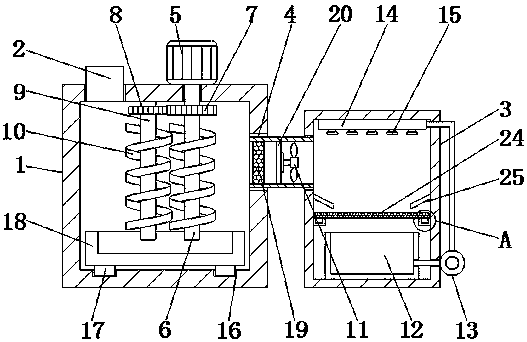

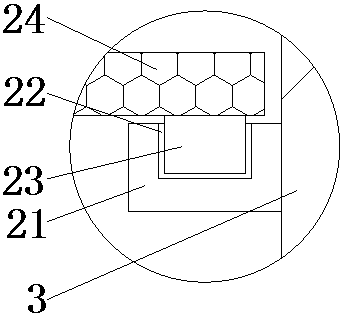

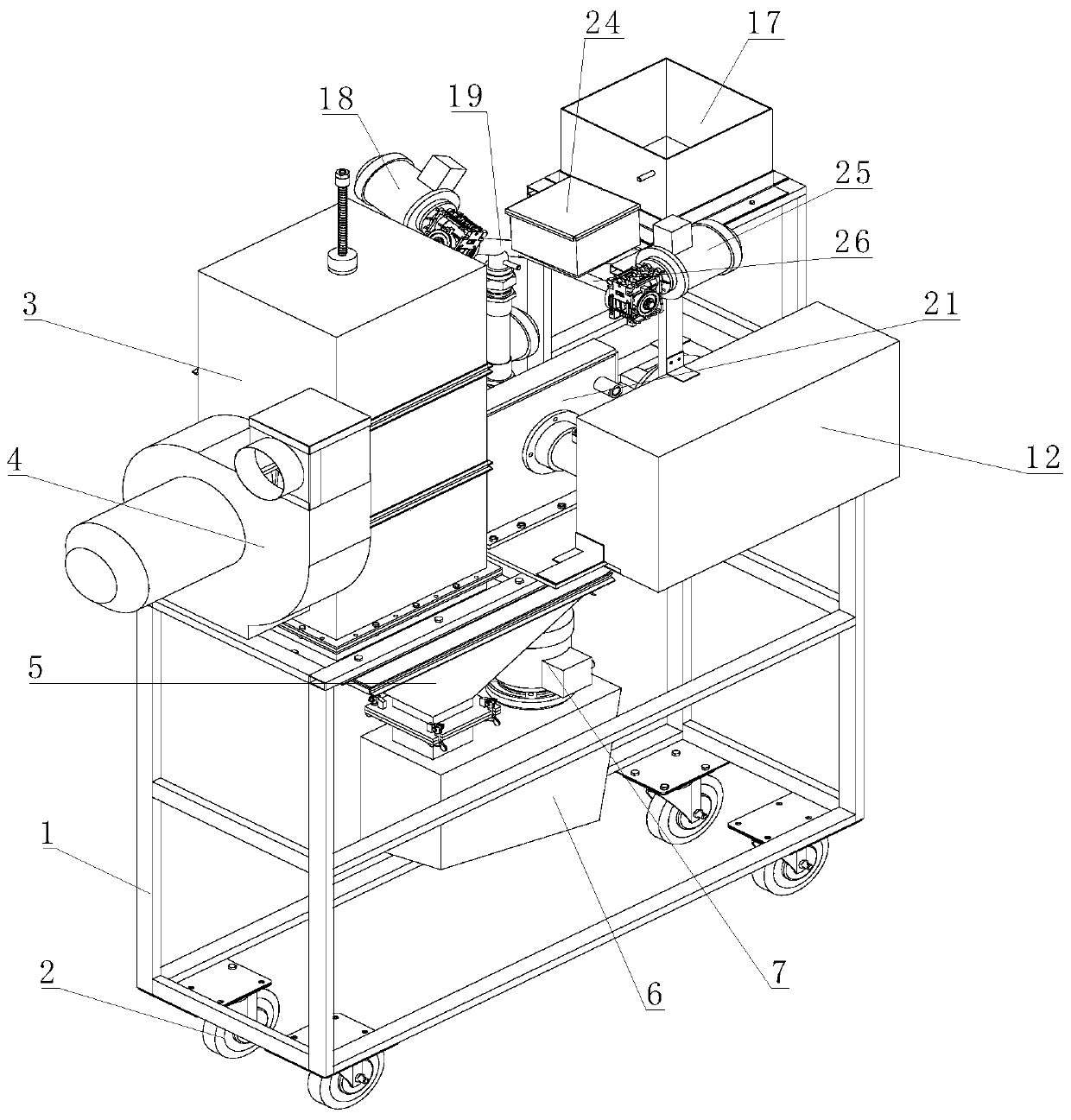

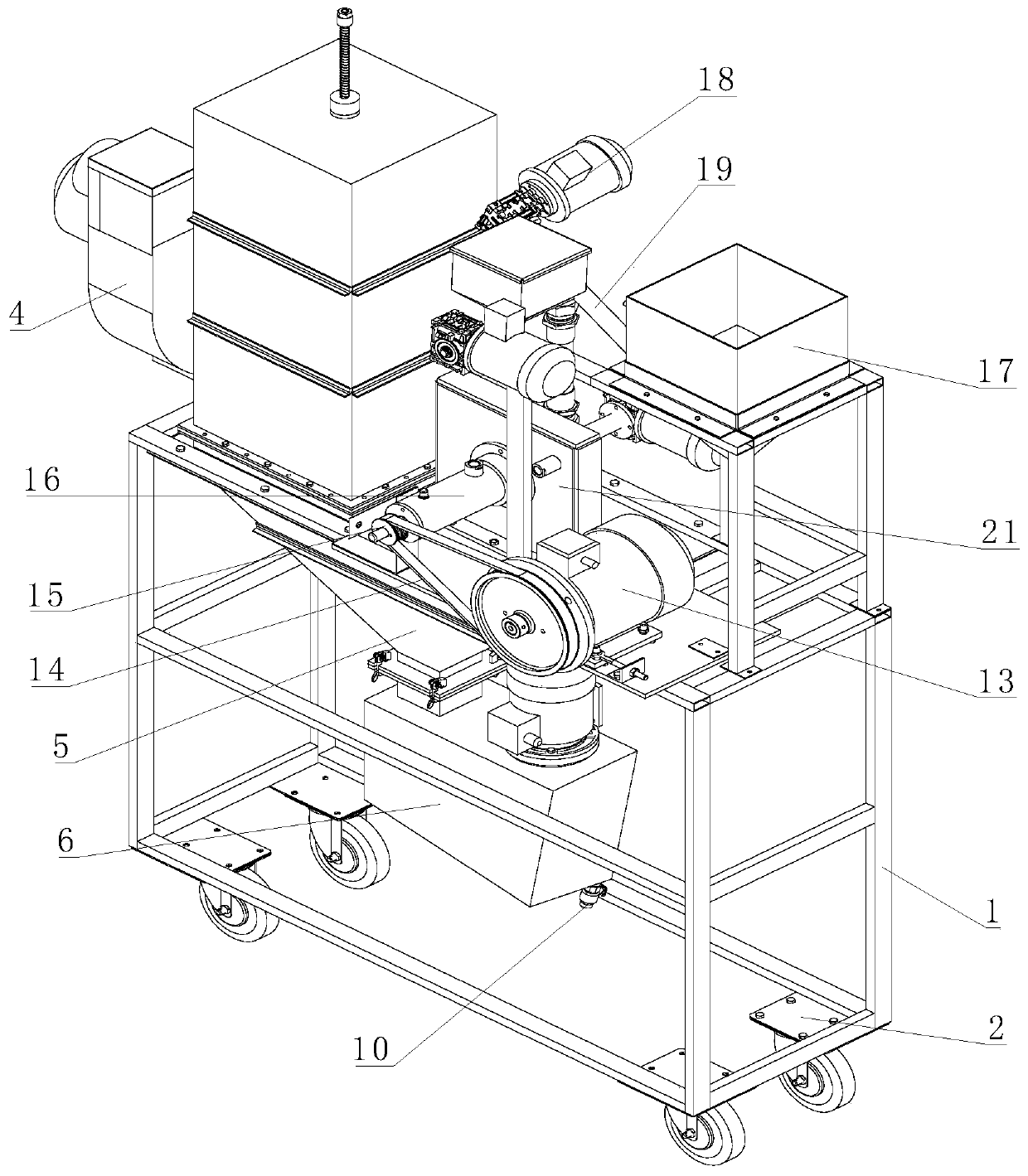

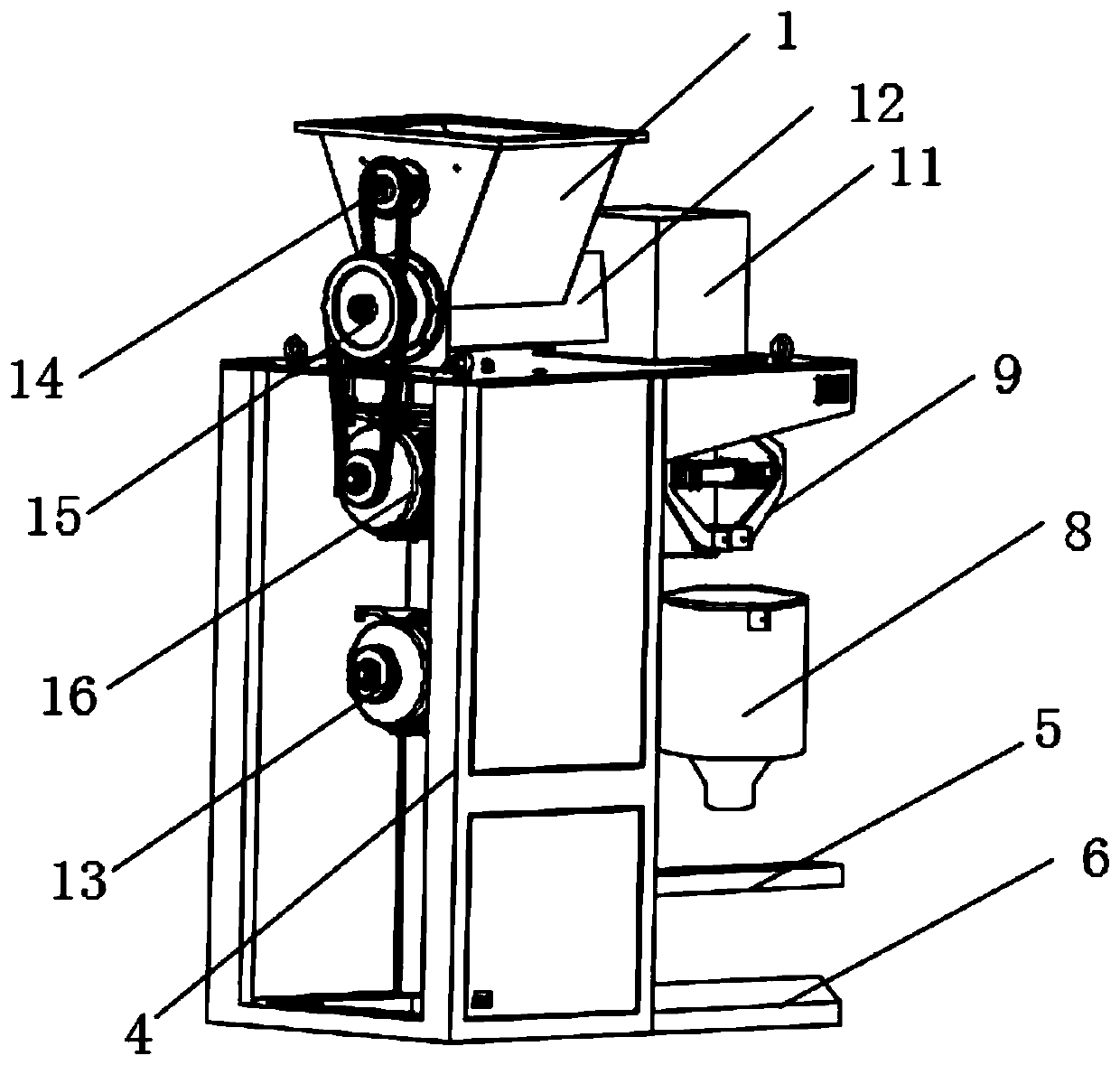

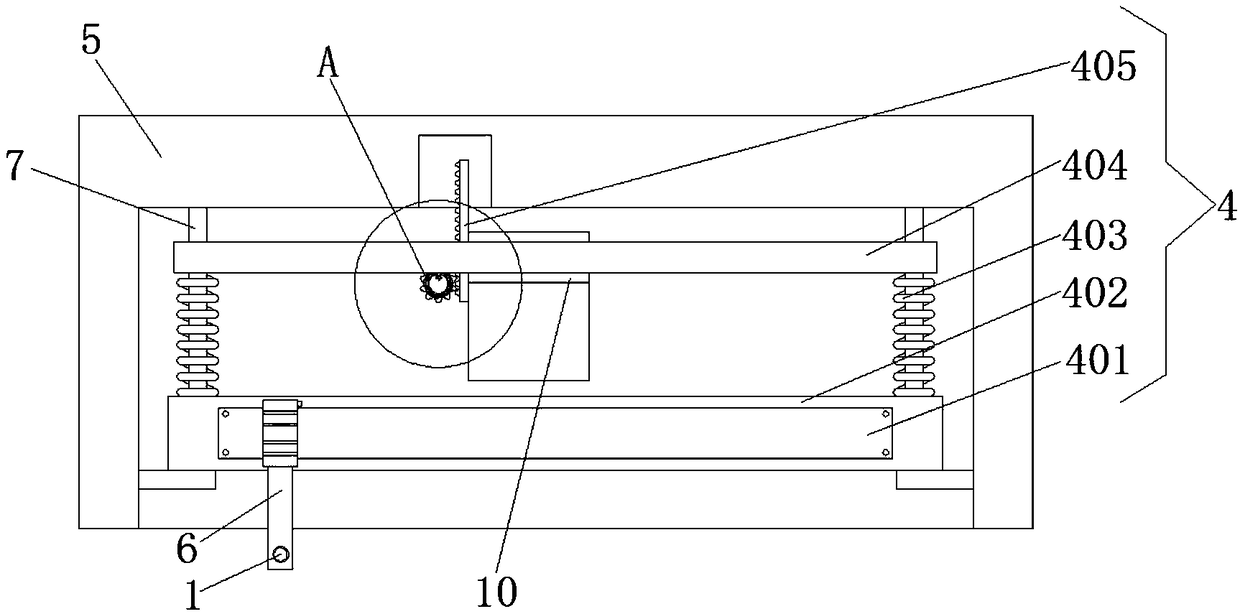

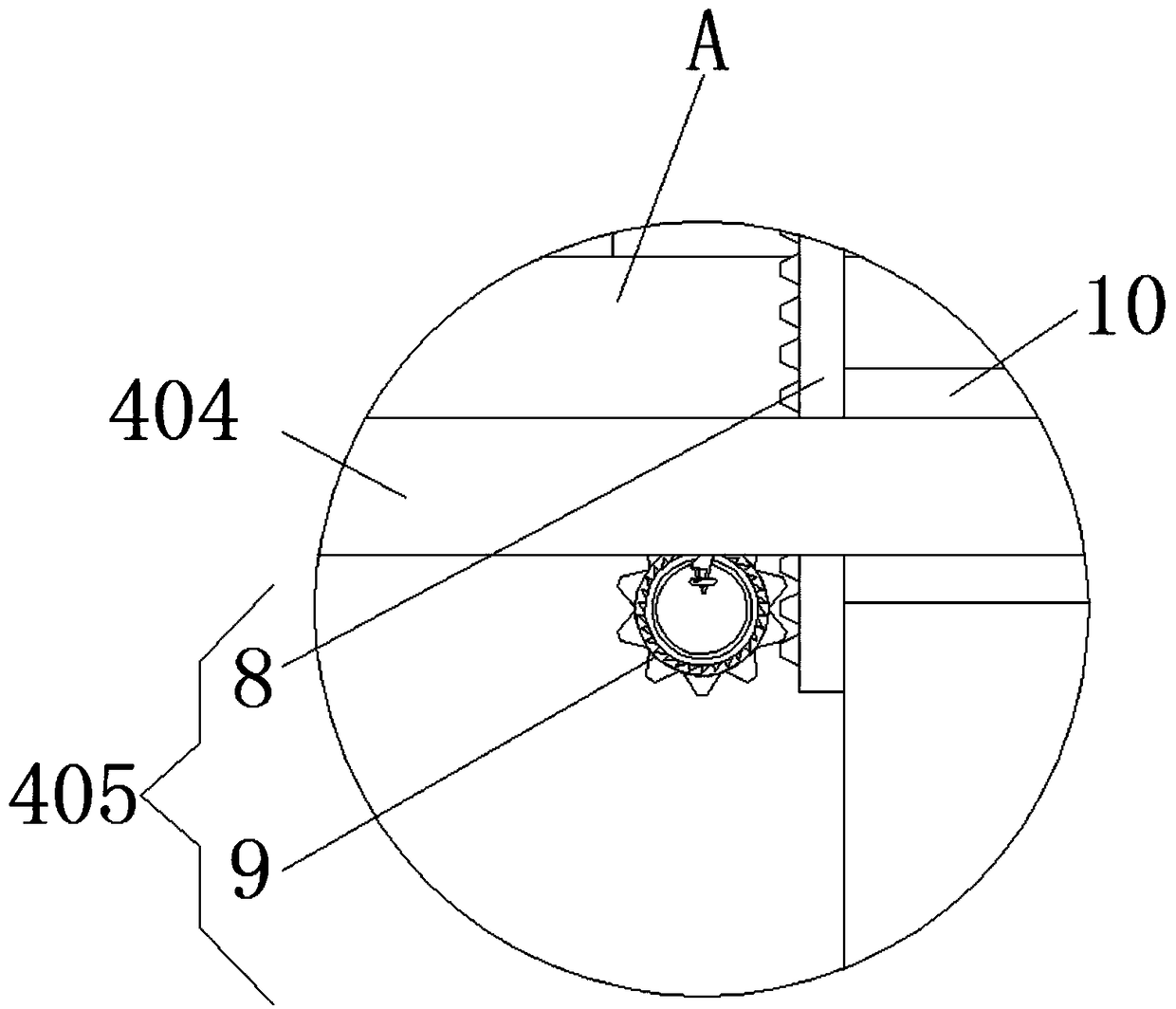

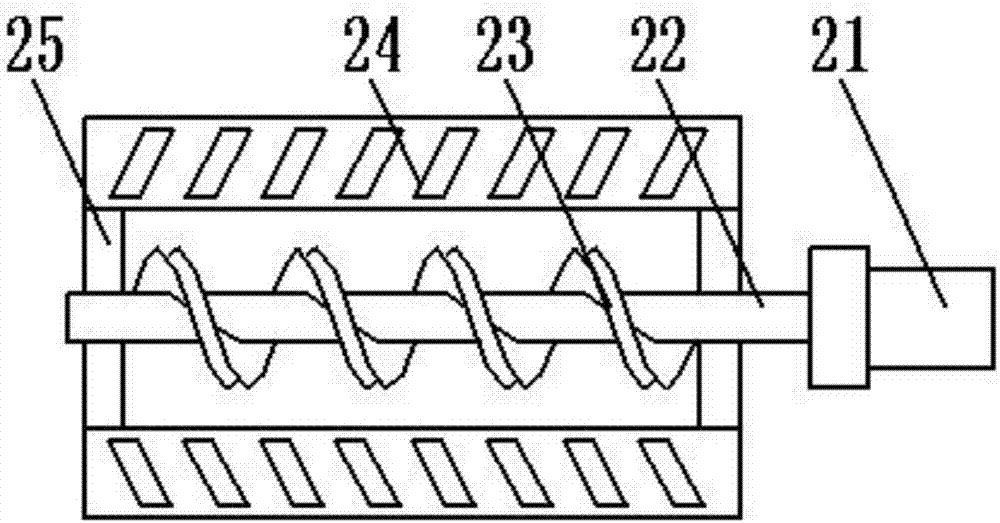

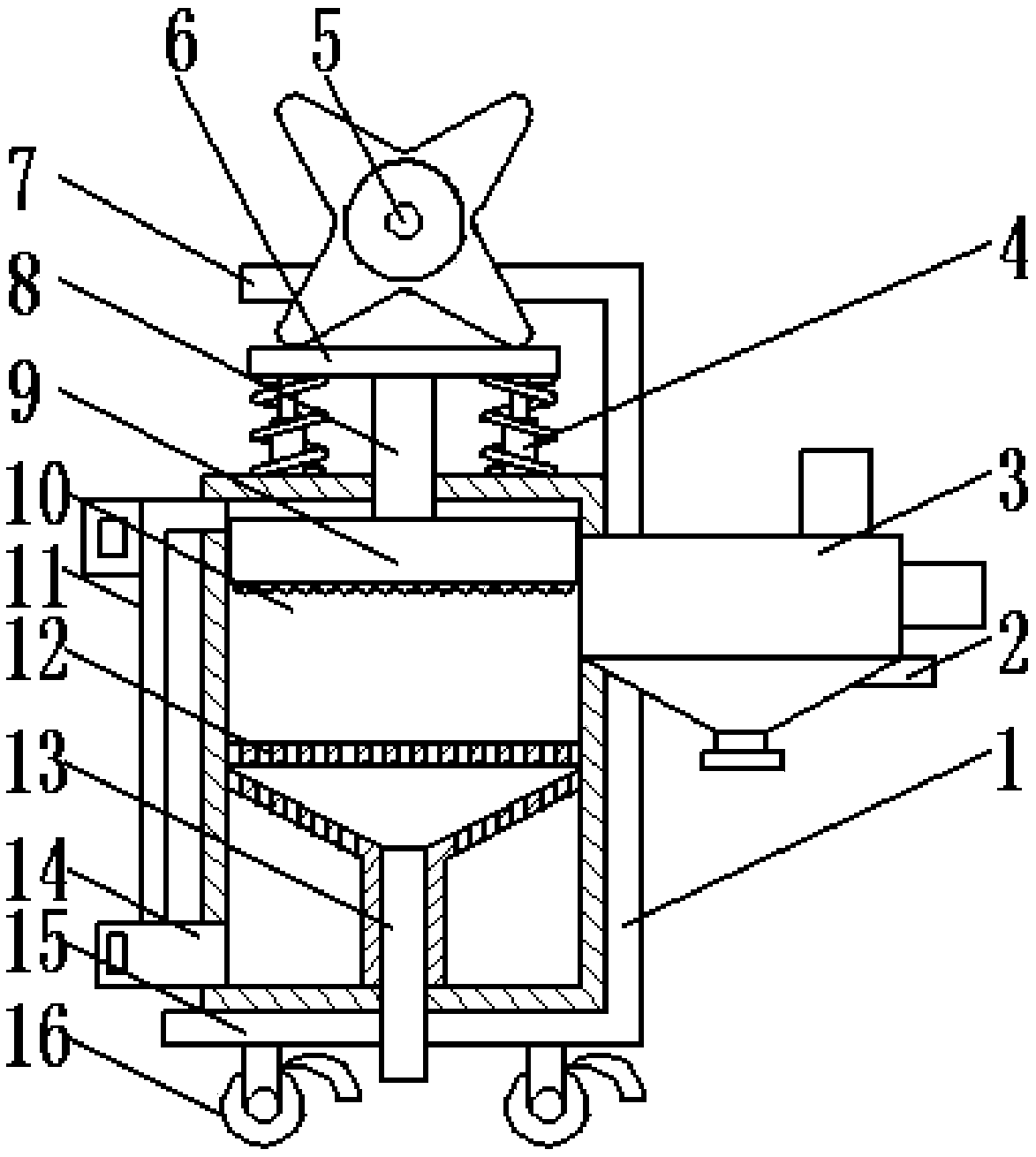

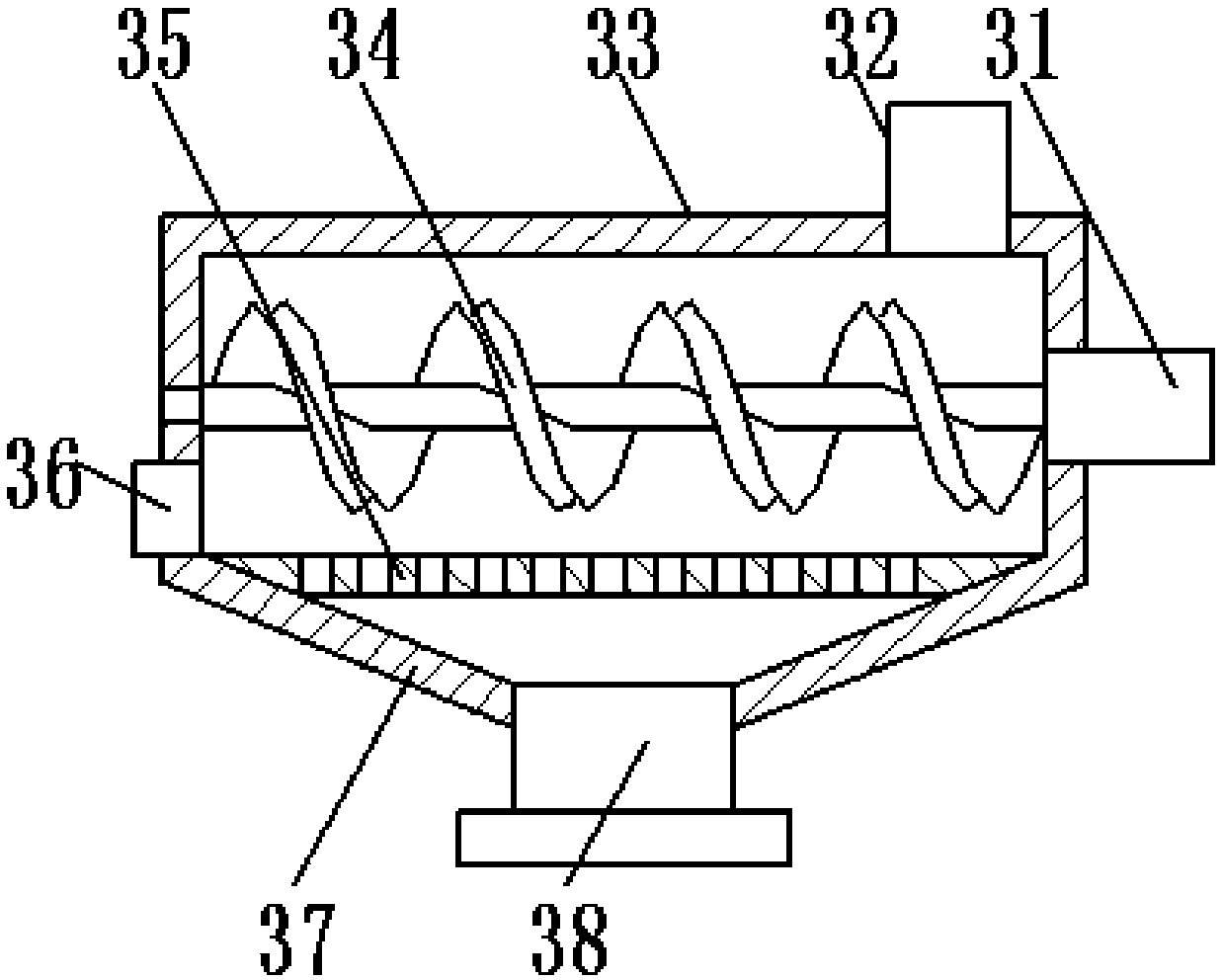

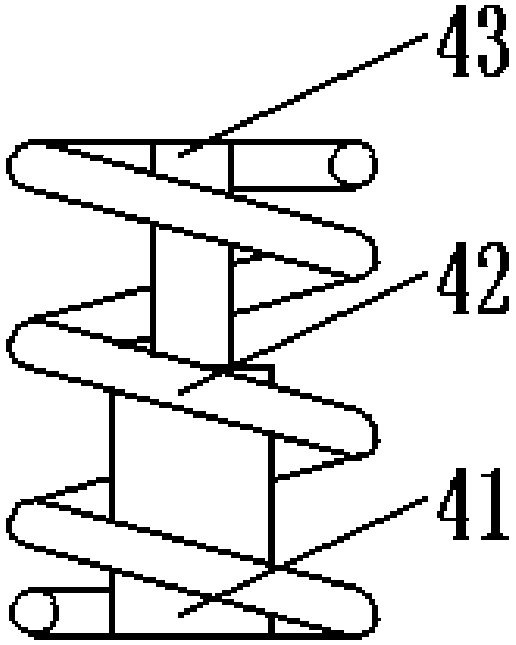

