Cassava starch production equipment and method using three-pass drum and air flow combined drying

A production equipment and three-pass technology, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of increased moisture content, increased energy consumption, and large water consumption, etc., to achieve simple production and fast travel speed , to prevent the effect of flying around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

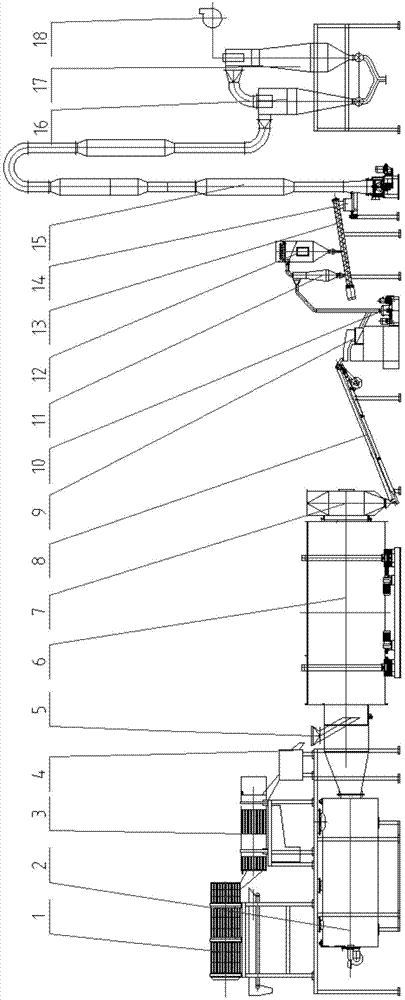

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] A cassava flour production equipment combined with three-pass drum and airflow drying, mainly including a peeling and dicing system, a three-pass drum drying system, a crushing system, and an airflow drying system. Among them, the peeling and dicing system is mainly composed of a drum dry cleaning peeling machine 1, a drum washing peeling machine 3, and a dicing machine 4. These three devices are installed on the second-floor platform. The peeling machine 3 is connected, and the outlet of the drum washing and peeling machine 3 is connected with the inlet of the dicing machine; the three-pass drum drying system is mainly composed of a coal-fired hot blast stove 2, a slide pipe 5, a three-pass drum dryer 6, and a three-pass drum dryer. Composed of hopper 7, coal-fired hot air stove 2 is fixed on the ground, directly below the peeling and dicing system, the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com