Device for preparing fine grains through variable section angular pressing and method thereof

A technology of corner extrusion and variable section, applied in the field of metal plastic processing, can solve problems such as easy cracking, and achieve the effect of saving time, improving efficiency and uniform extrusion deformation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

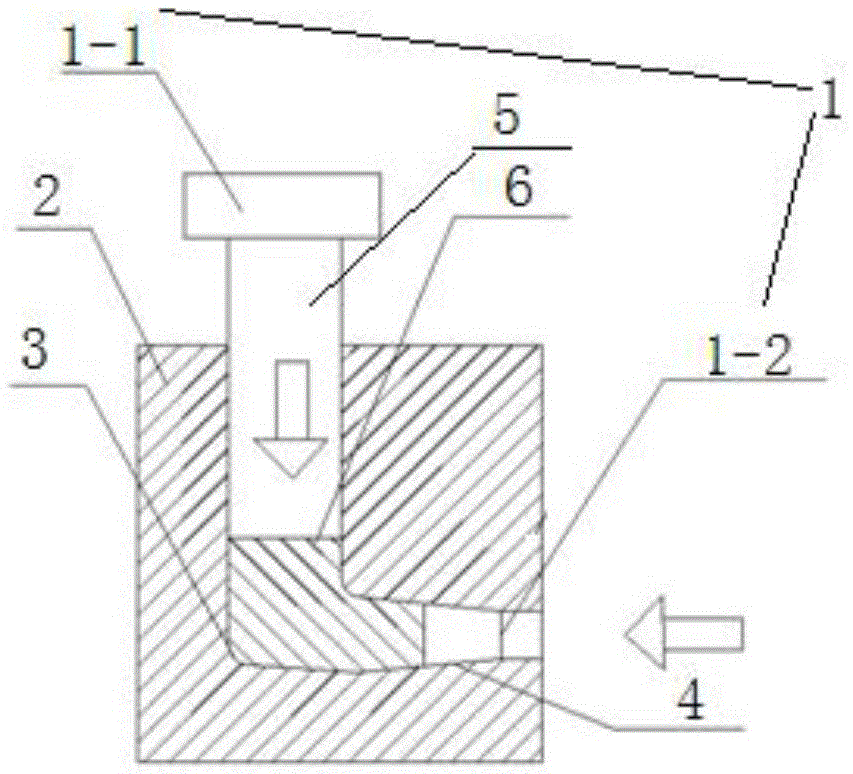

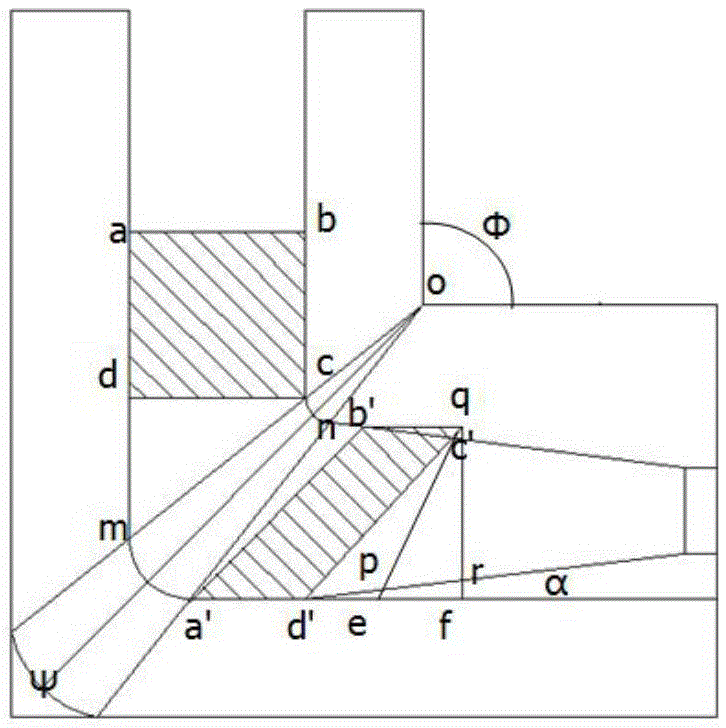

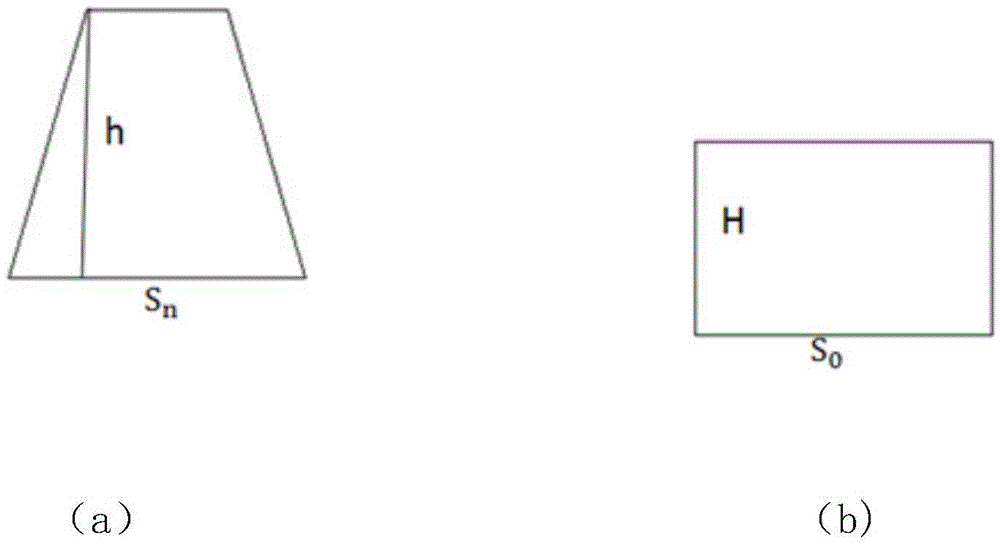

[0029] Comply with the above-mentioned technical scheme, see figure 1 , the device for preparing fine grains by variable cross-section angular extrusion of the present invention includes a mold 2 and an extrusion rod 1, a cylindrical mold cavity 5 and a conical mold cavity 4 are arranged in the mold 2, and the taper of the conical mold cavity 4 is α; the cylindrical cavity 5 and the conical cavity 4 are connected, and the connecting position of the two forms a corner 3; Internal reciprocating motion. Wherein, the cylindrical mold cavity 5 is vertically arranged, and the conical mold cavity 4 is horizontally arranged.

[0030] The working principle of the device of the present invention is as follows: the extrusion workpiece 6 is placed in the cylinder cavity 5, the extrusion rod 1 is used to extrude the extrusion workpiece 6, and the extrusion workpiece 6 passes through the corner 3 under the action of pressure to make a corner After deformation, reach the conical body mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com