Main valve element for reversing valve

A main spool and reversing valve technology, which is applied in the direction of multi-way valves, valve devices, mechanical equipment, etc., can solve the problems of deformation easily affected by external force, enhanced liquid erosion ability, complex working environment, etc. Strong toughness, improved fluidity, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

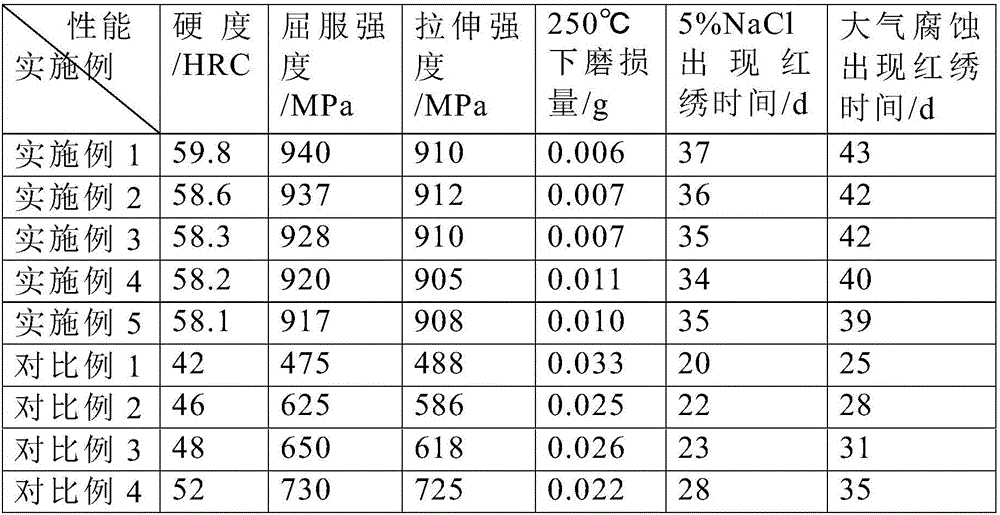

Embodiment 1

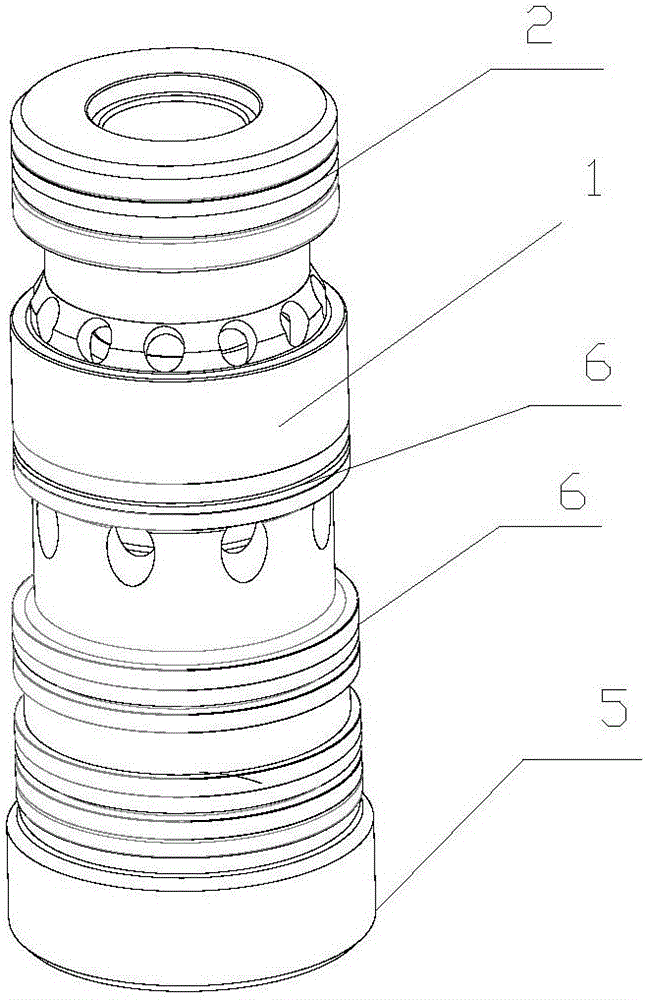

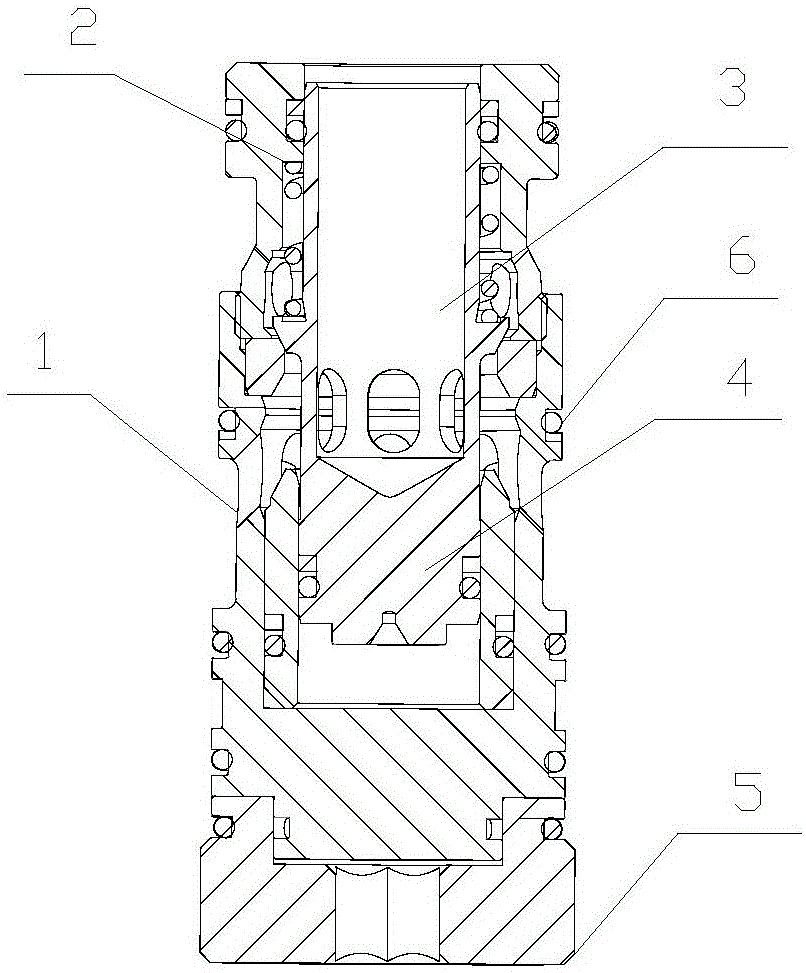

[0028] In this example, if figure 1 , 2 As shown, the main valve core in a reversing valve includes an upper valve sleeve 1, a lower valve sleeve 2, and a valve core 3. The lower valve sleeve 2 is inserted into the upper valve sleeve 1 and connected with the upper valve sleeve 1. The sleeve is provided with a piston 4, the valve core 3 is located in the lower valve sleeve 2 and extends into the piston 4, the upper valve sleeve 1 has an opening and an end cap 5 is provided at the opening; the lower valve sleeve 2 and the upper valve sleeve 1 Sealing rings 6 made of composite materials are provided on the outer walls.

[0029] The sealing ring composite material includes the following components by weight: nitrile rubber: 100 parts, white carbon black: 15 parts, silicon powder: 18 parts, modified nano titanium dioxide: 4 parts, surface modifier: 5 parts, Zinc oxide: 5 parts, anti-aging agent: 25 parts, vulcanizing agent: 5 parts.

[0030] The upper valve sleeve, lower valve s...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is only:

[0037] In this embodiment, the sealing ring composite material includes the following components in parts by weight: nitrile rubber: 100 parts, white carbon black: 13 parts, silicon powder: 25 parts, modified nano-titanium dioxide: 2 parts, surface modifier : 4 parts, zinc oxide: 6 parts, anti-aging agent: 20 parts, vulcanizing agent: 4 parts.

[0038] The alloy steel materials used for upper valve sleeve, lower valve sleeve and valve core are: C: 0.14%, Cr: 1.6%, Si: 0.32%, Mn: 0.9%, Al: 0.048%, N: 0.048%, Mo: 0.27% , Cu: 0.038%, S: 0.008%, V: 0.14%, RE: 0.09%, P≤0.015%, the balance is Fe and unavoidable impurities, of which RE is based on the total mass of RE: Ce49%, La31 .5%, Pr3.5%, and the balance is Nd. The surface layer of the main valve core main body is doped with additives, and the content of the additive silicon dioxide in the main body is 0.4wt%.

[0039] The upper valve sleeve, lower valv...

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is only:

[0045] In this embodiment, the sealing ring composite material includes the following components in parts by weight: nitrile rubber: 100 parts, white carbon black: 15 parts, silicon powder: 20 parts, modified nano titanium dioxide: 3 parts, surface modifier : 6 parts, zinc oxide: 4 parts, anti-aging agent: 15 parts, vulcanizing agent: 6 parts.

[0046] The alloy steel material of the main body of the main valve core is: C: 0.13%, Cr: 1.8%, Si: 0.25%, Mn: 1.1%, Al: 0.058%, N: 0.032%, Mo: 0.34%, Cu: 0.026 %, S: 0.020%, V: 0.09%, RE: 0.14%, P ≤ 0.015%, the balance is Fe and unavoidable impurities, of which RE is based on the total mass of RE: Ce452%, La30.5%, Pr4.5%, the balance is Nd.

[0047] The upper valve sleeve, lower valve sleeve and valve core of the main valve core are processed by the following process:

[0048] Pre-treatment: According to the composition elements and mass percentages of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com