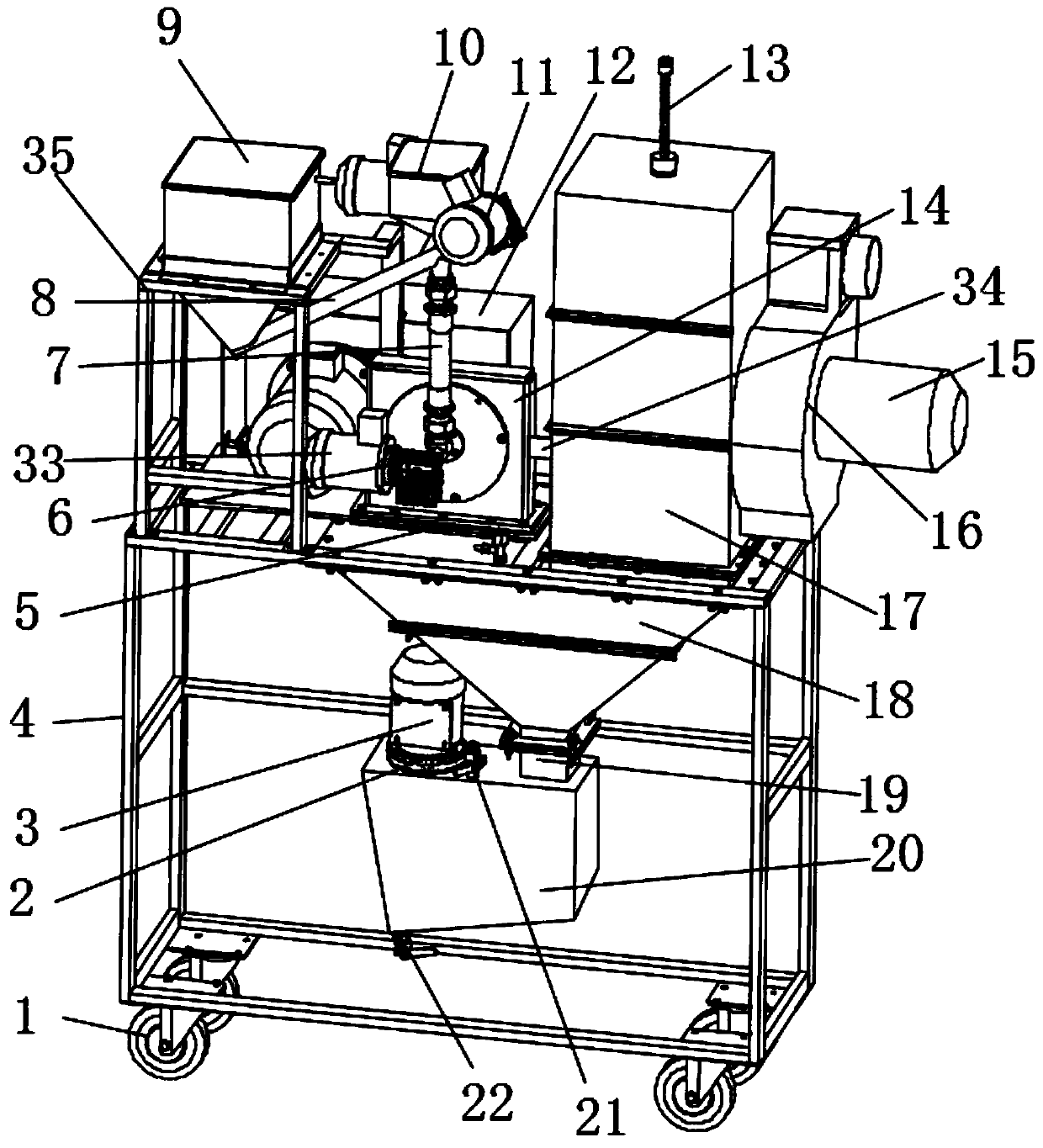

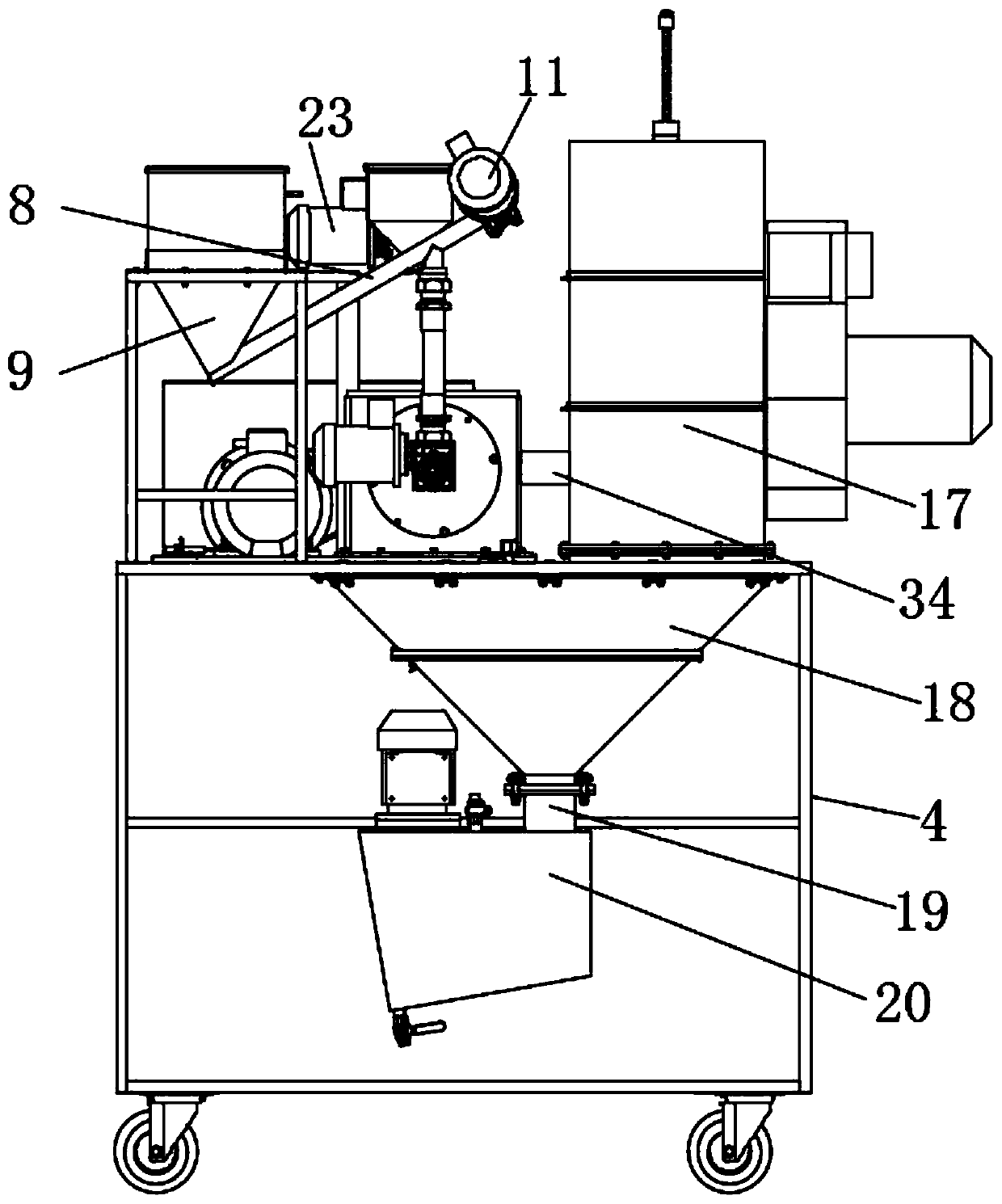

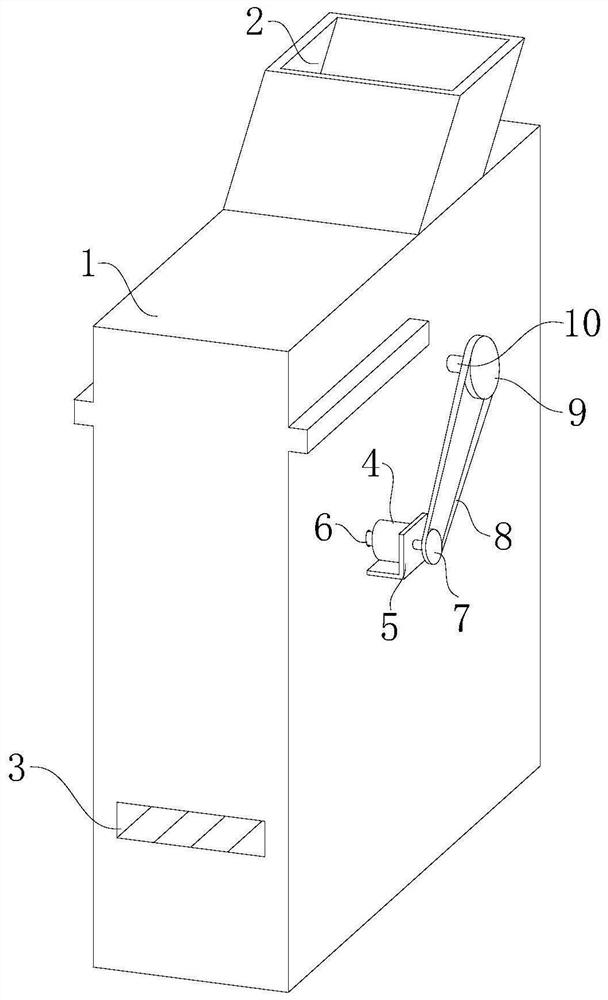

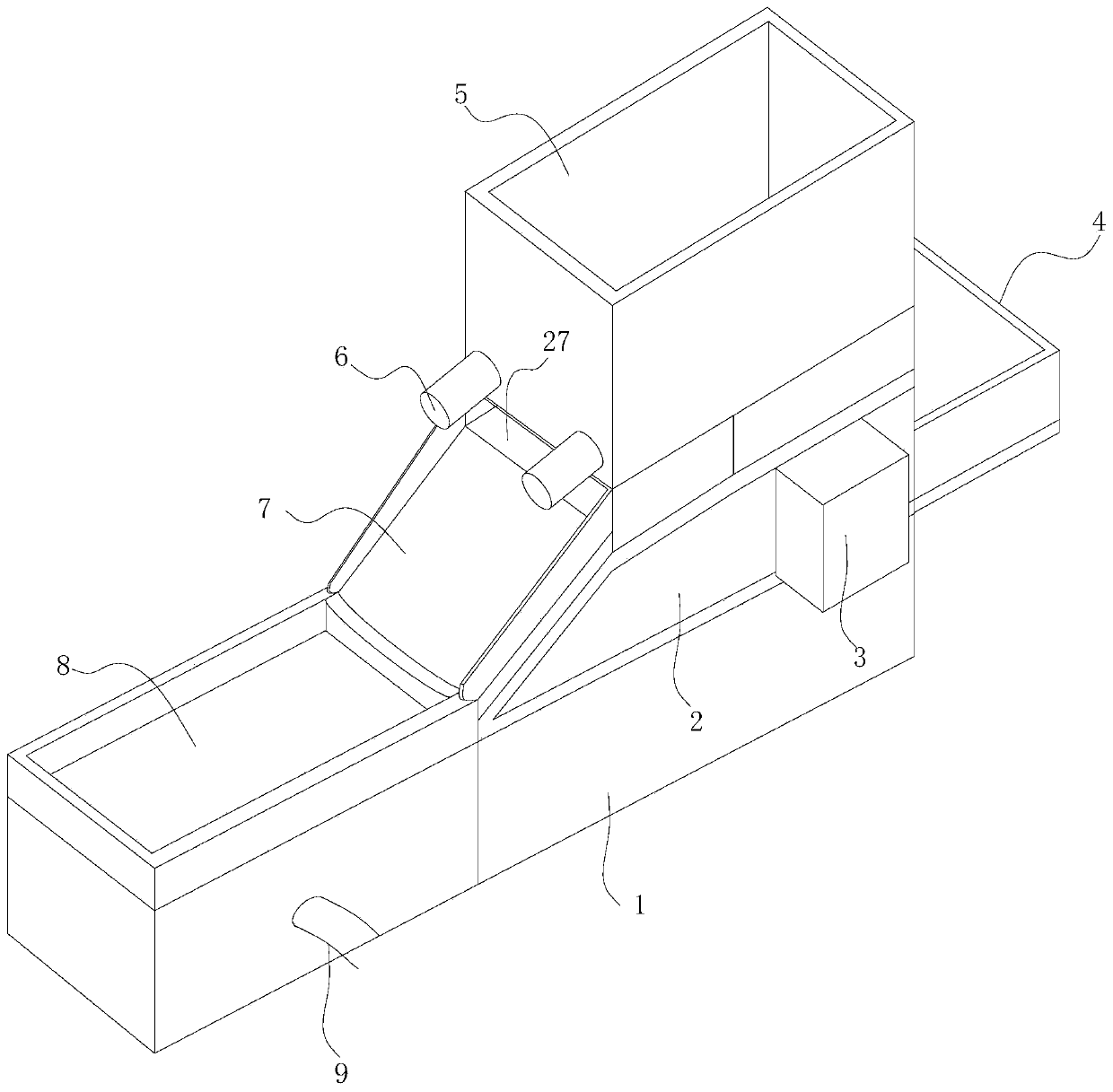

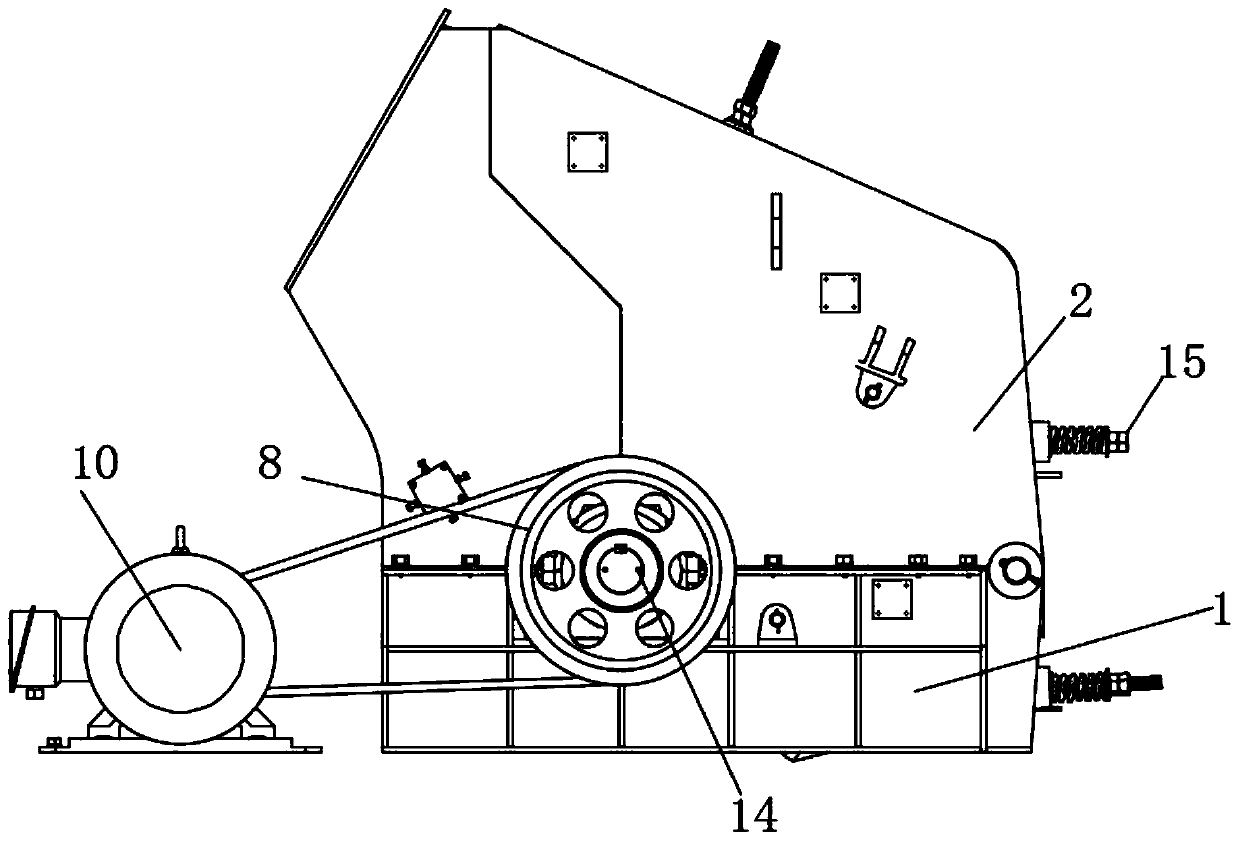

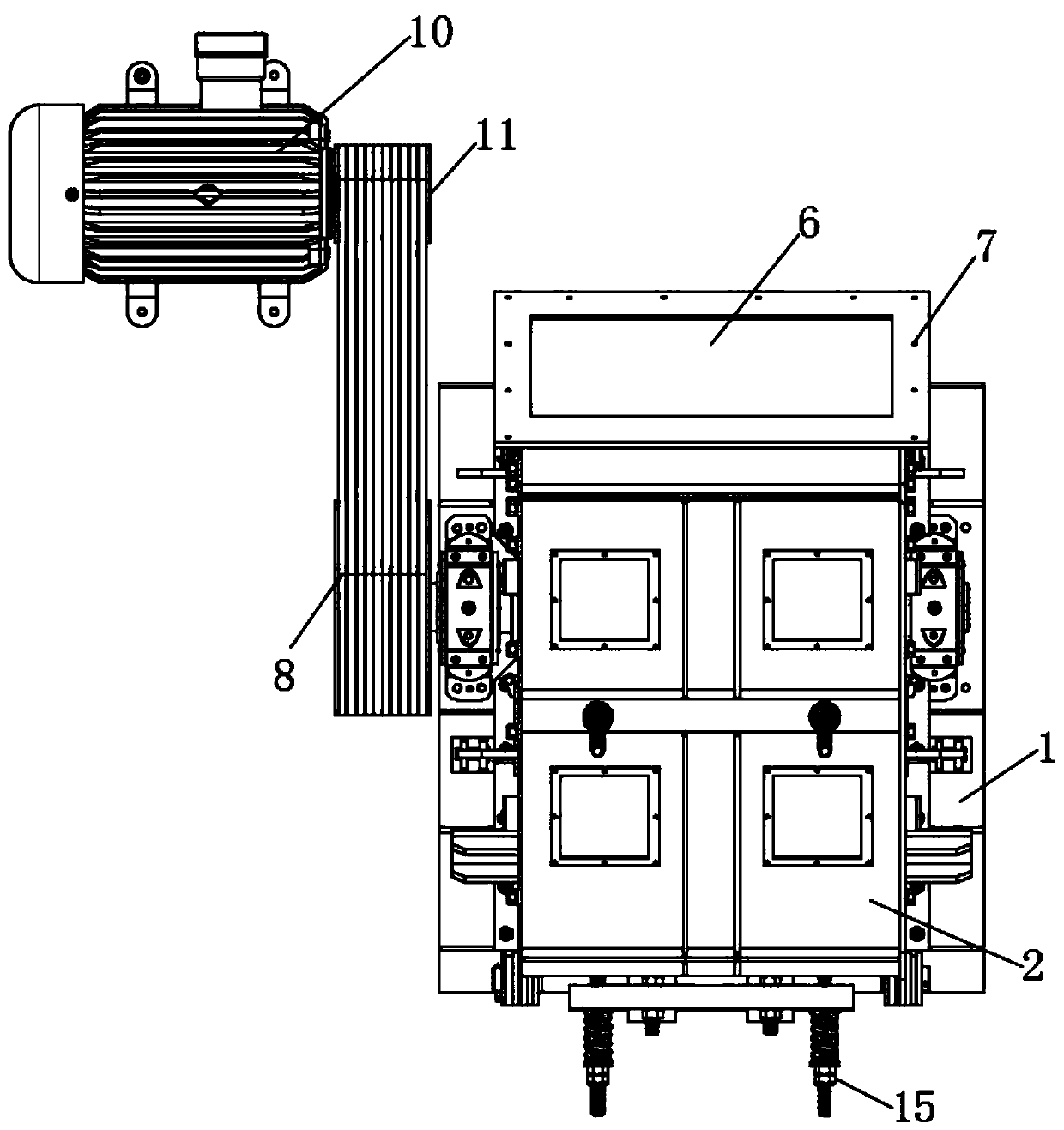

Movable coal crushing device with dual crushing function

InactiveCN108014865AEasy to crushTo achieve the crushing effectFeeding-stuffDirt cleaningDrive motorEngineering

