Method for preparing gradient structure metal material through incremental-cumulative ply rolling

A technology of cumulative stacking and gradient structure, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of indistinct microstructure gradient distribution and cumbersome preparation process, and achieve good strength-toughness matching performance, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

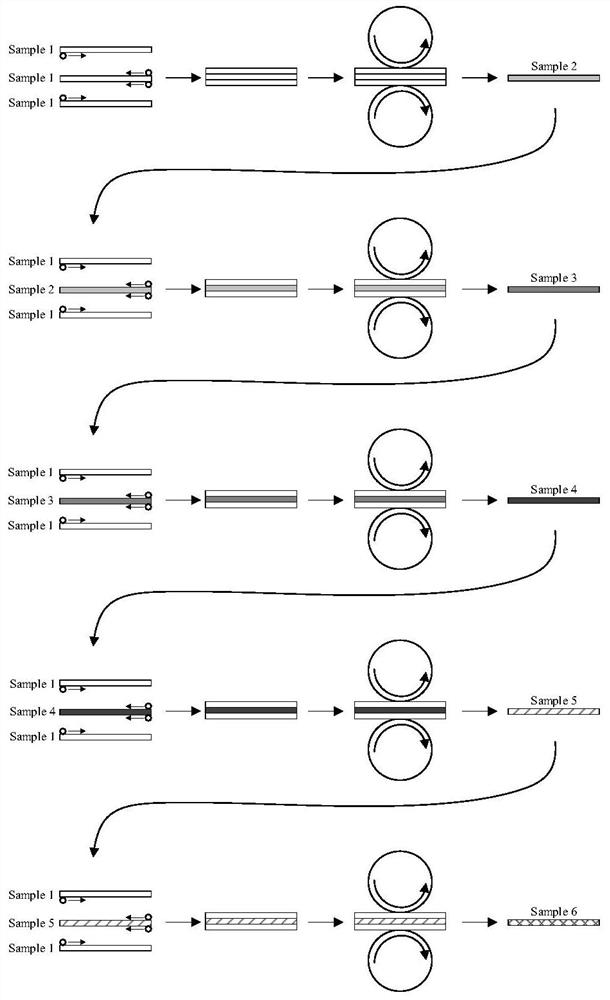

[0031] refer to figure 1 , the specific steps of the preparation method of the present invention are as follows:

[0032] The first step: use aluminum alloy or copper alloy as the raw material sample1, the thickness of the raw material sample1 is 0.5mm ~ 2mm, the width is 100mm ~ 1200mm, and sample1 is subjected to heat treatment, the heat treatment temperature is 0.3 ~ 0.4Tm, and the time is 30min ~ 24h, Tm is the melting point of the processed metal material;

[0033] Step 2: Remove oxides and dirt with wire brush and acetone respectively, and treat the surface of each board to be bonded;

[0034] Step 3: Take 3 pieces of raw material sample1, place them in a rolling mill for rolling, and prepare the core layer to obtain sample2, and set the reduction to 50% to 80%;

[0035] Step 4: Place two processed plates on the upper and lower surfaces of the material obtained by stacking and rolling, and process them to the same size. At the same time, the four corners of the stacked...

