Pulverizing soil dispersal ditching device matched with rotary cultivator

A rotary tiller and soil crushing technology, which is applied in the fields of tillage machines, agricultural machinery and implements, etc., can solve the problems affecting the quality of ditching, unfavorable ditching width, soil scattered in the ditch, etc., and achieve ditching quality and High efficiency, high application and promotion value, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the accompanying drawings, a specific implementation of a broken soil throwing and ditching device matched with a rotary tiller will be further described in detail.

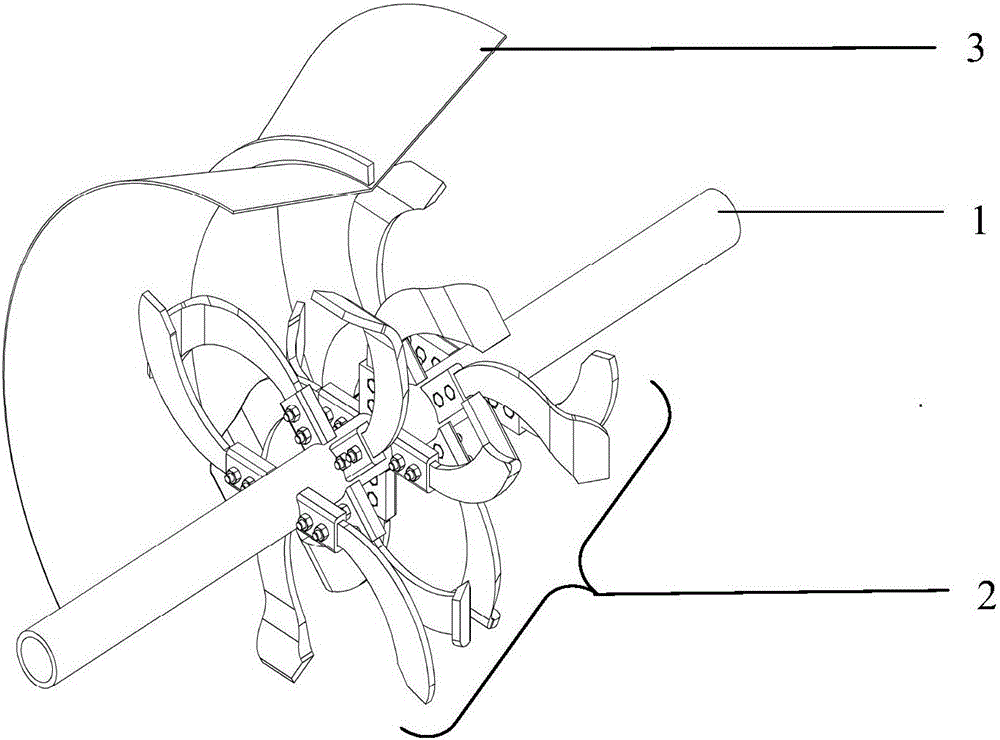

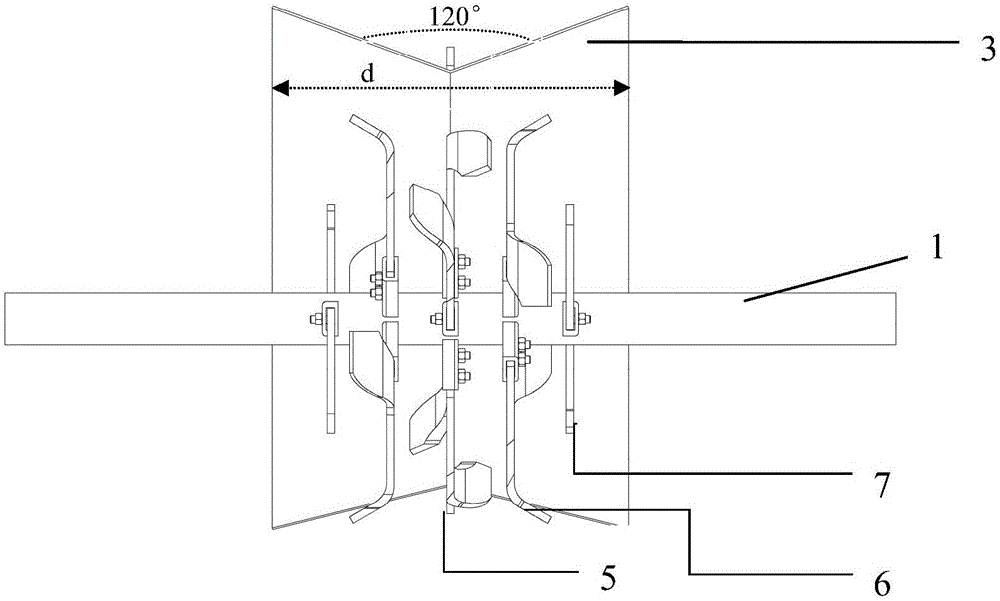

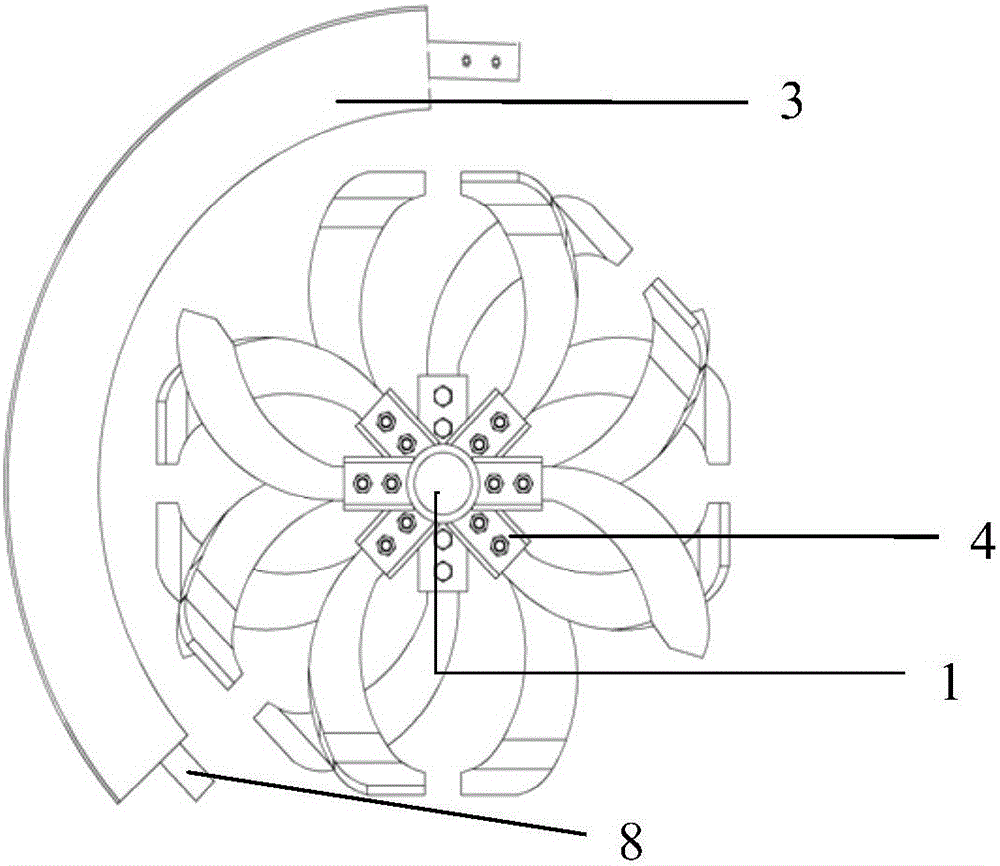

[0022] Such as Figure 1 to Figure 3 As shown, a kind of broken soil ditching device supporting the rotary tiller comprises a cutter shaft 1, a rotary tiller disc 2 and a soil dividing plate. In this example, the dividing soil plate is 3, and the cutter shaft 1 is fixed on the On the power output shaft, the rotary tiller 2 includes a first scimitar 5, a second scimitar 6 and a straight cutter 7, and the first scimitar 5 includes four cross-shaped and A first right-angle machete with a straight edge, the tails of adjacent first right-angle machetes bend in opposite directions, and the second machete includes four second right-angle machetes arranged in a cross shape and having a straight edge. Knife, the tail of the second right-angle machete is bent towards the straight cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com