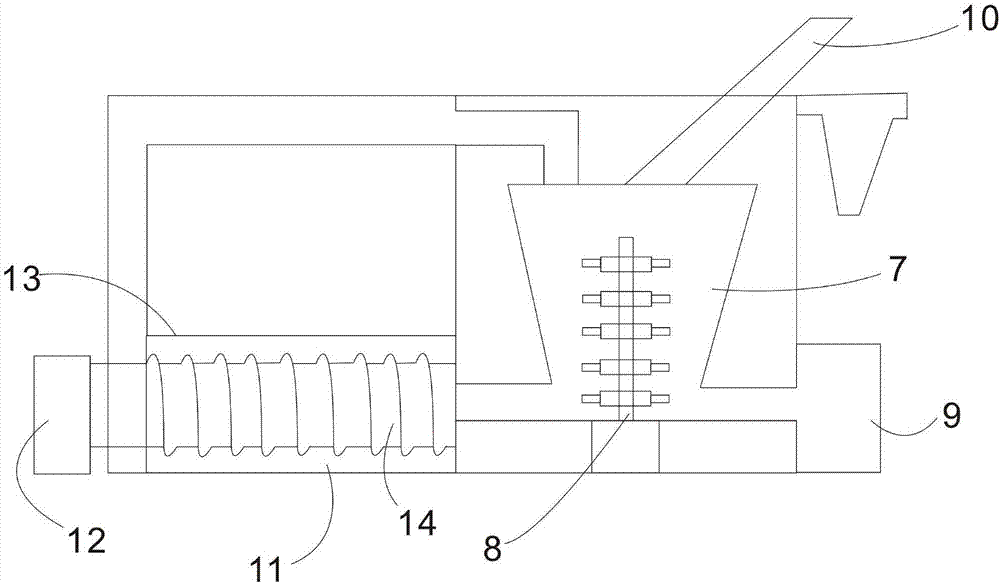

The invention provides a movable coal crushing device with a dual crushing function, and belongs to the technical field of chemical engineering. The device comprises an universal wheel; a baseplate isarranged at the top of the universal wheel; a stirring and crushing chamber and a support vertical rod are arranged at the top of the baseplate; a crushing device is arranged in the stirring and crushing chamber; and a discharge pipe is arranged on the left side of the stirring and crushing chamber. The device is simple in structure, reasonable in design and convenient to use; through arrangementof the universal wheel, the device is convenient to move, and workers are more convenient to use the device; through arrangement of a crushing block, a return device and a driving device, under the effect of the driving device, a driving motor drives a rotating wheel to rotate and drives the crushing block to downwards move to crush materials; under the effect of the return device, the crushing block is driven to upwards move for resetting; the driving motor drives the crushing block to downwards move again; and through repeated movement, the material crushing effect is achieved.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Plastic production stirring and mixing device with smashing function