Embodiment 1

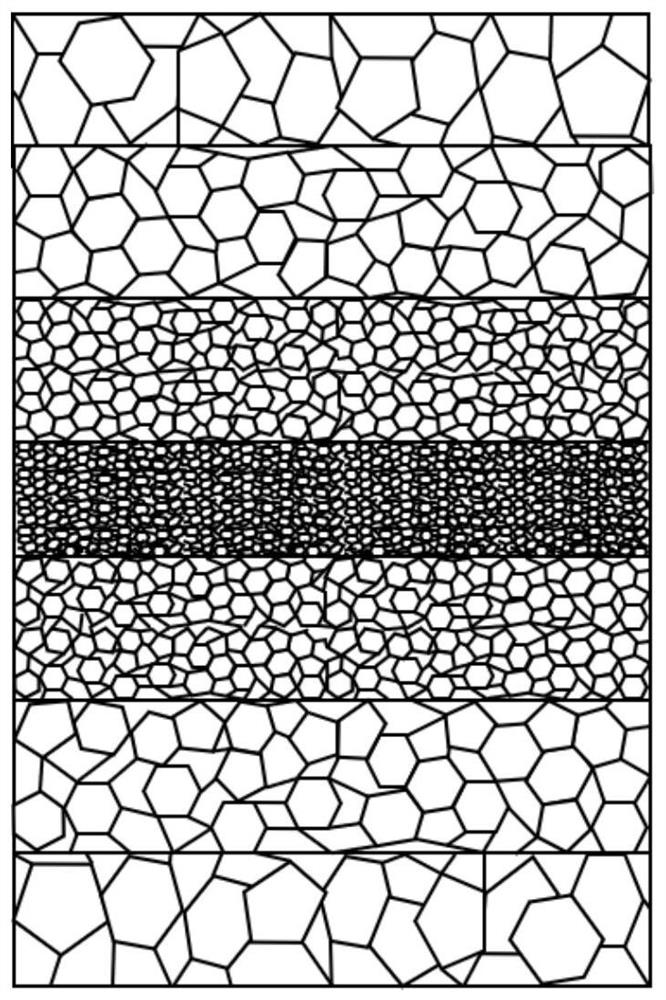

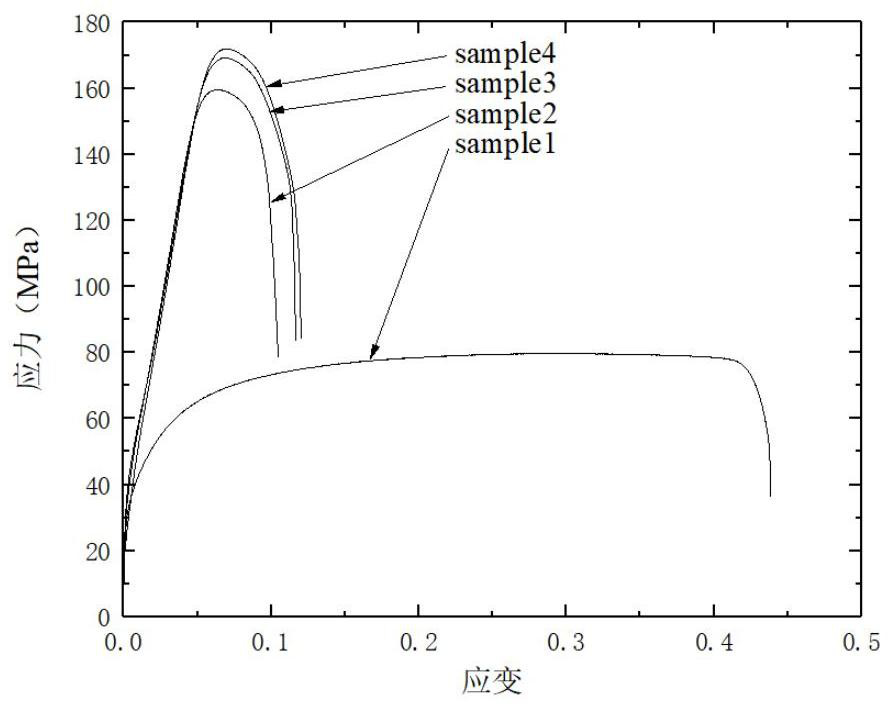

[0039] Example 1: Preparation of 7-layer aluminum alloy plate with gradient structure

[0040] The first step: using aluminum alloy 1050 plate as raw material, the thickness of the raw material is 0.6mm, the width is 300mm, and annealed at 250°C for 2h in an annealing furnace.

[0041] Step 2: Remove oxides and dirt with a wire brush and acetone, respectively, and treat the surface to be bonded of the aluminum alloy sheet.

[0042] Step 3: Take 3 aluminum alloy plates, place them in a rolling mill at room temperature with a reduction of 60%, and roll them to prepare a core layer.

[0043] Step 4: Another two processed aluminum alloys are respectively placed on the upper and lower surfaces of the material obtained by stacking and rolling, and they are processed to the same size, and at the same time, they are fixed with rivets.

[0044] Step 5: rolling the stacked three-layer plates at a reduction of 60% at room temperature to obtain a 5-layer aluminum alloy plate with a gradi...

Embodiment 2

[0047] Example 2: Preparation of 9-layer gradient copper alloy sheet

[0048] Step 1: Take the copper alloy TU1 plate as the raw material, the thickness of the raw material is 1mm, and the width is 100mm, annealing in an annealing furnace at 400°C for 24h.

[0049] Step 2: Use steel wire brush and acetone to remove oxides and dirt respectively, and treat the surface to be bonded of TU1 sheet.

[0050] Step 3: Take 3 pieces of TU1 plates, anneal at 200° C. for 5 minutes before rolling, and then place them in a rolling mill at a reduction of 80% for rolling to prepare a core layer.

[0051] Step 4: Another two processed TU1 plates are respectively placed on the upper and lower surfaces of the material obtained by stacking and rolling, processed to the same size, and fixed with rivets at the same time.

[0052] Step 5: Roll the stacked three-layer plates at 200°C for 5 minutes before rolling with a reduction of 80% to obtain a 5-layer plate with a gradient structure.

[0053] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com