High temperature-resistant porous ceramic material and preparation method thereof

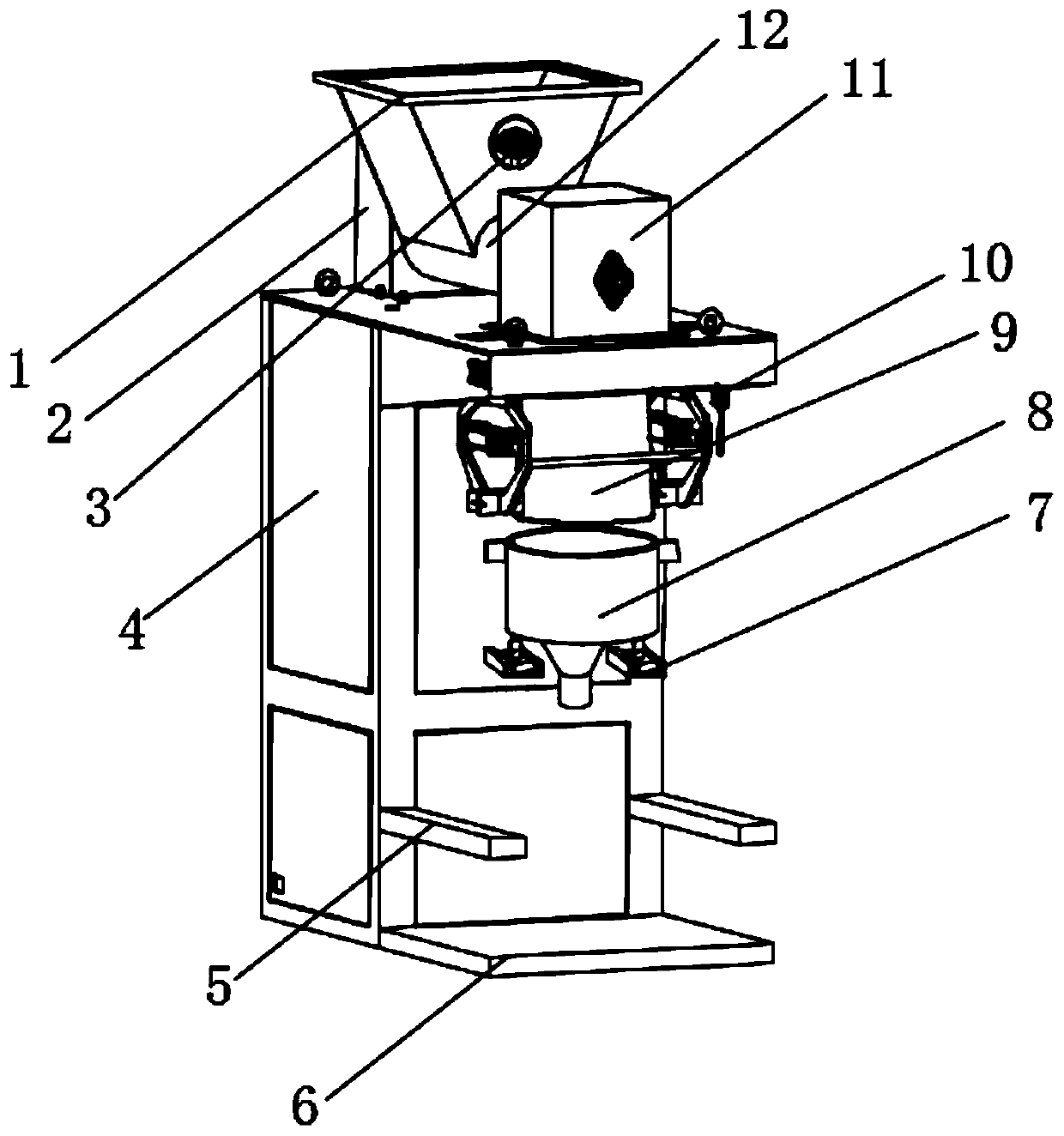

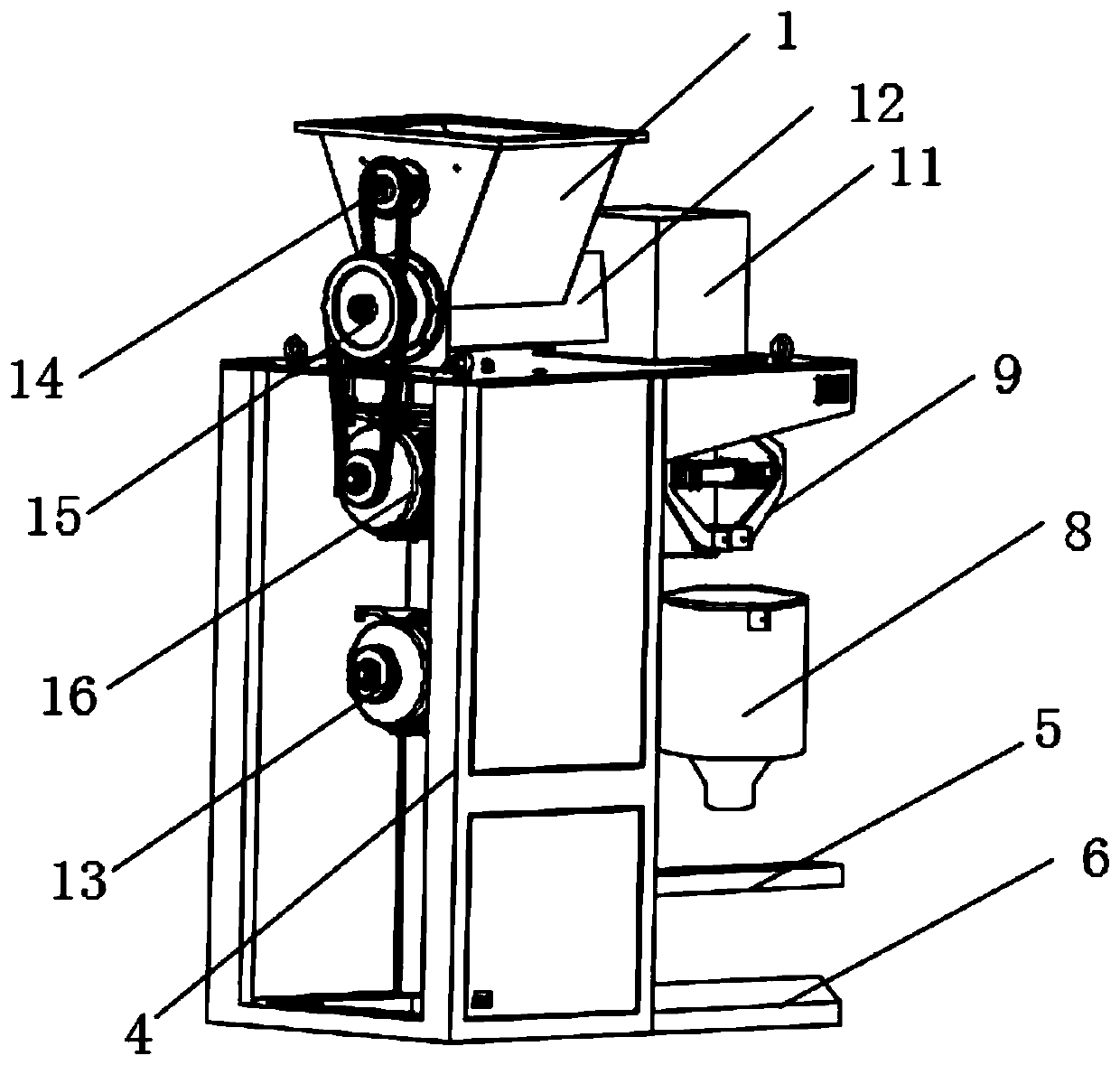

A technology of porous ceramics and high temperature resistance, which is applied in the field of ceramic materials, and can solve the problems of SiC whisker-reinforced porous ceramic materials, lack of porosity, high temperature resistance and flexural strength, and no research on SiC porous ceramic materials. , to achieve the effect of improving gas permeability, facilitating installation and disassembly of the screening mechanism, and facilitating maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A high-temperature-resistant porous ceramic material, prepared from the following weight Kg raw materials, silicon carbide 25Kg, silicon carbide whiskers 4Kg, zirconia 5Kg, aluminum oxide 5Kg, polyvinyl alcohol 1Kg, n-octanol 1Kg, activated carbon 1Kg and humic Sodium acid 0.5Kg;

[0044] Wherein, the high temperature resistant porous ceramic material is prepared through the following steps:

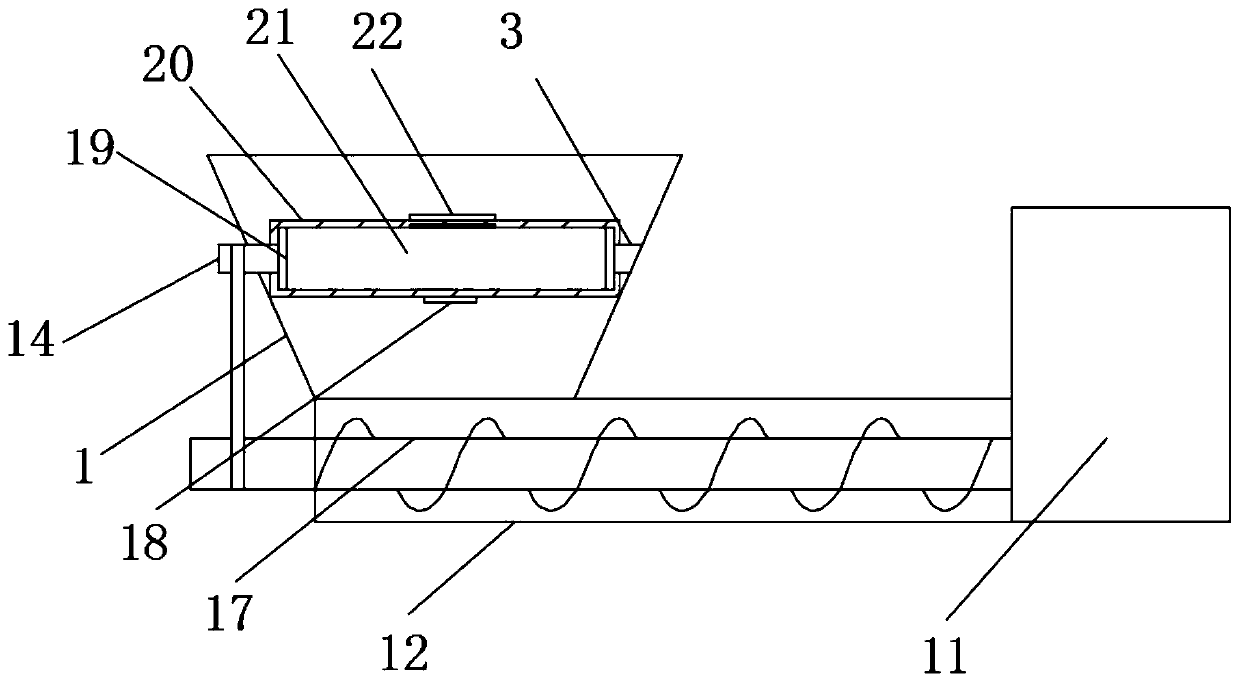

[0045] Step 1. First weigh the above-mentioned various raw materials, place the mold on the tray 6, fix it by the manipulator 5, then open the box cover 22, and put silicon carbide, silicon carbide whiskers, zirconia, aluminum oxide, Alcohol and activated carbon are evenly mixed and added to the inner cylinder 21, water with 10% of the total weight of raw materials is added, sodium humate and polyvinyl alcohol are added, and then the second motor 16 is driven to drive the inner cylinder 21 and the screw rod 17 to rotate. The cylinder 21 rotates to perform ball milling on the raw ...

Embodiment 2

[0050] A high-temperature-resistant porous ceramic material is prepared from the following weight Kg raw materials, silicon carbide 40Kg, silicon carbide whiskers 6Kg, magnesium oxide 7.5Kg, titanium dioxide 7.5Kg, polyvinyl alcohol 5Kg, n-octanol 5Kg, activated carbon 5Kg and rotten Sodium phytate 1Kg;

[0051] Wherein, the high temperature resistant porous ceramic material is prepared through the following steps:

[0052] Step 1, first weigh the above-mentioned various raw materials, place the mold on the tray 6, fix it by the manipulator 5, then open the case cover 22, and place silicon carbide, silicon carbide whiskers, magnesium oxide, titanium dioxide, n-octanol and After the active carbon is mixed evenly, add it to the inner cylinder 21, add 30% water of the total weight of raw materials, and add sodium humate and polyvinyl alcohol, and then drive the second motor 16 to drive the inner cylinder 21 and the screw rod 17 to rotate. 21 rotations to perform ball milling on ...

Embodiment 3

[0057] A high-temperature-resistant porous ceramic material is prepared from the following weight Kg raw materials, silicon carbide 25Kg, silicon carbide whiskers 6Kg, nickel oxide 5Kg, silicon dioxide 7.5Kg, polyvinyl alcohol 1Kg, n-octanol 5Kg, activated carbon 1Kg and Sodium humate 1Kg;

[0058] Wherein, the high temperature resistant porous ceramic material is prepared through the following steps:

[0059] Step 1. First weigh the above-mentioned various raw materials, put the mold on the tray 6, fix it by the manipulator 5, then open the box cover 22, and put the silicon carbide, silicon carbide whiskers, nickel oxide, silicon dioxide, normal Octanol and activated carbon are evenly mixed and added to the inner cylinder 21, water with 20% of the total weight of the raw materials is added, sodium humate and polyvinyl alcohol are added, and then the second motor 16 is driven to drive the inner cylinder 21 and the screw rod 17 to rotate. The inner cylinder 21 rotates to perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com