The invention provides a plastic production stirring and mixing device with a smashing function, and belongs to the technical field of chemical engineering. The device comprises supporting legs, and astirring and mixing chamber is arranged on the tops of the supporting legs; the supporting legs are welded to the bottom of the stirring and mixing chamber; a stirring device is arranged in the stirring and mixing chamber; a material discharging pipe is arranged on the left side of the stirring and mixing chamber; the material discharging pipe is welded to the left side of the stirring and mixingchamber; a filter plate is arranged on the top of the stirring and mixing chamber; a smashing cavity is formed in the top of the filter plate; the smashing cavity is internally provided with a smashing block, a vertical connection rod, a transverse supporting rod, reset devices and a baffle. The device is simple in structure and reasonable in design; due to the arrangement of a material inlet box, materials are easily gathered and input into the smashing cavity; under the action of a smashing block, the materials are smashed, the smashed materials are uniformly input into the stirring and mixing chamber through the filter plate and then stirred and mixed, and the material stirring and mixing speed is greatly increased.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

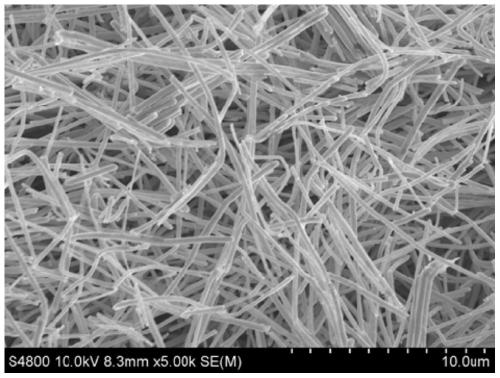

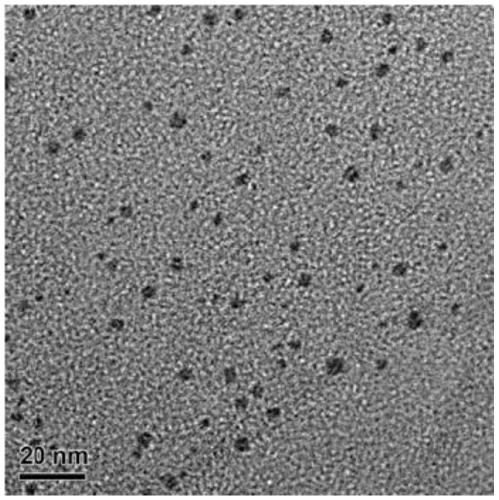

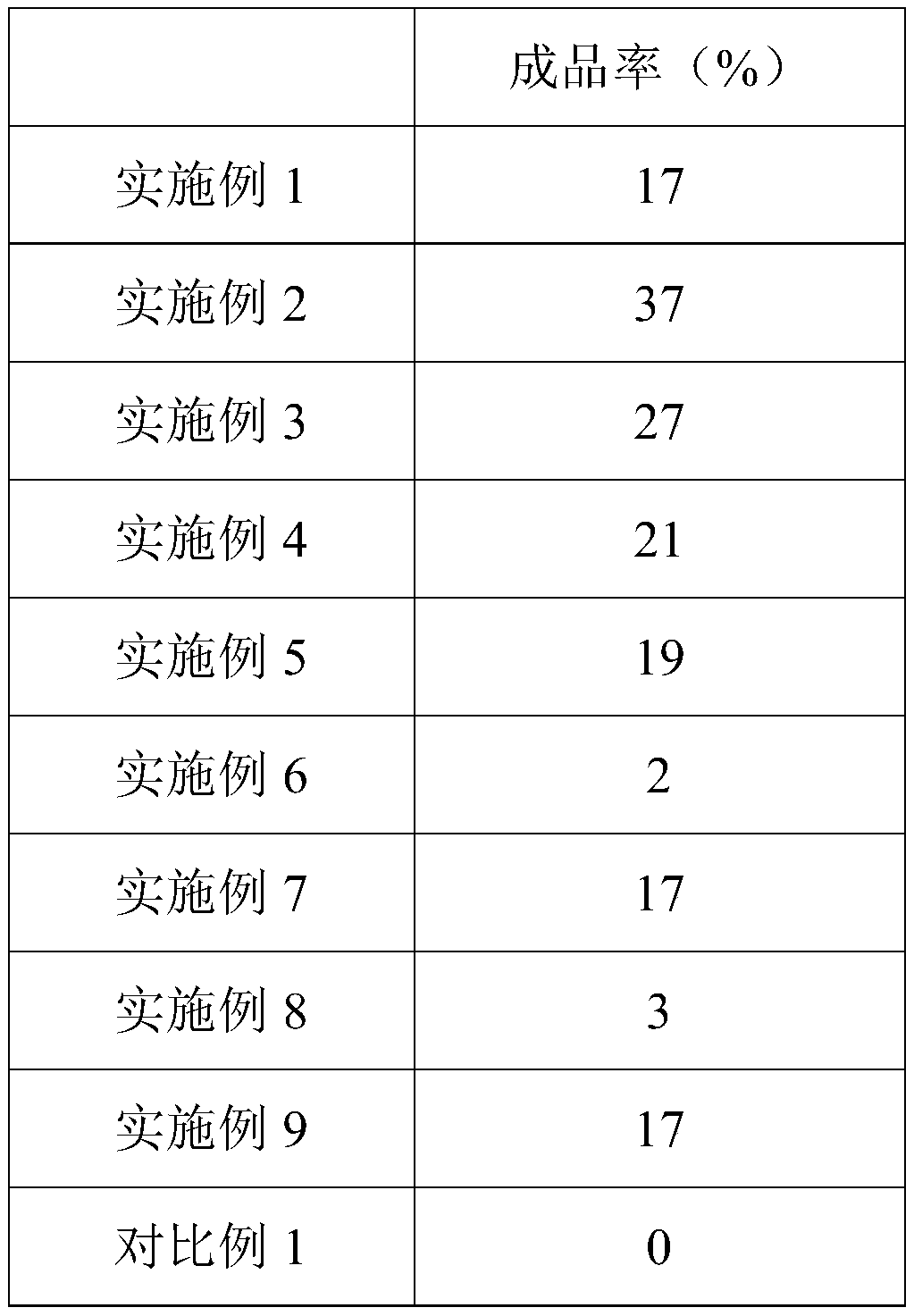

Method for converting nanowires into quantum dots and prepared quantum dots

The invention relates to a method for converting nanowires into quantum dots and the prepared quantum dots. The method comprises the following steps: (1) mixing the nanowires and a grinding aid material to obtain a mixed crude product; and (2) dispersing the mixed crude product in step (1) in a solvent, and carrying out ultrasonic treatment to obtain the quantum dots. The preparation method has the advantages of high efficiency, environmental friendliness, simplicity in operation, low cost and the like, is suitable for large-scale production, and has good application prospect; and the preparedquantum dots are high in purity, high in yield, uniform in particle size and controllable in size.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

