Composite plastic for power supply bracket and preparation method of composite plastic

A technology of composite plastics and power supply brackets, applied in the field of power supply brackets, can solve the problems of damage to internal components of storage, affecting product quality, and unstable power supply, and achieves inhibition of thermal decomposition, excellent mechanical properties, and improvement of processing fluidity and thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

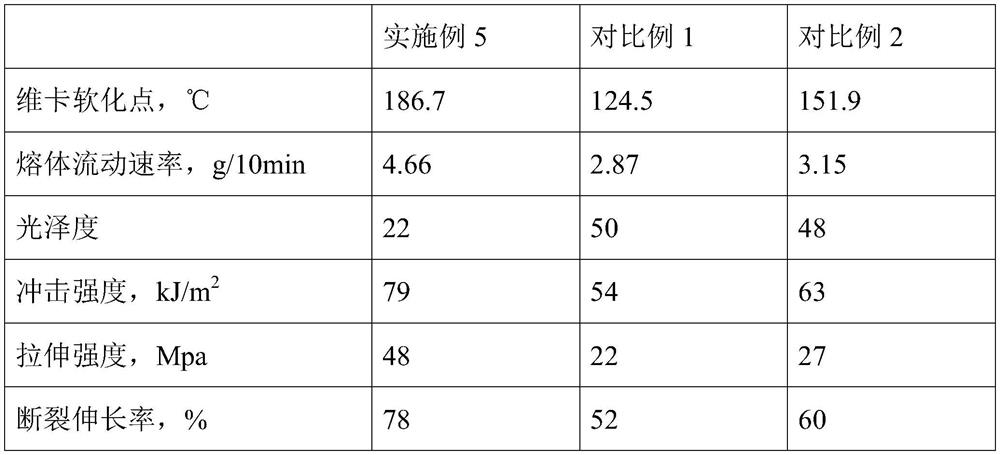

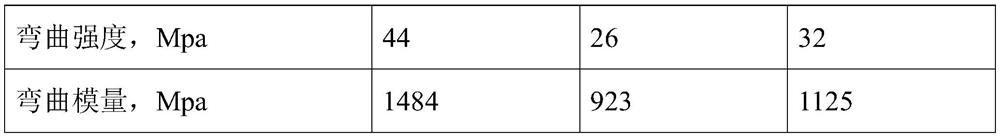

Examples

Embodiment 1

[0025] A method for preparing a composite plastic for a power supply bracket, comprising the steps of:

[0026] S1. Mix 20kg of expanded graphite and 140kg of 30% ethanol aqueous solution by mass fraction, ultrasonically disperse for 30min, and the ultrasonic power is 35kHz, then stir for 1h under reflux at 90°C, the stirring speed is 500r / min, drop to 40°C, and adjust with ammonia water The pH value of the system is 7.4-8 to obtain pretreated expanded graphite;

[0027] S2. Stir 150kg of pretreated expanded graphite, slowly add 5kg of tetraethyl orthosilicate dropwise under the stirring state, the stirring speed is 1500r / min, continue to stir for 2h after the addition is complete, drop to room temperature, wash with ethanol aqueous solution after suction filtration until neutral, dispersed in 50% ethanol aqueous solution, and spray-dried to obtain a silica-expanded graphite composite;

[0028] S3, 100kg α-crystalline polypropylene, 15kg styrene-based thermoplastic elastomer,...

Embodiment 2

[0030] A method for preparing a composite plastic for a power supply bracket, comprising the steps of:

[0031] S1. Mix 25kg of expanded graphite and 100kg of 40% ethanol aqueous solution by mass fraction, ultrasonically disperse for 20min, the ultrasonic power is 45kHz, then stir for 2h under reflux at 80°C, the stirring speed is 400r / min, drop to 50°C, adjust with ammonia water The pH value of the system is 7.4-8 to obtain pretreated expanded graphite;

[0032] S2. Stir 120kg of pretreated expanded graphite, slowly add 8kg of tetraethyl orthosilicate dropwise under the stirring state, the stirring speed is 1200r / min, continue to stir for 4h after the addition is complete, drop to room temperature, wash with ethanol aqueous solution after suction filtration Until it is neutral, it is dispersed in a 40% ethanol aqueous solution by mass fraction, and spray-dried to obtain a silica-expanded graphite composite;

[0033] S3, 100kg α-crystalline polypropylene, 25kg styrene-based t...

Embodiment 3

[0035] A method for preparing a composite plastic for a power supply bracket, comprising the steps of:

[0036] S1. Mix 22kg of expanded graphite and 130kg of 33% ethanol aqueous solution by mass fraction, ultrasonically disperse for 28min, and the ultrasonic power is 38kHz, then stir for 1.3h under reflux at 87°C, the stirring speed is 480r / min, drop to 43°C, and use ammonia water The pH value of the adjustment system is 7.4-8 to obtain pretreated expanded graphite;

[0037] S2. Stir 140kg of pretreated expanded graphite, slowly add 6kg of tetraethyl orthosilicate dropwise under the stirring state, the stirring speed is 1400r / min, continue to stir for 2.5h after the addition is complete, drop to room temperature, and use ethanol aqueous solution after suction filtration Wash until neutral, disperse in 47% ethanol aqueous solution, spray dry to obtain silica-expanded graphite composite;

[0038]S3, 100kg of α-crystalline polypropylene, 18kg of styrene-based thermoplastic elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com