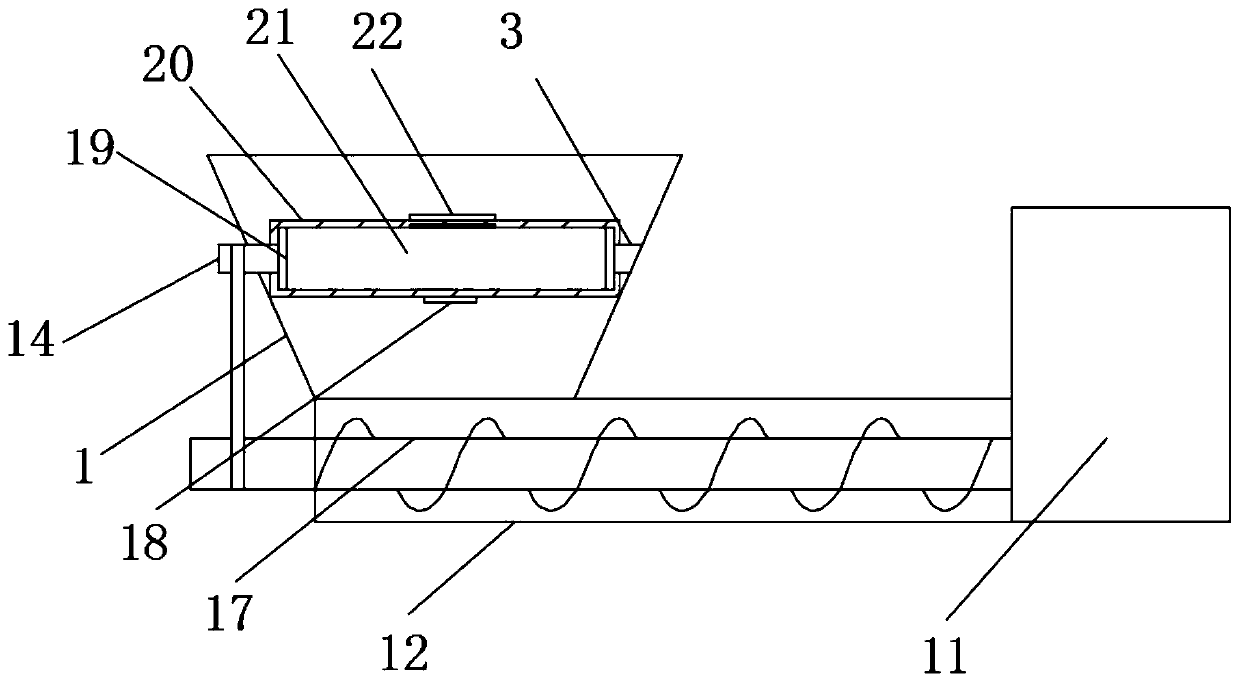

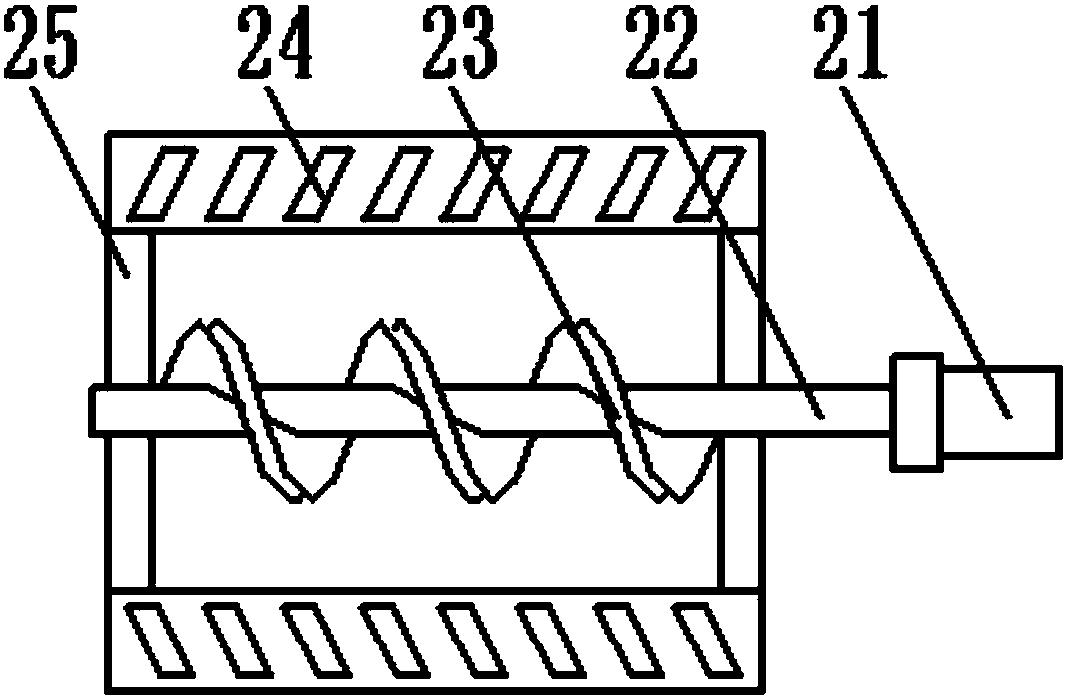

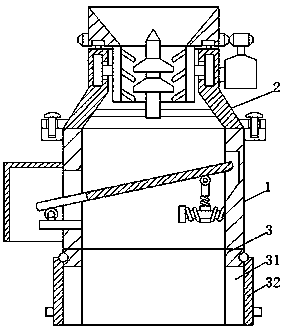

Mobile chemical raw material screening and crushing equipment

InactiveCN108187790ATo achieve the crushing effectTo achieve the effect of crushing againGrain treatmentsChemical industryFilter funnel

The invention provides mobile chemical raw material screening and crushing equipment and belongs to the technical field of chemical industry. The mobile chemical raw material screening and crushing equipment comprises universal wheels; the tops of the universal wheels are welded at the bottom of a base plate; the top of the base plate is provided with a crushing chamber and a supporting vertical rod; the crushing chamber is internally provided with a filter funnel, a flow equalizing plate and a crushing block; the flow equalizing plate is arranged inside the crushing chamber; the left and right ends of the flow equalizing plate are welded on the left and right inner walls of the crushing chamber; the filter funnel is arranged at the bottom of the flow equalizing plate; and the crushing block is arranged inside the crushing chamber. The mobile chemical raw material screening and crushing equipment is simple in structure and reasonable in design; by arranging the universal wheels, the mobile chemical raw material screening and crushing equipment can be moved and installed conveniently; by arranging a feeding device, a material can be intensively input into an equipment housing via afeeding pipe; under the effect of an electromotor, a spiral feeding shaft is driven to input the material into the crushing chamber, and simultaneously the material can be primarily screened, and theprimarily screened material is discharged from a second discharging pipe.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Crushing equipment for beneficiation

InactiveCN108435382ATo achieve the crushing effectGuaranteed stabilityGrain treatmentsEngineeringLarge size

The invention discloses crushing equipment for beneficiation. The crushing equipment comprises a screening box, a screening hole is formed in one end of the screening box, a supporting plate is fixedly connected to the lower end of the inner side of the screening hole, a first shaft sleeve is connected to the upper end of the supporting plate through a shaft, an inclined plate is fixedly connectedto the outer side of the first shaft sleeve, a protective cover is fixedly connected to the opening position of the outer side of the screening hole, a screen is embedded in the inclined plate, a limiting groove is formed in the other end of the inner side of the screening box, and the other end of the screen is connected to the inner side of the limiting groove in a sliding mode. According to the crushing equipment for beneficiation, a crushing cylinder drives extrusion protrusions to perform rotary crushing, the extrusion of extrusion circular truncated cones is coordinated, so that the crushing effect can be achieved, in addition, the discharging stability can also be ensured, meanwhile, when the screen is stressed, the screen can vibrate up and down through a second spring, so that particles can be screened out from ore powder, and large-size ores can be recycled.

Owner:冯沈明

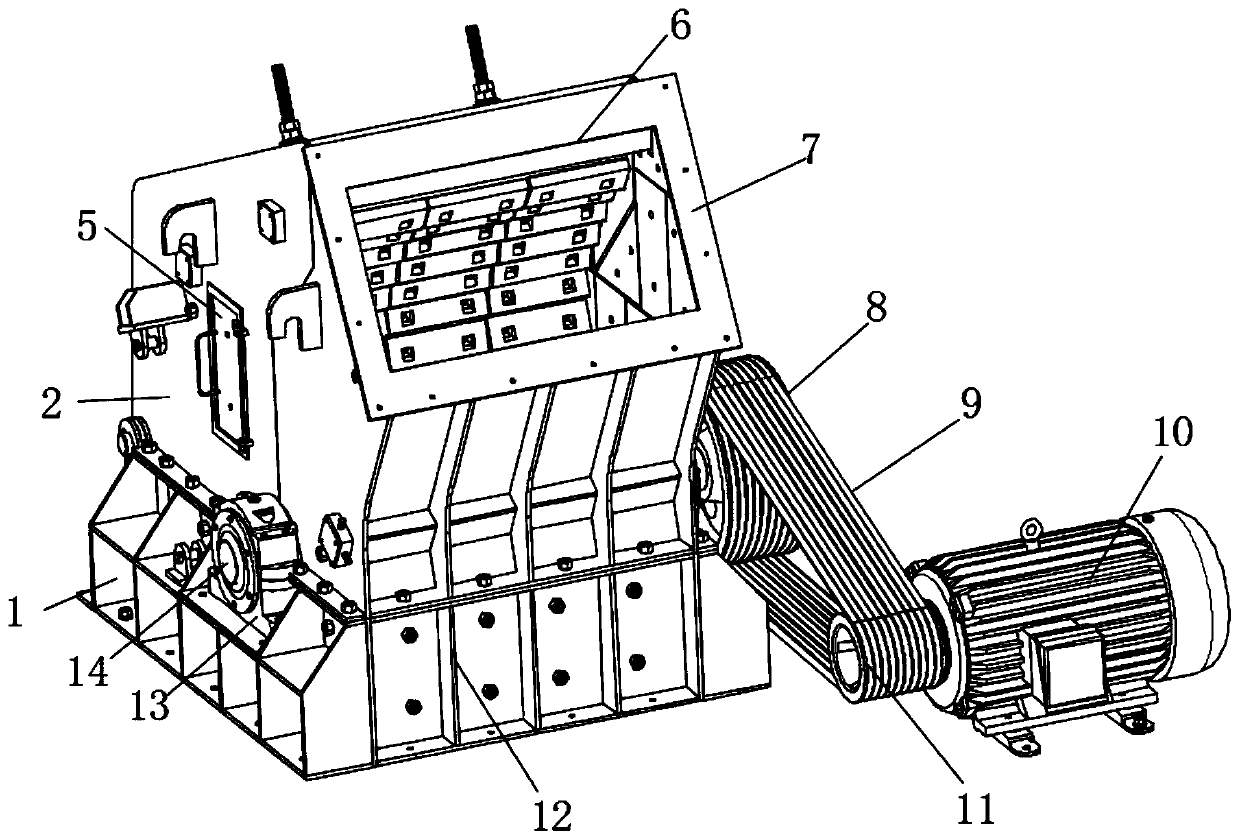

Efficient dust-free soil crusher

InactiveCN106824488AInhibited DiffusionAvoid cloggingUsing liquid separation agentGrain treatmentsElectrical controlEngineering

The invention discloses a high-efficiency dust-free dust machine, which comprises a feeding hopper, a body main body, a belt, a motor, a discharge port, a crushing knife, a water tank and a water sprayer. The feeding hopper is fixed on the body of the machine body. Above, the discharge port is fixedly connected to the lower part of the main body of the fuselage, the outside of the pulverizer is connected with a pulverizer fixing rod, the right side of the water tank is provided with a water pump, and the left side of the water pump is connected with an electrical control box. The right side of the water dispenser is provided with a water spray hole with the orifice facing the inside of the discharge port, and a filter screen is provided outside the water spray hole. A high-efficiency dust-free dust machine of the present invention is equipped with a water tank and a water pump, which can humidify the crushed soil coming out of the discharge port, reduce the generation of dust, prevent the dust from spreading, and the water spray holes are evenly distributed in the On the sprinkler, the outside of the sprinkler is provided with a filter screen, so that the water sprayed from the water spray hole is more uniform, and the filter screen can prevent dust from blocking the water spray hole, so that the water spray is smoother.

Owner:WUXI AOYUTE NEW TECH DEV

Automatic garbage recovery device and recovery method thereof

InactiveCN110813978ATo removeEasy to crush in cold zoneSolid waste disposalGrain treatmentsElectric machineryGarbage collection

The invention discloses an automatic garbage recovery device. The automatic garbage recovery device comprises a base, a feed box and a crushing box. A mounting rack is fixedly arranged at one end of the top of the base. The feed box is arranged on the top of the mounting rack. The bottom of the feed box is provided with a feed pipe. A cover plate is arranged in the position, on one side of the mounting rack, of the top of the base. The top of the cover plate is fixedly provided with supporting columns. Crushed garbage is fed into a collection box from the bottom of the crushing box and goes into a storage box through a transition pipe. The bottom surface of the storage box is an inclined plane, and a discharge port is arranged at the bottom of the inclined plane, so that the crushed garbage slides to the discharge port under the action of gravity and is discharged from the discharge port. Meanwhile, the output end of an unchoking motor drives an unchoking shaft to rotate, and unchokingblades on the unchoking shaft rotate to stir the crushed garbage to move, so that the crushed garbage can be discharged from the discharge port. The automatic garbage recovery device achieves the crushed garbage unchoking effect to protect materials against accumulation and blockage.

Owner:苏州德君环卫服务有限公司

Processing and crushing device for food engineering

ActiveCN111957410AReasonable designEasy to operateGrain treatmentsElectric machineryProcess engineering

The invention relates to a processing and crushing device for food engineering. The processing and crushing device comprises a crushing box, a feeding hopper and a discharging hole, wherein the feeding hopper is arranged on a top plate of the crushing box and is connected with the inner part of the crushing box; the discharging hole is formed in a side wall of the crushing box; and a double-head driving motor is arranged outside the crushing box. According to the processing and crushing device provided by the invention, food grains are crushed by adopting a multi-crushing manner, so that the food grains can be continuously reduced along with a crushing procedure in a food grain crushing process, and furthermore, the crushing effect is realized; meanwhile, a crushing mechanism is reasonablein design and simple to operate; a power source is provided and only the single double-head driving motor needs to be provided, so that the energy-saving effect is realized; and in the crushing process, the efficient crushing effect can be realized, so that the crushing time is shortened, and furthermore, the food processing process is efficient and meets market requirements better.

Owner:湖南益百益优生物科技有限公司

Margarya melanoide meat-shell separating equipment

The invention relates to the technical field of margarya melanoides and discloses margarya melanoide meat-shell separating equipment. The equipment includes a separating equipment body. Margarya melanoide shelling machines separate margarya melanoide shells and margarya melanoide meat by rolling margarya melanoides, but the machines have many disadvantages, for example, the tail parts of most margarya melanoide meat are connected to guts, the rolled margarya melanoide shells can be pressed on the surfaces of the margarya melanoide meat, large margarya melanoides cannot be crashed if the largemargarya melanoides are put into the machines, the whole margarya melanoides can block crashing carriers and operation process can be influenced, and through the equipment, the above-mentioned problems can be solved; the feeding box fixedly connected to the top of the separating equipment body can collect the margarya melanoides; and the feeding box is divided into an upper part and a lower part,and the upper part can heat the margarya melanoides so as to make the covers of the margarya melanoides separate.

Owner:徐宁

Multi-dimensional crushing device for solid wastes

PendingCN110756278ARealize crushing workPrevent extrusionGrain treatmentsDrive wheelElectric machinery

The invention discloses a multi-dimensional crushing device for solid wastes. The device comprises a bottom box and a top box; the top box is arranged at the top of the bottom box; the bottom box communicates with the internal of the top box; a motor is arranged on one side of the bottom box; a driving wheel is arranged at one end of the motor; an output end of the motor is in transmission connection with the driving wheel; a first fixed nut is rotated; due to the effect of elastic force of a compression spring, a first return rod pushes a first clamp to rotate along a first rotating rod, andthe bottom end of the first clamp is adjusted to control the distance from a crushing block to a movable block; the crushing block is matched with the movable block to form an engagement effect to achieve a crushing effect on small-particle solid wastes; the distance from the first clamp to a crushing wheel is increased to achieve the crushing effect on solid wastes with different particle sizes,so that the primarily crushed wastes are crushed again; and through dual crushing, the phenomenon of halfway crushing by traditional machinery is prevented.

Owner:耿言华

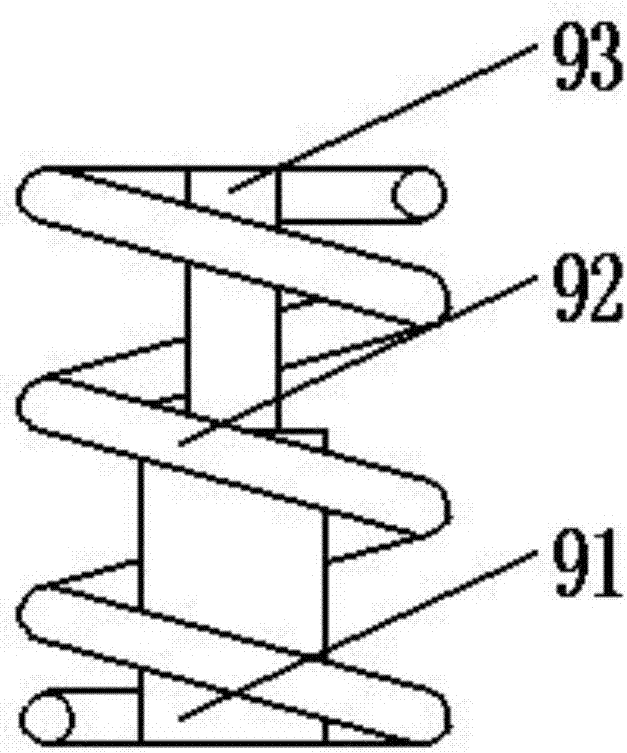

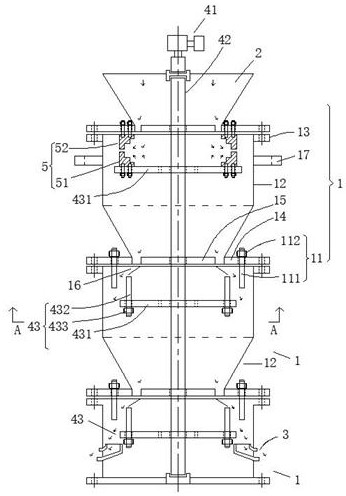

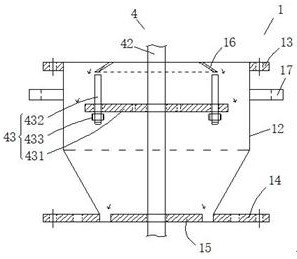

Wet material smashing device

PendingCN113426547AEvenly crushedSolve the technical problems of long crushing operation time and low crushing efficiencyCocoaGrain treatmentsProcess engineeringIndustrial engineering

The invention provides a wet material smashing device and belongs to the technical field of wet material smashing. The wet material smashing device comprises smashing mechanisms, a feeding assembly, a step tooth structure, a discharging assembly and a driving mechanism, the driving mechanism rotates in the multiple sets of smashing mechanisms and is matched with the multiple smashing assemblies to conduct extrusion, and wet materials can be smashed through extrusion of the smashing mechanisms and the driving mechanism; and the multiple sets of smashing mechanisms are stacked up and down, the smashing granularity of the wet materials by the multiple smashing assemblies is gradually reduced from top to bottom, the materials are fed into the smashing mechanisms through the feeding assembly, the materials are discharged from the smashing mechanism at the bottom end through the discharging assembly, the wet materials are sequentially and gradually smashed from top to bottom in the multiple sets of smashing mechanisms, and finally the smashing effect is achieved. The wet material smashing device has the advantages that the wet material smashing operation time is short, the wet materials are uniformly smashed in the smashing mechanisms, the smashing requirement can be met, the smashing efficiency is high, and the operation progress of the smashing procedure is met.

Owner:河北赞弘机械设备有限公司

Energy-saving building block garbage crushing and recycling treatment device

ActiveCN112827628AAvoid consumptionEnergy-saving effectCocoaGrain treatmentsGear wheelConstruction engineering

The invention relates to the technical field of building block treatment devices, and particularly relates to an energy-saving building block garbage crushing and recycling treatment device. The energy-saving building block garbage crushing and recycling treatment device comprises a shell, a grinding space is arranged in the shell, and the energy-saving building block garbage crushing and recycling treatment device further comprises a main shaft, a grinding mechanism and an anti-blocking device; the grinding mechanism comprises a grinding disc, a first rotating shaft, a crushing pendulum bob and a torsional spring; the grinding disc is mounted at the upper end of the main shaft; the first rotating shaft is vertically arranged and is rotatably mounted on the grinding disc; the crushing pendulum bob is mounted at the upper end of the first rotating shaft and located on the upper side of the grinding disc; the torsional spring is arranged between the first rotating shaft and the grinding disc; and the anti-blocking device comprises a knocking pendulum bob, a transmission assembly, a deflection wheel, a pressure spring, a second rotating shaft, a first gear, a second gear, a third rotating shaft and a gear ring. When the crushing pendulum bob is about to be blocked when encountering large building block garbage, the pre-blocked building block garbage is knocked through the anti-blocking device to knock out or crush the building blocks, so that consumption caused by restarting of the treatment device due to blocking is avoided.

Owner:张达

Biomass material crushing device capable of limiting loading amount

The invention relates to the technical field of new energies and discloses a biomass material crushing device capable of limiting loading amount. The device comprises a box body, wherein a rotating shaft is rotatably connected to the inner top wall of the box body, a convex rod and a rotating drum are connected outside the rotating shaft in a sleeving manner, a ratchet wheel is fixedly connected to the bottom of the rotating shaft, a crushing knife is fixedly connected outside the rotating drum, a motor is fixedly connected to the inner bottom wall of the box body, a rotating disc is rotatablyconnected to the top of the motor, a lifting lever is rotatably connected to the top of the rotating disc, a fixed plate and a movable plate are arranged in the box body, two sliding plates are movably connected to the top of the fixed plate, and two stripping plates are fixedly connected to the inner top wall of the box body. As the motor drives the rotating disc to rotate, the rotating disc ismatched with the lifting lever, the ratchet wheel, the rotating shaft and the convex rod to drive the two sliding plates to slide in opposite directions, so that a through hole and an emptying hole are superposed. Biomass materials fall above the movable plate through the through hole and the emptying hole, so that it is convenient for follow-up crushing treatment.

Owner:金华乙源生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com